Thermal Analysis Protocols (DSC/TGA) For Tracking Network Evolution During Rework

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Analysis Background and Objectives

Thermal analysis techniques, particularly Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), have evolved significantly over the past several decades as essential tools for materials characterization. These analytical methods provide critical insights into the thermal behavior, stability, and composition of materials by measuring heat flow and mass changes as a function of temperature. In the context of electronic manufacturing and assembly processes, these techniques have become increasingly important for understanding the complex network evolution that occurs during rework procedures.

The historical development of thermal analysis began in the early 20th century, with significant advancements occurring in the 1960s when commercial DSC and TGA instruments became widely available. Since then, these technologies have undergone continuous refinement, with improvements in sensitivity, resolution, and automation. Modern thermal analysis systems now offer unprecedented precision, with temperature control accurate to fractions of a degree and the ability to detect heat flow changes in the microwatt range.

The evolution of polymeric materials in electronic assemblies has created a parallel need for advanced thermal characterization methods. As electronic components become more complex and miniaturized, the thermal properties of the materials used in their construction become increasingly critical to performance and reliability. Particularly in rework scenarios, where components are subjected to multiple heating cycles, understanding the network evolution of polymeric materials is essential for ensuring product integrity.

The primary objective of developing thermal analysis protocols for tracking network evolution during rework is to establish standardized, reproducible methodologies that can accurately characterize the changes occurring in material structures. These protocols aim to provide quantitative metrics for assessing the degree of cure, crosslinking density, thermal stability, and degradation behavior of polymeric networks subjected to rework conditions.

Furthermore, these protocols seek to correlate thermal analysis data with mechanical and electrical performance parameters, enabling predictive modeling of material behavior during and after rework processes. By understanding the relationship between thermal history and network structure, manufacturers can optimize rework parameters to minimize material degradation while ensuring proper component functionality.

Another critical goal is to develop in-situ monitoring capabilities that allow real-time tracking of network evolution during actual rework operations. This would represent a significant advancement over current methodologies, which typically rely on post-process analysis of samples that may not fully represent the conditions experienced during actual manufacturing.

The technological trajectory in this field points toward integration with other analytical techniques, such as spectroscopic methods and mechanical testing, to provide comprehensive characterization of material properties and behavior during thermal cycling. This multi-modal approach promises to deliver more robust and informative data for process optimization and quality control in electronic manufacturing.

The historical development of thermal analysis began in the early 20th century, with significant advancements occurring in the 1960s when commercial DSC and TGA instruments became widely available. Since then, these technologies have undergone continuous refinement, with improvements in sensitivity, resolution, and automation. Modern thermal analysis systems now offer unprecedented precision, with temperature control accurate to fractions of a degree and the ability to detect heat flow changes in the microwatt range.

The evolution of polymeric materials in electronic assemblies has created a parallel need for advanced thermal characterization methods. As electronic components become more complex and miniaturized, the thermal properties of the materials used in their construction become increasingly critical to performance and reliability. Particularly in rework scenarios, where components are subjected to multiple heating cycles, understanding the network evolution of polymeric materials is essential for ensuring product integrity.

The primary objective of developing thermal analysis protocols for tracking network evolution during rework is to establish standardized, reproducible methodologies that can accurately characterize the changes occurring in material structures. These protocols aim to provide quantitative metrics for assessing the degree of cure, crosslinking density, thermal stability, and degradation behavior of polymeric networks subjected to rework conditions.

Furthermore, these protocols seek to correlate thermal analysis data with mechanical and electrical performance parameters, enabling predictive modeling of material behavior during and after rework processes. By understanding the relationship between thermal history and network structure, manufacturers can optimize rework parameters to minimize material degradation while ensuring proper component functionality.

Another critical goal is to develop in-situ monitoring capabilities that allow real-time tracking of network evolution during actual rework operations. This would represent a significant advancement over current methodologies, which typically rely on post-process analysis of samples that may not fully represent the conditions experienced during actual manufacturing.

The technological trajectory in this field points toward integration with other analytical techniques, such as spectroscopic methods and mechanical testing, to provide comprehensive characterization of material properties and behavior during thermal cycling. This multi-modal approach promises to deliver more robust and informative data for process optimization and quality control in electronic manufacturing.

