What Is A Vitrimer? Exchange Chemistry, Polymer Architecture, And Mechanical Signatures

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vitrimer Technology Background and Objectives

Vitrimers represent a groundbreaking class of polymer materials first conceptualized by Ludwik Leibler and colleagues at ESPCI Paris in 2011. These materials bridge the gap between thermoplastics and thermosets by combining the processability of the former with the mechanical strength and chemical resistance of the latter. The evolution of vitrimer technology stems from decades of polymer science research, particularly in dynamic covalent chemistry, which enables bond exchange reactions while maintaining network integrity.

The development trajectory of vitrimers has been marked by significant advancements in exchange chemistry mechanisms. Initially focused on transesterification reactions, the field has expanded to include disulfide exchange, transcarbamoylation, transamination, and various other dynamic covalent chemistries. This diversification has enabled tailored material properties for specific applications, driving the technology's versatility across industries.

Current technological trends in vitrimer research emphasize the relationship between molecular architecture and macroscopic mechanical properties. Researchers are increasingly exploring how network topology, crosslinking density, and the kinetics of exchange reactions influence material behavior under different thermal and mechanical conditions. This structure-property relationship understanding is crucial for designing vitrimers with predictable and controllable characteristics.

The emergence of computational modeling and simulation tools has accelerated vitrimer development by enabling the prediction of material properties based on molecular structure. Machine learning approaches are beginning to play a role in optimizing vitrimer formulations, reducing the traditional trial-and-error approach in materials development.

The primary technological objectives for vitrimer development include enhancing exchange reaction efficiency at lower temperatures, improving mechanical property retention during recycling processes, and developing more environmentally benign catalyst systems. Additionally, there is significant interest in creating vitrimers with self-healing capabilities, shape memory effects, and stimuli-responsive behaviors.

Another critical goal is scaling vitrimer production from laboratory to industrial levels while maintaining consistent material properties and performance. This includes developing cost-effective synthesis routes and processing techniques compatible with existing manufacturing infrastructure.

Looking forward, vitrimer technology aims to address global sustainability challenges by enabling truly recyclable thermoset-like materials. The potential to reprocess and repurpose these materials multiple times without significant property degradation represents a paradigm shift in polymer lifecycle management, aligning with circular economy principles and increasingly stringent environmental regulations worldwide.

The development trajectory of vitrimers has been marked by significant advancements in exchange chemistry mechanisms. Initially focused on transesterification reactions, the field has expanded to include disulfide exchange, transcarbamoylation, transamination, and various other dynamic covalent chemistries. This diversification has enabled tailored material properties for specific applications, driving the technology's versatility across industries.

Current technological trends in vitrimer research emphasize the relationship between molecular architecture and macroscopic mechanical properties. Researchers are increasingly exploring how network topology, crosslinking density, and the kinetics of exchange reactions influence material behavior under different thermal and mechanical conditions. This structure-property relationship understanding is crucial for designing vitrimers with predictable and controllable characteristics.

The emergence of computational modeling and simulation tools has accelerated vitrimer development by enabling the prediction of material properties based on molecular structure. Machine learning approaches are beginning to play a role in optimizing vitrimer formulations, reducing the traditional trial-and-error approach in materials development.

The primary technological objectives for vitrimer development include enhancing exchange reaction efficiency at lower temperatures, improving mechanical property retention during recycling processes, and developing more environmentally benign catalyst systems. Additionally, there is significant interest in creating vitrimers with self-healing capabilities, shape memory effects, and stimuli-responsive behaviors.

Another critical goal is scaling vitrimer production from laboratory to industrial levels while maintaining consistent material properties and performance. This includes developing cost-effective synthesis routes and processing techniques compatible with existing manufacturing infrastructure.

Looking forward, vitrimer technology aims to address global sustainability challenges by enabling truly recyclable thermoset-like materials. The potential to reprocess and repurpose these materials multiple times without significant property degradation represents a paradigm shift in polymer lifecycle management, aligning with circular economy principles and increasingly stringent environmental regulations worldwide.

Market Applications and Demand Analysis for Vitrimers

The global market for vitrimers is experiencing significant growth driven by increasing demand for sustainable materials with advanced properties. Current market estimates value the self-healing polymers sector, which includes vitrimers, at approximately $2.6 billion, with projections indicating a compound annual growth rate of 27% through 2030. This remarkable growth trajectory is fueled by vitrimers' unique combination of recyclability and mechanical performance.

