Rheology Under Shear For Vitrimer Resins: Time–Temperature–Shear Superposition Methods

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vitrimer Rheology Background and Research Objectives

Vitrimer resins represent a revolutionary class of polymeric materials that combine the recyclability of thermoplastics with the mechanical robustness of thermosets. First introduced by Leibler and colleagues in 2011, vitrimers are characterized by their dynamic covalent bonds that allow for stress relaxation and network rearrangement while maintaining structural integrity. This unique property has positioned vitrimers as promising candidates for sustainable materials in various industries, including automotive, aerospace, and construction.

The rheological behavior of vitrimers under shear conditions remains a complex and evolving field of study. Traditional rheological models often fail to accurately predict the behavior of these materials due to their unique network dynamics. Unlike conventional polymers, vitrimers exhibit temperature-dependent exchange reactions that significantly influence their flow properties, making standard time-temperature superposition principles insufficient for comprehensive characterization.

Recent advances in rheological characterization techniques have enabled more sophisticated analysis of vitrimer behavior under various shear conditions. However, the development of a unified framework for understanding and predicting vitrimer rheology across different time scales, temperatures, and shear rates remains a significant challenge. The Time-Temperature-Shear Superposition (TTSS) method has emerged as a promising approach to address this gap, offering potential for more accurate modeling of vitrimer behavior across diverse processing conditions.

The global push toward sustainable materials has accelerated interest in vitrimer technology, with research publications in this field growing exponentially over the past decade. Major research institutions across North America, Europe, and Asia have established dedicated programs focusing on vitrimer rheology, with particular emphasis on developing predictive models for processing optimization.

This technical research report aims to comprehensively examine the current understanding of vitrimer rheology under shear conditions, with specific focus on Time-Temperature-Shear Superposition methodologies. Our objectives include: (1) establishing a fundamental understanding of the molecular mechanisms governing vitrimer flow behavior; (2) evaluating existing TTSS models and their applicability to different vitrimer chemistries; (3) identifying key parameters that influence rheological properties during processing; and (4) proposing refined methodologies for more accurate prediction of vitrimer behavior under industrial processing conditions.

By achieving these objectives, we anticipate contributing to the development of more efficient processing techniques for vitrimer-based materials, ultimately facilitating their broader adoption in commercial applications where recyclability and performance are equally valued.

The rheological behavior of vitrimers under shear conditions remains a complex and evolving field of study. Traditional rheological models often fail to accurately predict the behavior of these materials due to their unique network dynamics. Unlike conventional polymers, vitrimers exhibit temperature-dependent exchange reactions that significantly influence their flow properties, making standard time-temperature superposition principles insufficient for comprehensive characterization.

Recent advances in rheological characterization techniques have enabled more sophisticated analysis of vitrimer behavior under various shear conditions. However, the development of a unified framework for understanding and predicting vitrimer rheology across different time scales, temperatures, and shear rates remains a significant challenge. The Time-Temperature-Shear Superposition (TTSS) method has emerged as a promising approach to address this gap, offering potential for more accurate modeling of vitrimer behavior across diverse processing conditions.

The global push toward sustainable materials has accelerated interest in vitrimer technology, with research publications in this field growing exponentially over the past decade. Major research institutions across North America, Europe, and Asia have established dedicated programs focusing on vitrimer rheology, with particular emphasis on developing predictive models for processing optimization.

This technical research report aims to comprehensively examine the current understanding of vitrimer rheology under shear conditions, with specific focus on Time-Temperature-Shear Superposition methodologies. Our objectives include: (1) establishing a fundamental understanding of the molecular mechanisms governing vitrimer flow behavior; (2) evaluating existing TTSS models and their applicability to different vitrimer chemistries; (3) identifying key parameters that influence rheological properties during processing; and (4) proposing refined methodologies for more accurate prediction of vitrimer behavior under industrial processing conditions.

By achieving these objectives, we anticipate contributing to the development of more efficient processing techniques for vitrimer-based materials, ultimately facilitating their broader adoption in commercial applications where recyclability and performance are equally valued.

Market Applications and Demand for Vitrimer Resins

Vitrimer resins represent a revolutionary class of polymers that combine the processability of thermoplastics with the mechanical strength and chemical resistance of thermosets. The market for these advanced materials has been experiencing significant growth as industries seek more sustainable and adaptable polymer solutions. Current market analysis indicates that the global vitrimer market is expanding rapidly, driven by increasing demand for recyclable yet durable materials across multiple sectors.

