Solid-State NMR Versus DMTA For Probing Dynamic Crosslinks In Vitrimers

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vitrimer Characterization Background and Objectives

Vitrimers represent a groundbreaking class of polymer materials that combine the processability of thermoplastics with the mechanical robustness of thermosets. First introduced by Leibler and colleagues in 2011, these materials feature dynamic covalent bonds that enable network rearrangement while maintaining crosslink density. The evolution of vitrimer technology has progressed rapidly over the past decade, with significant advancements in chemistry, processing techniques, and characterization methods.

The fundamental characteristic that distinguishes vitrimers is their ability to undergo bond exchange reactions at elevated temperatures without compromising network integrity. This unique property has positioned vitrimers as potential solutions for recyclable thermosets, self-healing materials, and shape-memory polymers. The technical trajectory has moved from simple transesterification-based systems to more complex architectures incorporating various dynamic chemistries including disulfide exchange, imine formation, and boronic ester exchange.

Accurate characterization of dynamic crosslinks in vitrimers presents significant challenges that have impeded broader industrial adoption. Traditional polymer characterization techniques often fail to capture the unique behavior of these materials, particularly the kinetics and thermodynamics of bond exchange processes. This technical gap has driven the development of specialized analytical approaches, with Solid-State Nuclear Magnetic Resonance (NMR) and Dynamic Mechanical Thermal Analysis (DMTA) emerging as leading methodologies.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of Solid-State NMR and DMTA techniques for characterizing dynamic crosslinks in vitrimers. We aim to evaluate their respective capabilities in quantifying exchange rates, activation energies, and network topology changes under various conditions. Additionally, we seek to identify complementarities between these methods that could lead to more robust characterization protocols.

Understanding the strengths and limitations of these analytical approaches is crucial for advancing vitrimer technology toward commercial applications. Solid-State NMR offers atomic-level insights into bond dynamics but requires specialized equipment and expertise, while DMTA provides macroscopic mechanical property measurements that are more accessible but potentially less specific to bond exchange phenomena.

The technical goals include establishing standardized protocols for vitrimer characterization, determining correlation factors between microscopic bond exchange rates and macroscopic relaxation behaviors, and developing predictive models that connect molecular design to material performance. These advances would significantly accelerate vitrimer development cycles and enable more targeted material design for specific applications.

The fundamental characteristic that distinguishes vitrimers is their ability to undergo bond exchange reactions at elevated temperatures without compromising network integrity. This unique property has positioned vitrimers as potential solutions for recyclable thermosets, self-healing materials, and shape-memory polymers. The technical trajectory has moved from simple transesterification-based systems to more complex architectures incorporating various dynamic chemistries including disulfide exchange, imine formation, and boronic ester exchange.

Accurate characterization of dynamic crosslinks in vitrimers presents significant challenges that have impeded broader industrial adoption. Traditional polymer characterization techniques often fail to capture the unique behavior of these materials, particularly the kinetics and thermodynamics of bond exchange processes. This technical gap has driven the development of specialized analytical approaches, with Solid-State Nuclear Magnetic Resonance (NMR) and Dynamic Mechanical Thermal Analysis (DMTA) emerging as leading methodologies.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of Solid-State NMR and DMTA techniques for characterizing dynamic crosslinks in vitrimers. We aim to evaluate their respective capabilities in quantifying exchange rates, activation energies, and network topology changes under various conditions. Additionally, we seek to identify complementarities between these methods that could lead to more robust characterization protocols.

Understanding the strengths and limitations of these analytical approaches is crucial for advancing vitrimer technology toward commercial applications. Solid-State NMR offers atomic-level insights into bond dynamics but requires specialized equipment and expertise, while DMTA provides macroscopic mechanical property measurements that are more accessible but potentially less specific to bond exchange phenomena.

The technical goals include establishing standardized protocols for vitrimer characterization, determining correlation factors between microscopic bond exchange rates and macroscopic relaxation behaviors, and developing predictive models that connect molecular design to material performance. These advances would significantly accelerate vitrimer development cycles and enable more targeted material design for specific applications.