Industry Applications and Demand Analysis

Thermal analysis protocols utilizing Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) for tracking network evolution during rework processes have gained significant traction across multiple industries. The demand for these analytical methods stems primarily from sectors where material integrity and performance under thermal stress are critical quality parameters.

The electronics manufacturing industry represents the largest market segment utilizing these thermal analysis techniques. With the increasing complexity of electronic components and the miniaturization trend, manufacturers require precise methods to evaluate how multiple rework cycles affect the polymer networks in printed circuit boards (PCBs) and electronic packaging materials. The global electronics manufacturing services market, particularly in Asia-Pacific regions, drives substantial demand for advanced thermal analysis protocols.

Aerospace and automotive industries constitute another major application area, where safety-critical components must maintain structural integrity under extreme conditions. These sectors demand thermal analysis protocols that can accurately predict material behavior after repair or rework processes, especially for composite materials and high-performance polymers used in structural applications.

Medical device manufacturing has emerged as a rapidly growing application field, particularly for implantable devices and surgical instruments that undergo multiple sterilization cycles. Regulatory requirements in this sector necessitate comprehensive material characterization methods that can track subtle changes in polymer networks resulting from repeated thermal exposures.

The semiconductor industry represents a specialized but high-value market segment for these analytical techniques. As chip manufacturing processes become more sophisticated, the need for precise thermal characterization of packaging materials and substrates during rework operations has intensified, especially for advanced packaging technologies like 3D integration.

Research institutions and material science laboratories constitute a consistent demand source, focusing on fundamental understanding of network evolution mechanisms and developing improved materials with enhanced rework capabilities. This segment drives innovation in protocol development and analytical methodologies.

The demand for standardized thermal analysis protocols has increased significantly with the global emphasis on sustainability and circular economy principles. Industries are seeking methods to determine how many rework cycles materials can withstand before their properties degrade beyond acceptable limits, supporting extended product lifecycles and reduced waste generation.

Regional market analysis indicates that North America and Europe lead in protocol development and implementation, while Asia-Pacific regions show the fastest growth rate in adoption, corresponding to their expanding manufacturing base in electronics and automotive sectors.

The electronics manufacturing industry represents the largest market segment utilizing these thermal analysis techniques. With the increasing complexity of electronic components and the miniaturization trend, manufacturers require precise methods to evaluate how multiple rework cycles affect the polymer networks in printed circuit boards (PCBs) and electronic packaging materials. The global electronics manufacturing services market, particularly in Asia-Pacific regions, drives substantial demand for advanced thermal analysis protocols.

Aerospace and automotive industries constitute another major application area, where safety-critical components must maintain structural integrity under extreme conditions. These sectors demand thermal analysis protocols that can accurately predict material behavior after repair or rework processes, especially for composite materials and high-performance polymers used in structural applications.

Medical device manufacturing has emerged as a rapidly growing application field, particularly for implantable devices and surgical instruments that undergo multiple sterilization cycles. Regulatory requirements in this sector necessitate comprehensive material characterization methods that can track subtle changes in polymer networks resulting from repeated thermal exposures.

The semiconductor industry represents a specialized but high-value market segment for these analytical techniques. As chip manufacturing processes become more sophisticated, the need for precise thermal characterization of packaging materials and substrates during rework operations has intensified, especially for advanced packaging technologies like 3D integration.

Research institutions and material science laboratories constitute a consistent demand source, focusing on fundamental understanding of network evolution mechanisms and developing improved materials with enhanced rework capabilities. This segment drives innovation in protocol development and analytical methodologies.

The demand for standardized thermal analysis protocols has increased significantly with the global emphasis on sustainability and circular economy principles. Industries are seeking methods to determine how many rework cycles materials can withstand before their properties degrade beyond acceptable limits, supporting extended product lifecycles and reduced waste generation.

Regional market analysis indicates that North America and Europe lead in protocol development and implementation, while Asia-Pacific regions show the fastest growth rate in adoption, corresponding to their expanding manufacturing base in electronics and automotive sectors.

Current Challenges in Rework Network Evolution Tracking

The current landscape of thermal analysis for tracking network evolution during rework processes faces several significant challenges that impede accurate characterization and reliable quality control. Traditional Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) protocols often struggle with the complex nature of reworked materials, particularly in advanced electronic assemblies and composite structures.

