Manufacturing Yield Improvement For Prussian White Electrode Coating

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Prussian White Electrode Coating Technology Background and Objectives

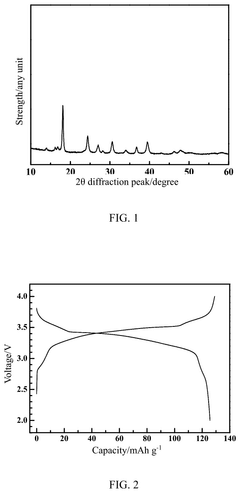

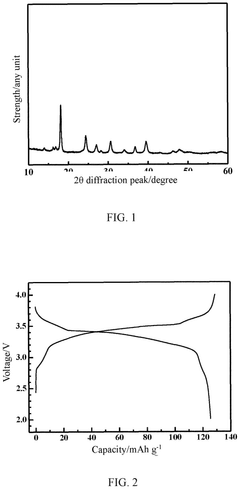

Prussian White electrode materials, a subset of Prussian Blue Analogs (PBAs), have emerged as promising candidates for next-generation energy storage systems, particularly in sodium-ion and potassium-ion batteries. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to lithium-ion battery materials due to concerns about lithium resource limitations and cost escalation.

The technological trajectory of Prussian White electrodes has been characterized by significant advancements in synthesis methods, from simple precipitation techniques to more sophisticated controlled crystallization processes. These developments have been driven by the material's attractive theoretical capacity, structural stability during ion insertion/extraction, and environmental compatibility compared to conventional electrode materials.

Despite these advantages, manufacturing yield issues have persistently challenged large-scale commercialization efforts. Historical data indicates that coating uniformity, adhesion properties, and material consistency have been major hurdles in transitioning from laboratory-scale production to industrial manufacturing. Coating defects such as cracking, delamination, and non-uniform thickness distribution have resulted in yield rates as low as 40-60% in early production attempts.

Current technological objectives focus on achieving manufacturing yield improvements to exceed 90% while maintaining or enhancing electrochemical performance metrics. This involves optimizing slurry formulations, refining coating parameters, and developing in-line quality control methodologies specifically tailored for Prussian White materials. The unique crystal structure and water sensitivity of these materials present distinct challenges compared to conventional electrode coating processes.

The global research community has established several benchmark targets for successful Prussian White electrode manufacturing, including uniform particle size distribution (coefficient of variation <10%), consistent coating thickness (±5% tolerance), minimal cracking (<5% of coated area), and excellent adhesion strength (>15 N/cm). These parameters directly influence the electrochemical performance, cycle life, and production economics of the final battery products.

Recent technological roadmaps from industry consortia and research institutions have highlighted the need for interdisciplinary approaches combining materials science, chemical engineering, and advanced manufacturing techniques to address yield challenges. The convergence of these fields is expected to enable breakthrough solutions that could position Prussian White electrodes as commercially viable alternatives in the rapidly expanding energy storage market.

The ultimate goal of current research efforts is to establish scalable, reproducible manufacturing protocols that can be implemented in gigafactory settings, supporting the transition toward sustainable energy storage solutions with reduced dependence on critical raw materials like cobalt and nickel that dominate current lithium-ion battery technologies.

The technological trajectory of Prussian White electrodes has been characterized by significant advancements in synthesis methods, from simple precipitation techniques to more sophisticated controlled crystallization processes. These developments have been driven by the material's attractive theoretical capacity, structural stability during ion insertion/extraction, and environmental compatibility compared to conventional electrode materials.

Despite these advantages, manufacturing yield issues have persistently challenged large-scale commercialization efforts. Historical data indicates that coating uniformity, adhesion properties, and material consistency have been major hurdles in transitioning from laboratory-scale production to industrial manufacturing. Coating defects such as cracking, delamination, and non-uniform thickness distribution have resulted in yield rates as low as 40-60% in early production attempts.

Current technological objectives focus on achieving manufacturing yield improvements to exceed 90% while maintaining or enhancing electrochemical performance metrics. This involves optimizing slurry formulations, refining coating parameters, and developing in-line quality control methodologies specifically tailored for Prussian White materials. The unique crystal structure and water sensitivity of these materials present distinct challenges compared to conventional electrode coating processes.

