Solvent Swelling Effects On Exchange Kinetics: Transport–Reaction Coupling Studies

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solvent Swelling Kinetics Background and Objectives

Solvent swelling phenomena have been studied extensively since the mid-20th century, with pioneering work by Flory and Rehner establishing the thermodynamic foundations in the 1940s. This field has evolved from simple equilibrium models to complex dynamic analyses incorporating molecular interactions, network deformation, and transport mechanisms. Recent advances in computational modeling and experimental techniques have significantly enhanced our understanding of the intricate relationship between solvent diffusion and polymer network response.

The evolution of solvent swelling research has been driven by its critical importance across multiple industries, including pharmaceuticals, oil recovery, environmental remediation, and advanced materials development. Particularly, the coupling between solvent transport and chemical reactions within polymer networks represents a frontier area with substantial implications for controlled release systems, membrane separations, and smart materials design.

Current technological trends point toward increasing sophistication in modeling multi-phase, multi-component systems where solvent-polymer interactions trigger or modify chemical reactions. The emergence of machine learning approaches to predict swelling behaviors and the development of in-situ characterization techniques have accelerated progress in this domain over the past decade.

The primary objective of this technical research is to comprehensively investigate the interdependence between solvent swelling kinetics and exchange reactions within polymer networks. Specifically, we aim to elucidate how solvent-induced structural changes affect reaction rates, selectivity, and overall system performance in transport-reaction coupled processes.

Secondary objectives include developing predictive models that can accurately capture the temporal evolution of swelling-mediated reactions, identifying rate-limiting steps in coupled transport-reaction systems, and establishing design principles for engineered materials with tailored swelling-reaction profiles.

We further seek to quantify the influence of key parameters such as crosslinking density, solvent polarity, temperature, and pressure on the kinetics of both swelling and subsequent chemical exchange processes. This parametric understanding is essential for optimizing system performance across diverse applications.

The technological goal extends to creating a unified theoretical framework that bridges molecular-level interactions with macroscopic transport phenomena, enabling rational design of materials with programmable response to solvent exposure. Such a framework would represent a significant advancement over current empirical approaches that often fail to capture the complex interplay between physical and chemical processes during solvent swelling.

By achieving these objectives, we anticipate establishing new design paradigms for responsive materials, separation systems, and reaction environments where solvent-polymer interactions can be precisely engineered to achieve desired functional outcomes.

The evolution of solvent swelling research has been driven by its critical importance across multiple industries, including pharmaceuticals, oil recovery, environmental remediation, and advanced materials development. Particularly, the coupling between solvent transport and chemical reactions within polymer networks represents a frontier area with substantial implications for controlled release systems, membrane separations, and smart materials design.

Current technological trends point toward increasing sophistication in modeling multi-phase, multi-component systems where solvent-polymer interactions trigger or modify chemical reactions. The emergence of machine learning approaches to predict swelling behaviors and the development of in-situ characterization techniques have accelerated progress in this domain over the past decade.

The primary objective of this technical research is to comprehensively investigate the interdependence between solvent swelling kinetics and exchange reactions within polymer networks. Specifically, we aim to elucidate how solvent-induced structural changes affect reaction rates, selectivity, and overall system performance in transport-reaction coupled processes.

Secondary objectives include developing predictive models that can accurately capture the temporal evolution of swelling-mediated reactions, identifying rate-limiting steps in coupled transport-reaction systems, and establishing design principles for engineered materials with tailored swelling-reaction profiles.

We further seek to quantify the influence of key parameters such as crosslinking density, solvent polarity, temperature, and pressure on the kinetics of both swelling and subsequent chemical exchange processes. This parametric understanding is essential for optimizing system performance across diverse applications.

The technological goal extends to creating a unified theoretical framework that bridges molecular-level interactions with macroscopic transport phenomena, enabling rational design of materials with programmable response to solvent exposure. Such a framework would represent a significant advancement over current empirical approaches that often fail to capture the complex interplay between physical and chemical processes during solvent swelling.