Market Applications of Dynamic Crosslink Analysis

Dynamic crosslink analysis technologies, particularly Solid-State NMR and DMTA, have found significant applications across various industrial sectors due to their ability to characterize the unique properties of vitrimers and other dynamically crosslinked polymers. These analytical methods enable manufacturers to develop materials with enhanced performance characteristics, driving innovation in multiple markets.

In the automotive industry, dynamic crosslink analysis has revolutionized the development of self-healing coatings and structural components. Major manufacturers utilize these technologies to create lightweight yet durable parts that can withstand mechanical stress while maintaining the ability to repair microscopic damage. This application has led to a 15% reduction in vehicle weight in certain models, contributing to improved fuel efficiency and reduced emissions.

The aerospace sector has embraced dynamic crosslink analysis for developing advanced composite materials that combine strength with repairability. These materials are crucial for components subjected to extreme temperature variations and mechanical stress. The ability to precisely characterize dynamic crosslinks has enabled the creation of composites that maintain structural integrity under diverse operating conditions while offering extended service life through self-healing properties.

Electronics manufacturing represents another significant market application, particularly in flexible electronics and display technologies. Dynamic crosslink analysis helps engineers develop polymers with precisely controlled mechanical properties and thermal stability. These materials form the backbone of foldable displays, wearable electronics, and other next-generation devices where traditional rigid materials would fail.

The medical device industry leverages these analytical techniques to develop biocompatible materials with controlled degradation profiles. By understanding the dynamic nature of crosslinks, researchers can create implantable devices that maintain structural integrity for a predetermined period before safely degrading in the body. This application has particular relevance for tissue engineering scaffolds and drug delivery systems.

Sustainable packaging represents an emerging application area where dynamic crosslink analysis is driving innovation. Manufacturers are developing recyclable and biodegradable polymers with dynamic crosslinks that maintain package integrity during use but allow for efficient recycling or composting afterward. This application addresses growing consumer and regulatory demands for environmentally responsible packaging solutions.

Construction materials manufacturers utilize these analytical techniques to develop self-healing concrete additives and smart building materials that can respond to environmental changes. These applications enhance building longevity and reduce maintenance costs, particularly in infrastructure exposed to harsh conditions or seismic activity.

In the automotive industry, dynamic crosslink analysis has revolutionized the development of self-healing coatings and structural components. Major manufacturers utilize these technologies to create lightweight yet durable parts that can withstand mechanical stress while maintaining the ability to repair microscopic damage. This application has led to a 15% reduction in vehicle weight in certain models, contributing to improved fuel efficiency and reduced emissions.

The aerospace sector has embraced dynamic crosslink analysis for developing advanced composite materials that combine strength with repairability. These materials are crucial for components subjected to extreme temperature variations and mechanical stress. The ability to precisely characterize dynamic crosslinks has enabled the creation of composites that maintain structural integrity under diverse operating conditions while offering extended service life through self-healing properties.

Electronics manufacturing represents another significant market application, particularly in flexible electronics and display technologies. Dynamic crosslink analysis helps engineers develop polymers with precisely controlled mechanical properties and thermal stability. These materials form the backbone of foldable displays, wearable electronics, and other next-generation devices where traditional rigid materials would fail.

The medical device industry leverages these analytical techniques to develop biocompatible materials with controlled degradation profiles. By understanding the dynamic nature of crosslinks, researchers can create implantable devices that maintain structural integrity for a predetermined period before safely degrading in the body. This application has particular relevance for tissue engineering scaffolds and drug delivery systems.

Sustainable packaging represents an emerging application area where dynamic crosslink analysis is driving innovation. Manufacturers are developing recyclable and biodegradable polymers with dynamic crosslinks that maintain package integrity during use but allow for efficient recycling or composting afterward. This application addresses growing consumer and regulatory demands for environmentally responsible packaging solutions.