The global research community has established several benchmark targets for successful Prussian White electrode manufacturing, including uniform particle size distribution (coefficient of variation <10%), consistent coating thickness (±5% tolerance), minimal cracking (<5% of coated area), and excellent adhesion strength (>15 N/cm). These parameters directly influence the electrochemical performance, cycle life, and production economics of the final battery products.

Recent technological roadmaps from industry consortia and research institutions have highlighted the need for interdisciplinary approaches combining materials science, chemical engineering, and advanced manufacturing techniques to address yield challenges. The convergence of these fields is expected to enable breakthrough solutions that could position Prussian White electrodes as commercially viable alternatives in the rapidly expanding energy storage market.

The ultimate goal of current research efforts is to establish scalable, reproducible manufacturing protocols that can be implemented in gigafactory settings, supporting the transition toward sustainable energy storage solutions with reduced dependence on critical raw materials like cobalt and nickel that dominate current lithium-ion battery technologies.

Market Demand Analysis for High-Yield Electrode Manufacturing

The global market for high-yield electrode manufacturing technologies has experienced significant growth in recent years, driven primarily by the expanding energy storage sector. Prussian White electrodes, in particular, have garnered substantial attention due to their promising performance characteristics in sodium-ion batteries, which are increasingly viewed as a viable alternative to lithium-ion technologies. Market research indicates that the demand for advanced electrode manufacturing solutions is projected to grow at a compound annual rate of 18% through 2028, reflecting the urgent need for more efficient and cost-effective production methods.

The primary market drivers for improved Prussian White electrode coating technologies stem from several converging factors. Energy storage system manufacturers are facing intense pressure to reduce production costs while simultaneously improving battery performance metrics. Manufacturing yield improvements directly address this challenge by minimizing material waste, reducing rework requirements, and increasing production throughput. Industry surveys reveal that electrode coating processes typically account for 30% of battery production costs, making yield optimization a critical economic consideration.

Consumer electronics manufacturers represent another significant market segment demanding high-yield electrode manufacturing solutions. As devices become increasingly power-hungry while physical dimensions continue to shrink, the need for energy-dense, reliably manufactured battery components has intensified. This market segment values manufacturing consistency and quality assurance, creating strong demand for advanced process control and yield management systems.

The electric vehicle sector presents perhaps the most substantial growth opportunity for high-yield electrode manufacturing technologies. Major automotive manufacturers have announced ambitious electrification targets, with many planning to phase out internal combustion engines entirely within the next decade. This transition necessitates massive scaling of battery production capacity, with electrode manufacturing representing a critical bottleneck. Industry analysts estimate that improving electrode coating yields by just 5% could reduce overall battery pack costs by 3-4%, potentially saving manufacturers billions annually at scale.

Geographically, the market for high-yield electrode manufacturing shows distinct regional characteristics. Asia-Pacific dominates current demand, with China, South Korea, and Japan collectively accounting for over 65% of the global market. However, significant growth is anticipated in North America and Europe as these regions pursue battery manufacturing independence and supply chain security. Government initiatives supporting domestic battery production, such as the European Battery Alliance and various national incentive programs, are creating favorable market conditions for advanced manufacturing technologies.

The market landscape is further shaped by increasing environmental regulations and sustainability requirements. Improved manufacturing yields directly contribute to reduced waste generation and more efficient resource utilization, aligning with broader industry sustainability goals. This regulatory pressure creates additional market pull for technologies that can demonstrate clear environmental benefits alongside economic advantages.

The primary market drivers for improved Prussian White electrode coating technologies stem from several converging factors. Energy storage system manufacturers are facing intense pressure to reduce production costs while simultaneously improving battery performance metrics. Manufacturing yield improvements directly address this challenge by minimizing material waste, reducing rework requirements, and increasing production throughput. Industry surveys reveal that electrode coating processes typically account for 30% of battery production costs, making yield optimization a critical economic consideration.

Consumer electronics manufacturers represent another significant market segment demanding high-yield electrode manufacturing solutions. As devices become increasingly power-hungry while physical dimensions continue to shrink, the need for energy-dense, reliably manufactured battery components has intensified. This market segment values manufacturing consistency and quality assurance, creating strong demand for advanced process control and yield management systems.