Sample preparation inconsistency represents a primary obstacle, as reworked materials frequently exhibit heterogeneous compositions and varying degrees of thermal history. This heterogeneity makes it difficult to obtain representative samples that accurately reflect the overall network structure, leading to significant data variability between analyses and compromising reproducibility.

Thermal lag effects during analysis pose another substantial challenge, especially when examining thick or thermally insulating materials common in modern electronic packaging. This thermal gradient across samples results in broadened transition peaks and shifted reaction temperatures, obscuring subtle network changes that occur during rework processes. Current instrumentation often lacks the sensitivity to detect these minor but critical structural modifications.

Signal interpretation complexity further complicates analysis, as overlapping thermal events frequently occur in multi-component systems. Distinguishing between cure advancement, degradation, and physical aging becomes particularly problematic in reworked materials where these phenomena may occur simultaneously. The absence of standardized deconvolution methods for these complex thermal signatures leads to subjective interpretations and inconsistent conclusions across different laboratories.

Reference material limitations also hinder progress, as suitable standards that accurately mimic the complex network structures of reworked materials remain scarce. Without proper calibration references, quantitative assessment of network evolution becomes challenging, forcing researchers to rely on relative comparisons that lack absolute benchmarks.

Environmental sensitivity during testing introduces additional variables, as moisture absorption and oxidation can significantly alter thermal behavior. These effects are particularly pronounced in reworked materials with potentially compromised barrier properties, yet current protocols rarely account for these environmental interactions adequately.

Finally, correlation challenges between thermal analysis data and actual mechanical or electrical performance persist. Establishing reliable relationships between thermal signatures and functional properties remains difficult, especially for reworked materials where the structure-property relationships may differ from virgin materials. This disconnect limits the predictive capability of thermal analysis for quality assurance in rework applications.

Sample preparation inconsistency represents a primary obstacle, as reworked materials frequently exhibit heterogeneous compositions and varying degrees of thermal history. This heterogeneity makes it difficult to obtain representative samples that accurately reflect the overall network structure, leading to significant data variability between analyses and compromising reproducibility.

Thermal lag effects during analysis pose another substantial challenge, especially when examining thick or thermally insulating materials common in modern electronic packaging. This thermal gradient across samples results in broadened transition peaks and shifted reaction temperatures, obscuring subtle network changes that occur during rework processes. Current instrumentation often lacks the sensitivity to detect these minor but critical structural modifications.

Signal interpretation complexity further complicates analysis, as overlapping thermal events frequently occur in multi-component systems. Distinguishing between cure advancement, degradation, and physical aging becomes particularly problematic in reworked materials where these phenomena may occur simultaneously. The absence of standardized deconvolution methods for these complex thermal signatures leads to subjective interpretations and inconsistent conclusions across different laboratories.

Reference material limitations also hinder progress, as suitable standards that accurately mimic the complex network structures of reworked materials remain scarce. Without proper calibration references, quantitative assessment of network evolution becomes challenging, forcing researchers to rely on relative comparisons that lack absolute benchmarks.

Environmental sensitivity during testing introduces additional variables, as moisture absorption and oxidation can significantly alter thermal behavior. These effects are particularly pronounced in reworked materials with potentially compromised barrier properties, yet current protocols rarely account for these environmental interactions adequately.

Finally, correlation challenges between thermal analysis data and actual mechanical or electrical performance persist. Establishing reliable relationships between thermal signatures and functional properties remains difficult, especially for reworked materials where the structure-property relationships may differ from virgin materials. This disconnect limits the predictive capability of thermal analysis for quality assurance in rework applications.

Established DSC/TGA Methodologies for Network Monitoring

01 DSC/TGA thermal analysis systems for network monitoring

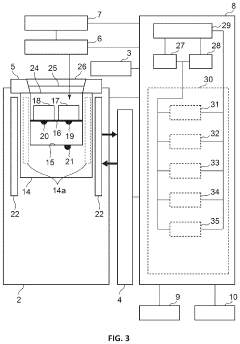

Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) systems have been integrated with network capabilities to enable remote monitoring and control. These networked thermal analysis systems allow researchers to monitor experiments in real-time, collect data from multiple instruments simultaneously, and analyze results from different locations. The evolution of these systems includes improved data transmission protocols and security features to ensure reliable operation across laboratory networks.- Thermal analysis network systems for material characterization: Advanced network systems have been developed to integrate thermal analysis instruments like DSC (Differential Scanning Calorimetry) and TGA (Thermogravimetric Analysis) for comprehensive material characterization. These systems enable real-time data collection, analysis, and sharing across connected devices, allowing researchers to monitor thermal properties and structural changes in materials remotely. The networked approach facilitates collaborative research and improves efficiency in materials science laboratories.

