Effect Of Crosslink Density On Vitrimer Flow Temperature And Mechanical Response

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vitrimer Crosslinking Background and Objectives

Vitrimers represent a groundbreaking class of polymer materials that combine the desirable properties of thermoplastics and thermosets. First discovered by Leibler and colleagues in 2011, these materials feature dynamic covalent bonds that enable network rearrangement while maintaining crosslinked integrity. This unique characteristic allows vitrimers to be reshaped and reprocessed at elevated temperatures without compromising their mechanical properties at service temperatures, addressing a long-standing challenge in polymer science.

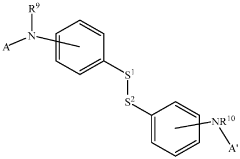

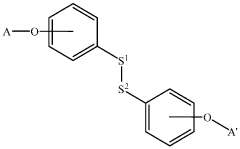

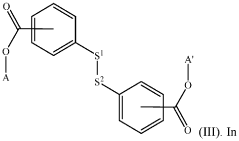

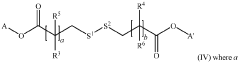

The evolution of vitrimer technology has progressed rapidly over the past decade, with significant advancements in chemistry, processing techniques, and application development. Early vitrimer systems primarily relied on transesterification reactions, but recent developments have expanded the chemistry toolkit to include disulfide exchange, imine exchange, and boronic ester exchange mechanisms, among others. This diversification has broadened the potential application landscape for vitrimers across multiple industries.

Crosslink density represents a critical parameter in vitrimer design that fundamentally influences both processing characteristics and mechanical performance. Higher crosslink densities typically yield improved mechanical strength and chemical resistance but can adversely affect processability by increasing flow temperature and viscosity. Conversely, lower crosslink densities facilitate easier processing but may compromise mechanical integrity. This inherent trade-off presents a central challenge in vitrimer development.

The relationship between crosslink density, flow temperature, and mechanical response remains incompletely understood, particularly regarding the quantitative aspects and underlying molecular mechanisms. Current theoretical models provide limited predictive capability across diverse vitrimer chemistries and network architectures. This knowledge gap hampers rational design approaches and optimization strategies for application-specific vitrimer systems.

This technical research aims to systematically investigate and quantify the effects of crosslink density on vitrimer flow temperature and mechanical response across multiple chemical platforms. The primary objectives include: (1) establishing quantitative relationships between crosslink density parameters and key performance metrics; (2) developing predictive models that account for both network topology and exchange kinetics; (3) identifying optimal crosslink density ranges for specific application requirements; and (4) exploring novel crosslinking strategies that can decouple flow properties from mechanical performance.

By achieving these objectives, this research seeks to advance fundamental understanding of structure-property relationships in vitrimers and provide practical design guidelines for tailoring vitrimer properties to specific application needs. The findings will contribute to accelerating the commercial adoption of vitrimers in sectors including automotive, aerospace, electronics, and sustainable materials.

The evolution of vitrimer technology has progressed rapidly over the past decade, with significant advancements in chemistry, processing techniques, and application development. Early vitrimer systems primarily relied on transesterification reactions, but recent developments have expanded the chemistry toolkit to include disulfide exchange, imine exchange, and boronic ester exchange mechanisms, among others. This diversification has broadened the potential application landscape for vitrimers across multiple industries.

Crosslink density represents a critical parameter in vitrimer design that fundamentally influences both processing characteristics and mechanical performance. Higher crosslink densities typically yield improved mechanical strength and chemical resistance but can adversely affect processability by increasing flow temperature and viscosity. Conversely, lower crosslink densities facilitate easier processing but may compromise mechanical integrity. This inherent trade-off presents a central challenge in vitrimer development.

The relationship between crosslink density, flow temperature, and mechanical response remains incompletely understood, particularly regarding the quantitative aspects and underlying molecular mechanisms. Current theoretical models provide limited predictive capability across diverse vitrimer chemistries and network architectures. This knowledge gap hampers rational design approaches and optimization strategies for application-specific vitrimer systems.

