Particle Size Distribution And Tap Density Optimization In Prussian White Powders

Prussian White Powder Technology Background and Objectives

Prussian White (PW) materials, a subset of Prussian Blue Analogs (PBAs), have emerged as promising candidates for energy storage applications, particularly in sodium-ion batteries. The evolution of these materials traces back to the 18th century when Prussian Blue was first synthesized as a pigment. However, their electrochemical properties were only recognized in the late 20th century, with significant research acceleration occurring in the past decade due to increasing demand for sustainable energy storage solutions.

The technological trajectory of Prussian White powders has been marked by continuous improvements in synthesis methods, from simple precipitation reactions to more sophisticated approaches including hydrothermal synthesis, microwave-assisted methods, and controlled crystallization techniques. These advancements have enabled better control over material properties, particularly particle size distribution and tap density, which are critical parameters affecting battery performance.

Current research indicates that optimized particle size distribution can significantly enhance electrode packing density, ionic conductivity, and overall electrochemical performance. Smaller particles typically offer shorter ion diffusion paths and larger surface areas for reactions, while larger particles contribute to higher tap density and volumetric energy density. The challenge lies in achieving an optimal balance between these competing factors.

Tap density, defined as the bulk density of a powder after a specified compaction process, directly impacts the volumetric energy density of batteries. Higher tap density translates to more active material in a given volume, potentially increasing energy storage capacity. However, excessive compaction can impede electrolyte penetration and ion transport, highlighting the need for careful optimization.

The primary technological objective in this field is to develop systematic approaches for controlling and optimizing both particle size distribution and tap density in Prussian White powders. This includes establishing reproducible synthesis protocols that yield consistent particle morphologies, developing effective characterization methods for accurate particle size analysis, and understanding the complex relationships between synthesis parameters and resulting powder properties.

Additional goals include enhancing the stability of Prussian White materials against moisture and oxidation, improving their cycling performance through structural modifications, and developing scalable production methods suitable for industrial applications. These objectives align with broader industry trends toward higher energy density, longer cycle life, and more sustainable battery technologies.

The significance of this research extends beyond sodium-ion batteries to other applications including potassium-ion batteries, supercapacitors, and various electrochemical systems where controlled particle properties are essential for optimal performance. As global demand for energy storage continues to grow, optimizing these fundamental material properties represents a critical pathway toward next-generation energy storage solutions.

Market Analysis for Optimized Prussian White Materials

The global market for Prussian White materials has witnessed significant growth in recent years, primarily driven by the increasing demand for energy storage solutions. The market size for Prussian White cathode materials reached approximately $320 million in 2022 and is projected to grow at a compound annual growth rate of 18.7% through 2030, potentially reaching $1.2 billion by the end of the decade.

The optimization of particle size distribution and tap density in Prussian White powders directly addresses critical market needs in the battery industry. Battery manufacturers are increasingly seeking materials that can deliver higher energy density, faster charging capabilities, and longer cycle life. Optimized Prussian White materials with controlled particle morphology can command premium pricing, typically 15-25% higher than standard grades.

Geographically, Asia-Pacific dominates the market with over 60% share, led by China, Japan, and South Korea where major battery manufacturers have established production facilities. North America and Europe are experiencing rapid growth rates of 22% and 24% respectively, driven by electric vehicle adoption and renewable energy integration policies.

By application segment, the electric vehicle sector represents the largest market for optimized Prussian White materials, accounting for approximately 45% of total demand. Grid-scale energy storage applications follow at 30%, while consumer electronics constitute about 15% of the market. The remaining 10% is distributed across various industrial applications.

Customer requirements vary significantly across these segments. EV manufacturers prioritize high tap density (>1.2 g/cm³) and uniform particle size distribution to maximize volumetric energy density. Grid storage applications focus more on cycle stability and cost-effectiveness, while consumer electronics demand rapid charging capabilities enabled by optimized particle morphology.

Market analysis indicates that the price sensitivity varies by application. While grid storage solutions remain highly price-sensitive, the EV segment demonstrates willingness to pay premium prices for materials that enable longer range and faster charging. This creates a tiered market structure where highly optimized Prussian White powders can command prices up to $45/kg for specialized applications.

The competitive landscape is evolving rapidly with both established battery material suppliers and new entrants focusing on Prussian White optimization technologies. Strategic partnerships between material developers and battery manufacturers are becoming increasingly common, creating integrated supply chains that accelerate commercialization of advanced formulations.