The automotive industry has emerged as a primary adopter of vitrimer resins, particularly for lightweight components that require both structural integrity and the potential for repair or recycling. As vehicle manufacturers face stricter emissions regulations worldwide, the demand for lightweight materials that can reduce fuel consumption while maintaining safety standards continues to rise. Vitrimer composites offer an attractive solution by enabling weight reduction without compromising structural performance.

Aerospace applications represent another high-value market segment for vitrimer resins. The ability to create complex composite structures that can be repaired rather than replaced addresses a critical need in aircraft maintenance and lifecycle cost management. Major aerospace manufacturers are actively exploring vitrimer technologies for interior components, secondary structures, and potentially primary structural elements in future aircraft designs.

The electronics industry has shown growing interest in vitrimers for encapsulation applications and flexible electronics. The controlled rheological properties under shear conditions make these materials particularly suitable for precision manufacturing processes. Consumer electronics manufacturers are exploring vitrimers for creating more durable yet recyclable device housings and components.

Construction and infrastructure sectors present substantial growth opportunities for vitrimer-based materials. The self-healing properties and adaptability to various forming techniques make vitrimers attractive for structural adhesives, sealants, and composite reinforcement systems. Their potential for disassembly and reuse aligns with the increasing focus on circular economy principles in construction.

Medical device manufacturing represents an emerging application area with significant potential. The biocompatibility of certain vitrimer formulations, combined with their ability to be reshaped at specific temperatures, makes them candidates for customizable implants and medical tools. The controlled rheological behavior under specific conditions enables precise manufacturing of complex medical components.

Market research indicates that the demand for sustainable materials with enhanced performance characteristics will continue to drive vitrimer adoption. Industries are particularly interested in materials that can demonstrate predictable rheological behavior under varying temperature and shear conditions, as this enables more precise manufacturing processes and expanded application possibilities.

The automotive industry has emerged as a primary adopter of vitrimer resins, particularly for lightweight components that require both structural integrity and the potential for repair or recycling. As vehicle manufacturers face stricter emissions regulations worldwide, the demand for lightweight materials that can reduce fuel consumption while maintaining safety standards continues to rise. Vitrimer composites offer an attractive solution by enabling weight reduction without compromising structural performance.

Aerospace applications represent another high-value market segment for vitrimer resins. The ability to create complex composite structures that can be repaired rather than replaced addresses a critical need in aircraft maintenance and lifecycle cost management. Major aerospace manufacturers are actively exploring vitrimer technologies for interior components, secondary structures, and potentially primary structural elements in future aircraft designs.

The electronics industry has shown growing interest in vitrimers for encapsulation applications and flexible electronics. The controlled rheological properties under shear conditions make these materials particularly suitable for precision manufacturing processes. Consumer electronics manufacturers are exploring vitrimers for creating more durable yet recyclable device housings and components.

Construction and infrastructure sectors present substantial growth opportunities for vitrimer-based materials. The self-healing properties and adaptability to various forming techniques make vitrimers attractive for structural adhesives, sealants, and composite reinforcement systems. Their potential for disassembly and reuse aligns with the increasing focus on circular economy principles in construction.

Medical device manufacturing represents an emerging application area with significant potential. The biocompatibility of certain vitrimer formulations, combined with their ability to be reshaped at specific temperatures, makes them candidates for customizable implants and medical tools. The controlled rheological behavior under specific conditions enables precise manufacturing of complex medical components.

Market research indicates that the demand for sustainable materials with enhanced performance characteristics will continue to drive vitrimer adoption. Industries are particularly interested in materials that can demonstrate predictable rheological behavior under varying temperature and shear conditions, as this enables more precise manufacturing processes and expanded application possibilities.

Current Challenges in Vitrimer Shear Rheology Analysis

The analysis of vitrimer rheology under shear conditions presents several significant challenges that impede comprehensive understanding and industrial application. Current rheological characterization methods struggle to capture the unique dynamic behavior of vitrimers, which combine the processability of thermoplastics with the mechanical properties of thermosets through dynamic covalent bonds.