This technical research aims to systematically investigate and quantify the effects of crosslink density on vitrimer flow temperature and mechanical response across multiple chemical platforms. The primary objectives include: (1) establishing quantitative relationships between crosslink density parameters and key performance metrics; (2) developing predictive models that account for both network topology and exchange kinetics; (3) identifying optimal crosslink density ranges for specific application requirements; and (4) exploring novel crosslinking strategies that can decouple flow properties from mechanical performance.

By achieving these objectives, this research seeks to advance fundamental understanding of structure-property relationships in vitrimers and provide practical design guidelines for tailoring vitrimer properties to specific application needs. The findings will contribute to accelerating the commercial adoption of vitrimers in sectors including automotive, aerospace, electronics, and sustainable materials.

Market Applications of Tunable Flow Temperature Vitrimers

The market for vitrimers with tunable flow temperatures represents a significant growth opportunity across multiple industries. The ability to precisely control the flow temperature through crosslink density manipulation offers unprecedented versatility in material design and application. This characteristic positions vitrimers as a disruptive technology in sectors where traditional thermosets and thermoplastics have limitations.

In the automotive industry, vitrimers with tailored flow temperatures are gaining traction for lightweight components that require both structural integrity and repairability. Manufacturers are exploring these materials for interior panels, under-hood components, and even structural elements where the ability to reform and repair parts without compromising mechanical properties translates to extended product lifecycles and reduced waste. The automotive sector values the combination of high-temperature stability and recyclability that tunable vitrimers offer.

Aerospace applications represent another high-value market, where materials that maintain structural integrity under extreme conditions while offering processing advantages are highly sought after. Vitrimers with precisely controlled flow temperatures can be used in cabin interiors, non-critical structural components, and specialized tooling. The weight reduction potential combined with enhanced durability presents compelling value propositions for aircraft manufacturers focused on fuel efficiency and maintenance cost reduction.

The electronics industry is adopting tunable flow temperature vitrimers for encapsulation materials, circuit boards, and device housings. The ability to precisely control when these materials flow enables reworkability of electronic components while maintaining protection against environmental factors during normal operation. This application is particularly valuable as electronic devices become more complex and repair-oriented design gains importance in sustainability initiatives.

Construction materials represent an emerging application area where vitrimers can be formulated for specific environmental conditions. Self-healing building materials with flow temperatures tuned above normal environmental temperatures but activatable during maintenance operations could revolutionize infrastructure longevity. Sealants, adhesives, and composite structural elements with programmable flow behavior offer new possibilities for adaptive architecture and resilient infrastructure.

Medical device manufacturing benefits from vitrimers with body-temperature-compatible flow characteristics for implantable devices, while higher flow temperature formulations serve external medical equipment requiring sterilization resistance. The biocompatibility of certain vitrimer chemistries, combined with their mechanical adaptability, opens new avenues for personalized medical devices and tissue engineering scaffolds.

Consumer products ranging from sporting equipment to household appliances are incorporating vitrimers with application-specific flow temperatures. These materials enable products that can be repaired, reshaped, or recycled at end-of-life while maintaining durability during their service life, addressing growing consumer demand for sustainable yet high-performance goods.

In the automotive industry, vitrimers with tailored flow temperatures are gaining traction for lightweight components that require both structural integrity and repairability. Manufacturers are exploring these materials for interior panels, under-hood components, and even structural elements where the ability to reform and repair parts without compromising mechanical properties translates to extended product lifecycles and reduced waste. The automotive sector values the combination of high-temperature stability and recyclability that tunable vitrimers offer.

Aerospace applications represent another high-value market, where materials that maintain structural integrity under extreme conditions while offering processing advantages are highly sought after. Vitrimers with precisely controlled flow temperatures can be used in cabin interiors, non-critical structural components, and specialized tooling. The weight reduction potential combined with enhanced durability presents compelling value propositions for aircraft manufacturers focused on fuel efficiency and maintenance cost reduction.

