Pouch Cell Safety Testing Of Prussian White Sodium-Ion Cells

Prussian White Na-Ion Battery Safety Background & Objectives

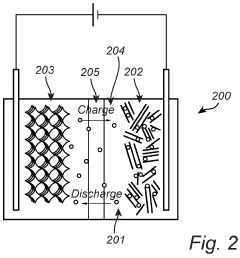

Sodium-ion batteries have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. Among various sodium-ion battery chemistries, Prussian White (PW) materials have gained significant attention as cathode materials owing to their open framework structure, which facilitates rapid sodium-ion insertion/extraction. The evolution of PW sodium-ion technology can be traced back to the early 2010s, when researchers began exploring Prussian Blue Analogues (PBAs) for energy storage applications.

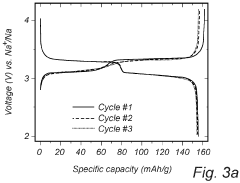

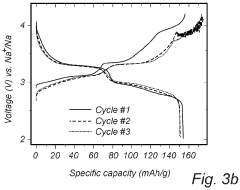

The technical trajectory of PW sodium-ion batteries has been marked by continuous improvements in energy density, cycle life, and structural stability. Early iterations suffered from poor capacity retention and limited energy density, primarily due to the presence of structural water and vacancies in the crystal lattice. Subsequent research focused on optimizing synthesis methods to produce water-free and vacancy-free PW materials, significantly enhancing electrochemical performance.

Safety considerations have become increasingly paramount as sodium-ion batteries transition from laboratory research to commercial applications. Unlike lithium-ion batteries, sodium-ion cells do not utilize flammable organic electrolytes containing LiPF6, which can generate toxic HF gas during thermal runaway. However, they present their own unique safety challenges that require thorough investigation, particularly in practical pouch cell configurations that more accurately represent commercial battery designs.

The primary objective of pouch cell safety testing for PW sodium-ion cells is to comprehensively evaluate their safety performance under various abuse conditions that might be encountered during real-world operation. These include mechanical abuse (crushing, puncture), electrical abuse (overcharge, over-discharge, external short circuit), and thermal abuse (high temperature exposure, thermal shock). Understanding the failure mechanisms and thermal runaway characteristics specific to PW chemistry is crucial for developing effective safety protocols and mitigation strategies.

Additionally, this technical research aims to establish standardized testing methodologies tailored specifically for sodium-ion batteries, as current safety standards are predominantly designed for lithium-ion systems. The development of sodium-ion-specific safety protocols will facilitate regulatory approval and accelerate market adoption of this emerging technology.

The ultimate goal is to position PW sodium-ion batteries as a viable, safe alternative to lithium-ion batteries in applications where cost considerations outweigh energy density requirements, such as stationary energy storage, grid stabilization, and certain electric mobility applications. By thoroughly characterizing the safety profile of pouch-format PW sodium-ion cells, this research will contribute to the broader technological evolution toward more sustainable and resource-efficient energy storage solutions.

Market Demand Analysis for Sodium-Ion Battery Technologies

The global energy storage market is witnessing a significant shift towards sustainable and cost-effective solutions, creating substantial demand for sodium-ion battery technologies. As lithium resources face increasing supply constraints and price volatility, sodium-ion batteries have emerged as a promising alternative due to sodium's natural abundance, comprising approximately 2.8% of the Earth's crust compared to lithium's 0.006%. This fundamental resource advantage translates to potentially 30-40% lower raw material costs for sodium-ion batteries.

Market research indicates that the global sodium-ion battery market is projected to grow at a compound annual growth rate of 18-20% between 2023 and 2030, with particular acceleration expected after 2025 when commercial-scale production becomes more widespread. The total addressable market could reach $9 billion by 2030, driven primarily by stationary energy storage applications, which are expected to account for 65% of demand initially.

The electric vehicle sector represents another significant market opportunity, particularly in regions prioritizing cost-effective transportation electrification. While sodium-ion batteries currently offer lower energy density than premium lithium-ion cells, their performance characteristics make them well-suited for mass-market electric vehicles where moderate range requirements are balanced against cost considerations. Industry analysts predict that by 2028, sodium-ion batteries could capture 10-15% of the low to mid-range electric vehicle battery market.

Grid-scale energy storage presents perhaps the most immediate commercial opportunity. Utility companies are increasingly seeking alternatives to lithium-ion technologies for large-scale installations where energy density is less critical than cycle life, safety, and total cost of ownership. The ability of Prussian White sodium-ion cells to operate effectively across wider temperature ranges (-20°C to 60°C) without expensive thermal management systems provides a compelling value proposition for this sector.