The electric vehicle sector presents perhaps the most substantial growth opportunity for high-yield electrode manufacturing technologies. Major automotive manufacturers have announced ambitious electrification targets, with many planning to phase out internal combustion engines entirely within the next decade. This transition necessitates massive scaling of battery production capacity, with electrode manufacturing representing a critical bottleneck. Industry analysts estimate that improving electrode coating yields by just 5% could reduce overall battery pack costs by 3-4%, potentially saving manufacturers billions annually at scale.

Geographically, the market for high-yield electrode manufacturing shows distinct regional characteristics. Asia-Pacific dominates current demand, with China, South Korea, and Japan collectively accounting for over 65% of the global market. However, significant growth is anticipated in North America and Europe as these regions pursue battery manufacturing independence and supply chain security. Government initiatives supporting domestic battery production, such as the European Battery Alliance and various national incentive programs, are creating favorable market conditions for advanced manufacturing technologies.

The market landscape is further shaped by increasing environmental regulations and sustainability requirements. Improved manufacturing yields directly contribute to reduced waste generation and more efficient resource utilization, aligning with broader industry sustainability goals. This regulatory pressure creates additional market pull for technologies that can demonstrate clear environmental benefits alongside economic advantages.

Current Challenges in Prussian White Electrode Coating Processes

The manufacturing of Prussian White electrodes faces several critical challenges that significantly impact production yield and quality consistency. One of the primary issues is the inherent instability of Prussian White materials during the coating process. Unlike conventional electrode materials, Prussian White compounds are highly sensitive to environmental conditions, particularly oxygen and moisture, which can trigger premature oxidation and compromise the electrochemical properties of the final product.

Slurry formulation represents another major challenge in the manufacturing process. Achieving the optimal viscosity and homogeneity is particularly difficult with Prussian White materials due to their tendency to agglomerate and form non-uniform dispersions. This often results in coating thickness variations and poor adhesion to current collectors, leading to increased rejection rates during quality control inspections.

The drying phase of electrode manufacturing presents unique challenges for Prussian White materials. Conventional drying temperatures and rates that work well for other electrode materials often cause structural degradation in Prussian White compounds. The material undergoes phase transitions at relatively low temperatures, requiring precise thermal management that many existing production lines are not equipped to provide.

Adhesion issues between the Prussian White active material and the current collector represent another significant yield-limiting factor. The interfacial chemistry between Prussian White and typical current collector materials like aluminum or copper is complex and often results in poor mechanical integrity. This leads to delamination during calendering or subsequent battery assembly steps.

Scaling up laboratory-proven formulations to industrial production volumes introduces additional complications. Parameters that work effectively at small scales often fail to translate directly to mass production environments. The rheological properties of Prussian White slurries change dramatically with batch size, requiring extensive reformulation and process adjustments.

Quality control methods for Prussian White electrodes remain underdeveloped compared to established battery materials. Traditional testing protocols may not adequately capture the unique failure modes of these electrodes, resulting in defects being discovered only at later stages of battery assembly or during final product testing, significantly increasing manufacturing costs.

Contamination control presents exceptional challenges for Prussian White electrode production. Even trace amounts of certain metal ions can catalyze unwanted side reactions within the material structure, compromising electrochemical performance. This necessitates extraordinarily clean manufacturing environments that exceed typical industry standards, adding substantial cost and complexity to the production process.

Slurry formulation represents another major challenge in the manufacturing process. Achieving the optimal viscosity and homogeneity is particularly difficult with Prussian White materials due to their tendency to agglomerate and form non-uniform dispersions. This often results in coating thickness variations and poor adhesion to current collectors, leading to increased rejection rates during quality control inspections.

The drying phase of electrode manufacturing presents unique challenges for Prussian White materials. Conventional drying temperatures and rates that work well for other electrode materials often cause structural degradation in Prussian White compounds. The material undergoes phase transitions at relatively low temperatures, requiring precise thermal management that many existing production lines are not equipped to provide.

Adhesion issues between the Prussian White active material and the current collector represent another significant yield-limiting factor. The interfacial chemistry between Prussian White and typical current collector materials like aluminum or copper is complex and often results in poor mechanical integrity. This leads to delamination during calendering or subsequent battery assembly steps.

Scaling up laboratory-proven formulations to industrial production volumes introduces additional complications. Parameters that work effectively at small scales often fail to translate directly to mass production environments. The rheological properties of Prussian White slurries change dramatically with batch size, requiring extensive reformulation and process adjustments.