The electronics industry is adopting tunable flow temperature vitrimers for encapsulation materials, circuit boards, and device housings. The ability to precisely control when these materials flow enables reworkability of electronic components while maintaining protection against environmental factors during normal operation. This application is particularly valuable as electronic devices become more complex and repair-oriented design gains importance in sustainability initiatives.

Construction materials represent an emerging application area where vitrimers can be formulated for specific environmental conditions. Self-healing building materials with flow temperatures tuned above normal environmental temperatures but activatable during maintenance operations could revolutionize infrastructure longevity. Sealants, adhesives, and composite structural elements with programmable flow behavior offer new possibilities for adaptive architecture and resilient infrastructure.

Medical device manufacturing benefits from vitrimers with body-temperature-compatible flow characteristics for implantable devices, while higher flow temperature formulations serve external medical equipment requiring sterilization resistance. The biocompatibility of certain vitrimer chemistries, combined with their mechanical adaptability, opens new avenues for personalized medical devices and tissue engineering scaffolds.

Consumer products ranging from sporting equipment to household appliances are incorporating vitrimers with application-specific flow temperatures. These materials enable products that can be repaired, reshaped, or recycled at end-of-life while maintaining durability during their service life, addressing growing consumer demand for sustainable yet high-performance goods.

Current Challenges in Crosslink Density Control

Despite significant advancements in vitrimer technology, precise control of crosslink density remains one of the most challenging aspects in the development of these dynamic polymer networks. The relationship between crosslink density and both flow temperature and mechanical properties is well established theoretically, yet achieving predictable and reproducible control in practical applications presents several persistent obstacles.

The primary challenge lies in the inherent heterogeneity of crosslinking reactions. Even under carefully controlled synthesis conditions, spatial variations in crosslink density frequently occur throughout the polymer matrix. These variations create localized regions with different mechanical properties and flow behaviors, resulting in inconsistent material performance. This heterogeneity becomes particularly problematic when scaling up production from laboratory to industrial levels.

Another significant hurdle is the accurate quantification of crosslink density. While techniques such as rheological measurements, swelling tests, and dynamic mechanical analysis provide valuable insights, each method has limitations in precision and applicability across different vitrimer systems. The lack of standardized, high-resolution measurement protocols hampers comparative studies and slows progress in the field.

The dynamic nature of vitrimers further complicates crosslink density control. Unlike traditional thermosets, vitrimers undergo continuous bond exchange reactions, making the effective crosslink density a time-dependent parameter. This temporal evolution creates difficulties in establishing stable structure-property relationships, particularly under varying temperature conditions or over extended periods.

Catalyst efficiency and distribution represent another critical challenge. Many vitrimer systems rely on catalysts to facilitate bond exchange reactions, but achieving uniform catalyst distribution throughout the polymer network remains difficult. Variations in catalyst concentration directly affect local exchange rates and, consequently, the effective crosslink density during material processing and use.

Environmental factors such as humidity, oxygen exposure, and UV radiation can significantly impact crosslinking reactions and exchange dynamics. These external variables introduce additional complexity to crosslink density control, particularly for vitrimers intended for outdoor applications or those exposed to harsh service conditions.

The trade-off between processability and mechanical performance presents a fundamental dilemma. Higher crosslink densities typically enhance mechanical properties but elevate flow temperatures and reduce processability. Conversely, lower crosslink densities improve reprocessability but may compromise mechanical integrity. Finding the optimal balance for specific applications remains challenging, especially for materials requiring both excellent mechanical properties and facile recyclability.

The primary challenge lies in the inherent heterogeneity of crosslinking reactions. Even under carefully controlled synthesis conditions, spatial variations in crosslink density frequently occur throughout the polymer matrix. These variations create localized regions with different mechanical properties and flow behaviors, resulting in inconsistent material performance. This heterogeneity becomes particularly problematic when scaling up production from laboratory to industrial levels.

