Moisture Stability And Crystal Water Control In Prussian White Production

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Prussian White Technology Background and Objectives

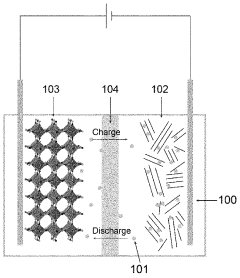

Prussian White, also known as potassium iron(II) hexacyanoferrate(II), represents a significant advancement in battery technology, particularly for sodium-ion batteries. The evolution of this material traces back to the discovery of Prussian Blue in the early 18th century, which has since evolved into various analogs with specialized applications. Over the past decade, Prussian White has emerged as a promising cathode material due to its open framework structure, which facilitates rapid ion insertion and extraction during battery cycling.

The technological trajectory of Prussian White has been marked by incremental improvements in synthesis methods, from traditional precipitation techniques to more sophisticated hydrothermal and microwave-assisted processes. These advancements have aimed to address persistent challenges in material quality, particularly regarding moisture stability and crystal water content control, which significantly impact electrochemical performance.

Current research objectives in Prussian White production center on developing scalable manufacturing processes that yield materials with consistent stoichiometry, minimal defects, and controlled water content. The presence of crystal water molecules within the Prussian White framework presents a double-edged sword: while some coordination water is beneficial for structural stability, excess zeolitic water can lead to decreased energy density and accelerated capacity fading during battery operation.

The moisture sensitivity of Prussian White compounds poses significant challenges for mass production and long-term storage. When exposed to ambient conditions, these materials readily absorb atmospheric moisture, altering their crystal structure and compromising electrochemical properties. Consequently, establishing precise protocols for moisture control during synthesis, processing, and storage has become a critical research priority.

Technical objectives in this field include developing innovative drying techniques that can remove excess water without causing structural collapse, implementing effective encapsulation strategies to shield the material from environmental moisture, and engineering compositional modifications that enhance intrinsic water resistance while maintaining electrochemical performance.

Additionally, researchers aim to establish standardized analytical methods for accurately quantifying different types of water molecules within the Prussian White structure, as current characterization techniques often struggle to differentiate between coordinated and zeolitic water. This fundamental understanding is essential for designing targeted approaches to water content management.

The ultimate goal of current research efforts is to enable industrial-scale production of Prussian White materials with precisely controlled moisture levels and crystal water content, thereby unlocking their full potential as cost-effective, high-performance electrode materials for next-generation energy storage systems.

The technological trajectory of Prussian White has been marked by incremental improvements in synthesis methods, from traditional precipitation techniques to more sophisticated hydrothermal and microwave-assisted processes. These advancements have aimed to address persistent challenges in material quality, particularly regarding moisture stability and crystal water content control, which significantly impact electrochemical performance.

Current research objectives in Prussian White production center on developing scalable manufacturing processes that yield materials with consistent stoichiometry, minimal defects, and controlled water content. The presence of crystal water molecules within the Prussian White framework presents a double-edged sword: while some coordination water is beneficial for structural stability, excess zeolitic water can lead to decreased energy density and accelerated capacity fading during battery operation.

The moisture sensitivity of Prussian White compounds poses significant challenges for mass production and long-term storage. When exposed to ambient conditions, these materials readily absorb atmospheric moisture, altering their crystal structure and compromising electrochemical properties. Consequently, establishing precise protocols for moisture control during synthesis, processing, and storage has become a critical research priority.

Technical objectives in this field include developing innovative drying techniques that can remove excess water without causing structural collapse, implementing effective encapsulation strategies to shield the material from environmental moisture, and engineering compositional modifications that enhance intrinsic water resistance while maintaining electrochemical performance.

Additionally, researchers aim to establish standardized analytical methods for accurately quantifying different types of water molecules within the Prussian White structure, as current characterization techniques often struggle to differentiate between coordinated and zeolitic water. This fundamental understanding is essential for designing targeted approaches to water content management.

The ultimate goal of current research efforts is to enable industrial-scale production of Prussian White materials with precisely controlled moisture levels and crystal water content, thereby unlocking their full potential as cost-effective, high-performance electrode materials for next-generation energy storage systems.