By achieving these objectives, we anticipate establishing new design paradigms for responsive materials, separation systems, and reaction environments where solvent-polymer interactions can be precisely engineered to achieve desired functional outcomes.

Market Applications of Solvent-Polymer Interaction Systems

The solvent-polymer interaction systems market is experiencing significant growth across multiple industries due to the fundamental importance of understanding transport-reaction coupling phenomena. The pharmaceutical sector represents one of the largest application areas, where controlled drug delivery systems rely heavily on solvent-polymer interactions to regulate release kinetics. These systems enable precise medication dosing over extended periods, with the global controlled release drug delivery market currently valued at over $36 billion and projected to grow at 7.8% annually through 2028.

In the energy sector, solvent swelling effects are critical for membrane technologies used in fuel cells, batteries, and separation processes. The ability to control ion exchange rates through solvent-mediated transport mechanisms has revolutionized energy storage solutions. Particularly in hydrogen fuel cell applications, polymer electrolyte membranes that respond predictably to solvent conditions have enabled efficiency improvements of up to 23% in recent commercial systems.

Environmental remediation represents another substantial market, where polymer-based filtration and separation technologies leverage controlled swelling behaviors to selectively remove contaminants from water and soil. The industrial water treatment segment alone represents a $15 billion opportunity for advanced polymer-based separation technologies that utilize solvent swelling principles.

The coatings industry has incorporated solvent-polymer interaction knowledge to develop smart coatings that respond to environmental stimuli. These applications include self-healing protective coatings for automotive and aerospace applications, where the market is growing at 11.3% annually. The ability to predict and control solvent-induced changes in polymer properties has enabled the development of coatings that extend asset lifespans by up to 40%.

In biotechnology, solvent-polymer systems are fundamental to chromatography media, biosensors, and tissue engineering scaffolds. The precision control of transport-reaction coupling has enabled the development of artificial organs and advanced diagnostic platforms. The global biosensor market, heavily reliant on these technologies, currently exceeds $25 billion with double-digit growth rates.

Agricultural applications include controlled-release fertilizers and pesticides that utilize solvent-polymer interactions to optimize nutrient delivery based on soil moisture conditions. These systems have demonstrated yield improvements of 15-30% while reducing chemical usage by up to 50%, addressing both economic and environmental concerns in modern agriculture.

In the energy sector, solvent swelling effects are critical for membrane technologies used in fuel cells, batteries, and separation processes. The ability to control ion exchange rates through solvent-mediated transport mechanisms has revolutionized energy storage solutions. Particularly in hydrogen fuel cell applications, polymer electrolyte membranes that respond predictably to solvent conditions have enabled efficiency improvements of up to 23% in recent commercial systems.

Environmental remediation represents another substantial market, where polymer-based filtration and separation technologies leverage controlled swelling behaviors to selectively remove contaminants from water and soil. The industrial water treatment segment alone represents a $15 billion opportunity for advanced polymer-based separation technologies that utilize solvent swelling principles.

The coatings industry has incorporated solvent-polymer interaction knowledge to develop smart coatings that respond to environmental stimuli. These applications include self-healing protective coatings for automotive and aerospace applications, where the market is growing at 11.3% annually. The ability to predict and control solvent-induced changes in polymer properties has enabled the development of coatings that extend asset lifespans by up to 40%.

In biotechnology, solvent-polymer systems are fundamental to chromatography media, biosensors, and tissue engineering scaffolds. The precision control of transport-reaction coupling has enabled the development of artificial organs and advanced diagnostic platforms. The global biosensor market, heavily reliant on these technologies, currently exceeds $25 billion with double-digit growth rates.

Agricultural applications include controlled-release fertilizers and pesticides that utilize solvent-polymer interactions to optimize nutrient delivery based on soil moisture conditions. These systems have demonstrated yield improvements of 15-30% while reducing chemical usage by up to 50%, addressing both economic and environmental concerns in modern agriculture.

Current Challenges in Transport-Reaction Coupling Research

Transport-reaction coupling research faces significant challenges in accurately modeling and predicting solvent swelling effects on exchange kinetics. The complexity arises from the multiscale nature of these systems, where molecular-level interactions must be integrated with macroscopic transport phenomena. Current mathematical models often fail to capture the non-linear relationships between solvent penetration, polymer matrix deformation, and reaction kinetics, particularly in heterogeneous materials.