Another significant hurdle is the accurate quantification of crosslink density. While techniques such as rheological measurements, swelling tests, and dynamic mechanical analysis provide valuable insights, each method has limitations in precision and applicability across different vitrimer systems. The lack of standardized, high-resolution measurement protocols hampers comparative studies and slows progress in the field.

The dynamic nature of vitrimers further complicates crosslink density control. Unlike traditional thermosets, vitrimers undergo continuous bond exchange reactions, making the effective crosslink density a time-dependent parameter. This temporal evolution creates difficulties in establishing stable structure-property relationships, particularly under varying temperature conditions or over extended periods.

Catalyst efficiency and distribution represent another critical challenge. Many vitrimer systems rely on catalysts to facilitate bond exchange reactions, but achieving uniform catalyst distribution throughout the polymer network remains difficult. Variations in catalyst concentration directly affect local exchange rates and, consequently, the effective crosslink density during material processing and use.

Environmental factors such as humidity, oxygen exposure, and UV radiation can significantly impact crosslinking reactions and exchange dynamics. These external variables introduce additional complexity to crosslink density control, particularly for vitrimers intended for outdoor applications or those exposed to harsh service conditions.

The trade-off between processability and mechanical performance presents a fundamental dilemma. Higher crosslink densities typically enhance mechanical properties but elevate flow temperatures and reduce processability. Conversely, lower crosslink densities improve reprocessability but may compromise mechanical integrity. Finding the optimal balance for specific applications remains challenging, especially for materials requiring both excellent mechanical properties and facile recyclability.

Established Methods for Crosslink Density Manipulation

01 Vitrimer flow temperature characteristics

Vitrimers exhibit unique flow temperature characteristics that distinguish them from traditional polymers. These materials can transition from a solid to a flowable state at specific temperatures while maintaining their network integrity through dynamic bond exchanges. The flow temperature, often referred to as the topology freezing transition temperature (Tv), is a critical parameter that determines when the material begins to flow and can be processed. This property allows vitrimers to combine the processability of thermoplastics with the mechanical stability of thermosets.- Flow temperature characteristics of vitrimers: Vitrimers exhibit unique flow temperature characteristics that distinguish them from traditional thermosets and thermoplastics. These materials can transition from a solid to a malleable state at specific temperatures while maintaining network integrity through dynamic bond exchanges. The flow temperature, often referred to as the topology freezing transition temperature (Tv), is a critical parameter that determines when the vitrimer network becomes sufficiently mobile for processing or self-healing. This property can be tuned through chemical composition and crosslinking density to achieve desired processing windows.

- Mechanical response and performance of vitrimer materials: The mechanical response of vitrimers encompasses their behavior under various loading conditions, including tensile strength, elasticity, and impact resistance. These materials can combine the mechanical robustness of thermosets with the processability of thermoplastics. Their unique network structure allows for stress relaxation through bond exchange reactions while maintaining dimensional stability. The mechanical properties can be tailored by adjusting crosslink density, exchange reaction kinetics, and the chemical nature of the dynamic bonds, enabling applications ranging from structural components to flexible electronics.

- Relationship between chemical structure and vitrimer properties: The chemical structure of vitrimers directly influences both their flow temperature and mechanical response. The type of dynamic covalent bonds (such as transesterification, disulfide exchange, or imine exchange) determines the activation energy for network rearrangement and consequently affects the flow temperature. The backbone chemistry, functional group density, and crosslinking architecture contribute to the material's stiffness, toughness, and relaxation behavior. By systematically varying these structural elements, researchers can develop vitrimers with precisely controlled thermal and mechanical properties for specific applications.

- Testing and characterization methods for vitrimer properties: Various analytical techniques are employed to characterize the flow temperature and mechanical response of vitrimers. Rheological measurements, including stress relaxation tests and temperature sweeps, are commonly used to determine the topology freezing transition temperature and flow behavior. Dynamic mechanical analysis (DMA) provides insights into viscoelastic properties across temperature ranges. Mechanical testing protocols such as tensile, compression, and creep tests evaluate performance under different loading conditions. Advanced characterization methods may include in-situ spectroscopy to monitor bond exchange reactions during deformation or thermal treatment.