Market Analysis for Moisture-Stable Prussian White Materials

The global market for Prussian White materials has been experiencing significant growth, primarily driven by the expanding energy storage sector. As a key component in sodium-ion batteries, moisture-stable Prussian White compounds are positioned to capture substantial market share in the rapidly evolving battery materials landscape. Current market valuations indicate that the sodium-ion battery market is growing at a compound annual growth rate exceeding 20%, with Prussian White materials representing a critical segment within this ecosystem.

Market demand for moisture-stable Prussian White materials stems from multiple sectors, with energy storage applications leading the charge. The electric vehicle industry's shift toward more cost-effective and resource-abundant battery technologies has created a substantial pull for sodium-based alternatives to lithium-ion systems. Grid-scale energy storage represents another significant market segment, where the lower cost and improved safety profile of sodium-ion batteries containing Prussian White materials offer compelling advantages over competing technologies.

Consumer electronics manufacturers are increasingly exploring sodium-ion batteries as complementary power solutions, particularly for applications where energy density requirements are moderate but cost considerations are paramount. This diversification of end-use applications is expanding the potential market footprint for moisture-stable Prussian White materials beyond traditional energy storage boundaries.

Regional market analysis reveals that Asia-Pacific currently dominates both production and consumption of Prussian White materials, with China leading manufacturing capacity development. European markets show accelerating adoption rates as part of broader strategic initiatives to develop sustainable battery supply chains independent of critical raw materials constraints. North American markets are gradually increasing investment in sodium-ion technology, though at a more measured pace than Asian counterparts.

Market barriers for moisture-stable Prussian White materials include competition from established lithium-ion technologies, technical challenges related to production scaling, and limited awareness among potential end-users about the benefits of sodium-ion alternatives. However, these barriers are progressively diminishing as technical advancements improve performance metrics and manufacturing economics.

Price sensitivity analysis indicates that moisture-stable Prussian White materials offer significant cost advantages over cathode materials used in conventional lithium-ion batteries, particularly when considering total lifecycle costs. This economic advantage is expected to accelerate market penetration as production volumes increase and manufacturing processes mature.

Future market projections suggest that moisture-stable Prussian White materials will experience continued strong growth, potentially capturing up to 15% of the overall battery materials market within the next decade. This growth trajectory is supported by increasing commercial deployment of sodium-ion batteries and ongoing research advancements that continue to improve the performance characteristics of Prussian White compounds.

Market demand for moisture-stable Prussian White materials stems from multiple sectors, with energy storage applications leading the charge. The electric vehicle industry's shift toward more cost-effective and resource-abundant battery technologies has created a substantial pull for sodium-based alternatives to lithium-ion systems. Grid-scale energy storage represents another significant market segment, where the lower cost and improved safety profile of sodium-ion batteries containing Prussian White materials offer compelling advantages over competing technologies.

Consumer electronics manufacturers are increasingly exploring sodium-ion batteries as complementary power solutions, particularly for applications where energy density requirements are moderate but cost considerations are paramount. This diversification of end-use applications is expanding the potential market footprint for moisture-stable Prussian White materials beyond traditional energy storage boundaries.

Regional market analysis reveals that Asia-Pacific currently dominates both production and consumption of Prussian White materials, with China leading manufacturing capacity development. European markets show accelerating adoption rates as part of broader strategic initiatives to develop sustainable battery supply chains independent of critical raw materials constraints. North American markets are gradually increasing investment in sodium-ion technology, though at a more measured pace than Asian counterparts.

Market barriers for moisture-stable Prussian White materials include competition from established lithium-ion technologies, technical challenges related to production scaling, and limited awareness among potential end-users about the benefits of sodium-ion alternatives. However, these barriers are progressively diminishing as technical advancements improve performance metrics and manufacturing economics.

Price sensitivity analysis indicates that moisture-stable Prussian White materials offer significant cost advantages over cathode materials used in conventional lithium-ion batteries, particularly when considering total lifecycle costs. This economic advantage is expected to accelerate market penetration as production volumes increase and manufacturing processes mature.

Future market projections suggest that moisture-stable Prussian White materials will experience continued strong growth, potentially capturing up to 15% of the overall battery materials market within the next decade. This growth trajectory is supported by increasing commercial deployment of sodium-ion batteries and ongoing research advancements that continue to improve the performance characteristics of Prussian White compounds.