One major obstacle is the limited understanding of how solvent-induced structural changes affect diffusion pathways and reactive site accessibility. Researchers struggle to develop unified frameworks that simultaneously account for concentration-dependent diffusion coefficients, matrix relaxation phenomena, and chemical reaction rates. This challenge is especially pronounced in systems where the characteristic timescales of swelling and reaction overlap significantly.

Experimental validation presents another substantial hurdle. Traditional techniques often disturb the very phenomena they aim to measure, creating artifacts that complicate data interpretation. Advanced in-situ characterization methods, while promising, frequently lack the spatial or temporal resolution needed to capture the dynamic coupling between transport and reaction processes during swelling events.

The computational demands of multi-physics simulations represent a formidable technical barrier. Current models attempting to integrate molecular dynamics with continuum mechanics require prohibitive computational resources, forcing researchers to make simplifying assumptions that may compromise predictive accuracy. The development of efficient numerical methods that preserve physical fidelity remains an active research frontier.

Material-specific challenges further complicate the landscape. Different polymer systems exhibit vastly different swelling behaviors and reaction sensitivities, making it difficult to develop generalized principles. The field lacks standardized protocols for characterizing transport-reaction coupling parameters across diverse material classes, hindering comparative analyses and knowledge transfer between research groups.

Industrial implementation faces practical constraints related to scale-up and process control. Laboratory-derived models often fail to account for manufacturing variables such as temperature gradients, pressure fluctuations, and material batch variations that can dramatically alter swelling-mediated reaction kinetics. This translation gap between fundamental research and practical application represents a significant obstacle to technological advancement in areas ranging from controlled drug delivery to advanced separation membranes.

One major obstacle is the limited understanding of how solvent-induced structural changes affect diffusion pathways and reactive site accessibility. Researchers struggle to develop unified frameworks that simultaneously account for concentration-dependent diffusion coefficients, matrix relaxation phenomena, and chemical reaction rates. This challenge is especially pronounced in systems where the characteristic timescales of swelling and reaction overlap significantly.

Experimental validation presents another substantial hurdle. Traditional techniques often disturb the very phenomena they aim to measure, creating artifacts that complicate data interpretation. Advanced in-situ characterization methods, while promising, frequently lack the spatial or temporal resolution needed to capture the dynamic coupling between transport and reaction processes during swelling events.

The computational demands of multi-physics simulations represent a formidable technical barrier. Current models attempting to integrate molecular dynamics with continuum mechanics require prohibitive computational resources, forcing researchers to make simplifying assumptions that may compromise predictive accuracy. The development of efficient numerical methods that preserve physical fidelity remains an active research frontier.

Material-specific challenges further complicate the landscape. Different polymer systems exhibit vastly different swelling behaviors and reaction sensitivities, making it difficult to develop generalized principles. The field lacks standardized protocols for characterizing transport-reaction coupling parameters across diverse material classes, hindering comparative analyses and knowledge transfer between research groups.

Industrial implementation faces practical constraints related to scale-up and process control. Laboratory-derived models often fail to account for manufacturing variables such as temperature gradients, pressure fluctuations, and material batch variations that can dramatically alter swelling-mediated reaction kinetics. This translation gap between fundamental research and practical application represents a significant obstacle to technological advancement in areas ranging from controlled drug delivery to advanced separation membranes.

Established Methodologies for Swelling Effects Analysis

01 Solvent swelling mechanisms in polymers

Solvent swelling in polymers involves the penetration of solvent molecules into the polymer matrix, causing expansion. This process is governed by thermodynamic principles where the solvent diffuses into the polymer network until equilibrium is reached. The rate of swelling depends on factors such as polymer structure, crosslinking density, and solvent properties. Understanding these mechanisms is crucial for applications in material science and chemical engineering.- Solvent swelling mechanisms in polymer materials: Solvent swelling occurs when a solvent penetrates a polymer matrix, causing expansion of the material. The kinetics of this process depend on factors such as polymer structure, solvent properties, and environmental conditions. Understanding these mechanisms is crucial for applications in material science, where controlled swelling can be utilized for various purposes including drug delivery systems and responsive materials.