- Evolution of DSC/TGA protocols for polymer network analysis: Specialized thermal analysis protocols have evolved for studying polymer network formation and degradation. These protocols utilize precise temperature control and heating rates in DSC and TGA instruments to analyze crosslinking density, thermal stability, and network evolution in polymeric materials. Modern approaches incorporate multi-step heating programs and modulated temperature techniques to separate overlapping thermal events, providing deeper insights into network structure development during polymerization and curing processes.

- Cloud-based thermal analysis data management systems: Cloud-based platforms have transformed how thermal analysis data from DSC/TGA instruments is stored, processed, and shared. These systems enable secure storage of large datasets, automated analysis using advanced algorithms, and remote access to results. The evolution of these networks has facilitated integration with laboratory information management systems (LIMS), enabling seamless workflow from sample preparation to final reporting, while maintaining data integrity and providing collaborative tools for research teams working across different locations.

- Real-time monitoring and control systems for thermal analysis: Advanced network architectures have been developed for real-time monitoring and control of thermal analysis experiments. These systems integrate sensors, controllers, and analytical software to provide immediate feedback during DSC/TGA measurements. The evolution of these networks has enabled adaptive experimental protocols that can automatically adjust parameters based on observed thermal events, improving the accuracy and efficiency of thermal analysis. These systems also incorporate fault detection mechanisms to prevent instrument damage and ensure data quality.

- Machine learning integration with thermal analysis networks: The integration of machine learning algorithms with networked thermal analysis instruments represents a significant evolution in DSC/TGA protocols. These systems can identify patterns in thermal data that might be missed by conventional analysis methods, predict material properties based on thermal signatures, and optimize experimental parameters automatically. The network architecture allows for continuous learning as new data is collected, improving the accuracy of predictions over time and enabling more efficient materials development processes through intelligent data analysis.

02 Network evolution for thermal analysis data management

Advanced network architectures have been developed specifically for thermal analysis data management, allowing for efficient storage, retrieval, and analysis of large datasets generated by DSC/TGA instruments. These systems incorporate distributed databases, cloud storage solutions, and specialized protocols for handling the unique characteristics of thermal analysis data. The network evolution in this area focuses on scalability, data integrity, and integration with laboratory information management systems (LIMS).Expand Specific Solutions03 Real-time collaborative thermal analysis through network protocols

Network protocols have evolved to support real-time collaboration in thermal analysis research. These protocols enable multiple researchers to simultaneously view, analyze, and discuss DSC/TGA data across different locations. The systems incorporate features such as shared workspaces, annotation tools, and version control mechanisms specifically designed for thermal analysis workflows. This collaborative approach accelerates research and development processes by facilitating immediate feedback and decision-making based on thermal analysis results.Expand Specific Solutions04 Security protocols for networked thermal analysis systems

As thermal analysis systems become increasingly connected to networks, specialized security protocols have been developed to protect sensitive research data and ensure system integrity. These protocols address authentication, encryption, access control, and audit trails specifically tailored to the requirements of DSC/TGA systems. The evolution of these security measures includes adaptive mechanisms that can respond to emerging threats while maintaining the performance and reliability needed for precise thermal analysis applications.Expand Specific Solutions05 Integration of AI and machine learning with networked thermal analysis

The latest evolution in networked thermal analysis involves the integration of artificial intelligence and machine learning algorithms to enhance data interpretation and experimental design. These advanced systems can automatically identify patterns in thermal data, predict material behaviors, and optimize experimental parameters. The network architecture has evolved to support the computational requirements of these AI applications, including distributed processing capabilities and specialized data exchange formats for thermal analysis results.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Thermal Analysis Protocols for tracking network evolution during rework is currently in an emerging growth phase, with increasing market adoption across pharmaceutical and materials science sectors. The global market size for thermal analysis technologies is expanding, driven by demand for quality control in manufacturing processes. Technologically, Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) methodologies are reaching maturity, with established players like TA Instruments-Waters, Mettler-Toledo, Rigaku, and Netzsch Gerätebau offering sophisticated solutions. Pharmaceutical companies including AstraZeneca, Sunshine Lake Pharma, and Intra-Cellular Therapies are increasingly implementing these protocols for formulation development and stability testing. Research institutions such as The Ohio State University and Chinese Academy of Sciences are advancing fundamental understanding, while instrument manufacturers continue refining automation and data analysis capabilities.