Current Challenges in Crystal Water Control Technology

Despite significant advancements in Prussian White production techniques, controlling crystal water content remains one of the most challenging aspects of the manufacturing process. The hygroscopic nature of Prussian White compounds creates inherent instability in moisture content, leading to inconsistent product quality and performance variations in battery applications. Current production methods struggle to maintain precise hydration levels throughout the synthesis, drying, and storage phases.

The primary challenge lies in the dynamic equilibrium between bound crystal water and environmental moisture. Prussian White structures can contain variable amounts of zeolitic water molecules within their cubic lattice framework, with the formula often represented as AxM[Fe(CN)6]y·nH2O (where A is an alkali metal, M is a transition metal). This water content significantly impacts electrochemical performance, structural stability, and cycle life in battery applications.

Temperature and humidity fluctuations during production create substantial obstacles for maintaining consistent crystal water content. Even minor variations in ambient conditions can trigger water absorption or desorption processes, altering the final product composition. Current drying technologies often fail to achieve the narrow target range of water content required for optimal electrochemical performance.

Analytical challenges further complicate crystal water control efforts. Real-time monitoring of water content during production remains difficult, with most manufacturers relying on post-production testing that cannot provide immediate feedback for process adjustments. Thermogravimetric analysis (TGA) and Karl Fischer titration are commonly employed but have limitations in accuracy and throughput for industrial-scale production.

The distinction between surface-adsorbed water and lattice-integrated crystal water presents another significant technical hurdle. Current dehydration methods often remove both types indiscriminately, whereas optimal performance requires selective removal of surface moisture while maintaining specific crystal water content. This selective control remains elusive with conventional drying technologies.

Scale-up challenges intensify these issues, as larger batch sizes exhibit greater heterogeneity in moisture distribution. Industrial production facilities struggle to maintain uniform drying conditions throughout large material volumes, resulting in inconsistent product quality. The energy-intensive nature of current drying processes also raises cost and sustainability concerns.

Packaging and storage solutions have proven inadequate for maintaining stable crystal water content after production. Even with moisture-barrier packaging, gradual water exchange with the environment occurs during storage and transportation, potentially compromising product quality before end-use application. This necessitates the development of more effective moisture control strategies throughout the entire product lifecycle.

The primary challenge lies in the dynamic equilibrium between bound crystal water and environmental moisture. Prussian White structures can contain variable amounts of zeolitic water molecules within their cubic lattice framework, with the formula often represented as AxM[Fe(CN)6]y·nH2O (where A is an alkali metal, M is a transition metal). This water content significantly impacts electrochemical performance, structural stability, and cycle life in battery applications.

Temperature and humidity fluctuations during production create substantial obstacles for maintaining consistent crystal water content. Even minor variations in ambient conditions can trigger water absorption or desorption processes, altering the final product composition. Current drying technologies often fail to achieve the narrow target range of water content required for optimal electrochemical performance.

Analytical challenges further complicate crystal water control efforts. Real-time monitoring of water content during production remains difficult, with most manufacturers relying on post-production testing that cannot provide immediate feedback for process adjustments. Thermogravimetric analysis (TGA) and Karl Fischer titration are commonly employed but have limitations in accuracy and throughput for industrial-scale production.

The distinction between surface-adsorbed water and lattice-integrated crystal water presents another significant technical hurdle. Current dehydration methods often remove both types indiscriminately, whereas optimal performance requires selective removal of surface moisture while maintaining specific crystal water content. This selective control remains elusive with conventional drying technologies.

Scale-up challenges intensify these issues, as larger batch sizes exhibit greater heterogeneity in moisture distribution. Industrial production facilities struggle to maintain uniform drying conditions throughout large material volumes, resulting in inconsistent product quality. The energy-intensive nature of current drying processes also raises cost and sustainability concerns.

Packaging and storage solutions have proven inadequate for maintaining stable crystal water content after production. Even with moisture-barrier packaging, gradual water exchange with the environment occurs during storage and transportation, potentially compromising product quality before end-use application. This necessitates the development of more effective moisture control strategies throughout the entire product lifecycle.