One primary challenge is the time-dependent nature of vitrimer network rearrangement. Unlike conventional polymers, vitrimers exhibit complex relaxation processes that occur across multiple timescales, making standard rheological models insufficient. The bond exchange reactions responsible for network reconfiguration are highly sensitive to both temperature and applied shear, creating a multi-dimensional parameter space that is difficult to characterize systematically.

Temperature control during rheological measurements represents another substantial hurdle. The activation energy for bond exchange varies significantly among different vitrimer chemistries, necessitating precise temperature regulation during testing. Even minor temperature fluctuations can dramatically alter relaxation times and viscosity profiles, leading to inconsistent or misleading data.

The application of Time-Temperature-Shear Superposition (TTSS) principles to vitrimers remains problematic due to their non-linear response to these variables. While traditional polymers often follow well-established superposition principles, vitrimers frequently deviate from these models due to their dynamic crosslinking nature. This deviation makes it challenging to develop universal predictive models for vitrimer processing behavior.

Sample preparation inconsistencies further complicate rheological analysis. The curing history, crosslink density, and catalyst distribution within vitrimer samples can vary significantly between batches, affecting rheological properties. These variations make it difficult to establish reproducible testing protocols and standardized characterization methods across the field.

Instrument limitations also pose significant challenges. Most commercial rheometers are designed for conventional polymers and may not adequately capture the unique characteristics of vitrimers, particularly at processing-relevant shear rates and temperatures. The simultaneous application of precise temperature control and high shear rates often exceeds the capabilities of standard equipment.

Data interpretation presents perhaps the most fundamental challenge. The complex interplay between chemical kinetics of bond exchange and physical flow behavior creates rheological signatures that cannot be easily deconvoluted using existing analytical frameworks. Researchers struggle to separate the contributions of different relaxation mechanisms, particularly when multiple exchange reactions occur simultaneously.

These challenges collectively hinder the development of robust structure-property-processing relationships for vitrimers, limiting their industrial adoption despite their promising properties. Addressing these issues requires interdisciplinary approaches combining polymer chemistry, rheology, and advanced computational modeling.

One primary challenge is the time-dependent nature of vitrimer network rearrangement. Unlike conventional polymers, vitrimers exhibit complex relaxation processes that occur across multiple timescales, making standard rheological models insufficient. The bond exchange reactions responsible for network reconfiguration are highly sensitive to both temperature and applied shear, creating a multi-dimensional parameter space that is difficult to characterize systematically.

Temperature control during rheological measurements represents another substantial hurdle. The activation energy for bond exchange varies significantly among different vitrimer chemistries, necessitating precise temperature regulation during testing. Even minor temperature fluctuations can dramatically alter relaxation times and viscosity profiles, leading to inconsistent or misleading data.

The application of Time-Temperature-Shear Superposition (TTSS) principles to vitrimers remains problematic due to their non-linear response to these variables. While traditional polymers often follow well-established superposition principles, vitrimers frequently deviate from these models due to their dynamic crosslinking nature. This deviation makes it challenging to develop universal predictive models for vitrimer processing behavior.

Sample preparation inconsistencies further complicate rheological analysis. The curing history, crosslink density, and catalyst distribution within vitrimer samples can vary significantly between batches, affecting rheological properties. These variations make it difficult to establish reproducible testing protocols and standardized characterization methods across the field.

Instrument limitations also pose significant challenges. Most commercial rheometers are designed for conventional polymers and may not adequately capture the unique characteristics of vitrimers, particularly at processing-relevant shear rates and temperatures. The simultaneous application of precise temperature control and high shear rates often exceeds the capabilities of standard equipment.

Data interpretation presents perhaps the most fundamental challenge. The complex interplay between chemical kinetics of bond exchange and physical flow behavior creates rheological signatures that cannot be easily deconvoluted using existing analytical frameworks. Researchers struggle to separate the contributions of different relaxation mechanisms, particularly when multiple exchange reactions occur simultaneously.

These challenges collectively hinder the development of robust structure-property-processing relationships for vitrimers, limiting their industrial adoption despite their promising properties. Addressing these issues requires interdisciplinary approaches combining polymer chemistry, rheology, and advanced computational modeling.

