Sodium Inventory Balancing For Prussian White Hard-Carbon Full Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Battery Technology Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries (LIBs) due to the abundance and low cost of sodium resources. The development of SIBs can be traced back to the 1970s, but significant research momentum has only been gained in the past decade as concerns about lithium supply chain vulnerabilities and cost escalation have intensified. The evolution of sodium battery technology has been characterized by incremental improvements in electrode materials, electrolytes, and cell design, with recent breakthroughs in energy density and cycle life.

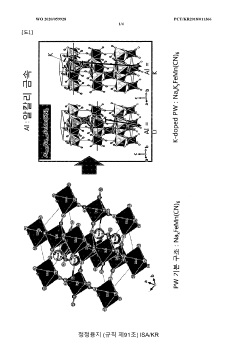

The specific focus on Prussian White (PW) cathodes paired with Hard Carbon (HC) anodes represents one of the most promising directions in SIB development. Prussian White materials, with their open framework structure and high theoretical capacity, offer advantages in terms of sodium ion insertion/extraction kinetics. Meanwhile, Hard Carbon anodes provide relatively high capacity and suitable working potential for sodium-ion storage. However, the optimization of these full cells faces significant challenges, particularly in terms of sodium inventory balancing.

Sodium inventory balancing refers to the critical process of optimizing the amount of sodium ions available within the cell system to ensure maximum capacity utilization and cycle life. Unlike lithium-ion systems, sodium-ion batteries often suffer from irreversible capacity loss during initial cycles, primarily due to the formation of solid electrolyte interphase (SEI) on the anode and irreversible structural changes in electrode materials. This necessitates precise engineering of the initial sodium content in the system.

The technical objectives for advancing Prussian White-Hard Carbon full cells include achieving optimal sodium inventory balance to maximize initial Coulombic efficiency and capacity retention. This requires developing strategies for pre-sodiation of electrodes, electrolyte optimization, and precise control of electrode loading ratios. Additionally, understanding the dynamic changes in sodium distribution during cycling is essential for long-term performance stability.

Current research aims to achieve energy densities exceeding 160 Wh/kg at the cell level, with cycle life surpassing 2000 cycles at 80% capacity retention. These targets would position sodium-ion technology as commercially viable for grid storage applications and potentially for certain electric vehicle applications where energy density requirements are less stringent than premium EV segments.

The technological trajectory suggests that with proper sodium inventory management, PW-HC full cells could reach performance metrics that enable market penetration in cost-sensitive applications within the next 3-5 years. This would represent a significant milestone in the diversification of battery technologies beyond the current lithium-ion dominated landscape.

The specific focus on Prussian White (PW) cathodes paired with Hard Carbon (HC) anodes represents one of the most promising directions in SIB development. Prussian White materials, with their open framework structure and high theoretical capacity, offer advantages in terms of sodium ion insertion/extraction kinetics. Meanwhile, Hard Carbon anodes provide relatively high capacity and suitable working potential for sodium-ion storage. However, the optimization of these full cells faces significant challenges, particularly in terms of sodium inventory balancing.

Sodium inventory balancing refers to the critical process of optimizing the amount of sodium ions available within the cell system to ensure maximum capacity utilization and cycle life. Unlike lithium-ion systems, sodium-ion batteries often suffer from irreversible capacity loss during initial cycles, primarily due to the formation of solid electrolyte interphase (SEI) on the anode and irreversible structural changes in electrode materials. This necessitates precise engineering of the initial sodium content in the system.

The technical objectives for advancing Prussian White-Hard Carbon full cells include achieving optimal sodium inventory balance to maximize initial Coulombic efficiency and capacity retention. This requires developing strategies for pre-sodiation of electrodes, electrolyte optimization, and precise control of electrode loading ratios. Additionally, understanding the dynamic changes in sodium distribution during cycling is essential for long-term performance stability.

Current research aims to achieve energy densities exceeding 160 Wh/kg at the cell level, with cycle life surpassing 2000 cycles at 80% capacity retention. These targets would position sodium-ion technology as commercially viable for grid storage applications and potentially for certain electric vehicle applications where energy density requirements are less stringent than premium EV segments.

The technological trajectory suggests that with proper sodium inventory management, PW-HC full cells could reach performance metrics that enable market penetration in cost-sensitive applications within the next 3-5 years. This would represent a significant milestone in the diversification of battery technologies beyond the current lithium-ion dominated landscape.

