Fast-Charging Protocols For Prussian White Based Sodium-Ion Batteries

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Prussian White SIB Fast-Charging Background and Objectives

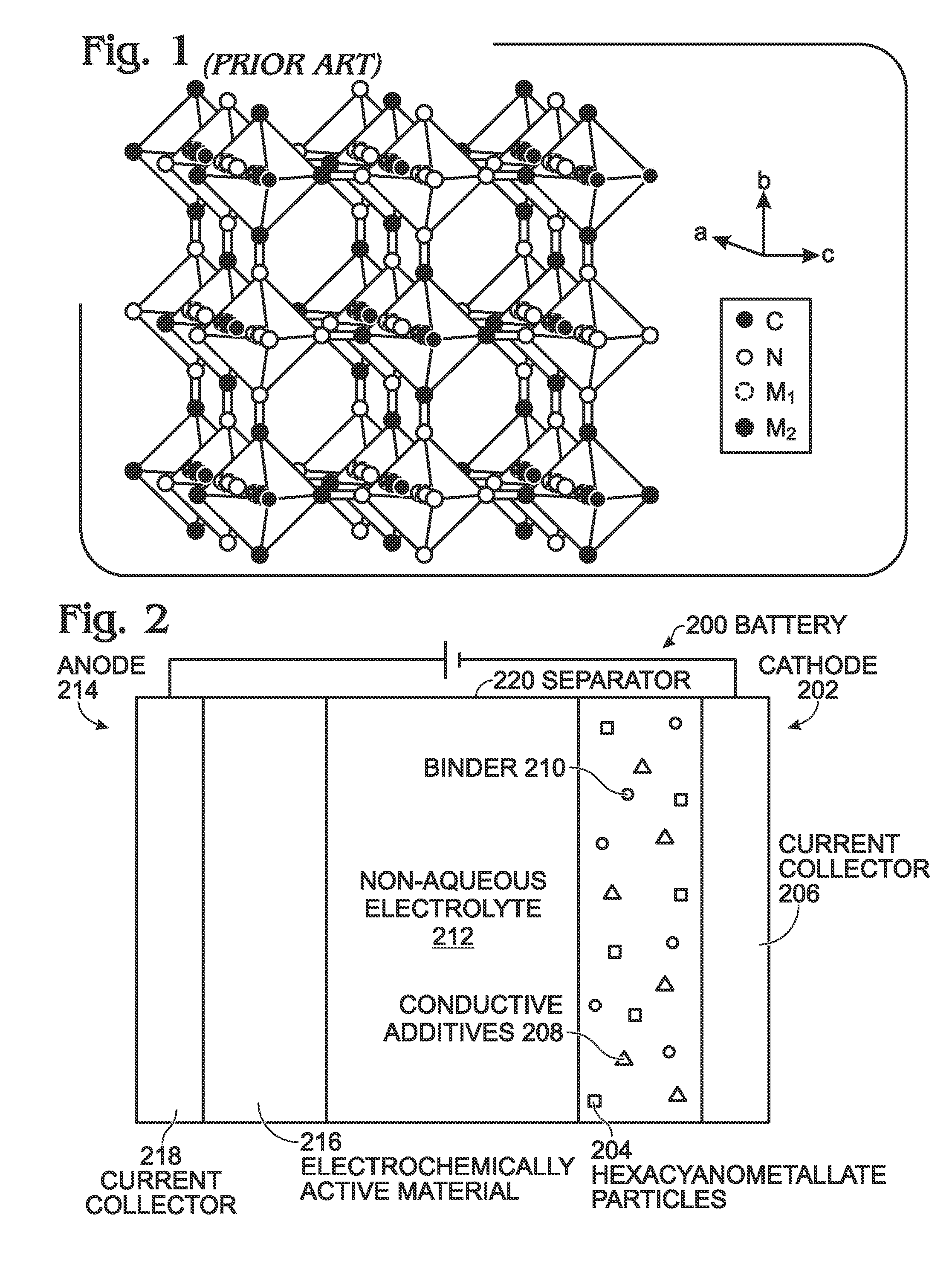

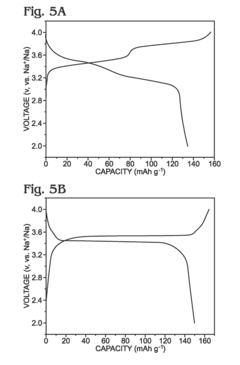

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. Among various cathode materials for SIBs, Prussian White (PW) compounds have attracted significant attention owing to their open framework structure, high theoretical capacity, and excellent cycling stability. The development trajectory of PW-based SIBs has accelerated notably in the past decade, with research focusing on improving energy density, cycle life, and rate capability.

Fast charging capability represents a critical technological frontier for energy storage systems, particularly in applications such as electric vehicles and portable electronics where minimizing charging time is essential for consumer adoption. The evolution of fast-charging protocols for PW-based SIBs has progressed from basic constant current-constant voltage (CC-CV) approaches to more sophisticated pulse charging and multi-stage protocols designed to address the unique electrochemical characteristics of these materials.

The fundamental challenge in developing fast-charging protocols for PW-based SIBs lies in balancing charging speed with battery longevity and safety. Traditional charging methods often lead to accelerated degradation when applied at high rates due to increased mechanical stress, electrolyte decomposition, and sodium plating. Recent technological advancements have focused on mitigating these issues through innovative charging algorithms that consider the structural dynamics of PW materials during rapid sodium insertion.