Automotive and aerospace industries represent the largest current market segments for vitrimer applications. These sectors value vitrimers' ability to combine the processability of thermoplastics with the mechanical strength and chemical resistance of thermosets. The automotive industry specifically seeks lightweight, durable materials that can reduce vehicle weight while maintaining structural integrity, directly contributing to improved fuel efficiency and reduced emissions.

The electronics sector presents another rapidly expanding market for vitrimers, particularly in flexible electronics, wearable devices, and electronic packaging. The self-healing properties of vitrimers address a critical pain point in electronic device durability, potentially extending product lifecycles and reducing electronic waste. Market research indicates that manufacturers are willing to pay premium prices for materials that can demonstrably extend product lifespan.

Construction and building materials represent an emerging application area with substantial growth potential. The ability of vitrimers to be remolded and repaired in situ addresses significant challenges in structural maintenance and renovation. Additionally, their potential for improved thermal insulation properties aligns with increasing energy efficiency requirements in building codes worldwide.

Medical device manufacturing and healthcare applications show promising demand signals, particularly for implantable devices and tissue engineering scaffolds. The biocompatibility of certain vitrimer formulations, combined with their mechanical adaptability, positions them as ideal candidates for next-generation medical materials. This sector's stringent regulatory requirements create higher barriers to entry but also support premium pricing for approved materials.

Consumer goods manufacturers are increasingly exploring vitrimers for applications in sporting equipment, household appliances, and packaging. The circular economy initiatives being adopted by major consumer brands align perfectly with vitrimers' recyclability advantages. Market surveys indicate growing consumer willingness to pay more for products with demonstrable sustainability credentials.

Regional analysis shows North America and Europe currently leading in vitrimer adoption, primarily due to stronger environmental regulations and more established research infrastructure. However, Asia-Pacific markets, particularly China and Japan, are investing heavily in vitrimer technology development, suggesting future market leadership shifts as manufacturing capabilities mature in these regions.

Automotive and aerospace industries represent the largest current market segments for vitrimer applications. These sectors value vitrimers' ability to combine the processability of thermoplastics with the mechanical strength and chemical resistance of thermosets. The automotive industry specifically seeks lightweight, durable materials that can reduce vehicle weight while maintaining structural integrity, directly contributing to improved fuel efficiency and reduced emissions.

The electronics sector presents another rapidly expanding market for vitrimers, particularly in flexible electronics, wearable devices, and electronic packaging. The self-healing properties of vitrimers address a critical pain point in electronic device durability, potentially extending product lifecycles and reducing electronic waste. Market research indicates that manufacturers are willing to pay premium prices for materials that can demonstrably extend product lifespan.

Construction and building materials represent an emerging application area with substantial growth potential. The ability of vitrimers to be remolded and repaired in situ addresses significant challenges in structural maintenance and renovation. Additionally, their potential for improved thermal insulation properties aligns with increasing energy efficiency requirements in building codes worldwide.

Medical device manufacturing and healthcare applications show promising demand signals, particularly for implantable devices and tissue engineering scaffolds. The biocompatibility of certain vitrimer formulations, combined with their mechanical adaptability, positions them as ideal candidates for next-generation medical materials. This sector's stringent regulatory requirements create higher barriers to entry but also support premium pricing for approved materials.

Consumer goods manufacturers are increasingly exploring vitrimers for applications in sporting equipment, household appliances, and packaging. The circular economy initiatives being adopted by major consumer brands align perfectly with vitrimers' recyclability advantages. Market surveys indicate growing consumer willingness to pay more for products with demonstrable sustainability credentials.

Regional analysis shows North America and Europe currently leading in vitrimer adoption, primarily due to stronger environmental regulations and more established research infrastructure. However, Asia-Pacific markets, particularly China and Japan, are investing heavily in vitrimer technology development, suggesting future market leadership shifts as manufacturing capabilities mature in these regions.