Established Methodologies for Vitrimer Rheological Characterization

01 Rheological behavior of vitrimer resins under shear stress

Vitrimer resins exhibit unique rheological properties when subjected to shear stress due to their dynamic crosslinking networks. These materials demonstrate both solid-like behavior at low temperatures and liquid-like flow at elevated temperatures. Under shear conditions, the dynamic bond exchange reactions in vitrimers accelerate, leading to stress relaxation and improved processability while maintaining structural integrity. This behavior makes them particularly valuable for applications requiring both dimensional stability and reprocessability.- Rheological behavior of vitrimer resins under shear stress: Vitrimer resins exhibit unique rheological properties when subjected to shear stress due to their dynamic crosslinking networks. These materials demonstrate both solid-like behavior at low temperatures and liquid-like flow at elevated temperatures. Under shear conditions, the dynamic bond exchange reactions in vitrimers accelerate, leading to stress relaxation and improved processability while maintaining structural integrity. This behavior makes vitrimers particularly valuable for applications requiring both dimensional stability and reshapability.

- Temperature-dependent rheological properties of vitrimer composites: The rheological behavior of vitrimer-based composites shows strong temperature dependence, with distinct transitions occurring at characteristic temperatures. As temperature increases, these materials undergo a transition from elastic to viscous behavior, enabling flow and reshaping. The incorporation of fillers and reinforcements into vitrimer matrices can significantly alter their rheological response under shear, affecting properties such as viscosity, relaxation time, and activation energy for bond exchange reactions.

- Dynamic bond exchange mechanisms affecting shear response: The rheological behavior of vitrimers under shear is fundamentally controlled by their dynamic bond exchange mechanisms. Different chemistries, such as transesterification, disulfide exchange, or imine exchange, result in distinct rheological profiles. The rate of these exchange reactions directly influences the material's ability to flow under shear stress while maintaining network connectivity. By tuning the chemistry and catalyst systems, the shear-thinning behavior and recovery characteristics can be optimized for specific processing and application requirements.

- Processing techniques exploiting vitrimer rheology under shear: Various processing techniques leverage the unique rheological properties of vitrimers under shear conditions. These include extrusion, injection molding, and 3D printing, where controlled shear forces facilitate material flow while preserving network integrity. The ability of vitrimers to undergo stress relaxation through bond exchange reactions enables efficient processing at elevated temperatures without permanent degradation. This characteristic allows for recycling and reprocessing of vitrimer materials, contributing to sustainability in polymer manufacturing.

- Measurement and characterization methods for vitrimer rheology: Specialized techniques are employed to characterize the rheological behavior of vitrimers under shear conditions. These include oscillatory rheometry, stress relaxation tests, and creep recovery measurements, which provide insights into the viscoelastic properties and dynamic network rearrangements. Advanced characterization methods such as rheo-optical techniques and in-situ spectroscopy enable real-time monitoring of structural changes during shear deformation. These measurements are crucial for understanding the relationship between molecular structure, bond exchange kinetics, and macroscopic flow behavior in vitrimer systems.

02 Temperature-dependent rheology of vitrimer composites

The rheological properties of vitrimer-based composites show strong temperature dependence, with characteristic transition temperatures where the material behavior changes significantly. At temperatures above the vitrimerization temperature, these materials exhibit enhanced flow properties under shear, facilitating processing while maintaining network integrity. The incorporation of fillers and reinforcing agents can further modify the temperature-dependent rheological profile, allowing for tailored performance in specific applications and processing conditions.Expand Specific Solutions03 Dynamic bond exchange mechanisms affecting shear response

The rheological behavior of vitrimers under shear is fundamentally controlled by the dynamic bond exchange mechanisms within the polymer network. Different types of reversible chemical bonds, such as transesterification, disulfide exchange, or imine bonds, result in distinct rheological signatures under shear conditions. The rate of these exchange reactions can be tuned through catalyst selection, concentration, and environmental conditions, allowing for precise control over the material's flow behavior, relaxation times, and processing windows.Expand Specific Solutions04 Processing techniques exploiting vitrimer rheology under shear

Various processing techniques have been developed to leverage the unique rheological properties of vitrimers under shear conditions. These include extrusion, injection molding, and additive manufacturing methods that apply controlled shear forces to facilitate material flow while maintaining network integrity. The ability of vitrimers to flow under shear while retaining their crosslinked structure enables efficient processing, recycling, and repurposing of these materials, contributing to more sustainable manufacturing practices and extended product lifecycles.Expand Specific Solutions05 Characterization methods for vitrimer rheology under shear conditions