Rigaku Corp.

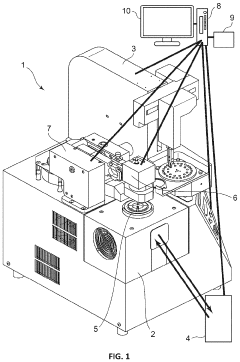

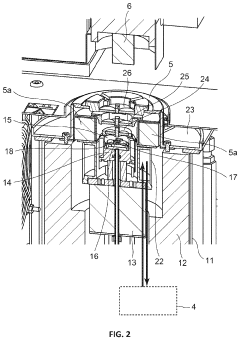

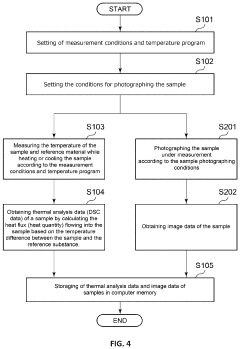

Technical Solution: Rigaku has developed the Thermo plus EVO series specifically designed for tracking network evolution during thermal processes including rework operations. Their systems feature high-sensitivity DSC sensors with temperature-modulated capabilities that can detect subtle changes in network structure even at low heating rates. For polymer network analysis, Rigaku has implemented specialized sample preparation protocols that maintain sample integrity while providing representative thermal data. Their TG-DTA systems incorporate simultaneous differential thermal analysis with thermogravimetry, allowing correlation between mass changes and thermal events during network evolution. Rigaku's proprietary software includes advanced kinetic analysis tools specifically optimized for tracking cross-linking reactions and network formation during multiple heating cycles. Their instruments feature automatic sample changers with controlled atmosphere capabilities that enable high-throughput analysis of network evolution under various environmental conditions simulating different rework scenarios. Rigaku has also developed specialized calibration methods for their thermal analyzers that ensure measurement accuracy across different temperature ranges relevant to polymer processing and rework operations. Their systems can be coupled with evolved gas analysis techniques to provide additional chemical information about volatile compounds released during network reorganization.

Strengths: Their instruments offer excellent stability for long-duration experiments needed to fully characterize network evolution during extended rework processes. Their software provides comprehensive kinetic analysis tools specifically designed for polymer network characterization. Weaknesses: Their systems sometimes require more complex calibration procedures compared to competitors, and their advanced analysis features may have steeper learning curves for new users.

Waters Technology Corp.

Technical Solution: Waters Technology has developed specialized thermal analysis protocols integrating their expertise in separation science with thermal analysis for tracking network evolution during rework processes. Their approach combines traditional DSC/TGA techniques with their proprietary chromatographic methods to provide comprehensive characterization of polymer networks. For rework analysis, Waters has implemented unique sample preparation techniques that preserve network structure while enabling high-resolution thermal analysis. Their thermal analysis systems feature advanced temperature control algorithms that ensure precise heating rates and isothermal holds critical for studying network reorganization kinetics. Waters' data analysis software incorporates chemometric approaches that can identify subtle pattern changes in thermal data associated with network evolution that might be missed by conventional analysis methods. Their systems can be integrated with their mass spectrometry platforms to provide detailed chemical information about degradation products or unreacted components during network formation or breakdown. Waters has also developed specialized reference materials for calibrating thermal analysis instruments specifically for polymer network characterization, ensuring measurement accuracy across different temperature ranges relevant to rework processes.

Strengths: Their integrated approach combining thermal analysis with separation science provides more comprehensive characterization of complex network structures than thermal analysis alone. Their chemometric data analysis tools can detect subtle pattern changes in thermal data that might indicate network reorganization. Weaknesses: Their integrated systems tend to be more complex to operate than standalone thermal analyzers, and their specialized protocols sometimes require more extensive method development time compared to conventional approaches.