Current research trends indicate a shift toward adaptive charging protocols that dynamically adjust parameters based on real-time battery state monitoring. These approaches leverage machine learning algorithms to optimize charging profiles according to battery age, temperature, and state of charge. Simultaneously, materials engineering efforts are focusing on enhancing the intrinsic fast-charging capabilities of PW compounds through controlled doping, defect engineering, and particle morphology optimization.

The primary objective of fast-charging protocol development for PW-based SIBs is to achieve charging times comparable to or better than lithium-ion counterparts while maintaining cycle life and safety standards. Specifically, the industry targets 80% charge in under 15 minutes without significant capacity fade over 1000+ cycles. Secondary goals include developing protocols that function effectively across wide temperature ranges and battery aging states.

Looking forward, the technological roadmap for PW-based SIB fast charging will likely converge with advances in battery management systems, thermal management strategies, and electrode architecture design. The integration of these complementary technologies promises to overcome current limitations and establish PW-based SIBs as a viable, rapidly rechargeable energy storage solution for next-generation applications.

Fast charging capability represents a critical technological frontier for energy storage systems, particularly in applications such as electric vehicles and portable electronics where minimizing charging time is essential for consumer adoption. The evolution of fast-charging protocols for PW-based SIBs has progressed from basic constant current-constant voltage (CC-CV) approaches to more sophisticated pulse charging and multi-stage protocols designed to address the unique electrochemical characteristics of these materials.

The fundamental challenge in developing fast-charging protocols for PW-based SIBs lies in balancing charging speed with battery longevity and safety. Traditional charging methods often lead to accelerated degradation when applied at high rates due to increased mechanical stress, electrolyte decomposition, and sodium plating. Recent technological advancements have focused on mitigating these issues through innovative charging algorithms that consider the structural dynamics of PW materials during rapid sodium insertion.

Current research trends indicate a shift toward adaptive charging protocols that dynamically adjust parameters based on real-time battery state monitoring. These approaches leverage machine learning algorithms to optimize charging profiles according to battery age, temperature, and state of charge. Simultaneously, materials engineering efforts are focusing on enhancing the intrinsic fast-charging capabilities of PW compounds through controlled doping, defect engineering, and particle morphology optimization.

The primary objective of fast-charging protocol development for PW-based SIBs is to achieve charging times comparable to or better than lithium-ion counterparts while maintaining cycle life and safety standards. Specifically, the industry targets 80% charge in under 15 minutes without significant capacity fade over 1000+ cycles. Secondary goals include developing protocols that function effectively across wide temperature ranges and battery aging states.

Looking forward, the technological roadmap for PW-based SIB fast charging will likely converge with advances in battery management systems, thermal management strategies, and electrode architecture design. The integration of these complementary technologies promises to overcome current limitations and establish PW-based SIBs as a viable, rapidly rechargeable energy storage solution for next-generation applications.

Market Analysis for Fast-Charging Sodium-Ion Battery Technologies

The global market for fast-charging sodium-ion battery technologies is experiencing significant growth, driven by the increasing demand for sustainable energy storage solutions. The market size for sodium-ion batteries was valued at approximately $420 million in 2022 and is projected to reach $1.2 billion by 2028, with a compound annual growth rate (CAGR) of 19.3%. Fast-charging capabilities represent a critical differentiator in this emerging market, with Prussian White-based chemistries gaining particular attention.

Consumer electronics currently represents the largest application segment for fast-charging sodium-ion batteries, accounting for 38% of the market share. This is followed by renewable energy storage (27%), electric vehicles (21%), and grid-scale applications (14%). The demand for rapid charging protocols is particularly strong in the electric vehicle sector, where charging time remains a significant barrier to adoption.

Geographically, Asia-Pacific dominates the market with 45% share, led by China's aggressive investments in sodium-ion technology. Europe follows at 30%, driven by stringent environmental regulations and sustainability goals. North America accounts for 20% of the market, while the rest of the world comprises the remaining 5%.

Key market drivers include the lower cost of sodium compared to lithium (sodium is approximately 1000 times more abundant in the Earth's crust), reduced supply chain vulnerabilities, and improved safety profiles. The average cost of sodium-ion cells is currently $137/kWh, compared to $151/kWh for lithium-ion, representing a cost advantage that is expected to widen as production scales.

Market challenges include performance limitations compared to lithium-ion batteries, particularly in energy density (currently 160 Wh/kg for sodium-ion versus 250 Wh/kg for lithium-ion). However, fast-charging capabilities present a significant opportunity to overcome adoption barriers, with Prussian White-based chemistries demonstrating particular promise in this regard.

Consumer surveys indicate that 78% of potential electric vehicle buyers consider charging time a critical factor in purchase decisions. The ability to charge to 80% capacity in under 20 minutes is considered the threshold for mainstream adoption, making fast-charging protocols for sodium-ion batteries a potentially disruptive technology in the market.

Industry forecasts suggest that by 2030, sodium-ion batteries could capture up to 15% of the global battery market, with fast-charging variants representing approximately 40% of this segment. The market for Prussian White-based sodium-ion batteries specifically is expected to grow at a CAGR of 23.7% through 2028, outpacing the broader sodium-ion battery market.