Quality control methods for Prussian White electrodes remain underdeveloped compared to established battery materials. Traditional testing protocols may not adequately capture the unique failure modes of these electrodes, resulting in defects being discovered only at later stages of battery assembly or during final product testing, significantly increasing manufacturing costs.

Contamination control presents exceptional challenges for Prussian White electrode production. Even trace amounts of certain metal ions can catalyze unwanted side reactions within the material structure, compromising electrochemical performance. This necessitates extraordinarily clean manufacturing environments that exceed typical industry standards, adding substantial cost and complexity to the production process.

Current Yield Improvement Solutions for Electrode Coating

01 Electrode coating composition optimization

Optimizing the composition of Prussian White electrode coatings can significantly improve manufacturing yield. This includes careful selection of precursor materials, adjusting the ratio of iron and cyanide compounds, and incorporating specific additives that enhance stability and performance. The optimized composition leads to more uniform coatings with fewer defects, resulting in higher manufacturing yields and better electrochemical performance.- Electrode coating composition optimization: Optimizing the composition of Prussian White electrode coatings can significantly improve manufacturing yield. This includes adjusting the ratio of active materials, binders, and conductive additives to enhance adhesion to the substrate and prevent material loss during processing. Specific formulations may incorporate modified polymeric binders or specialized conductive agents that improve cohesion within the coating while maintaining electrochemical performance.

- Process parameter control for coating deposition: Precise control of process parameters during coating deposition is crucial for high manufacturing yields of Prussian White electrodes. This includes optimizing slurry viscosity, coating speed, drying temperature profiles, and curing conditions. Advanced process monitoring systems can be implemented to maintain consistent coating thickness and uniformity, reducing defects and material waste during production.

- Surface treatment and substrate preparation: Surface treatment of substrates prior to Prussian White coating application can significantly improve adhesion and coating quality, leading to higher manufacturing yields. Techniques include chemical etching, plasma treatment, or application of primer layers to create optimal surface energy and morphology. Proper cleaning protocols to remove contaminants from substrate surfaces are also essential for ensuring uniform coating adhesion.

- Advanced drying and curing techniques: Implementing advanced drying and curing techniques for Prussian White electrode coatings can enhance manufacturing yield by preventing cracking, delamination, and other defects. These techniques include controlled atmosphere drying, gradient temperature profiles, infrared or microwave assisted curing, and specialized post-treatment processes that optimize the microstructure of the coating while minimizing stress development during solvent removal.

- Quality control and defect detection systems: Implementation of advanced quality control and defect detection systems throughout the Prussian White electrode coating manufacturing process can significantly improve yields. This includes in-line monitoring using optical, spectroscopic, or electrochemical techniques to identify coating defects early in production. Machine learning algorithms can be employed to analyze process data and predict potential yield issues before they occur, allowing for real-time process adjustments.

02 Process parameter control techniques

Controlling process parameters during Prussian White electrode coating manufacturing is crucial for high yields. Key parameters include temperature, pH, reaction time, stirring speed, and deposition rate. Advanced monitoring systems and feedback control mechanisms help maintain optimal conditions throughout the manufacturing process, reducing batch-to-batch variations and increasing overall yield. Precise control of these parameters ensures consistent coating quality and thickness.Expand Specific Solutions03 Surface preparation and substrate treatment

Proper surface preparation and substrate treatment before applying Prussian White coatings significantly impact manufacturing yield. Techniques include surface cleaning, activation treatments, roughening processes, and application of primer layers. These preparatory steps improve adhesion between the substrate and the Prussian White coating, reducing delamination issues and enhancing coating uniformity, which directly contributes to higher manufacturing yields.Expand Specific Solutions04 Post-deposition treatment methods

Various post-deposition treatments can enhance the quality and yield of Prussian White electrode coatings. These include thermal annealing, controlled drying processes, surface passivation, and electrochemical conditioning. Such treatments help stabilize the crystal structure, remove impurities, reduce internal stresses, and improve the electrochemical properties of the coatings, resulting in higher manufacturing yields and better performing electrodes.Expand Specific Solutions05 Quality control and defect detection systems

Advanced quality control and defect detection systems play a crucial role in improving Prussian White electrode coating manufacturing yield. These include in-line monitoring techniques, optical inspection systems, electrochemical testing, and machine learning-based defect prediction. Early detection of coating irregularities allows for process adjustments and reduces waste, while comprehensive quality control ensures that only high-quality electrodes proceed to final assembly, maximizing overall manufacturing yield.Expand Specific Solutions