Market Analysis for Sodium-ion Battery Applications

The sodium-ion battery market is experiencing significant growth as a promising alternative to lithium-ion batteries, driven by increasing demand for sustainable energy storage solutions. Current market projections indicate that the sodium-ion battery market could reach $500 million by 2025, with a compound annual growth rate exceeding 20% over the next decade. This growth is primarily fueled by concerns over lithium supply chain constraints and price volatility.

The application landscape for sodium-ion batteries is diversifying rapidly. Stationary energy storage represents the largest current market segment, accounting for approximately 45% of potential applications. This includes grid-scale storage, renewable energy integration, and backup power systems where energy density requirements are less stringent than in mobile applications.

Electric mobility presents another emerging opportunity, particularly in two-wheelers, three-wheelers, and short-range electric vehicles in developing markets. These applications benefit from sodium-ion batteries' cost advantages and safety profile, despite their lower energy density compared to lithium-ion counterparts.

Consumer electronics manufacturers are also exploring sodium-ion technology for low-cost devices where battery performance requirements are moderate. This segment could represent 15-20% of the potential market by 2030, particularly in regions with limited access to lithium resources.

Geographically, China is leading sodium-ion battery development and commercialization, with companies like CATL and BYD making substantial investments. Europe follows with research initiatives focused on sustainable battery technologies, while North America shows increasing interest driven by energy security concerns.

The Prussian White Hard-Carbon full cell configuration specifically addresses market demands for improved cycle life and energy density in sodium-ion batteries. This technology combination offers a potential cost reduction of 20-30% compared to lithium-ion batteries, making it particularly attractive for price-sensitive applications.

Market adoption faces challenges including performance perception, manufacturing scale-up, and competition from established lithium-ion technology. However, sodium inventory balancing innovations in Prussian White Hard-Carbon cells could accelerate market penetration by addressing key performance limitations.

Industry analysts predict that successful commercialization of advanced sodium-ion technologies like optimized Prussian White Hard-Carbon full cells could capture up to 10% of the global battery market by 2035, representing a significant opportunity for early movers in this technology space.

The application landscape for sodium-ion batteries is diversifying rapidly. Stationary energy storage represents the largest current market segment, accounting for approximately 45% of potential applications. This includes grid-scale storage, renewable energy integration, and backup power systems where energy density requirements are less stringent than in mobile applications.

Electric mobility presents another emerging opportunity, particularly in two-wheelers, three-wheelers, and short-range electric vehicles in developing markets. These applications benefit from sodium-ion batteries' cost advantages and safety profile, despite their lower energy density compared to lithium-ion counterparts.

Consumer electronics manufacturers are also exploring sodium-ion technology for low-cost devices where battery performance requirements are moderate. This segment could represent 15-20% of the potential market by 2030, particularly in regions with limited access to lithium resources.

Geographically, China is leading sodium-ion battery development and commercialization, with companies like CATL and BYD making substantial investments. Europe follows with research initiatives focused on sustainable battery technologies, while North America shows increasing interest driven by energy security concerns.

The Prussian White Hard-Carbon full cell configuration specifically addresses market demands for improved cycle life and energy density in sodium-ion batteries. This technology combination offers a potential cost reduction of 20-30% compared to lithium-ion batteries, making it particularly attractive for price-sensitive applications.

Market adoption faces challenges including performance perception, manufacturing scale-up, and competition from established lithium-ion technology. However, sodium inventory balancing innovations in Prussian White Hard-Carbon cells could accelerate market penetration by addressing key performance limitations.

Industry analysts predict that successful commercialization of advanced sodium-ion technologies like optimized Prussian White Hard-Carbon full cells could capture up to 10% of the global battery market by 2035, representing a significant opportunity for early movers in this technology space.

Technical Challenges in Sodium Inventory Management

Managing sodium inventory in Prussian White Hard-Carbon full cells presents several significant technical challenges that impede the commercialization and widespread adoption of sodium-ion battery technology. The primary challenge stems from the inherent mismatch between the initial sodium content in cathode materials and the sodium storage capacity of anode materials during the first cycle.

Prussian White cathodes (Na2Fe[Fe(CN)6]) contain a high initial sodium content, while Hard-Carbon anodes typically start in a desodiated state. This imbalance necessitates precise pre-sodiation techniques to ensure optimal cell performance. Current methods for pre-sodiation, including electrochemical, chemical, and metallurgical approaches, each present their own technical difficulties in achieving uniform and controlled sodium distribution.