Construction materials manufacturers utilize these analytical techniques to develop self-healing concrete additives and smart building materials that can respond to environmental changes. These applications enhance building longevity and reduce maintenance costs, particularly in infrastructure exposed to harsh conditions or seismic activity.

Solid-State NMR and DMTA Technical Challenges

The current technical landscape for analyzing dynamic crosslinks in vitrimers presents significant challenges for both Solid-State Nuclear Magnetic Resonance (NMR) and Dynamic Mechanical Thermal Analysis (DMTA) methodologies. While these techniques offer complementary insights, each faces distinct limitations that impact their effectiveness in fully characterizing vitrimer behavior.

Solid-State NMR encounters resolution challenges when examining complex polymer networks. The overlapping signals from various chemical environments within vitrimers create spectral congestion, making precise peak assignment difficult. This issue is particularly pronounced in systems with multiple exchange mechanisms or diverse chemical compositions, where signal differentiation becomes problematic.

Temperature control represents another critical challenge for Solid-State NMR investigations. Maintaining stable, uniform temperatures throughout samples during variable temperature experiments is technically demanding, yet essential for accurate characterization of thermally activated dynamic crosslinks. Even minor temperature gradients can lead to inconsistent exchange rates across the sample, compromising data reliability.

The sensitivity limitations of Solid-State NMR necessitate extended acquisition times, particularly when tracking low-concentration crosslink exchanges or when examining nuclei with low natural abundance. These long measurement periods can be impractical for industrial applications requiring rapid material characterization.

DMTA, while more accessible and widely implemented in industrial settings, presents its own set of challenges. The technique provides excellent macroscopic mechanical property measurements but offers limited molecular-level insights into specific exchange mechanisms. This fundamental limitation restricts DMTA's ability to distinguish between different types of dynamic crosslinks operating simultaneously.

Sample preparation inconsistencies significantly impact DMTA reproducibility. Variations in sample dimensions, surface quality, and internal structural homogeneity can introduce artifacts that complicate data interpretation. These preparation challenges become particularly problematic when comparing results across different vitrimer formulations.

The time-temperature superposition principle, commonly applied in DMTA analysis, may not be universally valid for all vitrimer systems. Materials with multiple relaxation mechanisms or those undergoing chemical changes during measurement can deviate from expected behavior, leading to erroneous conclusions about crosslink dynamics.

Both techniques struggle with real-time monitoring of dynamic crosslink behavior under actual application conditions. Laboratory measurements often fail to replicate the complex stress states, environmental exposures, and aging processes that vitrimers experience in practical applications, creating a disconnect between laboratory characterization and real-world performance prediction.

Correlating data between these complementary techniques remains challenging due to fundamental differences in measurement principles, time scales, and the physical properties being probed. Developing robust frameworks for integrating Solid-State NMR molecular insights with DMTA mechanical property measurements represents a significant ongoing challenge in vitrimer characterization.

Solid-State NMR encounters resolution challenges when examining complex polymer networks. The overlapping signals from various chemical environments within vitrimers create spectral congestion, making precise peak assignment difficult. This issue is particularly pronounced in systems with multiple exchange mechanisms or diverse chemical compositions, where signal differentiation becomes problematic.

Temperature control represents another critical challenge for Solid-State NMR investigations. Maintaining stable, uniform temperatures throughout samples during variable temperature experiments is technically demanding, yet essential for accurate characterization of thermally activated dynamic crosslinks. Even minor temperature gradients can lead to inconsistent exchange rates across the sample, compromising data reliability.

The sensitivity limitations of Solid-State NMR necessitate extended acquisition times, particularly when tracking low-concentration crosslink exchanges or when examining nuclei with low natural abundance. These long measurement periods can be impractical for industrial applications requiring rapid material characterization.