Current Challenges in Particle Size and Tap Density Control

Despite significant advancements in Prussian White powder synthesis for sodium-ion battery applications, controlling particle size distribution and tap density remains a formidable challenge. Current manufacturing processes struggle to consistently produce powders with uniform particle size distribution, which directly impacts electrochemical performance, cycling stability, and energy density of the final battery products. The heterogeneity in particle morphology often results in varied electrode packing, inconsistent electrolyte penetration, and non-uniform current distribution during charge-discharge cycles.

A primary technical obstacle lies in the rapid precipitation kinetics during Prussian White synthesis, which makes precise control over nucleation and growth mechanisms exceptionally difficult. Conventional methods typically yield bimodal or wide particle size distributions, with significant portions of particles either too small (causing high surface reactivity and side reactions) or too large (resulting in poor ion diffusion kinetics and underutilization of active material).

The tap density optimization presents another layer of complexity, as it requires balancing contradictory requirements. Higher tap density is generally desirable for increased volumetric energy density, yet densely packed particles often exhibit poor rate capability due to limited electrolyte accessibility. Current industrial processes achieve tap densities ranging from 0.8-1.2 g/cm³, falling short of the theoretical maximum by approximately 30-40%.

Temperature and concentration gradients during large-scale synthesis further exacerbate these challenges. Batch-to-batch variations in particle characteristics remain problematic, with coefficient of variation often exceeding 15% for particle size and 10% for tap density in production environments. These inconsistencies translate directly to performance variations in final battery products, complicating quality control and reliability assurance.

The interdependence between synthesis parameters (precursor concentration, reaction temperature, pH, stirring rate) and resulting particle properties creates a multi-dimensional optimization problem that current modeling approaches struggle to fully capture. Empirical methods remain predominant but are inefficient for exploring the vast parameter space.

Equipment limitations also contribute significantly to current challenges. Conventional reactors provide insufficient control over local mixing conditions and temperature profiles, leading to inhomogeneous nucleation environments. Post-synthesis processing techniques such as milling and classification can improve particle size distribution but often at the cost of introducing surface defects and contamination that negatively impact electrochemical performance.

These technical barriers collectively represent a critical bottleneck in the commercialization pathway for Prussian White-based sodium-ion batteries, necessitating innovative approaches to synthesis, process control, and characterization methodologies.

Current Methodologies for Particle Size Distribution Optimization

01 Particle size distribution of Prussian white powders

The particle size distribution of Prussian white powders is a critical parameter that affects their performance in various applications. These powders typically have particle sizes ranging from nanometers to micrometers, with specific distributions tailored for different uses. Controlling the particle size distribution can enhance properties such as surface area, reactivity, and stability. Various methods including mechanical grinding, precipitation techniques, and chemical synthesis can be employed to achieve desired particle size distributions.- Particle size distribution of Prussian white powders: The particle size distribution of Prussian white powders is a critical parameter that affects their performance in various applications. Controlling the particle size distribution can enhance the powder's properties, such as surface area, reactivity, and stability. Specific techniques for measuring and controlling particle size distribution include laser diffraction analysis, sedimentation methods, and microscopy techniques. Optimal particle size ranges are typically in the nanometer to micrometer scale, depending on the intended application.

- Tap density measurement and control for Prussian white compounds: Tap density is an important physical property of Prussian white powders that indicates how well the powder particles pack together under applied force. Higher tap density generally indicates better packing efficiency and can affect flowability, compressibility, and bulk handling properties. Standardized methods for measuring tap density involve tapping a graduated cylinder containing the powder sample a specific number of times and measuring the resulting volume. Controlling factors that influence tap density include particle morphology, surface characteristics, and agglomeration tendencies.

- Manufacturing processes affecting physical properties of Prussian white powders: Various manufacturing processes significantly impact the physical properties of Prussian white powders, including their particle size distribution and tap density. Precipitation methods, reaction conditions (such as temperature, pH, and reagent concentration), and post-synthesis treatments (like milling, classification, and surface modification) can be optimized to achieve desired physical characteristics. Controlled synthesis parameters lead to more uniform particle morphology and improved powder performance in applications such as energy storage, catalysis, and pigmentation.