Another significant challenge is the irreversible capacity loss during the first cycle, commonly known as the first-cycle efficiency issue. Hard-Carbon anodes typically exhibit first-cycle efficiencies of only 70-85%, meaning a substantial portion of sodium ions become trapped in the solid electrolyte interphase (SEI) formation. This irreversible consumption of sodium ions directly impacts the cell's energy density and cycle life.

The stability of the sodium inventory throughout cycling poses additional challenges. Unlike lithium-ion batteries, sodium-ion systems often experience more pronounced sodium inventory fluctuations due to the larger ionic radius of sodium and its different chemical properties. This leads to accelerated capacity fading and reduced cycle life if not properly managed.

Temperature sensitivity further complicates sodium inventory management. At low temperatures, sodium diffusion kinetics slow significantly, leading to sodium plating risks and potential safety hazards. At elevated temperatures, enhanced side reactions can deplete the active sodium inventory more rapidly than in comparable lithium systems.

Manufacturing consistency presents another hurdle, as slight variations in electrode composition, thickness, or density can dramatically affect the sodium balance. The industry currently lacks standardized protocols for sodium inventory assessment and adjustment during the manufacturing process.

Electrolyte decomposition also contributes to continuous sodium loss during cycling. The development of electrolyte formulations that form stable SEI layers while minimizing ongoing sodium consumption remains an active research area with significant technical barriers.

Advanced in-situ and operando characterization techniques are needed to accurately monitor sodium distribution and migration during cell operation, but current technologies offer limited spatial and temporal resolution for real-time sodium inventory tracking.

Prussian White cathodes (Na2Fe[Fe(CN)6]) contain a high initial sodium content, while Hard-Carbon anodes typically start in a desodiated state. This imbalance necessitates precise pre-sodiation techniques to ensure optimal cell performance. Current methods for pre-sodiation, including electrochemical, chemical, and metallurgical approaches, each present their own technical difficulties in achieving uniform and controlled sodium distribution.

Another significant challenge is the irreversible capacity loss during the first cycle, commonly known as the first-cycle efficiency issue. Hard-Carbon anodes typically exhibit first-cycle efficiencies of only 70-85%, meaning a substantial portion of sodium ions become trapped in the solid electrolyte interphase (SEI) formation. This irreversible consumption of sodium ions directly impacts the cell's energy density and cycle life.

The stability of the sodium inventory throughout cycling poses additional challenges. Unlike lithium-ion batteries, sodium-ion systems often experience more pronounced sodium inventory fluctuations due to the larger ionic radius of sodium and its different chemical properties. This leads to accelerated capacity fading and reduced cycle life if not properly managed.

Temperature sensitivity further complicates sodium inventory management. At low temperatures, sodium diffusion kinetics slow significantly, leading to sodium plating risks and potential safety hazards. At elevated temperatures, enhanced side reactions can deplete the active sodium inventory more rapidly than in comparable lithium systems.

Manufacturing consistency presents another hurdle, as slight variations in electrode composition, thickness, or density can dramatically affect the sodium balance. The industry currently lacks standardized protocols for sodium inventory assessment and adjustment during the manufacturing process.

Electrolyte decomposition also contributes to continuous sodium loss during cycling. The development of electrolyte formulations that form stable SEI layers while minimizing ongoing sodium consumption remains an active research area with significant technical barriers.

Advanced in-situ and operando characterization techniques are needed to accurately monitor sodium distribution and migration during cell operation, but current technologies offer limited spatial and temporal resolution for real-time sodium inventory tracking.

Current Approaches to Sodium Inventory Balancing

01 Prussian white cathode materials for sodium-ion batteries

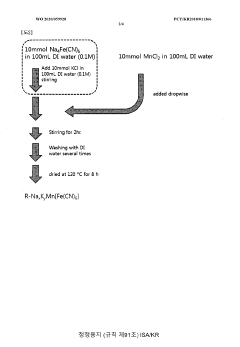

Prussian white compounds are used as cathode materials in sodium-ion batteries due to their high capacity and stable structure. These materials can be optimized through various synthesis methods to improve their electrochemical performance. The composition and structure of Prussian white materials significantly affect the sodium inventory and overall battery performance when paired with hard carbon anodes in full cells.- Prussian white cathode materials for sodium-ion batteries: Prussian white compounds serve as effective cathode materials in sodium-ion batteries due to their open framework structure that facilitates sodium ion insertion/extraction. These materials demonstrate high capacity, good rate capability, and cycling stability. The composition and synthesis methods of Prussian white cathodes can be optimized to improve electrochemical performance when paired with hard carbon anodes in full cells.