Critical Patents and Literature in Thermal Analysis Protocols

Thermal analysis apparatus and control software for thermal analysis apparatus

PatentActiveUS20240068876A1

Innovation

- A thermal analysis apparatus and control software that display thermal analysis data and color information graphs side by side without superimposition, along with a marker system for synchronized data points, allowing for detailed analysis of sample state changes and color variations over time.

Direct thermal injection thermal analysis

PatentPendingEP3545288A1

Innovation

- Direct thermal injection using electromagnetic radiation, such as a laser, to rapidly and controllably heat samples in thermal analysis instruments, eliminating the need for large furnaces and reducing power consumption.

Data Interpretation and Analysis Standards

Standardized interpretation frameworks are essential for extracting meaningful insights from thermal analysis data in rework processes. The establishment of clear data interpretation protocols ensures consistency across different operators and laboratories, enabling reliable tracking of network evolution during rework operations.

The primary challenge in thermal analysis data interpretation lies in distinguishing between meaningful network changes and experimental artifacts. Baseline correction methodologies must be rigorously defined, with specific attention to the selection of appropriate temperature ranges that capture the complete thermal transition without introducing noise. For DSC data, the determination of glass transition temperature (Tg) should follow a standardized tangent method, with clear guidelines for identifying the onset, midpoint, and endpoint of transitions.

Peak integration protocols require particular attention in network evolution studies. The establishment of consistent integration boundaries is critical for quantifying cure progression, especially when overlapping peaks are present. Integration algorithms should be specified (e.g., linear, sigmoidal, or polynomial baseline), with validation procedures to ensure reproducibility across different thermal profiles.

Conversion calculation standards must address the normalization of exothermic heat flow against appropriate reference values. For partially cured systems undergoing rework, the reference heat of reaction should be clearly defined—whether based on the theoretical maximum for the chemistry or calibrated against fully uncured samples of identical composition.

Kinetic parameter extraction demands standardized mathematical models appropriate for the specific resin system. Activation energy calculations should follow consistent methodologies (e.g., Kissinger, Ozawa, or model-fitting approaches) with explicit handling of complex, multi-step reactions that are common in rework scenarios.

Correlation protocols between DSC and TGA data enhance the comprehensive understanding of network evolution. Weight loss events in TGA should be systematically mapped to thermal transitions in DSC, with standardized procedures for identifying degradation onset temperatures and their relationship to cure advancement.

Statistical analysis requirements must specify minimum sample sizes, confidence intervals, and acceptable variance thresholds. Outlier identification and handling procedures should be explicitly defined to maintain data integrity while preventing the inappropriate exclusion of anomalous but valid results that might indicate unexpected network behavior during rework.

The primary challenge in thermal analysis data interpretation lies in distinguishing between meaningful network changes and experimental artifacts. Baseline correction methodologies must be rigorously defined, with specific attention to the selection of appropriate temperature ranges that capture the complete thermal transition without introducing noise. For DSC data, the determination of glass transition temperature (Tg) should follow a standardized tangent method, with clear guidelines for identifying the onset, midpoint, and endpoint of transitions.

Peak integration protocols require particular attention in network evolution studies. The establishment of consistent integration boundaries is critical for quantifying cure progression, especially when overlapping peaks are present. Integration algorithms should be specified (e.g., linear, sigmoidal, or polynomial baseline), with validation procedures to ensure reproducibility across different thermal profiles.

Conversion calculation standards must address the normalization of exothermic heat flow against appropriate reference values. For partially cured systems undergoing rework, the reference heat of reaction should be clearly defined—whether based on the theoretical maximum for the chemistry or calibrated against fully uncured samples of identical composition.

Kinetic parameter extraction demands standardized mathematical models appropriate for the specific resin system. Activation energy calculations should follow consistent methodologies (e.g., Kissinger, Ozawa, or model-fitting approaches) with explicit handling of complex, multi-step reactions that are common in rework scenarios.

Correlation protocols between DSC and TGA data enhance the comprehensive understanding of network evolution. Weight loss events in TGA should be systematically mapped to thermal transitions in DSC, with standardized procedures for identifying degradation onset temperatures and their relationship to cure advancement.

Statistical analysis requirements must specify minimum sample sizes, confidence intervals, and acceptable variance thresholds. Outlier identification and handling procedures should be explicitly defined to maintain data integrity while preventing the inappropriate exclusion of anomalous but valid results that might indicate unexpected network behavior during rework.