Consumer electronics currently represents the largest application segment for fast-charging sodium-ion batteries, accounting for 38% of the market share. This is followed by renewable energy storage (27%), electric vehicles (21%), and grid-scale applications (14%). The demand for rapid charging protocols is particularly strong in the electric vehicle sector, where charging time remains a significant barrier to adoption.

Geographically, Asia-Pacific dominates the market with 45% share, led by China's aggressive investments in sodium-ion technology. Europe follows at 30%, driven by stringent environmental regulations and sustainability goals. North America accounts for 20% of the market, while the rest of the world comprises the remaining 5%.

Key market drivers include the lower cost of sodium compared to lithium (sodium is approximately 1000 times more abundant in the Earth's crust), reduced supply chain vulnerabilities, and improved safety profiles. The average cost of sodium-ion cells is currently $137/kWh, compared to $151/kWh for lithium-ion, representing a cost advantage that is expected to widen as production scales.

Market challenges include performance limitations compared to lithium-ion batteries, particularly in energy density (currently 160 Wh/kg for sodium-ion versus 250 Wh/kg for lithium-ion). However, fast-charging capabilities present a significant opportunity to overcome adoption barriers, with Prussian White-based chemistries demonstrating particular promise in this regard.

Consumer surveys indicate that 78% of potential electric vehicle buyers consider charging time a critical factor in purchase decisions. The ability to charge to 80% capacity in under 20 minutes is considered the threshold for mainstream adoption, making fast-charging protocols for sodium-ion batteries a potentially disruptive technology in the market.

Industry forecasts suggest that by 2030, sodium-ion batteries could capture up to 15% of the global battery market, with fast-charging variants representing approximately 40% of this segment. The market for Prussian White-based sodium-ion batteries specifically is expected to grow at a CAGR of 23.7% through 2028, outpacing the broader sodium-ion battery market.

Technical Challenges in Prussian White SIB Fast-Charging

The development of fast-charging protocols for Prussian White (PW) based Sodium-Ion Batteries (SIBs) faces several significant technical challenges that must be addressed to achieve commercial viability. The primary obstacle lies in the structural stability of PW cathodes during rapid charging processes. When subjected to high current densities, these materials often experience accelerated degradation due to the mechanical stress induced by rapid sodium ion insertion and extraction.

Sodium ion diffusion kinetics presents another critical challenge. Unlike lithium ions, sodium ions have a larger ionic radius (1.02Å vs. 0.76Å), resulting in slower diffusion rates through electrode materials. This fundamental limitation creates a bottleneck for fast-charging capabilities, as the rate of ion transport cannot keep pace with the applied current during rapid charging scenarios.

Interface stability between the PW cathode and electrolyte deteriorates under fast-charging conditions. The high voltage gradients and localized heating at these interfaces can trigger parasitic reactions, leading to the formation of resistive surface films that impede ion transport. These surface films grow progressively thicker with cycling, causing capacity fade and increased internal resistance.

Thermal management emerges as a particularly challenging aspect of fast-charging PW-SIBs. The Joule heating generated during high-current operation can create thermal gradients within cells, potentially leading to accelerated side reactions, electrolyte decomposition, and in extreme cases, thermal runaway. The lower thermal conductivity of sodium-based materials compared to their lithium counterparts exacerbates this issue.

The electronic conductivity of PW frameworks represents another significant hurdle. The inherent semiconducting or insulating nature of many PW compounds limits electron transport during fast charging. While carbon coating and conductive additives offer partial solutions, they often reduce the overall energy density of the battery system.

Electrolyte formulation specifically optimized for fast-charging PW-SIBs remains underdeveloped. Current electrolytes struggle to maintain stability under the high voltage and current conditions required for rapid charging, often decomposing to form resistive layers on electrode surfaces.

Balancing the trade-off between fast-charging capability and cycle life presents perhaps the most complex challenge. Protocols that enable extremely rapid charging typically accelerate degradation mechanisms, significantly reducing battery lifespan. Finding the optimal charging profile that maximizes both charging speed and long-term durability requires sophisticated battery management systems capable of adaptive charging based on real-time battery state assessment.

Sodium ion diffusion kinetics presents another critical challenge. Unlike lithium ions, sodium ions have a larger ionic radius (1.02Å vs. 0.76Å), resulting in slower diffusion rates through electrode materials. This fundamental limitation creates a bottleneck for fast-charging capabilities, as the rate of ion transport cannot keep pace with the applied current during rapid charging scenarios.

Interface stability between the PW cathode and electrolyte deteriorates under fast-charging conditions. The high voltage gradients and localized heating at these interfaces can trigger parasitic reactions, leading to the formation of resistive surface films that impede ion transport. These surface films grow progressively thicker with cycling, causing capacity fade and increased internal resistance.

Thermal management emerges as a particularly challenging aspect of fast-charging PW-SIBs. The Joule heating generated during high-current operation can create thermal gradients within cells, potentially leading to accelerated side reactions, electrolyte decomposition, and in extreme cases, thermal runaway. The lower thermal conductivity of sodium-based materials compared to their lithium counterparts exacerbates this issue.