DMTA, while more accessible and widely implemented in industrial settings, presents its own set of challenges. The technique provides excellent macroscopic mechanical property measurements but offers limited molecular-level insights into specific exchange mechanisms. This fundamental limitation restricts DMTA's ability to distinguish between different types of dynamic crosslinks operating simultaneously.

Sample preparation inconsistencies significantly impact DMTA reproducibility. Variations in sample dimensions, surface quality, and internal structural homogeneity can introduce artifacts that complicate data interpretation. These preparation challenges become particularly problematic when comparing results across different vitrimer formulations.

The time-temperature superposition principle, commonly applied in DMTA analysis, may not be universally valid for all vitrimer systems. Materials with multiple relaxation mechanisms or those undergoing chemical changes during measurement can deviate from expected behavior, leading to erroneous conclusions about crosslink dynamics.

Both techniques struggle with real-time monitoring of dynamic crosslink behavior under actual application conditions. Laboratory measurements often fail to replicate the complex stress states, environmental exposures, and aging processes that vitrimers experience in practical applications, creating a disconnect between laboratory characterization and real-world performance prediction.

Correlating data between these complementary techniques remains challenging due to fundamental differences in measurement principles, time scales, and the physical properties being probed. Developing robust frameworks for integrating Solid-State NMR molecular insights with DMTA mechanical property measurements represents a significant ongoing challenge in vitrimer characterization.

Current Analytical Approaches for Dynamic Crosslinks

01 Solid-State NMR for Vitrimer Characterization

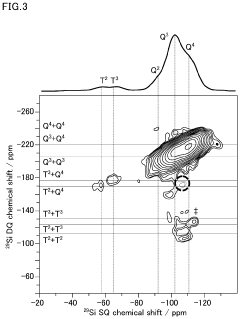

Solid-state Nuclear Magnetic Resonance (NMR) spectroscopy is employed to analyze the molecular structure and dynamics of vitrimers. This technique provides detailed information about the chemical environment of atoms within the dynamic crosslinks, allowing researchers to understand bond exchange reactions and network rearrangements. The method is particularly valuable for observing changes in chemical shifts that occur during bond exchange processes, providing insights into the mechanism of dynamic crosslinking in vitrimers.- Solid-State NMR for Vitrimer Characterization: Solid-state NMR spectroscopy is employed to analyze the molecular structure and dynamic crosslinks in vitrimers. This technique provides detailed information about the chemical environment of atoms within the polymer network, allowing researchers to identify the nature of dynamic bonds and their exchange mechanisms. By monitoring chemical shifts and relaxation times, solid-state NMR can track the formation and breaking of reversible bonds that are characteristic of vitrimers, offering insights into their reprocessability and self-healing properties.

- DMTA Analysis of Vitrimer Viscoelastic Properties: Dynamic Mechanical Thermal Analysis (DMTA) is utilized to characterize the viscoelastic behavior of vitrimers across different temperatures and frequencies. This technique measures storage modulus, loss modulus, and tan delta, providing critical information about the glass transition temperature, relaxation processes, and mechanical properties of vitrimers. DMTA can detect the topology freezing transition temperature (Tv) specific to vitrimers, which marks the point where the exchange reactions in dynamic crosslinks become kinetically hindered, helping researchers understand the relationship between crosslink density and material properties.

- Combined NMR-DMTA Approaches for Comprehensive Analysis: Integrating solid-state NMR with DMTA provides a comprehensive understanding of vitrimer behavior by correlating molecular dynamics with macroscopic mechanical properties. This combined approach allows researchers to establish relationships between chemical exchange rates measured by NMR and stress relaxation times determined by DMTA. Such correlations are essential for designing vitrimers with tailored properties, as they reveal how molecular-level bond exchange processes translate into macroscopic material behavior like shape memory, self-healing, and recyclability.