Consumer electronics manufacturers are also exploring sodium-ion technologies for applications where cost sensitivity outweighs the need for maximum energy density. The safety advantages demonstrated in pouch cell testing of Prussian White formulations—particularly their non-flammable nature and resistance to thermal runaway—address growing concerns about device safety among consumers and regulators alike.

Regionally, China is currently leading sodium-ion battery development and deployment, with several manufacturers already producing cells at pilot scale. European and North American markets are expected to follow, driven by energy security concerns and the strategic imperative to develop supply chains independent of lithium resource constraints.

Current Safety Testing Challenges for Pouch Cell Configurations

The safety testing of pouch cell configurations for Prussian White Sodium-Ion Cells presents several significant challenges that impede comprehensive safety evaluation. Traditional testing protocols developed for lithium-ion batteries often fail to address the unique characteristics of sodium-ion chemistry, particularly when combined with the pouch cell format.

One primary challenge is the lack of standardized testing procedures specifically designed for sodium-ion pouch cells. Current industry standards such as IEC 62660, UN 38.3, and UL 1642 were primarily developed for lithium-ion technologies, creating inconsistencies when applied to sodium-ion systems. This regulatory gap leads to uncertainty in certification processes and market acceptance.

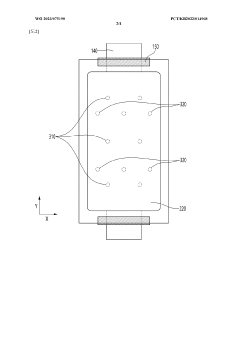

The physical deformation behavior of pouch cells during thermal runaway presents another significant testing challenge. Unlike cylindrical or prismatic cells with rigid casings, pouch cells can expand dramatically under thermal stress, complicating the containment and measurement of released gases and energy. The Prussian White cathode material's specific thermal decomposition characteristics further complicate this behavior, requiring specialized testing equipment capable of accommodating these unique expansion patterns.

Temperature control during abuse testing represents a critical challenge. Sodium-ion cells with Prussian White cathodes demonstrate different thermal profiles compared to lithium-ion counterparts, with distinct onset temperatures for exothermic reactions. Current testing equipment calibrated for lithium-ion thermal profiles may fail to accurately capture these differences, potentially missing critical safety thresholds.

Gas analysis during safety events poses additional difficulties. The composition of gases released during thermal events in sodium-ion cells differs significantly from lithium-ion cells, containing unique sodium compounds that may require specialized detection equipment. Many existing testing facilities lack the analytical capabilities to properly characterize these emissions.

The electrolyte compatibility with pouch cell materials creates further testing complexities. Sodium-based electrolytes interact differently with pouch cell components compared to lithium-based systems, potentially creating unique failure modes that current testing protocols might not adequately address.

Scale-up testing represents another significant gap. While small-format cell testing may be feasible with adapted equipment, larger pouch cells intended for commercial applications present additional challenges in terms of testing infrastructure, safety containment, and result interpretation. The energy density differences between sodium-ion and lithium-ion technologies further complicate the development of appropriate scaling factors.

Finally, accelerated aging protocols for safety assessment remain underdeveloped. The long-term degradation mechanisms of Prussian White sodium-ion cells differ from lithium-ion systems, necessitating new approaches to simulate end-of-life safety characteristics accurately. Current accelerated aging methods may not properly represent the actual safety profile of aged sodium-ion pouch cells.

Current Pouch Cell Safety Testing Protocols and Standards

01 Thermal stability and safety mechanisms

Prussian White sodium-ion cells incorporate various safety mechanisms to enhance thermal stability and prevent thermal runaway. These include specialized electrolyte formulations, protective coatings, and structural modifications that improve the cell's ability to withstand high temperatures. Advanced thermal management systems and safety valves are also implemented to release pressure and prevent catastrophic failure during overheating events.- Thermal stability and safety mechanisms: Prussian White sodium-ion cells incorporate various safety mechanisms to enhance thermal stability. These include specialized electrolyte formulations, thermal management systems, and structural modifications that prevent thermal runaway. The cells are designed to maintain stability under high-temperature conditions, reducing the risk of fire or explosion. Safety features such as pressure relief valves and thermal fuses are integrated to mitigate potential hazards during operation.

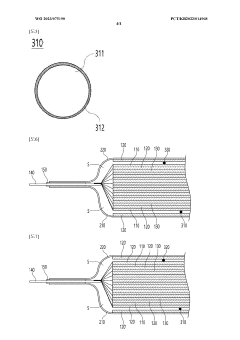

- Electrolyte safety enhancements: Advanced electrolyte formulations are developed specifically for Prussian White sodium-ion cells to improve safety profiles. These include non-flammable or flame-retardant additives, ionic liquid electrolytes, and solid-state electrolyte systems. The electrolyte compositions are designed to minimize reactivity with electrode materials, reduce gas generation during cycling, and prevent dendrite formation, all of which contribute to safer cell operation under various conditions.