The electronic conductivity of PW frameworks represents another significant hurdle. The inherent semiconducting or insulating nature of many PW compounds limits electron transport during fast charging. While carbon coating and conductive additives offer partial solutions, they often reduce the overall energy density of the battery system.

Electrolyte formulation specifically optimized for fast-charging PW-SIBs remains underdeveloped. Current electrolytes struggle to maintain stability under the high voltage and current conditions required for rapid charging, often decomposing to form resistive layers on electrode surfaces.

Balancing the trade-off between fast-charging capability and cycle life presents perhaps the most complex challenge. Protocols that enable extremely rapid charging typically accelerate degradation mechanisms, significantly reducing battery lifespan. Finding the optimal charging profile that maximizes both charging speed and long-term durability requires sophisticated battery management systems capable of adaptive charging based on real-time battery state assessment.

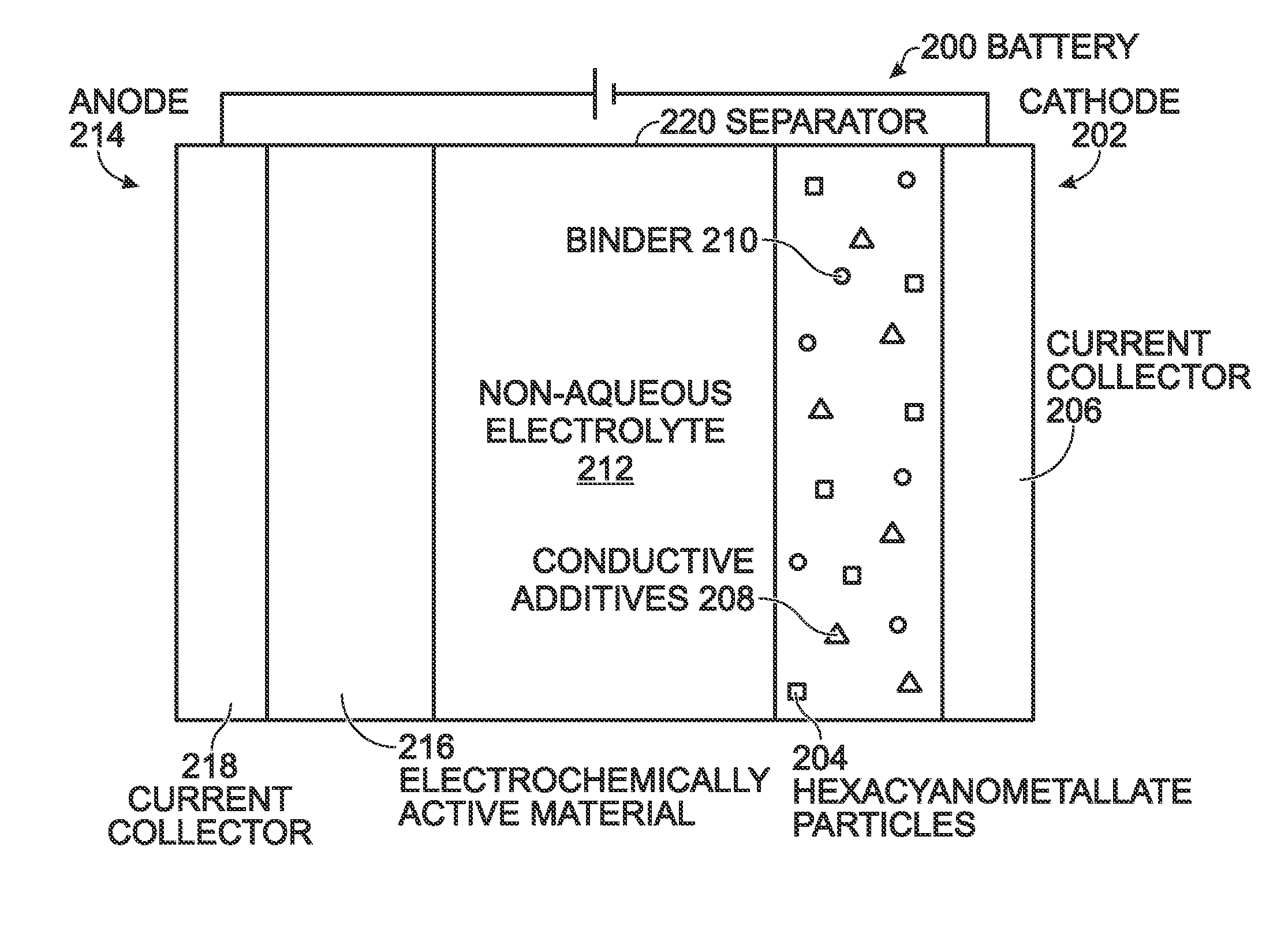

Current Fast-Charging Protocol Solutions for Prussian White SIBs

01 Prussian white electrode materials for fast-charging sodium-ion batteries

Prussian white compounds serve as excellent electrode materials for sodium-ion batteries due to their open framework structure that facilitates rapid sodium ion insertion/extraction. These materials feature large interstitial spaces and multiple redox-active sites, enabling fast charge transfer kinetics. The unique crystal structure of Prussian white allows for minimal volume changes during charging/discharging cycles, contributing to enhanced cycling stability and fast-charging capabilities.- Prussian white electrode materials for fast-charging sodium-ion batteries: Prussian white compounds serve as excellent electrode materials for sodium-ion batteries due to their open framework structure that facilitates rapid sodium ion insertion/extraction. These materials feature large interstitial spaces and multiple redox-active sites, enabling fast charge transfer kinetics. The unique crystal structure of Prussian white allows for minimal volume change during charging/discharging cycles, contributing to enhanced cycling stability and fast-charging capabilities.