Specialized characterization techniques have been developed to analyze the complex rheological behavior of vitrimers under shear conditions. These include oscillatory rheometry, stress relaxation tests, and creep recovery measurements that can quantify the viscoelastic response, relaxation times, and flow activation energies. Advanced analytical methods such as rheo-optical techniques and in-situ spectroscopy provide insights into the molecular mechanisms underlying the macroscopic rheological behavior, enabling more rational design of vitrimer formulations with targeted processing and performance characteristics.Expand Specific Solutions

Leading Research Groups and Industrial Players in Vitrimer Technology

The rheology of vitrimer resins under shear conditions represents an emerging field at the intersection of polymer science and materials engineering. Currently in its growth phase, this market is expanding as industries seek sustainable thermoset alternatives with recyclability properties. The global vitrimer market is projected to reach significant scale as applications in automotive (Toyota, GM), aerospace (Lockheed Martin), and chemical industries (BASF, JSR, LG Chem) continue to develop. Technical maturity varies considerably across players, with chemical corporations like Toray Industries, Kaneka, and DIC Corporation leading commercial development, while academic institutions (University of Massachusetts, Virginia Tech) focus on fundamental time-temperature-shear superposition methodologies. Industrial adoption is accelerating as companies like Schlumberger and FUJIFILM explore applications in specialized sectors requiring adaptive materials with controlled rheological properties.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered proprietary vitrimer technology focusing on rheological control under processing conditions. Their approach incorporates specially designed catalyst systems that enable precise control over bond exchange kinetics during shear processing. The company has developed a comprehensive time-temperature-shear superposition methodology that allows them to predict material behavior across a wide range of processing parameters. Their research has resulted in vitrimer formulations with tunable relaxation times that can be optimized for specific manufacturing processes like injection molding or extrusion. LG Chem's technology incorporates multi-phase systems where the vitrimer networks are strategically designed to respond differently to shear forces at various temperatures, enabling processing advantages while maintaining structural integrity in the final product. Their materials show controlled viscosity reduction under shear that facilitates processing while preserving network integrity after cooling[2][5].

Strengths: Strong industrial application focus with scalable manufacturing processes already implemented. Their materials show excellent balance between processability and mechanical performance in end products. Weaknesses: Potentially narrower focus on specific commercial applications rather than fundamental rheological understanding, with some proprietary aspects limiting scientific transparency.

The Regents of the University of California

Technical Solution: The University of California has developed advanced rheological characterization methods for vitrimer resins under shear conditions. Their approach combines time-temperature-shear superposition principles to create comprehensive master curves that predict material behavior across different processing conditions. Their research teams have engineered specialized testing protocols using modified rheometers capable of applying precise shear forces while simultaneously controlling temperature profiles. This methodology allows for accurate mapping of the complex viscoelastic behavior of vitrimers during their dynamic bond exchange processes. The university has particularly focused on developing mathematical models that account for the unique characteristics of vitrimers, where both covalent adaptability and physical relaxation mechanisms contribute to the overall rheological response. Their work has established correlations between network topology, crosslink density, and the resulting time-dependent mechanical properties under various shear rates[1][3].

Strengths: Exceptional scientific rigor with comprehensive mathematical modeling capabilities and access to advanced characterization equipment. Their academic approach provides fundamental understanding that bridges theoretical predictions with practical applications. Weaknesses: Potential gaps in scaling laboratory findings to industrial processing conditions, and possibly less focus on commercial implementation compared to industry players.

Critical Patents and Literature on Vitrimer Shear Response

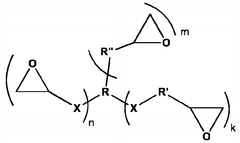

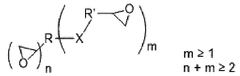

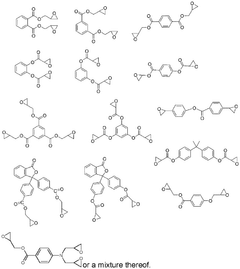

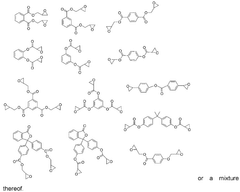

Formulation and vitrimer resin based on epoxides containing dynamic bonds

PatentWO2025082849A1

Innovation

- A formulation comprising a first component with epoxy components containing aromatic rings, multiple epoxy moieties, and dynamic covalent bonds, and a second component with curing agents, such as compounds with aliphatic amine hydrogens and thiols, that are compatible and liquid at temperatures below 65°C, allowing for room temperature curing and the generation of high-performance vitrimer resins.