Current Moisture Stability Solutions in Prussian White Manufacturing

01 Crystal water control methods for Prussian White stability

Various methods can be employed to control crystal water content in Prussian White compounds, which directly impacts their moisture stability. These techniques include controlled dehydration processes, precise temperature and humidity regulation during synthesis, and post-synthesis treatments to achieve optimal crystal water content. Maintaining specific hydration levels is crucial for preserving the structural integrity and electrochemical performance of Prussian White materials.- Crystal water control methods for Prussian White stability: Various methods can be employed to control crystal water content in Prussian White compounds, which directly impacts their moisture stability. These techniques include controlled dehydration processes, precise temperature and humidity regulation during synthesis, and post-synthesis treatments to achieve optimal crystal water content. Maintaining specific hydration levels is crucial for preserving the structural integrity and electrochemical performance of Prussian White materials.

- Protective coatings and encapsulation techniques: Applying protective coatings or encapsulation techniques can significantly enhance the moisture stability of Prussian White compounds. These approaches create physical barriers that prevent water molecules from interacting with the sensitive crystal structure. Various coating materials including polymers, carbon-based materials, and inorganic compounds can be utilized to shield Prussian White particles from environmental moisture while maintaining their functional properties.

- Chemical modification and doping strategies: Chemical modification and doping of Prussian White structures with specific elements or compounds can enhance their inherent moisture resistance. By incorporating hydrophobic groups, stabilizing ions, or creating stronger metal-ligand bonds within the crystal structure, the material becomes less susceptible to degradation from moisture exposure. These modifications can be implemented during synthesis or through post-synthesis treatments to achieve optimal moisture stability.

- Advanced drying and storage techniques: Specialized drying processes and storage conditions are critical for maintaining the moisture stability of Prussian White materials. These include vacuum drying, freeze-drying, controlled atmosphere storage, and the use of desiccants. By carefully managing the environment during processing and storage, the crystal water content can be maintained at optimal levels, preventing degradation from excess moisture or complete dehydration that could compromise structural integrity.

- Structural engineering for enhanced stability: Engineering the microstructure and morphology of Prussian White materials can significantly improve their moisture stability. Approaches include creating core-shell structures, controlling particle size and shape, developing hierarchical structures, and optimizing crystallinity. These structural modifications can reduce water accessibility to reactive sites, enhance mechanical strength, and improve overall resistance to moisture-induced degradation while maintaining the functional properties of the material.

02 Chemical modification for moisture resistance

Chemical modifications to Prussian White structures can significantly enhance their moisture stability. These modifications include surface coating with hydrophobic materials, incorporation of stabilizing ions or functional groups, and creation of composite structures. Such chemical treatments create barriers against moisture penetration and strengthen the crystal lattice against degradation in humid environments, thereby extending the material's functional lifespan.Expand Specific Solutions03 Doping strategies to enhance hydration stability

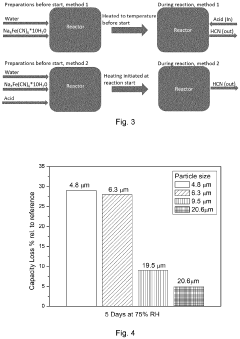

Introducing specific dopants into the Prussian White structure can improve its resistance to moisture-induced degradation. Various metal ions and compounds can be incorporated during synthesis to occupy interstitial sites, strengthen chemical bonds, or alter the electronic structure. These doping strategies effectively modify the hydration behavior of Prussian White materials, resulting in enhanced stability under varying moisture conditions.Expand Specific Solutions04 Advanced synthesis techniques for controlled hydration

Specialized synthesis methods have been developed to produce Prussian White materials with precisely controlled hydration levels. These techniques include modified co-precipitation approaches, hydrothermal synthesis under controlled conditions, and microwave-assisted methods. By carefully managing reaction parameters such as temperature, pH, and reagent concentrations, these processes yield Prussian White compounds with optimized crystal water content and superior moisture stability.Expand Specific Solutions05 Encapsulation and protective strategies

Encapsulation techniques provide effective protection for Prussian White materials against moisture exposure. These approaches include polymer coating, carbon encapsulation, and formation of core-shell structures. Such protective layers create physical barriers that prevent water molecules from interacting with the Prussian White crystal structure, thereby maintaining the material's stability and electrochemical performance even under challenging environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Prussian White Production