- Doping and modification strategies for Prussian white materials: Various doping and modification strategies can significantly improve the fast-charging performance of Prussian white-based sodium-ion batteries. Incorporating transition metal ions (such as Mn, Fe, Co, Ni) or non-metal elements can enhance electronic conductivity and structural stability. Surface modifications and composite formations with carbon materials help reduce charge transfer resistance and improve rate capability, enabling faster charging while maintaining capacity retention.

- Electrolyte optimization for fast-charging Prussian white sodium-ion batteries: Electrolyte composition plays a crucial role in enabling fast-charging capabilities of Prussian white-based sodium-ion batteries. Optimized electrolytes with appropriate sodium salts, solvents, and additives can enhance ionic conductivity and form stable solid electrolyte interphases. Advanced electrolyte formulations help mitigate side reactions during rapid charging, reduce interfacial resistance, and improve sodium ion transport kinetics at the electrode-electrolyte interface.

- Nanostructured Prussian white materials for enhanced fast-charging: Nanostructuring Prussian white materials significantly improves fast-charging performance by shortening ion diffusion paths and increasing active surface area. Various morphologies such as nanoparticles, nanowires, nanosheets, and 3D hierarchical structures can be synthesized through controlled preparation methods. These nanostructured materials exhibit superior rate capability, reduced polarization, and enhanced kinetics during rapid charging processes compared to their bulk counterparts.

- Advanced electrode design and engineering for fast-charging applications: Innovative electrode design and engineering approaches enhance the fast-charging performance of Prussian white-based sodium-ion batteries. These include developing porous electrode architectures, optimizing electrode thickness and density, incorporating conductive additives, and designing flexible electrode structures. Advanced manufacturing techniques like 3D printing and roll-to-roll processing can create electrodes with optimized ion transport channels and electronic pathways, facilitating rapid charging while maintaining structural integrity.

02 Doping and modification strategies for Prussian white cathodes

Various doping and modification strategies can significantly improve the fast-charging performance of Prussian white cathodes. Incorporating transition metal ions (such as Mn, Fe, Co, Ni) or non-metal elements can enhance electronic conductivity and structural stability. Surface modifications using carbon coatings or conductive polymers reduce interfacial resistance and improve rate capability. These modifications optimize the electron/ion transport pathways, resulting in superior fast-charging performance while maintaining high capacity retention.Expand Specific Solutions03 Nanostructured Prussian white composites for enhanced sodium storage

Nanostructuring Prussian white materials creates composites with enhanced sodium storage capabilities and fast-charging performance. Techniques include synthesizing nanoparticles, nanowires, or hierarchical structures to shorten ion diffusion paths. Combining Prussian white with conductive carbon materials (graphene, carbon nanotubes) creates hybrid electrodes with improved electronic conductivity. These nanostructured composites demonstrate reduced charge transfer resistance and superior rate performance for fast-charging applications.Expand Specific Solutions04 Electrolyte optimization for fast-charging Prussian white batteries

Electrolyte composition plays a crucial role in the fast-charging performance of Prussian white sodium-ion batteries. Optimized electrolytes with appropriate sodium salts, solvents, and additives can enhance ionic conductivity and form stable solid-electrolyte interfaces. Novel electrolyte formulations reduce interfacial resistance and improve sodium ion transport kinetics. Electrolyte engineering strategies focus on widening the electrochemical stability window and minimizing side reactions during rapid charging processes.Expand Specific Solutions05 Advanced battery system design for Prussian white fast-charging applications

Innovative battery system designs maximize the fast-charging capabilities of Prussian white electrodes. These include optimized cell configurations, advanced current collectors, and thermal management systems that enable high-rate charging while preventing overheating. Novel electrode architectures with controlled porosity and thickness optimize ion transport pathways. Battery management systems with specialized charging protocols specifically designed for Prussian white chemistry can significantly reduce charging times while maintaining battery safety and longevity.Expand Specific Solutions

Leading Companies and Research Institutions in SIB Fast-Charging

The fast-charging protocols for Prussian White-based sodium-ion batteries market is in an early growth stage, with increasing research activity but limited commercial deployment. The global sodium-ion battery market is projected to reach approximately $1.2 billion by 2026, with fast-charging technologies representing a significant growth opportunity. Technologically, Prussian White-based solutions are advancing rapidly, with companies like CATL, Altris AB, and StoreDot leading development. Academic institutions including Wuhan University of Technology and Huazhong University of Science & Technology are contributing fundamental research, while industrial players such as Hyundai Motor, Kia, and Bosch are exploring applications. The technology offers promising cost advantages over lithium-ion alternatives but requires further optimization for cycle stability and energy density before widespread commercial adoption.

StoreDot Ltd.