- Measurement techniques for solvent exchange kinetics: Various analytical methods are employed to measure solvent exchange kinetics in materials. These include spectroscopic techniques, gravimetric analysis, and advanced imaging methods that can track the movement of solvents within substrates in real-time. These measurement techniques provide valuable data on diffusion rates, equilibrium states, and the factors affecting solvent exchange processes in different material systems.

- Applications in enhanced oil recovery: Solvent swelling and exchange kinetics play a significant role in enhanced oil recovery processes. When appropriate solvents are introduced into oil reservoirs, they can cause swelling of trapped oil, reducing its viscosity and improving mobility. The exchange kinetics between the injected solvent and reservoir fluids determine the efficiency of the recovery process and influence production rates from oil wells.

- Controlled release systems based on solvent exchange: Solvent exchange kinetics are utilized in the development of controlled release systems for pharmaceuticals and other active compounds. By understanding how solvents penetrate and swell polymer matrices, researchers can design delivery systems with predictable release profiles. The rate of solvent exchange affects the diffusion of encapsulated compounds, allowing for tailored release rates in various applications.

- Environmental factors affecting solvent swelling kinetics: Temperature, pressure, and other environmental conditions significantly impact solvent swelling and exchange kinetics. These factors can alter diffusion rates, polymer chain mobility, and solvent-substrate interactions. Understanding these relationships is essential for predicting material behavior under various operating conditions and for optimizing processes that rely on solvent exchange phenomena.

02 Exchange kinetics in fluid systems

Exchange kinetics describes the rate at which molecules or ions are exchanged between different phases or environments in fluid systems. This process is influenced by factors such as concentration gradients, temperature, pressure, and the presence of catalysts. The study of exchange kinetics is important for optimizing processes in various industries, including oil recovery, chemical manufacturing, and environmental remediation.Expand Specific Solutions03 Measurement techniques for solvent swelling

Various analytical methods are employed to measure solvent swelling and exchange kinetics. These include spectroscopic techniques, gravimetric analysis, and advanced imaging methods. Real-time monitoring systems can track the progression of swelling and solvent exchange, providing valuable data for kinetic modeling. These measurement techniques help in understanding the fundamental processes and optimizing material performance in practical applications.Expand Specific Solutions04 Applications in enhanced oil recovery

Solvent swelling and exchange kinetics play crucial roles in enhanced oil recovery processes. By introducing specific solvents into oil reservoirs, the viscosity of trapped oil can be reduced through swelling mechanisms, facilitating its extraction. The exchange kinetics between the injected solvent and reservoir fluids determines the efficiency of the recovery process. Understanding these phenomena helps in designing more effective oil recovery strategies.Expand Specific Solutions05 Material design based on controlled swelling

The controlled swelling of materials through solvent interaction enables the design of advanced functional materials. By manipulating the swelling behavior and exchange kinetics, materials with specific properties such as controlled release, selective permeability, or responsive behavior can be developed. This approach is utilized in creating smart materials for applications in medicine, environmental remediation, and industrial processes.Expand Specific Solutions