- Hard carbon anode optimization for sodium inventory balance: Hard carbon materials derived from various carbon precursors serve as primary anodes in sodium-ion batteries. The optimization of hard carbon structure, porosity, and surface properties is crucial for sodium inventory balancing in full cells. Pre-sodiation techniques and tailored synthesis methods can enhance the initial coulombic efficiency and sodium storage capacity of hard carbon anodes, directly affecting the overall sodium inventory balance.

- Electrolyte formulations for sodium inventory management: Specialized electrolyte formulations play a critical role in managing sodium inventory in Prussian white/hard carbon full cells. Additives and solvent combinations can form stable solid electrolyte interphase (SEI) layers, reducing irreversible sodium consumption during initial cycles. Optimized electrolytes minimize side reactions and enhance sodium ion transport between electrodes, contributing to better sodium inventory balance and improved cycling performance.

- Pre-sodiation and electrode balancing techniques: Various pre-sodiation techniques are employed to compensate for initial sodium loss during SEI formation. These include chemical pre-sodiation of hard carbon anodes, electrode capacity ratio optimization, and controlled initial formation protocols. Proper balancing of negative-to-positive capacity ratios ensures optimal sodium inventory distribution throughout the cell life, preventing sodium depletion during cycling and extending battery lifespan.

- Advanced cell design and manufacturing processes: Innovative cell design and manufacturing processes are developed to address sodium inventory balancing challenges in Prussian white/hard carbon full cells. These include specialized electrode coating techniques, tailored electrode thickness ratios, and controlled calendering processes. Advanced cell assembly methods with precise electrolyte filling protocols and formation cycling procedures help establish optimal sodium distribution within the cell, enhancing overall performance and cycle life.

02 Hard carbon anode optimization for sodium storage

Hard carbon materials serve as effective anodes in sodium-ion batteries due to their ability to store sodium ions. The performance of hard carbon can be enhanced through structural modifications, surface treatments, and doping strategies. Optimizing the porosity, particle size, and surface functionality of hard carbon anodes is crucial for improving sodium inventory balancing in full cells with Prussian white cathodes.Expand Specific Solutions03 Sodium inventory balancing techniques in full cells

Balancing sodium inventory between cathode and anode is critical for optimal performance of Prussian white/hard carbon full cells. This can be achieved through pre-sodiation techniques, electrolyte optimization, and precise control of electrode mass ratios. Proper sodium inventory management prevents capacity fading and improves cycling stability of the battery system.Expand Specific Solutions04 Electrolyte formulations for Prussian white/hard carbon systems

Specialized electrolyte formulations play a crucial role in sodium-ion transport and interface stability in Prussian white/hard carbon full cells. Additives and solvent compositions can be optimized to enhance sodium ion mobility, reduce side reactions, and improve the solid electrolyte interphase formation. These electrolyte innovations directly impact sodium inventory balancing and overall cell performance.Expand Specific Solutions05 Cell design and engineering for sodium inventory optimization

Advanced cell design and engineering approaches are employed to optimize sodium inventory in Prussian white/hard carbon full cells. This includes innovations in electrode architecture, separator technology, and cell assembly techniques. Controlling parameters such as electrode thickness, porosity, and compression during cell manufacturing helps achieve optimal sodium distribution and utilization throughout the battery system.Expand Specific Solutions

Leading Companies in Sodium-ion Battery Development

The sodium inventory balancing for Prussian White Hard-Carbon full cells market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market size remains relatively modest but is expanding rapidly due to sodium-ion batteries' cost advantages and sustainability benefits. Technologically, this field is advancing from research to early commercialization, with companies like Altris AB leading in Prussian White framework material production and CATL making significant investments. Academic institutions including Wuhan University of Technology and Tsinghua University are contributing fundamental research, while specialized players such as Faradion and Northvolt are developing complementary technologies. The ecosystem shows a balanced mix of established battery manufacturers, specialized startups, and research institutions collaborating to overcome remaining technical challenges.