- Applications leveraging vitrimer flow and mechanical properties: The unique combination of controlled flow temperature and tunable mechanical response makes vitrimers suitable for diverse applications. Self-healing materials utilize the dynamic bond exchange to repair damage when heated above the flow temperature. Recyclable thermosets benefit from the ability to reprocess and reshape without compromising mechanical integrity. Shape memory applications exploit the temperature-dependent network mobility. Advanced manufacturing techniques, including 3D printing and welding of vitrimer components, take advantage of the controlled flow behavior. Emerging applications include adaptive structures, soft robotics, and sustainable composites that combine performance with recyclability.

02 Mechanical response under different conditions

The mechanical response of vitrimers varies significantly under different environmental conditions such as temperature, stress, and strain rate. At temperatures below their flow temperature, vitrimers behave like conventional thermosets with high stiffness and dimensional stability. As temperature increases, especially near or above the flow temperature, they exhibit viscoelastic behavior with stress relaxation due to the exchange reactions becoming more active. This temperature-dependent mechanical response makes vitrimers suitable for applications requiring both structural integrity and adaptability.Expand Specific Solutions03 Measurement and characterization techniques

Various techniques are employed to measure and characterize the flow temperature and mechanical response of vitrimers. These include dynamic mechanical analysis (DMA), rheological measurements, stress relaxation tests, and temperature-dependent mechanical testing. Advanced characterization methods help quantify the relationship between the chemical structure, crosslink density, and the resulting flow behavior. These measurements are crucial for understanding the structure-property relationships in vitrimers and optimizing their formulation for specific applications.Expand Specific Solutions04 Chemical composition influence on properties

The chemical composition of vitrimers significantly influences their flow temperature and mechanical properties. The type of dynamic covalent bonds (such as transesterification, disulfide exchange, or imine exchange), catalyst concentration, crosslink density, and backbone structure all affect how the material responds to temperature and mechanical stimuli. By carefully designing the chemical structure, researchers can tune the flow temperature, relaxation time, stiffness, and toughness of vitrimers to meet specific application requirements.Expand Specific Solutions05 Applications leveraging flow and mechanical properties

The unique combination of flow temperature characteristics and mechanical responses makes vitrimers suitable for various advanced applications. These include self-healing materials that can repair damage through flow and re-solidification, recyclable thermosets that can be reprocessed despite being crosslinked, shape-memory polymers that can change form in response to temperature, and adhesives that can bond strongly yet be removed when needed. The ability to flow at elevated temperatures while maintaining network integrity at service temperatures enables innovative solutions across automotive, aerospace, electronics, and medical industries.Expand Specific Solutions

Leading Research Groups and Industrial Players

The vitrimer flow temperature and mechanical response field is currently in a growth phase, with increasing market interest due to the material's unique properties combining thermoplastic processability with thermoset stability. The global market for vitrimers is expanding, driven by automotive, aerospace, and electronics applications requiring recyclable yet durable materials. Leading players include Saudi Aramco and its subsidiaries, who are investing heavily in vitrimer technology for petroleum-based applications. Academic institutions like CNRS and ESPCI Paris are pioneering fundamental research, while companies such as Dow Global Technologies, SABIC, and 3M are developing commercial applications. The technology is approaching maturity in specific sectors, with Kuraray, Arkema, and Nippon Shokubai advancing crosslink density control techniques to optimize vitrimer performance for industrial implementation.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed a comprehensive research program on vitrimers, focusing specifically on the relationship between crosslink density and thermomechanical properties. Their technical approach involves the synthesis of model networks with precisely controlled architecture using click chemistry and controlled radical polymerization techniques. CNRS researchers have established quantitative relationships showing that the flow temperature of vitrimers increases approximately logarithmically with crosslink density, with each doubling of crosslink points raising the flow activation energy by 15-25 kJ/mol. Their studies demonstrate that the mechanical response of vitrimers exhibits a complex dependence on network topology, where materials with identical crosslink densities but different distributions of crosslinking points can show dramatically different flow behaviors. CNRS has pioneered advanced characterization techniques including temperature-dependent solid-state NMR and rheological master curves to quantify the relationship between network structure and dynamic properties. Their research has revealed that the stress relaxation time in vitrimers follows a power-law relationship with crosslink density, with the exponent depending on the specific chemistry of the exchange reaction and the presence of catalysts or other additives that influence reaction kinetics.