Technical Solution: StoreDot has adapted its XFC (Extreme Fast Charging) technology for Prussian White sodium-ion batteries, focusing on silicon-dominant anode modifications that enhance sodium ion diffusion rates. Their protocol employs a proprietary gradient charging approach that varies current density across different stages of the charging process. The company's technology incorporates nano-structured current collectors with enhanced surface area that facilitate rapid ion transfer at the electrode interfaces. StoreDot's fast-charging protocol utilizes AI-driven thermal management that preemptively adjusts charging parameters based on predicted temperature changes rather than reactive adjustments. Their system includes specialized electrode designs with controlled porosity that maintains structural integrity during rapid sodium insertion/extraction cycles. The protocol also features a unique pre-conditioning phase that prepares the battery's crystalline structure for high-rate charging, reducing mechanical stress during the subsequent fast-charging phase.

Strengths: Exceptional charging speed capabilities (potentially under 10 minutes to 80% capacity); silicon-based technology that transfers well from lithium to sodium chemistry; strong IP portfolio. Weaknesses: Technology still primarily optimized for lithium systems with sodium adaptation in earlier stages; higher manufacturing complexity compared to conventional approaches.

Huazhong University of Science & Technology

Technical Solution: Huazhong University has developed an innovative academic approach to fast-charging protocols for Prussian White sodium-ion batteries focusing on fundamental electrochemical mechanisms. Their research has yielded a charging protocol that utilizes asymmetric current pulses with precisely calculated rest periods that allow for sodium-ion concentration gradient relaxation within the electrode structure. The university's approach incorporates in-situ characterization techniques that monitor structural changes in the Prussian White framework during fast charging, enabling real-time protocol adjustments. Their system employs novel electrolyte compositions with flame-retardant additives that maintain safety during high-rate charging while enhancing ionic conductivity. The protocol features a pre-lithiation technique that creates a protective solid electrolyte interphase (SEI) layer optimized for fast charging conditions. Additionally, their research has developed computational models that predict optimal charging parameters based on molecular dynamics simulations of sodium-ion transport through the Prussian White crystal structure.

Strengths: Strong fundamental scientific understanding of sodium-ion intercalation mechanisms; innovative approach to pulse charging that reduces mechanical stress; excellent safety considerations. Weaknesses: Less developed commercialization pathway compared to industry players; potential challenges in scaling laboratory protocols to production environments.

Key Patents and Research on Prussian White Fast-Charging Mechanisms

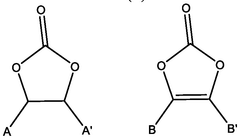

Prussian blue analogue electrolyte

PatentWO2025153731A1

Innovation

- Incorporating a sodium Prussian blue analogue electrode with a carbon-based anode and an electrolyte containing a combination of cyclic organic carbonates and organic sulfates as additives to form a robust solid electrolyte interface (SEI) layer, which enhances electrochemical stability and reduces impedance.