Key Industry Players in Electrode Manufacturing

The Prussian White electrode coating manufacturing yield improvement landscape is currently in a growth phase, with the market expanding due to increasing demand for advanced battery technologies. The global market size for this technology is estimated to reach significant scale as energy storage solutions become more critical. Companies like Ningde Amperex Technology Ltd. and CATL subsidiary Guangdong Bangpu Recycling Technology are leading commercial development, while academic institutions such as Beijing University of Technology and Hebei University of Science & Technology contribute valuable research. The technology is approaching maturity in certain applications but still faces challenges in mass production efficiency. Companies including TDK Corp., Kureha Corp., and Hunan Nafang New Energy Technology are actively developing proprietary coating processes to improve yield rates and reduce manufacturing costs.

Guangdong Bangpu Recycling Technology Co., Ltd.

Technical Solution: Guangdong Bangpu has developed an integrated recycling-to-manufacturing approach for Prussian White electrodes that utilizes recovered transition metals from spent batteries. Their process incorporates a proprietary synthesis method that produces Prussian White materials with controlled particle morphology and size distribution optimized for coating applications. The company employs a water-based slurry formulation with environmentally friendly binders that reduces toxic solvent usage while maintaining coating quality. Their manufacturing line features a precision intermittent coating system that reduces edge effects and material waste. Bangpu has implemented a closed-loop quality control system that analyzes electrode samples at multiple production stages, with feedback mechanisms to adjust process parameters in real-time. Their approach also includes a post-coating treatment step that enhances the interface between the active material and current collector, improving adhesion strength and reducing delamination issues.

Strengths: Their integrated recycling approach provides cost advantages and supply chain security while reducing environmental impact through circular economy principles. Weaknesses: The recycled material feedstock can introduce batch-to-batch variations that require more sophisticated quality control measures, potentially limiting production consistency.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex) has developed an advanced slurry formulation technique for Prussian White electrode coating that incorporates nano-sized conductive additives and specialized binders. Their process utilizes precise rheological control systems that adjust viscosity parameters in real-time based on temperature and humidity conditions. The company employs a multi-stage mixing protocol with controlled shear rates to ensure homogeneous dispersion of Prussian White particles while preventing agglomeration. Their coating process incorporates dual-sided simultaneous application with precision-controlled doctor blade systems, achieving thickness variations below 2μm across the electrode surface. CATL has also implemented AI-driven quality control systems that use machine vision to detect coating defects in real-time, allowing for immediate process adjustments to maintain high yields.

Strengths: Industry-leading thickness uniformity control and integrated AI quality monitoring systems provide exceptional consistency. Weaknesses: The complex multi-stage mixing process requires longer production cycles and specialized equipment, potentially limiting production flexibility and increasing capital costs.

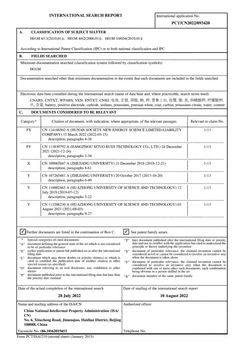

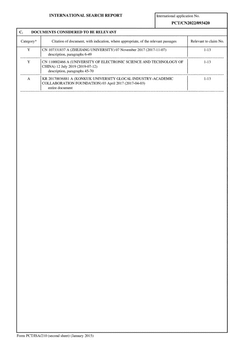

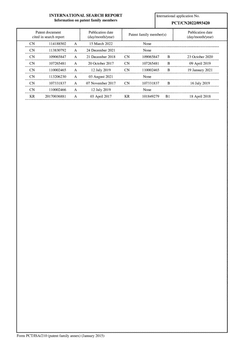

Critical Patents and Innovations in Coating Technology

Prussian white composite material, and preparation method therefor and use thereof

PatentPendingUS20250026653A1

Innovation

- A Prussian white composite material is developed, comprising an inner core with a specific chemical formula and a carbon coating layer, which enhances electrical conductivity and thermal stability while eliminating crystal water. The material is synthesized through a hydrothermal method followed by ion exchange and carbon coating.