Altris AB

Technical Solution: Altris AB专注于开发基于普鲁士白的钠离子电池技术,其核心技术方案"Fennac®"是一种无钴钠离子正极材料,基于普鲁士白结构。该公司采用专有的钠库存平衡策略,通过精确控制初始预钠化水平来优化普鲁士白与硬碳全电池系统。Altris的技术方案包括使用特殊的电解质添加剂来稳定SEI膜形成,并采用梯度预钠化处理,确保在充放电循环过程中钠离子的有效分配。此外,公司开发了专有的电极涂覆技术,可以减少首次循环中的不可逆容量损失,从而提高整体钠利用效率。

优势:专有的Fennac®材料具有高稳定性和优异的循环性能;生产过程环保且成本效益高;无钴配方避免了关键材料供应风险。劣势:相比锂离子电池,能量密度仍有提升空间;大规模商业化生产尚在发展阶段;在极端温度条件下性能可能受限。

Contemporary Amperex Technology Co., Ltd.

Technical Solution: 宁德时代(CATL)在钠离子电池领域的技术方案聚焦于普鲁士白-硬碳全电池系统的钠库存平衡优化。公司开发了一种多层次预钠化策略,通过在硬碳负极材料中预先嵌入精确计算的钠离子量,补偿首次循环中的不可逆容量损失。CATL的专利技术包括使用钠金属源进行预钠化处理,并结合特殊的电解质配方,含有氟化碳酸酯添加剂,可形成稳定的SEI膜。此外,公司采用创新的电极设计,优化了正负极容量比(N/P比),确保在长期循环过程中维持适当的钠离子库存。CATL还开发了先进的电池管理系统,通过实时监控和调整充放电参数,进一步优化钠离子在电池系统中的分布和利用效率。

优势:强大的研发能力和完整的产业链整合;大规模生产经验可快速实现技术商业化;先进的电池管理系统提供精确的钠库存控制。劣势:相比其成熟的锂离子电池技术,钠离子电池技术仍处于发展阶段;普鲁士白材料的结构稳定性在长期循环后可能面临挑战。

Key Patents in Prussian White-Hard Carbon Cell Design

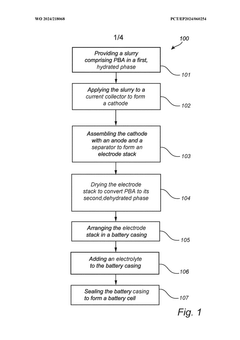

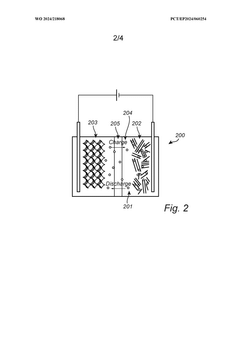

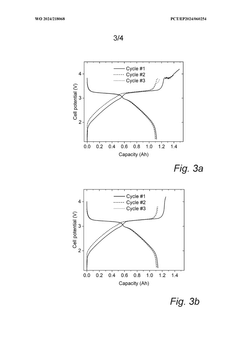

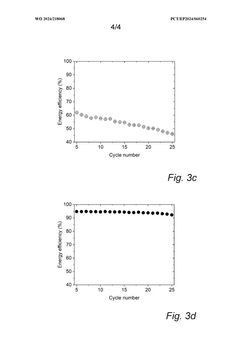

A method for manufacturing a sodium or potassium ion battery cell

PatentWO2024218068A1

Innovation

- A method involving a slurry of Prussian Blue analogue in a hydrated phase applied to a current collector, followed by drying under controlled conditions to achieve a dehydrated phase, with assembly and sealing performed in an atmosphere with a dew point temperature between -40°C to -80°C to prevent moisture reabsorption, allowing for efficient large-scale production.

Electrode composition for secondary battery and method for preparing same

PatentWO2020059928A1

Innovation

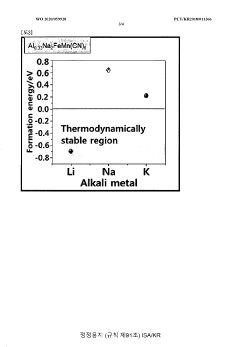

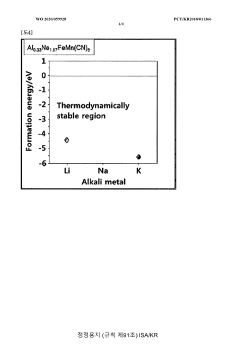

- Incorporating potassium ions with a large ionic radius into the Prussian White structure to prevent water trapping, using a method involving the addition of potassium chloride and manganese chloride solutions to form a compound like Na2-xKxMn[Fe(CN)6, which is then mixed with conductive materials and binders for electrode manufacturing.