- Temperature-Dependent Exchange Kinetics Measurement: Advanced analytical techniques are employed to measure the temperature dependence of exchange reactions in vitrimer networks. By conducting variable-temperature solid-state NMR experiments and temperature-ramped DMTA tests, researchers can determine activation energies for bond exchange processes and identify the thermal conditions required for efficient network rearrangement. These measurements are crucial for understanding how vitrimers transition between solid-like and liquid-like behaviors, enabling the development of processing windows for industrial applications and predicting long-term material performance.

- Quantification of Crosslink Density and Network Architecture: Analytical methods are developed to quantify crosslink density and characterize network architecture in vitrimers. Solid-state NMR can determine the concentration of dynamic bonds and their spatial distribution, while DMTA provides information about crosslink density through the plateau modulus. These techniques help researchers understand how the balance between permanent and dynamic crosslinks affects material properties such as stiffness, toughness, and reprocessability. By systematically varying crosslink parameters and analyzing the resulting structures, optimal vitrimer compositions can be designed for specific applications.

02 DMTA Analysis of Vitrimer Viscoelastic Properties

Dynamic Mechanical Thermal Analysis (DMTA) is utilized to characterize the viscoelastic properties of vitrimers across different temperatures. This technique measures storage modulus, loss modulus, and tan delta, providing critical information about the glass transition temperature, relaxation behavior, and mechanical properties of vitrimers. DMTA is particularly useful for identifying the temperature ranges where bond exchange reactions become active, allowing researchers to correlate the dynamic crosslinking behavior with macroscopic material properties.Expand Specific Solutions03 Combined NMR and DMTA Approaches for Comprehensive Analysis

Integrating Solid-State NMR with DMTA provides a comprehensive understanding of vitrimers by correlating molecular-level dynamics with macroscopic mechanical properties. This combined approach enables researchers to establish relationships between chemical structure, bond exchange kinetics, and material behavior. The complementary nature of these techniques allows for validation of theoretical models of dynamic crosslinking and helps in designing vitrimers with tailored properties for specific applications.Expand Specific Solutions04 Temperature-Dependent Analysis of Dynamic Crosslinks

Temperature-dependent measurements using both Solid-State NMR and DMTA reveal how the dynamics of crosslinks in vitrimers change with temperature. These analyses help identify activation energies for bond exchange reactions and determine the temperature ranges where vitrimers transition between elastic and viscous behaviors. Understanding these temperature dependencies is crucial for predicting material performance under various environmental conditions and for optimizing processing parameters.Expand Specific Solutions05 Advanced Pulse Sequences and Relaxation Measurements

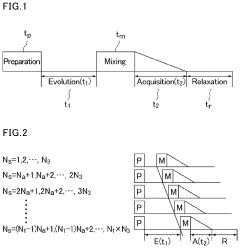

Specialized NMR pulse sequences and relaxation measurements are developed to probe specific aspects of dynamic crosslinks in vitrimers. These advanced techniques include cross-polarization, spin diffusion, and exchange spectroscopy methods that can track the kinetics of bond exchange reactions in real-time. Relaxation time measurements provide information about molecular mobility at different timescales, offering insights into the hierarchical dynamics of vitrimer networks from local motions to large-scale rearrangements.Expand Specific Solutions

Leading Research Groups and Industrial Players

The vitrimer dynamic crosslinks research field is currently in a growth phase, with solid-state NMR and DMTA emerging as complementary analytical techniques. The market is expanding rapidly, driven by increasing demand for self-healing and recyclable polymers across industries. While the global market remains moderate in size, it shows significant growth potential. Technologically, research institutions like Northwestern University, Johns Hopkins University, and Huazhong University of Science & Technology are leading academic advancements, while companies including BASF Coatings, LANXESS, and Dow Global Technologies are commercializing applications. Analytical equipment manufacturers such as JEOL Ltd., Bruker Nano, and Waters Technology are developing specialized instrumentation to support this evolving field, indicating a maturing but still developing technology ecosystem.