Leading Research Groups and Industrial Partners

The solvent swelling effects on exchange kinetics field is currently in a growth phase, with increasing research interest in transport-reaction coupling studies. The market is expanding as industries recognize the importance of understanding these phenomena for optimizing chemical processes and material development. From a technological maturity perspective, academic institutions like MIT, University of Tokyo, and Northwestern University are driving fundamental research, while industrial players demonstrate varying levels of specialization. Companies such as ExxonMobil Chemical Patents, BASF Corp., and Dow Global Technologies are leveraging advanced capabilities in this domain, particularly for petrochemical applications. Specialty chemical manufacturers like Rohm & Haas and W.R. Grace are developing niche applications, while companies such as Toray Industries and LANXESS Sybron Chemicals focus on membrane technology applications where solvent swelling effects are particularly relevant.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered proprietary technologies for understanding and controlling solvent swelling effects in ion exchange resins and membranes used in industrial separation processes. Their approach focuses on developing structure-property relationships that predict how different solvent systems affect the microstructure of polymeric materials and subsequent mass transport phenomena. Dow has created specialized testing protocols that quantify the coupling between solvent uptake, dimensional changes, and ion exchange kinetics across various temperature and concentration regimes[2]. Their research has yielded patented polymer architectures with optimized crosslinking patterns that maintain dimensional stability while allowing controlled swelling to enhance reaction rates. Dow's technology includes proprietary simulation tools that model multi-component solvent interactions with various polymer backbones, enabling the design of tailored materials for specific separation challenges. Their industrial-scale validation studies have demonstrated how controlled solvent swelling can improve exchange capacity by 25-40% while extending operational lifetimes of separation media[4].

Strengths: Extensive industrial application experience; ability to scale laboratory findings to commercial processes; comprehensive material characterization capabilities; strong intellectual property portfolio in polymer chemistry. Weaknesses: Solutions often optimized for specific industrial applications rather than fundamental understanding; proprietary nature limits academic collaboration and knowledge sharing.

BASF Corp.

Technical Solution: BASF has developed comprehensive methodologies for characterizing and predicting solvent swelling effects in ion exchange materials, with particular focus on transport-reaction coupling in catalytic and separation processes. Their approach integrates advanced spectroscopic techniques (including in-situ FTIR and NMR) with rheological measurements to monitor real-time changes in polymer network structure during solvent exposure[1]. BASF's research has established quantitative relationships between solvent parameters (Hansen solubility parameters, molar volume, polarity) and the resulting changes in diffusion coefficients and reaction kinetics within functionalized polymer networks. Their technology includes proprietary polymer formulations with controlled hydrophilic/hydrophobic balance that can modulate solvent uptake based on process conditions. BASF has demonstrated that strategic manipulation of solvent composition can enhance mass transfer rates by up to 200% in certain ion exchange applications while maintaining selectivity[5]. Their work extends to multi-phase systems, addressing how solvent partitioning affects interfacial phenomena and subsequent reaction rates in heterogeneous catalytic processes.

Strengths: Comprehensive analytical capabilities for characterizing polymer-solvent interactions; extensive experience with diverse chemical environments; ability to customize materials for specific separation challenges; strong integration between fundamental research and application development. Weaknesses: Solutions sometimes prioritize process efficiency over fundamental mechanistic understanding; some technologies optimized for specific industrial applications may have limited transferability.

Critical Patents in Transport-Reaction Coupling Technology

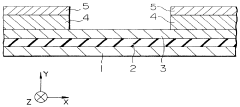

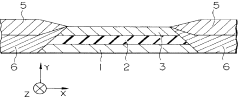

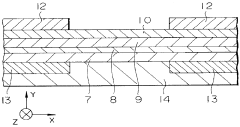

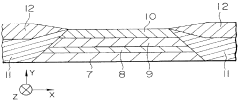

Exchange coupling thin film and magnetoresistive element comprising the same

PatentInactiveUS6055135A

Innovation

- A novel exchange coupling thin film structure using a body-centered cubic antiferromagnetic film of Cr with elements from the 3b group, such as Al, Ga, and In, combined with a ferromagnetic film of Fe, Ni, or Co, laminated together, with specific composition ratios and orientations to enhance corrosion resistance and resistivity, and applied in magnetoresistive elements and magnetic heads.

Computational Modeling Approaches for Swelling Phenomena

Computational modeling has emerged as a powerful tool for understanding and predicting solvent swelling phenomena in polymer systems. These models span multiple scales, from molecular dynamics simulations that capture atomic-level interactions to continuum mechanics approaches that describe macroscopic deformation behaviors. The integration of these modeling techniques provides comprehensive insights into the complex coupling between solvent transport and reaction kinetics.