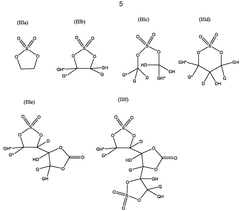

Prussian Blue Analogue Electrodes without Zeolitic Water Content

PatentActiveUS20150357630A1

Innovation

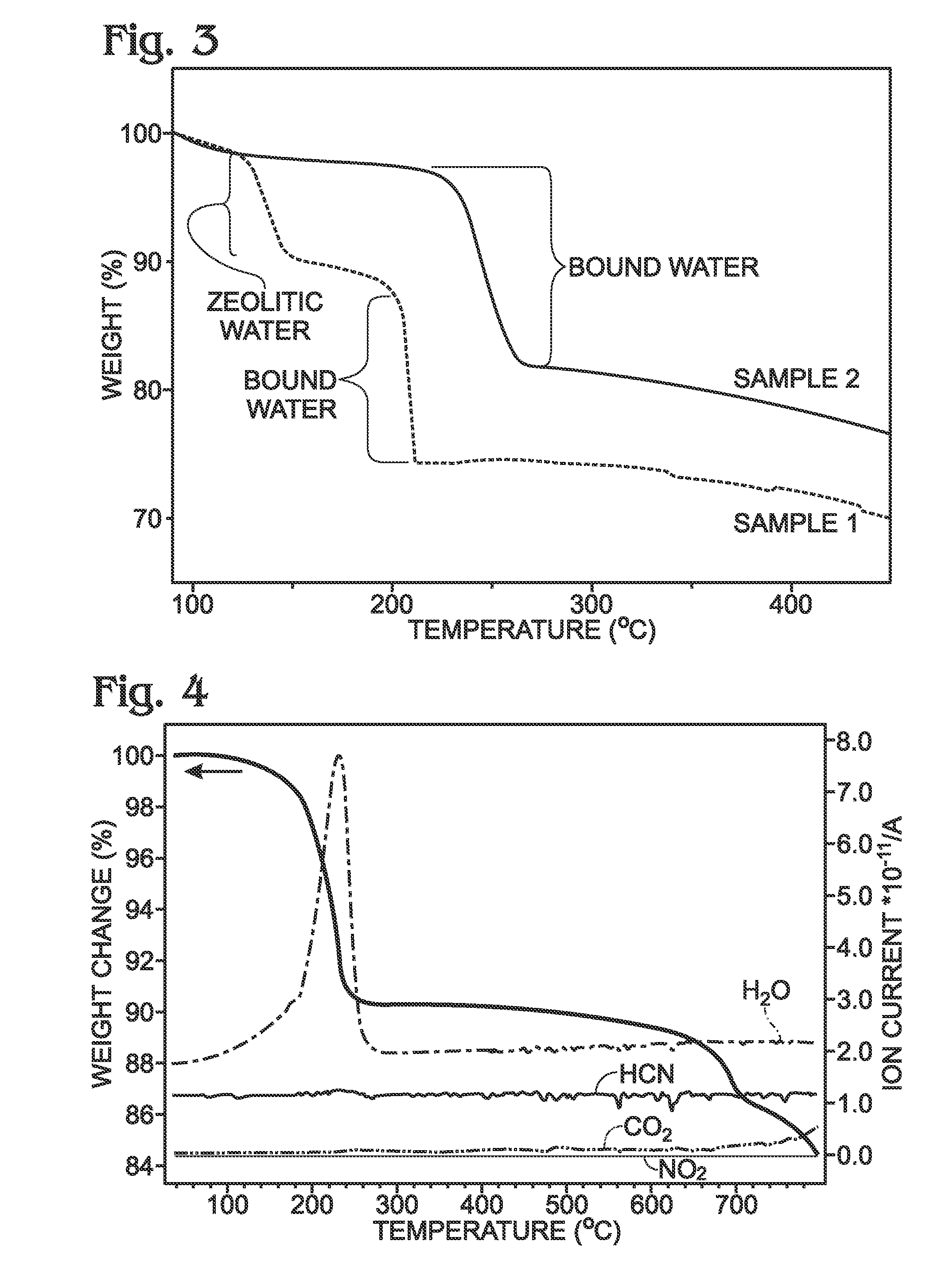

- A PBA material is formulated without zeolitic water content by dehydration annealing at temperatures between 120°C and 200°C, represented as AXM1MM2N(CN)Z.d[H2O]ZEO.e[H2O]BND, where d=0, to prevent zeolitic water contamination in non-aqueous electrolytes and minimize bound water, allowing for higher voltage and energy density operations.

Material Degradation Analysis During Rapid Charging Cycles

Material degradation during rapid charging cycles represents a critical challenge for Prussian White (PW) based sodium-ion batteries. When subjected to fast-charging protocols, these materials experience accelerated structural and chemical changes that significantly impact their long-term performance and cycle life. Electron microscopy studies reveal that rapid charging induces microfractures within the PW crystal structure, creating pathways for electrolyte penetration and subsequent side reactions.

X-ray diffraction analyses demonstrate that during high-rate charging, sodium extraction occurs unevenly throughout the material, leading to phase heterogeneity and lattice strain. This strain manifests as a gradual expansion of unit cell parameters over multiple fast-charging cycles, ultimately compromising the structural integrity of the cathode material. The degradation is particularly pronounced at charging rates exceeding 5C, where incomplete sodium diffusion creates concentration gradients within particles.

Spectroscopic investigations indicate that fast charging accelerates the oxidation of Fe2+ to Fe3+ at the particle surface, creating an electrochemically inactive layer that impedes sodium-ion transport. This surface degradation is compounded by electrolyte decomposition products that accumulate at the electrode-electrolyte interface, forming resistive films that further hinder ion mobility and increase cell impedance.

Thermal analysis reveals that rapid charging generates localized heating within the electrode structure, particularly at particle boundaries. This thermal stress accelerates the dissolution of transition metal ions into the electrolyte, leading to capacity fade through active material loss. Differential electrochemical mass spectrometry has detected increased gas evolution during fast-charging protocols, indicating parasitic reactions that consume both electrolyte and active material.

Computational modeling suggests that degradation pathways are highly dependent on particle morphology and size distribution. Larger PW particles (>500 nm) show more severe internal stress fracturing during rapid charging, while smaller particles (<100 nm) experience accelerated surface degradation due to their higher surface-to-volume ratio. This size-dependent degradation mechanism necessitates careful control of particle synthesis parameters to optimize fast-charging performance.

Recent in-situ characterization techniques have identified that sodium-ion concentration gradients during fast charging trigger a cascading effect of structural transformations, beginning with surface amorphization and progressing toward core degradation with continued cycling. These findings highlight the importance of developing gradient materials or core-shell structures that can better accommodate the mechanical stresses associated with rapid charging protocols.

X-ray diffraction analyses demonstrate that during high-rate charging, sodium extraction occurs unevenly throughout the material, leading to phase heterogeneity and lattice strain. This strain manifests as a gradual expansion of unit cell parameters over multiple fast-charging cycles, ultimately compromising the structural integrity of the cathode material. The degradation is particularly pronounced at charging rates exceeding 5C, where incomplete sodium diffusion creates concentration gradients within particles.

Spectroscopic investigations indicate that fast charging accelerates the oxidation of Fe2+ to Fe3+ at the particle surface, creating an electrochemically inactive layer that impedes sodium-ion transport. This surface degradation is compounded by electrolyte decomposition products that accumulate at the electrode-electrolyte interface, forming resistive films that further hinder ion mobility and increase cell impedance.

Thermal analysis reveals that rapid charging generates localized heating within the electrode structure, particularly at particle boundaries. This thermal stress accelerates the dissolution of transition metal ions into the electrolyte, leading to capacity fade through active material loss. Differential electrochemical mass spectrometry has detected increased gas evolution during fast-charging protocols, indicating parasitic reactions that consume both electrolyte and active material.