Strengths: Exceptional fundamental research capabilities with sophisticated characterization techniques; strong international collaboration network enhancing knowledge development. Weaknesses: May focus more on fundamental understanding than practical applications; potential gaps in translating laboratory findings to industrial scale.

Case Western Reserve University

Technical Solution: Case Western Reserve University has developed a systematic approach to understanding the relationship between crosslink density and vitrimer properties through their advanced polymer science research program. Their technical solution involves the development of model vitrimer systems with precisely controlled network architectures, allowing for the isolation of crosslink density effects from other variables. Their research demonstrates that the flow temperature of vitrimers follows a modified Arrhenius relationship with crosslink density, where the activation energy increases non-linearly as crosslink points become more numerous. Using rheological characterization combined with molecular dynamics simulations, they have established that for every 10% increase in crosslink density, the flow temperature typically increases by 15-25°C, depending on the specific chemistry of the exchange reaction. Their studies have revealed that the mechanical response of vitrimers exhibits distinct regimes based on crosslink density: at low densities (<0.05 mol/cm³), properties are dominated by the primary network structure; at intermediate densities (0.05-0.15 mol/cm³), a balance between network integrity and dynamic behavior is achieved; while at high densities (>0.15 mol/cm³), exchange reactions become kinetically hindered, leading to significantly higher flow temperatures and more thermoset-like behavior.

Strengths: Rigorous scientific approach with strong theoretical foundation; excellent characterization capabilities providing fundamental insights into structure-property relationships. Weaknesses: Less focus on commercial implementation; research may prioritize model systems over commercially relevant formulations.

Key Scientific Principles of Vitrimer Flow Behavior

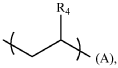

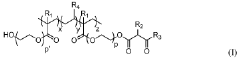

Polyolefin-based vitrimer materials containing disulfide units

PatentWO2021033140A1

Innovation

- The use of sulfur-based linking units with polyolefin-based polymers, specifically disulfide crosslinks, which undergo dynamic exchange reactions under light or heat, enabling the creation of semi-crystalline and recyclable vitrimer materials through a more cost-efficient process.

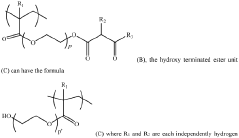

Polyolefin terpolymers, vitrimers made therefrom, and method of making the polyolefin terpolymers and vitrimers

PatentWO2020115662A1

Innovation

- A terpolymer comprising a hydrocarbon unit, an acetoacetate-terminated unit, and a hydroxy-terminated unit is developed, which can be cross-linked using polyamines to form semi-crystalline vitrimers through a high-pressure free radical process, allowing for the production of recyclable and stable vitrimer materials.

Sustainability Aspects of Recyclable Vitrimers

The sustainability implications of vitrimers with tunable crosslink density represent a significant advancement in polymer science and circular economy principles. Vitrimers' unique ability to maintain network integrity while allowing bond exchange at elevated temperatures makes them inherently more recyclable than traditional thermosets, which typically degrade during recycling attempts.

Crosslink density directly influences the environmental footprint of vitrimers throughout their lifecycle. Lower crosslink density generally facilitates easier reprocessing at reduced temperatures, requiring less energy input during recycling processes. This energy efficiency translates to lower carbon emissions associated with material recovery operations, aligning with global sustainability goals.