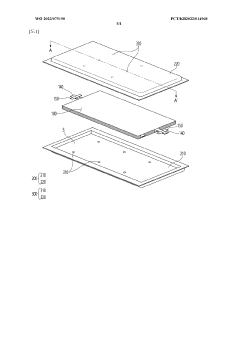

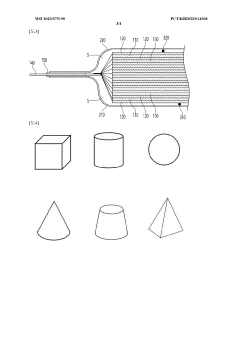

- Structural integrity and mechanical safety: The structural design of Prussian White sodium-ion cells focuses on mechanical safety aspects. This includes robust cell casings, improved separator designs that prevent internal short circuits, and enhanced electrode structures that maintain integrity during cycling. Special attention is given to the mechanical stability of the Prussian White framework to prevent structural collapse and particle shedding that could lead to safety issues during long-term operation.

- Overcharge and overdischarge protection: Safety mechanisms are implemented to protect Prussian White sodium-ion cells from overcharge and overdischarge conditions. These include electronic protection circuits, chemical shuttles that limit voltage extremes, and electrode materials designed to be inherently resistant to damage from voltage excursions. The cells incorporate features that prevent capacity degradation and thermal events that might occur during abnormal charging or discharging conditions.

- Environmental and operational safety: Prussian White sodium-ion cells are designed with environmental and operational safety considerations. This includes resistance to external factors such as moisture, impact, and vibration. The cells maintain safety performance across wide temperature ranges and under various operational conditions. Additionally, end-of-life safety features and environmentally friendly materials are incorporated to ensure safe disposal and recycling, minimizing environmental impact throughout the product lifecycle.

02 Electrolyte safety enhancements

Safety of Prussian White sodium-ion cells is significantly improved through specialized electrolyte formulations. These include flame-retardant additives, non-flammable electrolyte compositions, and ionic liquid electrolytes that reduce fire hazards. Solid-state and gel electrolytes are also being developed to eliminate leakage risks and improve overall cell safety while maintaining or enhancing electrochemical performance.Expand Specific Solutions03 Structural safety design and encapsulation

Enhanced structural designs for Prussian White sodium-ion cells focus on improved encapsulation techniques and mechanical stability. These include reinforced cell casings, advanced sealing methods, and internal structural supports that prevent physical damage and electrolyte leakage. Special attention is given to the interface between electrodes and current collectors to prevent short circuits and improve overall cell integrity under mechanical stress.Expand Specific Solutions04 Safety monitoring and control systems

Advanced monitoring and control systems are integrated into Prussian White sodium-ion cells to enhance safety. These include sensors for temperature, pressure, and voltage monitoring, coupled with intelligent battery management systems that can detect abnormal conditions and take preventive actions. Some designs incorporate self-healing mechanisms and automatic shutdown features that activate when unsafe operating conditions are detected.Expand Specific Solutions05 Material modifications for enhanced safety

Safety improvements in Prussian White sodium-ion cells are achieved through modifications to electrode materials and their interfaces. These include doping strategies, surface modifications, and novel composite structures that enhance structural stability and reduce side reactions. Specialized binders and conductive additives are also employed to improve mechanical integrity and prevent particle isolation during cycling, which could otherwise lead to safety hazards.Expand Specific Solutions

Key Industry Players in Sodium-Ion Battery Development

The sodium-ion battery safety testing market is in an early growth phase, characterized by increasing research activities but limited commercial deployment. The market size is expanding as sodium-ion technology emerges as a cost-effective alternative to lithium-ion batteries, with projections suggesting significant growth potential in the next decade. Technologically, Prussian White sodium-ion cell safety testing is advancing rapidly, with key players demonstrating varying levels of maturity. Companies like LG Energy Solution, Samsung SDI, and SK Innovation bring established battery testing infrastructure, while specialized players such as Altris AB and Faradion Ltd. offer focused sodium-ion expertise. Academic institutions including Zhejiang University, Nankai University, and Tongji University are contributing fundamental research to improve safety protocols. The technology is approaching commercial readiness, with companies like CATL (through Guangdong Bangpu) investing in manufacturing capabilities to address safety concerns at scale.

Samsung SDI Co., Ltd.

Faradion Ltd.