Computational modeling suggests that degradation pathways are highly dependent on particle morphology and size distribution. Larger PW particles (>500 nm) show more severe internal stress fracturing during rapid charging, while smaller particles (<100 nm) experience accelerated surface degradation due to their higher surface-to-volume ratio. This size-dependent degradation mechanism necessitates careful control of particle synthesis parameters to optimize fast-charging performance.

Recent in-situ characterization techniques have identified that sodium-ion concentration gradients during fast charging trigger a cascading effect of structural transformations, beginning with surface amorphization and progressing toward core degradation with continued cycling. These findings highlight the importance of developing gradient materials or core-shell structures that can better accommodate the mechanical stresses associated with rapid charging protocols.

Safety Standards and Thermal Management for Fast-Charging SIBs

The rapid development of fast-charging protocols for Prussian White based sodium-ion batteries (SIBs) necessitates robust safety standards and thermal management systems. Current international standards for lithium-ion batteries, such as IEC 62660 and UL 1642, provide foundational frameworks that are being adapted for SIBs, with specific considerations for the unique electrochemical properties of sodium-based systems.

Temperature control represents a critical safety factor during fast charging of Prussian White SIBs. Research indicates that these batteries typically operate optimally between 15-45°C, with thermal runaway risks increasing significantly above 60°C. Unlike their lithium counterparts, Prussian White SIBs demonstrate different thermal behavior patterns, requiring modified cooling strategies during rapid charging cycles.

Advanced thermal management solutions being implemented include phase change materials (PCMs) that absorb excess heat during fast charging. These materials, with melting points calibrated to the specific thermal profile of Prussian White cathodes, have demonstrated up to 30% improvement in temperature regulation compared to conventional cooling systems. Liquid cooling systems with sodium-compatible coolants are also showing promise in laboratory testing.

Real-time temperature monitoring systems utilizing embedded thermistors and infrared sensors are becoming standard in fast-charging protocols. These systems enable dynamic charging rate adjustments based on temperature feedback, preventing localized hotspots that could trigger thermal runaway. Recent studies indicate that implementing such adaptive charging algorithms can extend battery lifetime by up to 25% while maintaining fast-charging capabilities.

Safety certification processes for fast-charging Prussian White SIBs are evolving rapidly. Testing protocols now include accelerated cycling under thermal stress, nail penetration tests modified for sodium chemistry, and overcharge tolerance assessments. The National Battery Testing Centers in several countries are currently developing standardized testing procedures specifically for sodium-ion technologies.

Battery management systems (BMS) for fast-charging applications incorporate sophisticated thermal models that account for the unique heat generation characteristics of Prussian White structures. These systems implement predictive algorithms that anticipate thermal behavior based on charging current, state of charge, and ambient conditions, preemptively adjusting charging parameters to maintain safe operation.

Industry consortia including battery manufacturers, automotive companies, and regulatory bodies are collaborating to establish unified safety standards for fast-charging SIBs. The International Sodium Battery Association has proposed a preliminary framework that includes specific thermal management requirements, with final standards expected to be published within the next 18 months, potentially accelerating commercial adoption of fast-charging Prussian White battery technologies.

Temperature control represents a critical safety factor during fast charging of Prussian White SIBs. Research indicates that these batteries typically operate optimally between 15-45°C, with thermal runaway risks increasing significantly above 60°C. Unlike their lithium counterparts, Prussian White SIBs demonstrate different thermal behavior patterns, requiring modified cooling strategies during rapid charging cycles.

Advanced thermal management solutions being implemented include phase change materials (PCMs) that absorb excess heat during fast charging. These materials, with melting points calibrated to the specific thermal profile of Prussian White cathodes, have demonstrated up to 30% improvement in temperature regulation compared to conventional cooling systems. Liquid cooling systems with sodium-compatible coolants are also showing promise in laboratory testing.

Real-time temperature monitoring systems utilizing embedded thermistors and infrared sensors are becoming standard in fast-charging protocols. These systems enable dynamic charging rate adjustments based on temperature feedback, preventing localized hotspots that could trigger thermal runaway. Recent studies indicate that implementing such adaptive charging algorithms can extend battery lifetime by up to 25% while maintaining fast-charging capabilities.

Safety certification processes for fast-charging Prussian White SIBs are evolving rapidly. Testing protocols now include accelerated cycling under thermal stress, nail penetration tests modified for sodium chemistry, and overcharge tolerance assessments. The National Battery Testing Centers in several countries are currently developing standardized testing procedures specifically for sodium-ion technologies.

Battery management systems (BMS) for fast-charging applications incorporate sophisticated thermal models that account for the unique heat generation characteristics of Prussian White structures. These systems implement predictive algorithms that anticipate thermal behavior based on charging current, state of charge, and ambient conditions, preemptively adjusting charging parameters to maintain safe operation.

Industry consortia including battery manufacturers, automotive companies, and regulatory bodies are collaborating to establish unified safety standards for fast-charging SIBs. The International Sodium Battery Association has proposed a preliminary framework that includes specific thermal management requirements, with final standards expected to be published within the next 18 months, potentially accelerating commercial adoption of fast-charging Prussian White battery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!