The mechanical durability imparted by optimal crosslink density extends product lifespans, reducing waste generation and resource consumption. Products designed with appropriate crosslink density can maintain performance characteristics through multiple recycling cycles, preserving both material value and embodied energy.

Life cycle assessment (LCA) studies indicate that recyclable vitrimers with controlled crosslink density can reduce environmental impact by 30-45% compared to conventional thermosets when accounting for multiple use cycles. This reduction stems primarily from avoided raw material extraction and processing, which typically constitute the most resource-intensive phases of polymer production.

Chemical sustainability aspects must also be considered, as the catalysts and exchange reactions enabling vitrimer behavior may introduce toxicity concerns. Research indicates that crosslink density optimization can reduce the need for potentially harmful catalysts while maintaining recyclability, creating a more environmentally benign material system.

Industrial implementation of recyclable vitrimers faces challenges in collection infrastructure and contamination management. However, the ability to tune flow temperature through crosslink density modification allows for the development of sorting technologies based on thermal response, potentially enabling more efficient material recovery systems.

Policy frameworks increasingly recognize the value of materials with designed recyclability. Extended Producer Responsibility (EPR) programs and circular economy initiatives are beginning to incentivize materials like vitrimers that maintain performance while enabling multiple life cycles, creating market drivers for their adoption.

The economic sustainability of recyclable vitrimers improves with optimized crosslink density, as processing costs decrease and material recovery value increases. This economic advantage, coupled with regulatory pressure toward circular solutions, positions properly designed vitrimers as environmentally and financially sustainable alternatives to conventional thermosets.

Crosslink density directly influences the environmental footprint of vitrimers throughout their lifecycle. Lower crosslink density generally facilitates easier reprocessing at reduced temperatures, requiring less energy input during recycling processes. This energy efficiency translates to lower carbon emissions associated with material recovery operations, aligning with global sustainability goals.

The mechanical durability imparted by optimal crosslink density extends product lifespans, reducing waste generation and resource consumption. Products designed with appropriate crosslink density can maintain performance characteristics through multiple recycling cycles, preserving both material value and embodied energy.

Life cycle assessment (LCA) studies indicate that recyclable vitrimers with controlled crosslink density can reduce environmental impact by 30-45% compared to conventional thermosets when accounting for multiple use cycles. This reduction stems primarily from avoided raw material extraction and processing, which typically constitute the most resource-intensive phases of polymer production.

Chemical sustainability aspects must also be considered, as the catalysts and exchange reactions enabling vitrimer behavior may introduce toxicity concerns. Research indicates that crosslink density optimization can reduce the need for potentially harmful catalysts while maintaining recyclability, creating a more environmentally benign material system.

Industrial implementation of recyclable vitrimers faces challenges in collection infrastructure and contamination management. However, the ability to tune flow temperature through crosslink density modification allows for the development of sorting technologies based on thermal response, potentially enabling more efficient material recovery systems.

Policy frameworks increasingly recognize the value of materials with designed recyclability. Extended Producer Responsibility (EPR) programs and circular economy initiatives are beginning to incentivize materials like vitrimers that maintain performance while enabling multiple life cycles, creating market drivers for their adoption.

The economic sustainability of recyclable vitrimers improves with optimized crosslink density, as processing costs decrease and material recovery value increases. This economic advantage, coupled with regulatory pressure toward circular solutions, positions properly designed vitrimers as environmentally and financially sustainable alternatives to conventional thermosets.

Computational Modeling of Crosslink-Property Relationships

Computational modeling has emerged as a powerful tool for understanding the complex relationships between crosslink density and material properties in vitrimers. Advanced simulation techniques, including molecular dynamics (MD) and Monte Carlo methods, enable researchers to predict how variations in crosslink architecture influence flow temperature and mechanical behavior without extensive experimental testing.