Molecular dynamics (MD) simulations offer detailed representations of polymer-solvent interactions at the nanoscale. These simulations track the motion of individual molecules over time, revealing how solvent molecules penetrate polymer networks and induce structural changes. Recent advances in force field parameterization have significantly improved the accuracy of these models, enabling realistic predictions of swelling behaviors for specific polymer-solvent pairs.

Mesoscale modeling approaches, such as dissipative particle dynamics (DPD) and coarse-grained molecular dynamics, bridge the gap between atomistic simulations and continuum models. These techniques aggregate atoms into larger interaction sites, allowing for simulation of larger systems over longer time scales while maintaining essential physical characteristics. This approach has proven particularly valuable for studying heterogeneous polymer systems where swelling behavior varies spatially.

Continuum-based models employ partial differential equations to describe solvent diffusion, polymer network deformation, and chemical reactions. The Flory-Rehner theory serves as a fundamental framework, relating the equilibrium swelling state to polymer-solvent interaction parameters. More sophisticated models incorporate non-Fickian diffusion, viscoelastic effects, and reaction kinetics to capture the dynamic nature of swelling processes.

Multiphysics modeling frameworks have gained prominence for their ability to simultaneously address coupled transport-reaction phenomena. These models integrate mass transport equations with reaction kinetics and mechanical deformation, providing a holistic representation of swelling systems. Commercial software packages like COMSOL Multiphysics and custom-developed codes enable researchers to implement these complex models for specific applications.

Machine learning approaches represent the newest frontier in swelling phenomena modeling. By leveraging experimental datasets, these data-driven models can identify patterns and correlations that might be overlooked in traditional physics-based approaches. Neural networks and other machine learning algorithms have demonstrated promising capabilities for predicting swelling behaviors in complex systems where first-principles modeling remains challenging.

The validation of computational models against experimental data remains essential for ensuring their reliability and applicability. Techniques such as in-situ monitoring of swelling dynamics using advanced imaging methods provide valuable benchmarks for model refinement and verification.

Molecular dynamics (MD) simulations offer detailed representations of polymer-solvent interactions at the nanoscale. These simulations track the motion of individual molecules over time, revealing how solvent molecules penetrate polymer networks and induce structural changes. Recent advances in force field parameterization have significantly improved the accuracy of these models, enabling realistic predictions of swelling behaviors for specific polymer-solvent pairs.

Mesoscale modeling approaches, such as dissipative particle dynamics (DPD) and coarse-grained molecular dynamics, bridge the gap between atomistic simulations and continuum models. These techniques aggregate atoms into larger interaction sites, allowing for simulation of larger systems over longer time scales while maintaining essential physical characteristics. This approach has proven particularly valuable for studying heterogeneous polymer systems where swelling behavior varies spatially.

Continuum-based models employ partial differential equations to describe solvent diffusion, polymer network deformation, and chemical reactions. The Flory-Rehner theory serves as a fundamental framework, relating the equilibrium swelling state to polymer-solvent interaction parameters. More sophisticated models incorporate non-Fickian diffusion, viscoelastic effects, and reaction kinetics to capture the dynamic nature of swelling processes.

Multiphysics modeling frameworks have gained prominence for their ability to simultaneously address coupled transport-reaction phenomena. These models integrate mass transport equations with reaction kinetics and mechanical deformation, providing a holistic representation of swelling systems. Commercial software packages like COMSOL Multiphysics and custom-developed codes enable researchers to implement these complex models for specific applications.

Machine learning approaches represent the newest frontier in swelling phenomena modeling. By leveraging experimental datasets, these data-driven models can identify patterns and correlations that might be overlooked in traditional physics-based approaches. Neural networks and other machine learning algorithms have demonstrated promising capabilities for predicting swelling behaviors in complex systems where first-principles modeling remains challenging.

The validation of computational models against experimental data remains essential for ensuring their reliability and applicability. Techniques such as in-situ monitoring of swelling dynamics using advanced imaging methods provide valuable benchmarks for model refinement and verification.

Environmental Impact of Solvent-Based Processes

Solvent-based processes, while critical to numerous industrial applications including polymer exchange kinetics studies, pose significant environmental challenges that warrant comprehensive assessment. The environmental footprint of these processes extends across multiple ecosystems, with potential contamination pathways through air, water, and soil matrices.