The Prussian White production market is currently in a growth phase, with increasing demand driven by battery technology applications. The market size is expanding as companies like Altris AB and Northvolt AB scale up from laboratory to industrial production levels. Technological maturity varies significantly across competitors, with specialized firms like Altris AB leading in Prussian White framework material development, while established chemical companies such as BASF Corp. and Nippon Shokubai leverage their expertise in moisture control processes. Academic institutions including Tsinghua University and Wuhan University of Technology are advancing fundamental research on crystal water control. The competitive landscape features both battery technology specialists and diversified chemical manufacturers working to overcome moisture stability challenges, which remains a critical technical barrier to widespread commercial adoption.

Guangdong Bangpu Recycling Technology Co., Ltd.

Technical Solution: Guangdong Bangpu has developed an advanced moisture control system for Prussian White production that incorporates multi-stage dehydration processes. Their technology utilizes precise temperature-controlled vacuum drying chambers that gradually remove crystal water while maintaining the hexacyanoferrate structure integrity. The company employs in-line moisture sensors and real-time feedback systems to continuously monitor water content during synthesis and post-processing stages. Their proprietary stabilization method involves controlled atmosphere packaging with specialized desiccants that maintain optimal moisture levels during storage and transportation. Additionally, Bangpu has implemented a surface modification technique that creates a hydrophobic protective layer on Prussian White particles, significantly reducing moisture reabsorption from ambient air while preserving electrochemical performance.

Strengths: Superior moisture stability in high humidity environments; consistent crystal water content across production batches; extended shelf life of final products. Weaknesses: Higher production costs due to complex moisture control equipment; longer processing times compared to conventional methods; requires specialized handling during downstream applications.

Altris AB

Technical Solution: Altris AB has pioneered a breakthrough approach to moisture stability in Prussian White materials through their patented "SodiumIon" technology. Their process involves precise control of crystal water during the co-precipitation synthesis phase, where reaction parameters including temperature, pH, and reagent concentration are carefully optimized to achieve the desired hydration state. The company utilizes specialized drying protocols that incorporate stepwise temperature ramping under controlled humidity conditions, allowing for selective removal of surface-adsorbed water while preserving structural water molecules essential for optimal electrochemical performance. Altris has also developed an innovative encapsulation technique that forms a nanoscale protective barrier around Prussian White particles, effectively shielding them from environmental moisture fluctuations while maintaining ion transport pathways. Their manufacturing process includes in-situ X-ray diffraction monitoring to verify crystal structure integrity throughout the dehydration process.

Strengths: Exceptional cycle stability in sodium-ion battery applications; consistent performance across varying humidity conditions; scalable manufacturing process suitable for industrial production. Weaknesses: Relatively high production cost compared to conventional materials; limited compatibility with certain electrolyte systems; requires specialized handling during cell assembly.

Key Patents and Innovations in Crystal Water Control

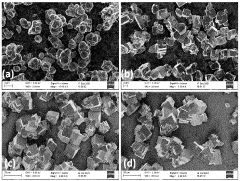

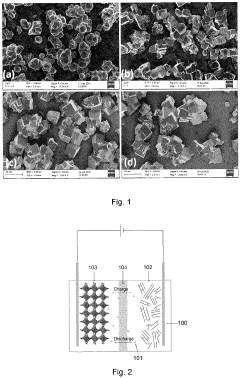

Sodium iron(II)-hexacyanoferrate(II) material

PatentWO2023217705A1

Innovation

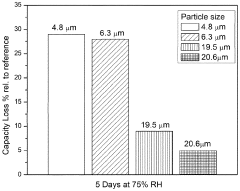

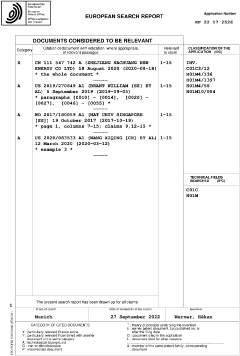

- A sodium iron(II)-hexacyanoferrate(II) material with a particle diameter D50 value between 4 μm and 50 μm and a BET specific surface area between 0.1 m²/g and 10 m²/g is developed, which reduces sodium loss and enhances moisture stability, maintaining high conductivity and capacity over time.