Cost Analysis of Sodium-ion vs Lithium-ion Technologies

The economic viability of sodium-ion battery technology represents a critical factor in its potential market adoption compared to the established lithium-ion technology. When specifically examining cost structures for Prussian White Hard-Carbon full cells versus lithium-ion counterparts, several significant economic advantages emerge.

Raw material costs constitute the primary economic advantage for sodium-ion technology. Sodium resources are approximately 1,000 times more abundant than lithium globally, with sodium carbonate priced at roughly $300/ton compared to lithium carbonate at $15,000-20,000/ton (as of 2023). This fundamental cost differential creates a baseline economic advantage that persists throughout the supply chain.

Cathode material costs show particular promise for cost reduction. Prussian White cathodes utilize iron and sodium-based compounds rather than costly nickel, cobalt, and lithium materials found in conventional lithium-ion batteries. Manufacturing analyses indicate potential cathode cost reductions of 30-40% compared to NMC (Nickel-Manganese-Cobalt) cathodes commonly used in lithium-ion cells.

Hard carbon anode materials derived from sustainable biomass sources present another cost advantage. While graphite remains the dominant anode material for lithium-ion batteries with prices ranging from $1,000-3,000/ton for synthetic graphite, hard carbon production pathways from agricultural waste or other carbon-rich precursors offer potential cost reductions of 15-25% at scale.

Manufacturing infrastructure compatibility represents an often-overlooked economic benefit. Sodium-ion cells utilizing Prussian White cathodes and hard carbon anodes can be manufactured using existing lithium-ion production equipment with minimal modifications. This compatibility significantly reduces capital expenditure requirements for battery manufacturers looking to diversify their technology portfolio.

End-of-life considerations also favor sodium-ion economics. The absence of critical materials like cobalt and nickel simplifies recycling processes and reduces associated costs. Preliminary recycling studies suggest 15-30% lower processing costs for sodium-ion batteries compared to lithium-ion equivalents.

Total cell-level cost projections indicate that Prussian White Hard-Carbon full cells could achieve 20-30% lower costs than comparable lithium-ion cells at equivalent production scales. However, these economic advantages must be balanced against current performance limitations, particularly lower energy density (approximately 30-40% lower than lithium-ion), which impacts application-specific total cost of ownership calculations.

Raw material costs constitute the primary economic advantage for sodium-ion technology. Sodium resources are approximately 1,000 times more abundant than lithium globally, with sodium carbonate priced at roughly $300/ton compared to lithium carbonate at $15,000-20,000/ton (as of 2023). This fundamental cost differential creates a baseline economic advantage that persists throughout the supply chain.

Cathode material costs show particular promise for cost reduction. Prussian White cathodes utilize iron and sodium-based compounds rather than costly nickel, cobalt, and lithium materials found in conventional lithium-ion batteries. Manufacturing analyses indicate potential cathode cost reductions of 30-40% compared to NMC (Nickel-Manganese-Cobalt) cathodes commonly used in lithium-ion cells.

Hard carbon anode materials derived from sustainable biomass sources present another cost advantage. While graphite remains the dominant anode material for lithium-ion batteries with prices ranging from $1,000-3,000/ton for synthetic graphite, hard carbon production pathways from agricultural waste or other carbon-rich precursors offer potential cost reductions of 15-25% at scale.

Manufacturing infrastructure compatibility represents an often-overlooked economic benefit. Sodium-ion cells utilizing Prussian White cathodes and hard carbon anodes can be manufactured using existing lithium-ion production equipment with minimal modifications. This compatibility significantly reduces capital expenditure requirements for battery manufacturers looking to diversify their technology portfolio.

End-of-life considerations also favor sodium-ion economics. The absence of critical materials like cobalt and nickel simplifies recycling processes and reduces associated costs. Preliminary recycling studies suggest 15-30% lower processing costs for sodium-ion batteries compared to lithium-ion equivalents.

Total cell-level cost projections indicate that Prussian White Hard-Carbon full cells could achieve 20-30% lower costs than comparable lithium-ion cells at equivalent production scales. However, these economic advantages must be balanced against current performance limitations, particularly lower energy density (approximately 30-40% lower than lithium-ion), which impacts application-specific total cost of ownership calculations.