Quality Control Implementation Strategies

Implementing effective quality control strategies for thermal analysis protocols requires a systematic approach that ensures consistent and reliable results. The integration of Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) into quality management systems demands standardized procedures, well-defined acceptance criteria, and regular validation protocols. Organizations should establish a multi-tiered quality control framework that encompasses instrument calibration, sample preparation standardization, and data interpretation guidelines.

Regular calibration of DSC and TGA instruments using certified reference materials is fundamental to maintaining measurement accuracy. This should follow a predetermined schedule based on usage frequency and manufacturer recommendations, with comprehensive documentation of all calibration activities. Temperature and enthalpy calibrations for DSC and mass calibrations for TGA should be performed at intervals that ensure data reliability throughout the analysis period.

Sample preparation protocols must be standardized to minimize variability in thermal analysis results. This includes specific guidelines for sample size, pan selection, atmosphere conditions, and heating rates appropriate for tracking network evolution during rework processes. Standard operating procedures should detail each step of the preparation process, including handling precautions to prevent contamination or premature reaction of sensitive materials.

Statistical process control techniques should be applied to thermal analysis data to identify trends and anomalies in network evolution patterns. Implementation of control charts for key parameters such as glass transition temperature, cure degree, and degradation onset can provide early warning of process deviations. These statistical tools enable quality engineers to distinguish between normal process variation and significant changes requiring intervention.

Automated data analysis systems can enhance consistency in interpretation of thermal analysis results. Software solutions that apply predefined algorithms for peak identification, baseline correction, and integration improve reproducibility across different operators and laboratories. These systems should include built-in quality checks that flag potentially problematic data patterns or results outside established specification limits.

Training programs for laboratory personnel constitute another critical component of quality control implementation. Technicians must receive comprehensive instruction on instrument operation, sample preparation techniques, data interpretation, and troubleshooting procedures. Periodic proficiency testing and certification ensure that all personnel maintain the necessary skills for accurate thermal analysis of network evolution during rework processes.

Documentation and traceability systems should be established to maintain records of all quality control activities. This includes instrument maintenance logs, calibration certificates, analyst qualifications, and complete test reports with raw data preservation. Electronic laboratory information management systems can facilitate this documentation process while enabling efficient retrieval of historical data for trend analysis and continuous improvement initiatives.

Regular calibration of DSC and TGA instruments using certified reference materials is fundamental to maintaining measurement accuracy. This should follow a predetermined schedule based on usage frequency and manufacturer recommendations, with comprehensive documentation of all calibration activities. Temperature and enthalpy calibrations for DSC and mass calibrations for TGA should be performed at intervals that ensure data reliability throughout the analysis period.

Sample preparation protocols must be standardized to minimize variability in thermal analysis results. This includes specific guidelines for sample size, pan selection, atmosphere conditions, and heating rates appropriate for tracking network evolution during rework processes. Standard operating procedures should detail each step of the preparation process, including handling precautions to prevent contamination or premature reaction of sensitive materials.

Statistical process control techniques should be applied to thermal analysis data to identify trends and anomalies in network evolution patterns. Implementation of control charts for key parameters such as glass transition temperature, cure degree, and degradation onset can provide early warning of process deviations. These statistical tools enable quality engineers to distinguish between normal process variation and significant changes requiring intervention.

Automated data analysis systems can enhance consistency in interpretation of thermal analysis results. Software solutions that apply predefined algorithms for peak identification, baseline correction, and integration improve reproducibility across different operators and laboratories. These systems should include built-in quality checks that flag potentially problematic data patterns or results outside established specification limits.

Training programs for laboratory personnel constitute another critical component of quality control implementation. Technicians must receive comprehensive instruction on instrument operation, sample preparation techniques, data interpretation, and troubleshooting procedures. Periodic proficiency testing and certification ensure that all personnel maintain the necessary skills for accurate thermal analysis of network evolution during rework processes.

Documentation and traceability systems should be established to maintain records of all quality control activities. This includes instrument maintenance logs, calibration certificates, analyst qualifications, and complete test reports with raw data preservation. Electronic laboratory information management systems can facilitate this documentation process while enabling efficient retrieval of historical data for trend analysis and continuous improvement initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!