Sodium iron(II)-hexacyanoferrate(II) material

PatentInactiveEP4276069A1

Innovation

- A sodium iron(II)-hexacyanoferrate(II) material with a particle diameter D50 value between 7 µm to 50 µm and a BET specific surface area between 0.1 m²/g to 10 m²/g is developed, which reduces sodium loss and enhances moisture stability, improving the material's capacity retention over time.

Environmental Impact Assessment of Prussian White Production

The production of Prussian White materials, while offering significant advantages for energy storage applications, presents several environmental considerations that warrant thorough assessment. The manufacturing process involves chemical reactions that generate waste streams containing potentially harmful compounds such as cyanide derivatives and heavy metal ions, which require proper treatment before discharge to prevent water contamination.

Energy consumption represents another significant environmental factor, as the synthesis of Prussian White compounds typically requires controlled temperature conditions and extensive mixing operations. The moisture control processes, particularly vacuum drying and controlled atmosphere environments, contribute substantially to the carbon footprint of production facilities. Quantitative life cycle assessments indicate that these energy-intensive steps may account for approximately 30-40% of the total environmental impact.

Water usage in Prussian White production presents a dual environmental challenge. The manufacturing process requires substantial quantities of purified water for reaction media and washing procedures, while simultaneously generating wastewater containing dissolved salts and trace metals. Advanced water recycling systems have demonstrated potential to reduce freshwater consumption by up to 70%, though implementation remains limited in current production facilities.

Raw material sourcing introduces additional environmental considerations, particularly regarding the extraction of transition metals like iron, nickel, and copper used in various Prussian White formulations. Mining operations associated with these materials contribute to habitat disruption, soil erosion, and potential groundwater contamination. Sustainable sourcing initiatives and increased use of recycled metal content offer pathways to mitigate these impacts.

The crystal water control processes essential for maintaining Prussian White stability involve chemical additives and specialized packaging materials that may present disposal challenges. Particularly concerning are the desiccants and moisture-resistant coatings that often contain compounds resistant to natural degradation. Recent innovations in biodegradable moisture barriers represent promising developments, though their performance characteristics still lag behind conventional alternatives.

Regulatory frameworks governing Prussian White production vary significantly across regions, with European standards typically imposing stricter environmental controls than those found in developing economies. This regulatory disparity has contributed to geographic shifts in production capacity, with potential implications for global environmental equity and emissions leakage. Harmonization of international standards represents a critical step toward ensuring consistent environmental protection across the industry.

Energy consumption represents another significant environmental factor, as the synthesis of Prussian White compounds typically requires controlled temperature conditions and extensive mixing operations. The moisture control processes, particularly vacuum drying and controlled atmosphere environments, contribute substantially to the carbon footprint of production facilities. Quantitative life cycle assessments indicate that these energy-intensive steps may account for approximately 30-40% of the total environmental impact.

Water usage in Prussian White production presents a dual environmental challenge. The manufacturing process requires substantial quantities of purified water for reaction media and washing procedures, while simultaneously generating wastewater containing dissolved salts and trace metals. Advanced water recycling systems have demonstrated potential to reduce freshwater consumption by up to 70%, though implementation remains limited in current production facilities.

Raw material sourcing introduces additional environmental considerations, particularly regarding the extraction of transition metals like iron, nickel, and copper used in various Prussian White formulations. Mining operations associated with these materials contribute to habitat disruption, soil erosion, and potential groundwater contamination. Sustainable sourcing initiatives and increased use of recycled metal content offer pathways to mitigate these impacts.

The crystal water control processes essential for maintaining Prussian White stability involve chemical additives and specialized packaging materials that may present disposal challenges. Particularly concerning are the desiccants and moisture-resistant coatings that often contain compounds resistant to natural degradation. Recent innovations in biodegradable moisture barriers represent promising developments, though their performance characteristics still lag behind conventional alternatives.