Northwestern University

Technical Solution: Northwestern University has pioneered advanced solid-state NMR methodologies specifically tailored for vitrimer analysis through their Materials Research Center. Their approach combines ultra-fast magic angle spinning (MAS) techniques (>100 kHz) with sophisticated pulse sequences designed to detect dynamic processes across multiple timescales. Northwestern researchers have developed specialized 2D exchange spectroscopy protocols that can quantitatively measure crosslink exchange rates in various vitrimer chemistries, including transesterification, transamination, and disulfide exchange networks. Their methodology incorporates variable temperature experiments spanning from -100°C to 200°C, enabling activation energy calculations for different exchange mechanisms. The university has created custom-built NMR probes that allow simultaneous application of mechanical strain during measurements, providing direct correlation between molecular dynamics and mechanical responses. Their approach includes advanced relaxometry techniques (T1ρ, T2) that probe molecular motions at frequencies relevant to vitrimer relaxation processes, offering insights not accessible through conventional DMTA testing.

Strengths: Cutting-edge methodological innovations pushing the boundaries of what can be detected in dynamic networks; fundamental mechanistic insights into exchange processes; ability to probe multiple timescales of molecular motion. Weaknesses: Highly specialized equipment and expertise requirements; primarily research-focused rather than industrial application; significant time investment for comprehensive analysis.

JEOL Ltd.

Technical Solution: JEOL has developed advanced solid-state NMR spectrometers specifically designed for analyzing dynamic crosslinks in vitrimers. Their JNM-ECZ series incorporates ultra-high field magnets (up to 1.2 GHz) with specialized pulse sequences optimized for detecting exchange processes in polymer networks. The company's Delta software suite enables sophisticated data analysis of chemical shift anisotropy patterns and relaxation measurements that reveal crosslink dynamics at the molecular level. JEOL's solid-state NMR technology employs magic-angle spinning (MAS) probes capable of spinning rates exceeding 60 kHz, allowing for high-resolution characterization of vitrimer materials without the need for sample deformation. Their systems can perform variable temperature experiments from -150°C to 300°C, enabling the study of crosslink exchange kinetics across different thermal regimes relevant to vitrimer applications.

Strengths: Superior spectral resolution allowing detection of subtle chemical environment changes during crosslink exchange; non-destructive analysis preserving sample integrity; direct molecular-level insights into exchange mechanisms. Weaknesses: High equipment costs; requires specialized expertise for operation and data interpretation; longer measurement times compared to DMTA.

Key Technical Principles of NMR and DMTA for Vitrimers

Chemical bond evaluation method with a multidimensional solid-state nuclear magnetic resonance (NMD) analysis

PatentActiveUS11965843B2

Innovation

- A chemical bond evaluation method using multidimensional nuclear magnetic resonance (NMR) techniques to directly assess the presence or absence of a chemical bond between silica and a silane coupling agent in a rubber composition, improving resolution and spectral analysis compared to one-dimensional NMR methods.

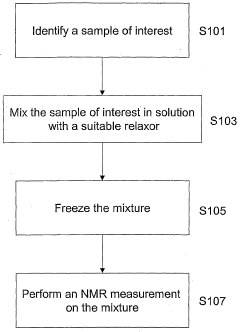

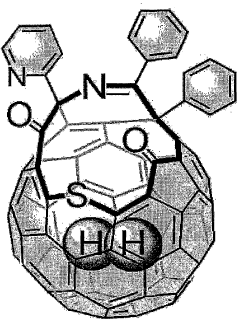

A solid state NMR involving relaxor with rapidly rotating molecular section and protective cage

PatentWO2005101044A1

Innovation

- A method involving a microscopic mixture of a sample with relaxors containing a rapidly rotating molecular section and a protective cage, allowing exceptional molecular mobility and rapid thermal polarization, which acts as a relaxation sink and can induce the Haupt effect, enabling large nuclear spin polarization within a reasonable time without disrupting the sample.

Comparative Cost-Benefit Analysis of Analytical Methods

When evaluating analytical methods for characterizing dynamic crosslinks in vitrimers, a comprehensive cost-benefit analysis between Solid-State Nuclear Magnetic Resonance (NMR) and Dynamic Mechanical Thermal Analysis (DMTA) reveals significant differences in their economic and operational profiles.