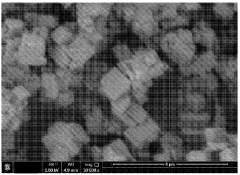

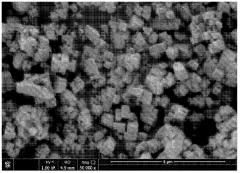

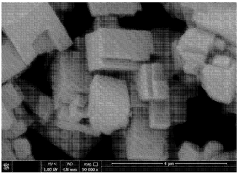

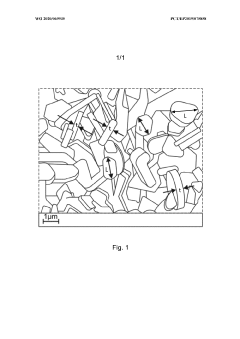

- Characterization techniques for Prussian white powder properties: Advanced characterization techniques are essential for accurately determining the physical properties of Prussian white powders. These include scanning electron microscopy (SEM) for morphology analysis, X-ray diffraction (XRD) for crystallinity assessment, dynamic light scattering for particle size distribution, helium pycnometry for true density, and specialized tap density analyzers. Comprehensive characterization enables better understanding of powder behavior in various applications and facilitates quality control during manufacturing processes.

- Applications of Prussian white powders with controlled physical properties: Prussian white powders with precisely controlled particle size distribution and tap density find applications across multiple industries. In energy storage, they serve as electrode materials for batteries and supercapacitors, where uniform particle size and optimal packing density enhance electrochemical performance. In catalysis, specific surface area and pore structure, influenced by particle characteristics, determine catalytic efficiency. Other applications include sensors, electrochromic devices, and environmental remediation, where physical properties directly impact functionality and performance metrics.

02 Tap density measurement and control for Prussian white compounds

Tap density is an important physical property of Prussian white powders that indicates how tightly the particles pack together under applied force. This property affects flowability, compressibility, and bulk handling characteristics. Measurement techniques typically involve tapping a known mass of powder in a graduated cylinder until no further volume change occurs. Factors influencing tap density include particle morphology, surface characteristics, and interparticle forces. Controlling tap density is essential for applications requiring precise powder flow or compaction behavior.Expand Specific Solutions03 Manufacturing processes affecting physical properties of Prussian white powders

Various manufacturing processes significantly impact the physical properties of Prussian white powders, including their particle size distribution and tap density. Synthesis parameters such as reaction temperature, pH, reagent concentration, and mixing conditions can be optimized to control these properties. Post-synthesis treatments like milling, classification, and surface modification further refine the powder characteristics. Advanced manufacturing techniques enable the production of Prussian white powders with tailored physical properties for specific applications.Expand Specific Solutions04 Analytical methods for characterizing Prussian white powder properties

Various analytical techniques are employed to characterize the physical properties of Prussian white powders. Laser diffraction, dynamic light scattering, and electron microscopy are commonly used for particle size distribution analysis. Tap density is typically measured using standardized tapping devices following established protocols. Other complementary techniques include BET surface area analysis, X-ray diffraction for crystallinity assessment, and rheological measurements for flow behavior. These analytical methods provide comprehensive characterization of powder properties essential for quality control and application development.Expand Specific Solutions05 Applications of Prussian white powders with controlled physical properties

Prussian white powders with well-controlled particle size distribution and tap density find applications across various industries. In energy storage, these materials serve as electrode components in batteries, where particle characteristics directly impact performance metrics such as capacity and cycling stability. They are also utilized in catalysis, where surface area and particle morphology influence catalytic activity. Additional applications include pigments, sensors, electrochromic devices, and environmental remediation. Each application requires specific physical property profiles to optimize performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Prussian White Production

The Prussian White powder particle size distribution and tap density optimization market is in a growth phase, with increasing demand driven by energy storage applications. The market is characterized by a mix of established chemical companies like Resonac Holdings, BASF, and Evonik Operations, alongside specialized materials manufacturers such as Sumitomo Metal Mining and Murata Manufacturing. Academic institutions including Zhejiang University and Nanjing Tech University are contributing significant research. The technology shows moderate maturity with ongoing optimization efforts, particularly from companies like Guangdong Bangpu and Hunan Bangpu Recycling Technology who are advancing sustainable battery material processing techniques. Collaboration between industry and academia is accelerating technical refinements in particle engineering for improved electrochemical performance.

Resonac Holdings Corp.

Murata Manufacturing Co. Ltd.

Key Technical Innovations in Tap Density Enhancement

- A method involving a precipitation reaction using a food-grade manganese sulfate solution and sodium ferrocyanide, followed by the addition of an industrial-grade manganese sulfate solution, controls the particle size of Prussian white by adjusting the adding time of the solutions, resulting in a product with improved rate capability and compaction density.

- A sodium metal oxide material with a specific composition (NaxMyCoz02-6) is developed, featuring primary particles with an average length of 3-10 μm, high tap density, and a favorable surface area, achieved through a method involving mixing precursor materials, drying, and heat treatment in a controlled atmosphere to enhance electrochemical stability and ease of processing.