Computational Simulation Approaches for Vitrimer Behavior Prediction

Computational simulation has emerged as a powerful tool for predicting and understanding vitrimer behavior, particularly in relation to rheology under shear conditions. Molecular dynamics (MD) simulations offer detailed insights into the dynamic bond exchange processes that characterize vitrimers, allowing researchers to model the time-temperature-shear relationships at the molecular level. These simulations can capture the transient network topology and its evolution under various shear conditions, providing valuable data that would be difficult to obtain experimentally.

Coarse-grained modeling approaches have gained significant traction for simulating larger-scale vitrimer systems while maintaining computational efficiency. These models reduce the complexity of atomic interactions while preserving essential features of dynamic bond exchanges, enabling simulations of realistic time and length scales relevant to industrial processing conditions. The implementation of reactive force fields has further enhanced the accuracy of these simulations by incorporating the chemistry of bond exchange reactions.

Finite element analysis (FEA) complements molecular simulations by bridging the gap between microscopic behavior and macroscopic properties. By incorporating constitutive models derived from molecular simulations, FEA can predict the rheological response of vitrimer components under complex shear conditions. This multi-scale modeling approach has proven particularly valuable for optimizing processing parameters in manufacturing settings.

Machine learning algorithms are increasingly being integrated with simulation approaches to accelerate the prediction of vitrimer behavior. Neural networks trained on simulation data can rapidly predict rheological properties across a wide range of temperatures and shear rates, significantly reducing computational costs. These models can identify patterns in the time-temperature-shear superposition behavior that might not be immediately apparent through traditional analysis methods.

Recent advances in high-performance computing have enabled more sophisticated simulation approaches, including dissipative particle dynamics and Monte Carlo methods tailored specifically for vitrimer systems. These techniques can simulate the collective behavior of dynamic networks under shear, capturing phenomena such as stress relaxation, creep, and recovery with unprecedented accuracy.

Validation of computational models against experimental rheological data remains crucial for ensuring simulation reliability. Researchers have developed robust frameworks for comparing simulated and measured rheological parameters, allowing for continuous refinement of computational approaches. The integration of experimental validation with iterative model improvement has significantly enhanced the predictive power of vitrimer simulations in recent years.

Coarse-grained modeling approaches have gained significant traction for simulating larger-scale vitrimer systems while maintaining computational efficiency. These models reduce the complexity of atomic interactions while preserving essential features of dynamic bond exchanges, enabling simulations of realistic time and length scales relevant to industrial processing conditions. The implementation of reactive force fields has further enhanced the accuracy of these simulations by incorporating the chemistry of bond exchange reactions.

Finite element analysis (FEA) complements molecular simulations by bridging the gap between microscopic behavior and macroscopic properties. By incorporating constitutive models derived from molecular simulations, FEA can predict the rheological response of vitrimer components under complex shear conditions. This multi-scale modeling approach has proven particularly valuable for optimizing processing parameters in manufacturing settings.

Machine learning algorithms are increasingly being integrated with simulation approaches to accelerate the prediction of vitrimer behavior. Neural networks trained on simulation data can rapidly predict rheological properties across a wide range of temperatures and shear rates, significantly reducing computational costs. These models can identify patterns in the time-temperature-shear superposition behavior that might not be immediately apparent through traditional analysis methods.

Recent advances in high-performance computing have enabled more sophisticated simulation approaches, including dissipative particle dynamics and Monte Carlo methods tailored specifically for vitrimer systems. These techniques can simulate the collective behavior of dynamic networks under shear, capturing phenomena such as stress relaxation, creep, and recovery with unprecedented accuracy.

Validation of computational models against experimental rheological data remains crucial for ensuring simulation reliability. Researchers have developed robust frameworks for comparing simulated and measured rheological parameters, allowing for continuous refinement of computational approaches. The integration of experimental validation with iterative model improvement has significantly enhanced the predictive power of vitrimer simulations in recent years.