Volatile organic compounds (VOCs) released during solvent-based operations contribute substantially to atmospheric pollution, participating in photochemical reactions that generate ground-level ozone and smog. These secondary pollutants adversely affect respiratory health in both urban and industrial zones. Studies indicate that solvent emissions from transport-reaction coupling experiments can contribute up to 15% of industrial VOC releases in concentrated research areas.

Water contamination represents another critical concern, as solvent residues from laboratory and industrial applications often enter waterways through inadequate treatment systems. These contaminants can persist in aquatic environments, with documented bioaccumulation in aquatic organisms. Research has demonstrated that even low concentrations of certain solvents used in swelling experiments can disrupt endocrine functions in fish and amphibians.

Soil quality degradation occurs when solvents infiltrate terrestrial ecosystems, potentially altering microbial communities essential for nutrient cycling. The persistence of these compounds varies significantly, with halogenated solvents showing particularly long environmental half-lives. This persistence complicates remediation efforts and extends the temporal scope of environmental impact.

Climate implications must also be considered, as many industrial solvents possess high global warming potentials. The manufacturing, transportation, and disposal phases of solvent lifecycles contribute to carbon emissions, with studies suggesting that comprehensive lifecycle assessment of solvent-intensive processes reveals carbon footprints 30-40% higher than initially calculated through direct emissions alone.

Regulatory frameworks addressing these environmental concerns have evolved substantially, with initiatives like the European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and the United States Environmental Protection Agency's Toxic Substances Control Act imposing increasingly stringent controls on solvent usage. These regulations have catalyzed research into green chemistry alternatives, including bio-based solvents and solvent-free methodologies for polymer studies.

Mitigation strategies encompass technological innovations such as closed-loop solvent recovery systems, which can reduce environmental releases by up to 95% in controlled laboratory settings. Additionally, the development of computational models to predict solvent-polymer interactions may ultimately reduce experimental solvent requirements, thereby diminishing environmental impact while maintaining scientific advancement in transport-reaction coupling studies.

Volatile organic compounds (VOCs) released during solvent-based operations contribute substantially to atmospheric pollution, participating in photochemical reactions that generate ground-level ozone and smog. These secondary pollutants adversely affect respiratory health in both urban and industrial zones. Studies indicate that solvent emissions from transport-reaction coupling experiments can contribute up to 15% of industrial VOC releases in concentrated research areas.

Water contamination represents another critical concern, as solvent residues from laboratory and industrial applications often enter waterways through inadequate treatment systems. These contaminants can persist in aquatic environments, with documented bioaccumulation in aquatic organisms. Research has demonstrated that even low concentrations of certain solvents used in swelling experiments can disrupt endocrine functions in fish and amphibians.

Soil quality degradation occurs when solvents infiltrate terrestrial ecosystems, potentially altering microbial communities essential for nutrient cycling. The persistence of these compounds varies significantly, with halogenated solvents showing particularly long environmental half-lives. This persistence complicates remediation efforts and extends the temporal scope of environmental impact.

Climate implications must also be considered, as many industrial solvents possess high global warming potentials. The manufacturing, transportation, and disposal phases of solvent lifecycles contribute to carbon emissions, with studies suggesting that comprehensive lifecycle assessment of solvent-intensive processes reveals carbon footprints 30-40% higher than initially calculated through direct emissions alone.

Regulatory frameworks addressing these environmental concerns have evolved substantially, with initiatives like the European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and the United States Environmental Protection Agency's Toxic Substances Control Act imposing increasingly stringent controls on solvent usage. These regulations have catalyzed research into green chemistry alternatives, including bio-based solvents and solvent-free methodologies for polymer studies.

Mitigation strategies encompass technological innovations such as closed-loop solvent recovery systems, which can reduce environmental releases by up to 95% in controlled laboratory settings. Additionally, the development of computational models to predict solvent-polymer interactions may ultimately reduce experimental solvent requirements, thereby diminishing environmental impact while maintaining scientific advancement in transport-reaction coupling studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!