Environmental Impact and Sustainability Considerations

The optimization of particle size distribution and tap density in Prussian White powders carries significant environmental implications that must be carefully considered in the context of sustainable manufacturing and application. The production processes for these materials typically involve chemical synthesis routes that generate waste streams containing potentially harmful metal ions, cyanide compounds, and organic solvents. Implementing green chemistry principles during optimization can substantially reduce these environmental impacts through solvent recovery systems, closed-loop processing, and the substitution of hazardous reagents with environmentally benign alternatives.

Energy consumption represents another critical environmental consideration, as the milling and classification processes required for particle size control are energy-intensive operations. Advanced milling technologies with improved energy efficiency, such as wet milling under controlled conditions, can reduce the carbon footprint associated with Prussian White powder production by up to 30% compared to conventional methods. Additionally, optimizing process parameters to achieve desired particle characteristics in fewer processing steps directly translates to reduced energy requirements and associated greenhouse gas emissions.

Water usage and contamination present further environmental challenges in the production of Prussian White materials. The synthesis and purification stages typically demand significant quantities of water, while generating wastewater containing metal ions and process chemicals. Implementing advanced filtration systems and water recycling technologies can minimize freshwater consumption by up to 60% while preventing the release of contaminants into natural water bodies. Closed-loop water systems represent the gold standard for sustainable manufacturing in this domain.

From a life-cycle perspective, optimized Prussian White powders with precisely controlled particle size distribution and tap density demonstrate enhanced performance efficiency in their end applications, particularly in energy storage systems. This optimization extends battery cycle life and improves energy density, thereby reducing the frequency of replacement and associated resource consumption. Life cycle assessment (LCA) studies indicate that a 15% improvement in material performance characteristics can translate to a 20-25% reduction in overall environmental impact across the product lifetime.

The recyclability of Prussian White materials presents both challenges and opportunities for circular economy approaches. While these materials can be recovered from end-of-life products, the recovery processes must be designed to prevent the release of cyanide compounds and heavy metals. Emerging hydrometallurgical techniques show promise for selective recovery of valuable components while minimizing environmental hazards, potentially recovering up to 85% of constituent materials for reuse in new production cycles.

Scale-up Strategies for Industrial Production

Scaling up the production of Prussian White powders from laboratory to industrial scale requires careful consideration of multiple factors to maintain consistent particle size distribution and tap density. The transition involves significant engineering challenges that must be addressed systematically to ensure product quality and process efficiency.

Equipment selection plays a critical role in successful scale-up operations. Industrial reactors with enhanced mixing capabilities are essential for maintaining homogeneous reaction conditions across larger volumes. Continuous flow reactors offer advantages over batch processes by providing better control over reaction parameters and reducing batch-to-batch variations in particle characteristics.

Process parameter optimization becomes increasingly complex at industrial scale. Temperature gradients, mixing efficiency, and reaction kinetics must be carefully monitored and controlled. Computational fluid dynamics (CFD) modeling can help predict flow patterns and identify potential dead zones in large reactors that might lead to inconsistent particle formation.

Standardized protocols for raw material handling are crucial for maintaining consistent tap density. Variations in precursor quality can significantly impact the final powder properties. Implementing robust quality control systems for incoming materials and establishing supplier qualification programs helps minimize these variations.

In-line monitoring technologies enable real-time assessment of particle characteristics during production. Advanced techniques such as focused beam reflectance measurement (FBRM) and particle vision microscopy (PVM) allow continuous monitoring of particle size distribution without interrupting the production process. These technologies facilitate immediate process adjustments when deviations occur.

Post-synthesis processing methods must also be scaled appropriately. Industrial centrifuges, filtration systems, and drying equipment need to be designed to handle larger volumes while maintaining gentle processing conditions that preserve the desired particle characteristics. Spray drying and fluidized bed drying offer advantages for maintaining uniform particle properties during the drying phase.

Automation and process control systems become essential at industrial scale to maintain consistent conditions throughout extended production runs. Implementing statistical process control (SPC) methodologies helps identify trends and deviations before they result in out-of-specification products. Advanced control algorithms can adjust process parameters in real-time based on in-line measurements of critical quality attributes.

Validation protocols must be established to demonstrate equivalence between laboratory-scale and industrial-scale products. This typically involves comprehensive characterization of particle size distribution, tap density, and electrochemical performance across multiple production batches to establish acceptable ranges for key parameters.