Environmental Impact and Sustainability Considerations

The development of sodium-ion battery technologies, particularly Prussian White Hard-Carbon Full Cells, represents a significant step toward more sustainable energy storage solutions. Unlike lithium-ion batteries, sodium-ion technologies utilize sodium, which is approximately 1,000 times more abundant in the Earth's crust than lithium, substantially reducing resource depletion concerns and extraction-related environmental impacts.

The sodium inventory balancing process in these cells contributes to sustainability through improved cycle life and efficiency, reducing the frequency of battery replacement and associated waste generation. This longevity factor is crucial when considering the complete life cycle assessment of energy storage technologies, as manufacturing processes typically account for a significant portion of environmental impacts.

Manufacturing Prussian White cathodes generally involves lower temperature synthesis compared to conventional lithium-ion cathode materials, potentially reducing energy consumption and associated carbon emissions during production. Additionally, the precursor materials for Prussian White structures are often less toxic and more environmentally benign than those used in some lithium-ion battery chemistries.

Hard carbon anodes derived from biomass or waste materials present another environmental advantage. These sustainable carbon sources can transform agricultural residues or food industry byproducts into valuable battery components, creating a circular economy pathway that reduces waste while avoiding competition with food production.

Water usage represents a critical environmental consideration in battery manufacturing. Sodium inventory balancing techniques that optimize electrolyte formulations may reduce water consumption during production and processing stages, addressing an often overlooked environmental impact of battery technologies.

End-of-life management for sodium-ion batteries presents fewer challenges compared to lithium-ion counterparts. The materials are generally less hazardous, and the recycling processes can be less energy-intensive. Effective sodium inventory balancing extends battery lifespan, delaying end-of-life issues while recycling infrastructure develops.

Carbon footprint analyses indicate that sodium-ion batteries with optimized sodium inventory could potentially reduce greenhouse gas emissions by 15-25% compared to equivalent lithium-ion systems when considering full lifecycle impacts. This reduction stems from less energy-intensive material extraction, processing, and potentially simplified recycling pathways.

Regulatory frameworks worldwide are increasingly emphasizing battery sustainability, with the EU Battery Directive and similar initiatives in North America and Asia establishing requirements for carbon footprint disclosure, ethical material sourcing, and recycling targets. Sodium-ion technologies with efficient inventory balancing are well-positioned to meet these evolving standards, potentially gaining market advantage as sustainability requirements become more stringent.

The sodium inventory balancing process in these cells contributes to sustainability through improved cycle life and efficiency, reducing the frequency of battery replacement and associated waste generation. This longevity factor is crucial when considering the complete life cycle assessment of energy storage technologies, as manufacturing processes typically account for a significant portion of environmental impacts.

Manufacturing Prussian White cathodes generally involves lower temperature synthesis compared to conventional lithium-ion cathode materials, potentially reducing energy consumption and associated carbon emissions during production. Additionally, the precursor materials for Prussian White structures are often less toxic and more environmentally benign than those used in some lithium-ion battery chemistries.

Hard carbon anodes derived from biomass or waste materials present another environmental advantage. These sustainable carbon sources can transform agricultural residues or food industry byproducts into valuable battery components, creating a circular economy pathway that reduces waste while avoiding competition with food production.

Water usage represents a critical environmental consideration in battery manufacturing. Sodium inventory balancing techniques that optimize electrolyte formulations may reduce water consumption during production and processing stages, addressing an often overlooked environmental impact of battery technologies.

End-of-life management for sodium-ion batteries presents fewer challenges compared to lithium-ion counterparts. The materials are generally less hazardous, and the recycling processes can be less energy-intensive. Effective sodium inventory balancing extends battery lifespan, delaying end-of-life issues while recycling infrastructure develops.

Carbon footprint analyses indicate that sodium-ion batteries with optimized sodium inventory could potentially reduce greenhouse gas emissions by 15-25% compared to equivalent lithium-ion systems when considering full lifecycle impacts. This reduction stems from less energy-intensive material extraction, processing, and potentially simplified recycling pathways.

Regulatory frameworks worldwide are increasingly emphasizing battery sustainability, with the EU Battery Directive and similar initiatives in North America and Asia establishing requirements for carbon footprint disclosure, ethical material sourcing, and recycling targets. Sodium-ion technologies with efficient inventory balancing are well-positioned to meet these evolving standards, potentially gaining market advantage as sustainability requirements become more stringent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!