Regulatory frameworks governing Prussian White production vary significantly across regions, with European standards typically imposing stricter environmental controls than those found in developing economies. This regulatory disparity has contributed to geographic shifts in production capacity, with potential implications for global environmental equity and emissions leakage. Harmonization of international standards represents a critical step toward ensuring consistent environmental protection across the industry.

Quality Control Standards and Testing Methodologies

Quality control in Prussian White production necessitates rigorous standards and methodologies to ensure moisture stability and crystal water control. The industry has established several key testing protocols that manufacturers must adhere to for consistent product quality.

Thermogravimetric Analysis (TGA) serves as a primary method for quantifying crystal water content in Prussian White compounds. This technique measures weight changes as a function of temperature under controlled atmosphere, allowing precise determination of water content with accuracy typically within ±0.5%. Modern TGA instruments can detect subtle variations in hydration levels between 0.1-15% by weight.

X-ray Diffraction (XRD) provides critical information about crystal structure integrity and phase purity. Quality standards typically require >95% phase purity with well-defined diffraction patterns matching reference standards. Shifts in peak positions or broadening can indicate improper crystal water incorporation, requiring immediate process adjustments.

Karl Fischer titration represents another essential methodology specifically for moisture content determination, with detection limits as low as 10 ppm. Industry standards typically specify moisture content below 2% for commercial-grade Prussian White materials to ensure stability during storage and application.

Environmental stability testing protocols have been standardized to evaluate product performance under varying humidity conditions. These tests typically involve exposing samples to controlled relative humidity environments (30-90% RH) for periods ranging from 24 hours to 30 days, with acceptable stability defined as less than 3% change in key performance parameters.

Spectroscopic methods, particularly FTIR and Raman spectroscopy, provide complementary quality control data by monitoring characteristic vibrational bands associated with crystal water. The CN stretching region (2000-2200 cm⁻¹) and OH stretching bands (3200-3600 cm⁻¹) serve as quality indicators, with established reference spectra for various hydration states.

Accelerated aging tests simulate long-term stability by subjecting materials to elevated temperatures (40-60°C) and humidity cycles. Quality standards typically require less than 5% degradation in functional properties after equivalent aging of 1-2 years under normal storage conditions.

Statistical process control methodologies have been implemented across the industry, with control charts monitoring critical parameters throughout production. Acceptance criteria typically include Cpk values exceeding 1.33 for moisture-related parameters, ensuring consistent quality with minimal batch-to-batch variation.

Thermogravimetric Analysis (TGA) serves as a primary method for quantifying crystal water content in Prussian White compounds. This technique measures weight changes as a function of temperature under controlled atmosphere, allowing precise determination of water content with accuracy typically within ±0.5%. Modern TGA instruments can detect subtle variations in hydration levels between 0.1-15% by weight.

X-ray Diffraction (XRD) provides critical information about crystal structure integrity and phase purity. Quality standards typically require >95% phase purity with well-defined diffraction patterns matching reference standards. Shifts in peak positions or broadening can indicate improper crystal water incorporation, requiring immediate process adjustments.

Karl Fischer titration represents another essential methodology specifically for moisture content determination, with detection limits as low as 10 ppm. Industry standards typically specify moisture content below 2% for commercial-grade Prussian White materials to ensure stability during storage and application.

Environmental stability testing protocols have been standardized to evaluate product performance under varying humidity conditions. These tests typically involve exposing samples to controlled relative humidity environments (30-90% RH) for periods ranging from 24 hours to 30 days, with acceptable stability defined as less than 3% change in key performance parameters.

Spectroscopic methods, particularly FTIR and Raman spectroscopy, provide complementary quality control data by monitoring characteristic vibrational bands associated with crystal water. The CN stretching region (2000-2200 cm⁻¹) and OH stretching bands (3200-3600 cm⁻¹) serve as quality indicators, with established reference spectra for various hydration states.

Accelerated aging tests simulate long-term stability by subjecting materials to elevated temperatures (40-60°C) and humidity cycles. Quality standards typically require less than 5% degradation in functional properties after equivalent aging of 1-2 years under normal storage conditions.

Statistical process control methodologies have been implemented across the industry, with control charts monitoring critical parameters throughout production. Acceptance criteria typically include Cpk values exceeding 1.33 for moisture-related parameters, ensuring consistent quality with minimal batch-to-batch variation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!