Critical Safety Mechanisms in Prussian White Na-Ion Cells

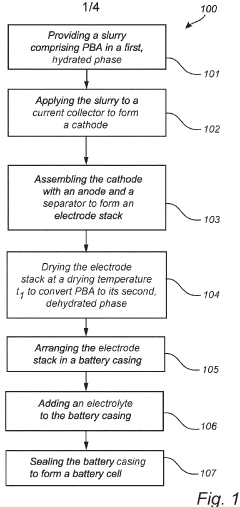

- A method involving a slurry with a hydrated Prussian Blue analogue that is converted to a dehydrated phase during the manufacturing process, specifically at a temperature of 150-300°C for 1-4 hours, and maintained in this phase throughout subsequent steps, eliminating the need for dry rooms and reducing drying time, while preventing unwanted phase transitions.

- Incorporating a rupture inducing part within the cell case that can rapidly rupture when internal pressure increases, preventing thermal runaway and facilitating easy identification of the battery cell's front and back for improved manufacturing efficiency.

Environmental Impact Assessment of Na-Ion Battery Technology

The environmental impact assessment of sodium-ion battery technology reveals significant advantages compared to traditional lithium-ion batteries. Sodium resources are approximately 1,000 times more abundant than lithium in the Earth's crust, with widespread global distribution that reduces geopolitical supply risks. This abundance translates to lower extraction impacts and reduced pressure on limited resources.

The manufacturing process for Prussian White sodium-ion cells demonstrates a notably smaller carbon footprint. Studies indicate that sodium-ion battery production generates approximately 20-30% less CO2 emissions compared to lithium-ion counterparts. This reduction stems primarily from lower energy requirements during material synthesis and cell assembly processes, as Prussian White compounds can be synthesized at lower temperatures.

Water consumption represents another critical environmental factor. Sodium extraction typically requires significantly less water than lithium extraction, particularly when compared to the water-intensive brine extraction methods used in South American lithium production. This aspect is particularly relevant in water-stressed regions where battery material mining occurs.

Toxicity profiles of sodium-ion battery materials present environmental advantages as well. The absence of cobalt and nickel in Prussian White formulations eliminates concerns related to toxic heavy metal contamination. Additionally, the electrolytes used in sodium-ion cells often contain less fluorinated compounds, reducing potential environmental hazards in case of leakage during safety testing or disposal.

End-of-life considerations further highlight sodium-ion technology's environmental benefits. The recycling process for sodium-ion batteries is potentially less energy-intensive than for lithium-ion batteries, with higher recovery rates for key materials. The absence of valuable metals like cobalt also reduces illegal disposal incentives, potentially improving collection rates.

Safety testing of pouch cell Prussian White sodium-ion batteries indicates fewer catastrophic failure modes with less severe thermal runaway events. This translates to reduced risk of environmental contamination from battery fires or explosions during use, transportation, or disposal phases. The lower operating temperatures of these cells also contribute to decreased cooling requirements in large-scale applications, indirectly reducing energy consumption and associated environmental impacts.

Scalability and Manufacturing Considerations for Safe Production

The transition from laboratory-scale production to industrial manufacturing of Prussian White Sodium-Ion pouch cells presents significant challenges that must be addressed to ensure safety at scale. Current manufacturing processes for lithium-ion batteries provide a foundation, but sodium-ion technology requires specific adaptations due to the unique properties of Prussian White cathodes and sodium-based chemistry.

Material handling during mass production represents a critical consideration. The hygroscopic nature of sodium salts necessitates stringent environmental controls throughout the manufacturing process. Humidity-controlled clean rooms with dew points below -40°C are essential to prevent moisture contamination that could compromise cell safety. Additionally, specialized equipment for handling Prussian White materials must be designed to prevent cross-contamination and ensure consistent quality.

Production line modifications for safety testing integration present another key challenge. Inline quality control systems must be adapted to monitor sodium-ion specific safety parameters. This includes real-time detection of impurities that could trigger exothermic reactions, as well as continuous monitoring of crystal structure integrity in Prussian White cathodes. Automated vision systems can be implemented to detect physical defects in pouch cells before electrolyte filling.

Scaling electrolyte preparation requires particular attention, as sodium-ion electrolytes often contain fluorinated compounds that demand careful handling. Closed-system mixing equipment with advanced filtration capabilities must be employed to maintain electrolyte purity at industrial scales. Temperature-controlled mixing vessels are necessary to prevent decomposition of electrolyte components during large-batch preparation.

Quality control protocols must evolve beyond those established for lithium-ion production. Statistical process control methods should be implemented at multiple stages, with particular emphasis on cathode material consistency. Non-destructive testing techniques such as ultrasonic scanning can be adapted to detect internal defects in sealed pouch cells without compromising production throughput.

Cost considerations cannot be separated from safety in scaled manufacturing. While implementing comprehensive safety measures increases initial capital expenditure, the long-term benefits include reduced rejection rates and minimized risk of catastrophic failures. Economic analysis indicates that investments in advanced safety testing infrastructure typically achieve return on investment within 2-3 years through improved yield and reduced liability exposure.