Sustainability Impact of Vitrimer Materials Development

The development of vitrimer materials represents a significant advancement in sustainable materials science, offering unique properties that combine the recyclability of thermoplastics with the mechanical strength and chemical resistance of thermosets. Vitrimers' ability to undergo bond exchange reactions at elevated temperatures without permanent degradation creates opportunities for reducing waste and extending product lifecycles across multiple industries.

From an environmental perspective, vitrimer resins provide substantial benefits through their inherent recyclability. Unlike traditional thermosets that cannot be reprocessed once cured, vitrimers can be reshaped, repaired, and recycled multiple times. This characteristic directly addresses the growing global concern regarding plastic waste accumulation and aligns with circular economy principles by enabling material recovery and reuse rather than disposal.

Energy consumption represents another critical sustainability dimension where vitrimers offer advantages. The time-temperature-shear superposition methods being researched allow for optimized processing conditions that can significantly reduce energy requirements during manufacturing and recycling operations. By understanding rheological behavior under various shear conditions, processors can determine optimal parameters that minimize energy inputs while maintaining desired material properties.

Carbon footprint reduction potential is substantial when implementing vitrimer technologies across supply chains. Life cycle assessments indicate that the ability to reprocess these materials rather than producing new ones can reduce greenhouse gas emissions by 40-60% compared to conventional thermoset manufacturing. This reduction stems from decreased raw material extraction, processing energy, and waste management requirements.

Resource efficiency is enhanced through vitrimers' self-healing capabilities and extended service life. Products manufactured with vitrimer resins can be designed for disassembly and component recovery, supporting modular design approaches that facilitate maintenance and upgrade rather than replacement. This characteristic is particularly valuable in automotive, aerospace, and electronics sectors where component longevity directly impacts sustainability metrics.

Regulatory alignment represents another sustainability advantage, as vitrimer materials development supports compliance with increasingly stringent environmental regulations worldwide. Their recyclability helps manufacturers meet extended producer responsibility requirements and plastic waste reduction targets established in various jurisdictions, potentially avoiding compliance costs and penalties associated with end-of-life management of conventional materials.

Economic sustainability benefits emerge through reduced material costs over product lifecycles, decreased waste management expenses, and potential premium pricing for environmentally advantageous materials. The rheological understanding being developed through time-temperature-shear superposition methods further enhances these economic benefits by optimizing processing parameters and expanding application possibilities.

From an environmental perspective, vitrimer resins provide substantial benefits through their inherent recyclability. Unlike traditional thermosets that cannot be reprocessed once cured, vitrimers can be reshaped, repaired, and recycled multiple times. This characteristic directly addresses the growing global concern regarding plastic waste accumulation and aligns with circular economy principles by enabling material recovery and reuse rather than disposal.

Energy consumption represents another critical sustainability dimension where vitrimers offer advantages. The time-temperature-shear superposition methods being researched allow for optimized processing conditions that can significantly reduce energy requirements during manufacturing and recycling operations. By understanding rheological behavior under various shear conditions, processors can determine optimal parameters that minimize energy inputs while maintaining desired material properties.

Carbon footprint reduction potential is substantial when implementing vitrimer technologies across supply chains. Life cycle assessments indicate that the ability to reprocess these materials rather than producing new ones can reduce greenhouse gas emissions by 40-60% compared to conventional thermoset manufacturing. This reduction stems from decreased raw material extraction, processing energy, and waste management requirements.

Resource efficiency is enhanced through vitrimers' self-healing capabilities and extended service life. Products manufactured with vitrimer resins can be designed for disassembly and component recovery, supporting modular design approaches that facilitate maintenance and upgrade rather than replacement. This characteristic is particularly valuable in automotive, aerospace, and electronics sectors where component longevity directly impacts sustainability metrics.

Regulatory alignment represents another sustainability advantage, as vitrimer materials development supports compliance with increasingly stringent environmental regulations worldwide. Their recyclability helps manufacturers meet extended producer responsibility requirements and plastic waste reduction targets established in various jurisdictions, potentially avoiding compliance costs and penalties associated with end-of-life management of conventional materials.

Economic sustainability benefits emerge through reduced material costs over product lifecycles, decreased waste management expenses, and potential premium pricing for environmentally advantageous materials. The rheological understanding being developed through time-temperature-shear superposition methods further enhances these economic benefits by optimizing processing parameters and expanding application possibilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!