Prussian white composite material, and preparation method therefor and use thereof

PatentPendingEP4443532A1

Innovation

- A Prussian white composite material is developed with a carbon coating layer on an inner core of Na x Mn 1-y M y [Fe(CN) 6 ] z, synthesized through a hydrothermal method and ion exchange process, optimizing electronic conductivity and thermal stability by removing crystal water and maintaining a stable crystal lattice structure.

Quality Control Methodologies for Electrode Manufacturing

Quality control in electrode manufacturing represents a critical factor in achieving high manufacturing yields for Prussian White electrodes. Effective quality control methodologies must be implemented throughout the entire production process, from raw material inspection to final product testing, to ensure consistent electrode performance and minimize defects.

Statistical Process Control (SPC) techniques form the foundation of modern electrode manufacturing quality systems. By continuously monitoring key process parameters such as coating thickness, uniformity, adhesion strength, and material composition, manufacturers can detect deviations before they result in significant yield losses. Implementation of control charts for critical parameters enables real-time process adjustments and prevents the production of out-of-specification electrodes.

Advanced inspection technologies have revolutionized quality control for Prussian White electrode coating. Non-destructive testing methods including optical microscopy, scanning electron microscopy (SEM), and X-ray fluorescence (XRF) provide detailed information about coating morphology, composition, and potential defects. Inline monitoring systems utilizing these technologies allow for 100% inspection rather than traditional sampling approaches, significantly improving defect detection rates.

Machine vision systems coupled with artificial intelligence algorithms represent the cutting edge of electrode quality control. These systems can detect subtle visual anomalies in coating appearance, texture, and uniformity that might escape human inspection. The integration of deep learning models trained on historical defect data has demonstrated particular promise in identifying complex defect patterns specific to Prussian White electrode manufacturing.

Process capability analysis serves as a quantitative tool for evaluating manufacturing process performance against specifications. By calculating process capability indices (Cpk and Ppk) for critical electrode parameters, manufacturers can objectively assess process stability and identify opportunities for improvement. Processes with higher capability indices consistently produce electrodes within specification limits, directly contributing to higher manufacturing yields.

Design of Experiments (DOE) methodology enables systematic optimization of process parameters affecting electrode quality. By conducting structured experimental trials, manufacturers can identify optimal settings for coating speed, slurry composition, drying conditions, and other variables that maximize yield while maintaining product quality. This data-driven approach eliminates trial-and-error adjustments and accelerates process optimization.

Supplier quality management represents another crucial aspect of electrode manufacturing quality control. Establishing rigorous specifications for raw materials, conducting supplier audits, and implementing incoming material inspection protocols ensures that quality issues are prevented at the source. For Prussian White electrodes, the purity and consistency of precursor chemicals directly impact final electrode performance and manufacturing yield.

Statistical Process Control (SPC) techniques form the foundation of modern electrode manufacturing quality systems. By continuously monitoring key process parameters such as coating thickness, uniformity, adhesion strength, and material composition, manufacturers can detect deviations before they result in significant yield losses. Implementation of control charts for critical parameters enables real-time process adjustments and prevents the production of out-of-specification electrodes.

Advanced inspection technologies have revolutionized quality control for Prussian White electrode coating. Non-destructive testing methods including optical microscopy, scanning electron microscopy (SEM), and X-ray fluorescence (XRF) provide detailed information about coating morphology, composition, and potential defects. Inline monitoring systems utilizing these technologies allow for 100% inspection rather than traditional sampling approaches, significantly improving defect detection rates.

Machine vision systems coupled with artificial intelligence algorithms represent the cutting edge of electrode quality control. These systems can detect subtle visual anomalies in coating appearance, texture, and uniformity that might escape human inspection. The integration of deep learning models trained on historical defect data has demonstrated particular promise in identifying complex defect patterns specific to Prussian White electrode manufacturing.

Process capability analysis serves as a quantitative tool for evaluating manufacturing process performance against specifications. By calculating process capability indices (Cpk and Ppk) for critical electrode parameters, manufacturers can objectively assess process stability and identify opportunities for improvement. Processes with higher capability indices consistently produce electrodes within specification limits, directly contributing to higher manufacturing yields.

Design of Experiments (DOE) methodology enables systematic optimization of process parameters affecting electrode quality. By conducting structured experimental trials, manufacturers can identify optimal settings for coating speed, slurry composition, drying conditions, and other variables that maximize yield while maintaining product quality. This data-driven approach eliminates trial-and-error adjustments and accelerates process optimization.