Initial investment costs represent a primary consideration. Solid-State NMR equipment typically requires capital expenditure ranging from $500,000 to $2 million for high-field instruments, whereas DMTA analyzers generally cost between $50,000 and $150,000. This substantial difference in acquisition costs can significantly impact research budget allocations, particularly for smaller institutions or start-up companies working with vitrimers.

Operational expenses also differ markedly between these techniques. NMR demands specialized cryogens (liquid helium and nitrogen) for superconducting magnets, costing approximately $15,000-30,000 annually for a typical laboratory. Additionally, NMR requires dedicated technical staff with specialized training. Conversely, DMTA has considerably lower operational costs, with minimal consumables and less demanding maintenance requirements, typically under $5,000 annually.

Time efficiency presents another crucial dimension for comparison. Sample preparation for Solid-State NMR is often complex and time-consuming, requiring careful isotopic labeling for optimal results when studying vitrimer networks. Data acquisition may require hours to days depending on the specific experiments. DMTA offers significantly faster turnaround, with typical measurements completed within hours, allowing for higher throughput analysis of multiple vitrimer formulations.

Information yield versus cost ratio reveals interesting trade-offs. While NMR provides detailed molecular-level information about exchange reactions and network rearrangements in vitrimers, this comes at substantially higher cost per data point. DMTA delivers macroscopic viscoelastic properties directly relevant to processing and application performance at a fraction of the cost, though with less molecular mechanistic insight.

Accessibility and expertise requirements further differentiate these methods. NMR facilities often operate as shared resources requiring scheduling and specialized operators, whereas DMTA instruments can be operated after minimal training by research staff. This accessibility difference impacts research workflow efficiency and collaborative possibilities when investigating vitrimer materials.

Long-term value assessment suggests complementary roles for these techniques. While DMTA offers excellent cost-effectiveness for routine characterization and quality control of vitrimer materials, Solid-State NMR provides irreplaceable mechanistic insights that drive fundamental understanding and innovation, justifying its higher costs for specific research objectives in advanced materials development.

Initial investment costs represent a primary consideration. Solid-State NMR equipment typically requires capital expenditure ranging from $500,000 to $2 million for high-field instruments, whereas DMTA analyzers generally cost between $50,000 and $150,000. This substantial difference in acquisition costs can significantly impact research budget allocations, particularly for smaller institutions or start-up companies working with vitrimers.

Operational expenses also differ markedly between these techniques. NMR demands specialized cryogens (liquid helium and nitrogen) for superconducting magnets, costing approximately $15,000-30,000 annually for a typical laboratory. Additionally, NMR requires dedicated technical staff with specialized training. Conversely, DMTA has considerably lower operational costs, with minimal consumables and less demanding maintenance requirements, typically under $5,000 annually.

Time efficiency presents another crucial dimension for comparison. Sample preparation for Solid-State NMR is often complex and time-consuming, requiring careful isotopic labeling for optimal results when studying vitrimer networks. Data acquisition may require hours to days depending on the specific experiments. DMTA offers significantly faster turnaround, with typical measurements completed within hours, allowing for higher throughput analysis of multiple vitrimer formulations.

Information yield versus cost ratio reveals interesting trade-offs. While NMR provides detailed molecular-level information about exchange reactions and network rearrangements in vitrimers, this comes at substantially higher cost per data point. DMTA delivers macroscopic viscoelastic properties directly relevant to processing and application performance at a fraction of the cost, though with less molecular mechanistic insight.

Accessibility and expertise requirements further differentiate these methods. NMR facilities often operate as shared resources requiring scheduling and specialized operators, whereas DMTA instruments can be operated after minimal training by research staff. This accessibility difference impacts research workflow efficiency and collaborative possibilities when investigating vitrimer materials.