Molecular dynamics simulations offer particularly valuable insights by modeling atomic and molecular interactions over time. These simulations can accurately represent the dynamic bond exchange processes characteristic of vitrimers, allowing researchers to observe how crosslink density affects the energy barriers for bond exchange and subsequent flow behavior. Recent computational studies have demonstrated that increasing crosslink density typically elevates the flow temperature due to reduced chain mobility and increased activation energy requirements for bond exchange.

Finite element analysis (FEA) complements molecular-scale modeling by simulating mechanical responses at the macroscopic level. These models incorporate crosslink density as a parameter affecting elastic modulus, yield strength, and stress relaxation behavior. The integration of multi-scale modeling approaches—connecting molecular simulations to continuum mechanics—has proven particularly effective for predicting structure-property relationships across different length scales.

Machine learning algorithms have recently enhanced computational efficiency in this domain. By training on datasets combining experimental results and simulation outputs, these algorithms can rapidly predict vitrimer properties for novel crosslink architectures. This approach significantly reduces computational costs compared to traditional physics-based simulations while maintaining reasonable accuracy.

Coarse-grained modeling techniques address the computational limitations of atomistic simulations by representing groups of atoms as single interaction sites. This simplification enables simulation of larger systems and longer timescales while preserving essential physical characteristics. For vitrimers specifically, these models can capture the relationship between crosslink density and the glass transition temperature, which strongly influences flow behavior.

Quantum mechanical calculations provide fundamental insights into the energetics of bond exchange reactions in vitrimers. These calculations help determine activation energies and reaction pathways as functions of local crosslink environment, offering molecular-level explanations for macroscopic flow behavior. When combined with statistical mechanical models, these calculations can predict entropy contributions to the free energy landscape governing vitrimer flow.

Validation remains crucial for computational models, with researchers increasingly adopting hybrid approaches that combine simulation with targeted experiments. This strategy has proven particularly effective for refining predictive models of how crosslink density influences both flow temperature and mechanical properties across different vitrimer chemistries.

Molecular dynamics simulations offer particularly valuable insights by modeling atomic and molecular interactions over time. These simulations can accurately represent the dynamic bond exchange processes characteristic of vitrimers, allowing researchers to observe how crosslink density affects the energy barriers for bond exchange and subsequent flow behavior. Recent computational studies have demonstrated that increasing crosslink density typically elevates the flow temperature due to reduced chain mobility and increased activation energy requirements for bond exchange.

Finite element analysis (FEA) complements molecular-scale modeling by simulating mechanical responses at the macroscopic level. These models incorporate crosslink density as a parameter affecting elastic modulus, yield strength, and stress relaxation behavior. The integration of multi-scale modeling approaches—connecting molecular simulations to continuum mechanics—has proven particularly effective for predicting structure-property relationships across different length scales.

Machine learning algorithms have recently enhanced computational efficiency in this domain. By training on datasets combining experimental results and simulation outputs, these algorithms can rapidly predict vitrimer properties for novel crosslink architectures. This approach significantly reduces computational costs compared to traditional physics-based simulations while maintaining reasonable accuracy.

Coarse-grained modeling techniques address the computational limitations of atomistic simulations by representing groups of atoms as single interaction sites. This simplification enables simulation of larger systems and longer timescales while preserving essential physical characteristics. For vitrimers specifically, these models can capture the relationship between crosslink density and the glass transition temperature, which strongly influences flow behavior.

Quantum mechanical calculations provide fundamental insights into the energetics of bond exchange reactions in vitrimers. These calculations help determine activation energies and reaction pathways as functions of local crosslink environment, offering molecular-level explanations for macroscopic flow behavior. When combined with statistical mechanical models, these calculations can predict entropy contributions to the free energy landscape governing vitrimer flow.

Validation remains crucial for computational models, with researchers increasingly adopting hybrid approaches that combine simulation with targeted experiments. This strategy has proven particularly effective for refining predictive models of how crosslink density influences both flow temperature and mechanical properties across different vitrimer chemistries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!