Supplier quality management represents another crucial aspect of electrode manufacturing quality control. Establishing rigorous specifications for raw materials, conducting supplier audits, and implementing incoming material inspection protocols ensures that quality issues are prevented at the source. For Prussian White electrodes, the purity and consistency of precursor chemicals directly impact final electrode performance and manufacturing yield.

Environmental Impact of Prussian White Production Processes

The environmental impact of Prussian White electrode coating processes represents a critical consideration in the sustainable development of energy storage technologies. Traditional manufacturing methods for battery electrodes often involve energy-intensive processes and hazardous chemicals that pose significant environmental risks. Prussian White production, while offering advantages in battery performance, presents its own set of environmental challenges that must be addressed to ensure sustainable manufacturing practices.

Water consumption during Prussian White electrode coating represents a significant environmental concern. The synthesis and purification processes typically require substantial volumes of water, contributing to resource depletion in water-stressed regions. Additionally, wastewater from these processes often contains metal ions and chemical residues that require proper treatment before discharge to prevent contamination of natural water bodies.

Energy utilization throughout the production chain significantly influences the carbon footprint of Prussian White electrodes. From raw material extraction to synthesis and coating processes, each stage demands considerable energy input. The environmental impact varies substantially depending on the energy sources employed, with renewable energy integration offering potential for significant reduction in greenhouse gas emissions associated with manufacturing.

Chemical waste management presents another critical environmental challenge. The synthesis of Prussian White compounds involves various chemical precursors, including cyanide-containing compounds, which require careful handling and disposal protocols. Improper management of these substances can lead to soil contamination and pose risks to ecosystem health and biodiversity.

Air quality impacts arise primarily from solvent evaporation during coating processes and particulate emissions during powder handling. These emissions contribute to local air pollution and may pose occupational health risks to manufacturing personnel. Advanced filtration systems and closed-loop processing can significantly mitigate these impacts but add complexity and cost to production systems.

Life cycle assessment studies indicate that improvements in manufacturing yield directly correlate with reduced environmental impact per unit of energy storage capacity. Higher yields minimize resource consumption and waste generation across the entire production chain. Consequently, yield improvement strategies not only enhance economic viability but also serve as effective environmental sustainability measures.

Emerging green chemistry approaches offer promising pathways for reducing the environmental footprint of Prussian White production. These include aqueous processing techniques that minimize organic solvent usage, recovery and recycling of process chemicals, and development of less toxic precursor alternatives that maintain or enhance the functional properties of the final electrode materials.

Water consumption during Prussian White electrode coating represents a significant environmental concern. The synthesis and purification processes typically require substantial volumes of water, contributing to resource depletion in water-stressed regions. Additionally, wastewater from these processes often contains metal ions and chemical residues that require proper treatment before discharge to prevent contamination of natural water bodies.

Energy utilization throughout the production chain significantly influences the carbon footprint of Prussian White electrodes. From raw material extraction to synthesis and coating processes, each stage demands considerable energy input. The environmental impact varies substantially depending on the energy sources employed, with renewable energy integration offering potential for significant reduction in greenhouse gas emissions associated with manufacturing.

Chemical waste management presents another critical environmental challenge. The synthesis of Prussian White compounds involves various chemical precursors, including cyanide-containing compounds, which require careful handling and disposal protocols. Improper management of these substances can lead to soil contamination and pose risks to ecosystem health and biodiversity.

Air quality impacts arise primarily from solvent evaporation during coating processes and particulate emissions during powder handling. These emissions contribute to local air pollution and may pose occupational health risks to manufacturing personnel. Advanced filtration systems and closed-loop processing can significantly mitigate these impacts but add complexity and cost to production systems.

Life cycle assessment studies indicate that improvements in manufacturing yield directly correlate with reduced environmental impact per unit of energy storage capacity. Higher yields minimize resource consumption and waste generation across the entire production chain. Consequently, yield improvement strategies not only enhance economic viability but also serve as effective environmental sustainability measures.

Emerging green chemistry approaches offer promising pathways for reducing the environmental footprint of Prussian White production. These include aqueous processing techniques that minimize organic solvent usage, recovery and recycling of process chemicals, and development of less toxic precursor alternatives that maintain or enhance the functional properties of the final electrode materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!