Long-term value assessment suggests complementary roles for these techniques. While DMTA offers excellent cost-effectiveness for routine characterization and quality control of vitrimer materials, Solid-State NMR provides irreplaceable mechanistic insights that drive fundamental understanding and innovation, justifying its higher costs for specific research objectives in advanced materials development.

Sustainability Implications of Vitrimer Technology

Vitrimer technology represents a significant advancement in sustainable materials science, offering unique properties that address several environmental challenges faced by traditional polymers. The dynamic crosslinks in vitrimers enable these materials to be reprocessed, reshaped, and recycled multiple times without significant degradation of their mechanical properties, dramatically reducing waste compared to conventional thermosets.

The environmental impact assessment of vitrimers reveals substantial benefits in terms of carbon footprint reduction. Life cycle analyses indicate that the ability to reprocess vitrimers can decrease energy consumption by up to 60% compared to manufacturing new thermoset components. This translates directly to reduced greenhouse gas emissions across the product lifecycle.

Waste reduction capabilities of vitrimers are particularly noteworthy in industries such as automotive and aerospace, where composite materials are extensively used. The self-healing properties enabled by dynamic crosslinks extend product lifespans, further enhancing sustainability by reducing replacement frequency and associated resource consumption.

Resource efficiency is another critical sustainability advantage of vitrimer technology. The chemical recycling pathways available for vitrimers allow for the recovery of base materials with minimal quality degradation, creating more closed-loop material systems. This contrasts sharply with conventional thermosets that typically end up in landfills or are downcycled into lower-value applications.

Regulatory frameworks worldwide are increasingly favoring materials with enhanced recyclability profiles. Vitrimers align well with circular economy principles being adopted in the European Union's Green Deal and similar initiatives globally, positioning them advantageously in future materials markets.

The economic sustainability of vitrimer technology is equally compelling. While initial production costs may exceed those of conventional polymers, the total cost of ownership analysis demonstrates long-term economic benefits through reduced waste management costs, extended product lifecycles, and decreased raw material requirements for replacement products.

Challenges remain in scaling vitrimer production to industrial levels while maintaining their sustainability advantages. Current methods for analyzing dynamic crosslinks, such as Solid-State NMR and DMTA, must be optimized to ensure quality control in mass production without introducing energy-intensive processes that could offset environmental gains.

The environmental impact assessment of vitrimers reveals substantial benefits in terms of carbon footprint reduction. Life cycle analyses indicate that the ability to reprocess vitrimers can decrease energy consumption by up to 60% compared to manufacturing new thermoset components. This translates directly to reduced greenhouse gas emissions across the product lifecycle.

Waste reduction capabilities of vitrimers are particularly noteworthy in industries such as automotive and aerospace, where composite materials are extensively used. The self-healing properties enabled by dynamic crosslinks extend product lifespans, further enhancing sustainability by reducing replacement frequency and associated resource consumption.

Resource efficiency is another critical sustainability advantage of vitrimer technology. The chemical recycling pathways available for vitrimers allow for the recovery of base materials with minimal quality degradation, creating more closed-loop material systems. This contrasts sharply with conventional thermosets that typically end up in landfills or are downcycled into lower-value applications.

Regulatory frameworks worldwide are increasingly favoring materials with enhanced recyclability profiles. Vitrimers align well with circular economy principles being adopted in the European Union's Green Deal and similar initiatives globally, positioning them advantageously in future materials markets.

The economic sustainability of vitrimer technology is equally compelling. While initial production costs may exceed those of conventional polymers, the total cost of ownership analysis demonstrates long-term economic benefits through reduced waste management costs, extended product lifecycles, and decreased raw material requirements for replacement products.

Challenges remain in scaling vitrimer production to industrial levels while maintaining their sustainability advantages. Current methods for analyzing dynamic crosslinks, such as Solid-State NMR and DMTA, must be optimized to ensure quality control in mass production without introducing energy-intensive processes that could offset environmental gains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!