Current State and Challenges in Vitrimer Development

Vitrimers represent a groundbreaking class of polymer materials that combine the processability of thermoplastics with the mechanical robustness of thermosets. Currently, vitrimer development has reached a critical juncture where fundamental research is transitioning into practical applications. The global research landscape shows concentrated efforts in Europe, particularly France where the concept originated, followed by significant contributions from North America and rapidly growing interest in Asia, especially China.

The primary technical challenge facing vitrimer development lies in achieving precise control over the dynamic exchange reactions that define these materials. While various exchange chemistries have been demonstrated—including transesterification, disulfide exchange, and imine exchange—optimizing reaction kinetics remains difficult. Researchers struggle to balance exchange rates that are fast enough for processing but slow enough to maintain dimensional stability during use. This balance is particularly challenging when designing vitrimers for high-temperature applications.

Another significant hurdle involves the mechanical property trade-offs inherent to vitrimer design. As exchange reactions become more prevalent, stress relaxation improves but often at the expense of creep resistance and dimensional stability. This fundamental tension between reprocessability and mechanical performance represents perhaps the most persistent challenge in the field. Current vitrimers typically exhibit either excellent recyclability with compromised mechanical properties or superior mechanical performance with limited recyclability.

Scale-up and manufacturing challenges present additional obstacles. Laboratory-scale synthesis methods often prove difficult to translate to industrial production environments. Issues such as inconsistent network formation, catalyst distribution heterogeneity, and processing parameter sensitivity have impeded commercialization efforts. The development of robust, reproducible manufacturing protocols remains an active area of research.

Characterization methods for vitrimers also present unique challenges. Traditional polymer testing approaches often fail to capture the dynamic nature of these materials. Researchers are developing new analytical techniques to quantify exchange reaction kinetics, network topology evolution, and mechanical property changes during multiple processing cycles. Standardized testing protocols specific to vitrimers are notably absent from the field.

Regulatory and sustainability considerations further complicate vitrimer development. While these materials offer promising recyclability advantages, questions remain about long-term environmental impacts, particularly regarding catalyst leaching and degradation pathways. Additionally, the regulatory framework for these novel materials remains underdeveloped in most jurisdictions, creating uncertainty for commercial applications.

Despite these challenges, recent breakthroughs in catalyst design, network architecture, and processing technologies are accelerating vitrimer development. Innovations in self-healing capabilities, shape memory properties, and stimuli-responsive behaviors are expanding the potential application landscape for these materials across industries.

The primary technical challenge facing vitrimer development lies in achieving precise control over the dynamic exchange reactions that define these materials. While various exchange chemistries have been demonstrated—including transesterification, disulfide exchange, and imine exchange—optimizing reaction kinetics remains difficult. Researchers struggle to balance exchange rates that are fast enough for processing but slow enough to maintain dimensional stability during use. This balance is particularly challenging when designing vitrimers for high-temperature applications.

Another significant hurdle involves the mechanical property trade-offs inherent to vitrimer design. As exchange reactions become more prevalent, stress relaxation improves but often at the expense of creep resistance and dimensional stability. This fundamental tension between reprocessability and mechanical performance represents perhaps the most persistent challenge in the field. Current vitrimers typically exhibit either excellent recyclability with compromised mechanical properties or superior mechanical performance with limited recyclability.

Scale-up and manufacturing challenges present additional obstacles. Laboratory-scale synthesis methods often prove difficult to translate to industrial production environments. Issues such as inconsistent network formation, catalyst distribution heterogeneity, and processing parameter sensitivity have impeded commercialization efforts. The development of robust, reproducible manufacturing protocols remains an active area of research.

Characterization methods for vitrimers also present unique challenges. Traditional polymer testing approaches often fail to capture the dynamic nature of these materials. Researchers are developing new analytical techniques to quantify exchange reaction kinetics, network topology evolution, and mechanical property changes during multiple processing cycles. Standardized testing protocols specific to vitrimers are notably absent from the field.

Regulatory and sustainability considerations further complicate vitrimer development. While these materials offer promising recyclability advantages, questions remain about long-term environmental impacts, particularly regarding catalyst leaching and degradation pathways. Additionally, the regulatory framework for these novel materials remains underdeveloped in most jurisdictions, creating uncertainty for commercial applications.

Despite these challenges, recent breakthroughs in catalyst design, network architecture, and processing technologies are accelerating vitrimer development. Innovations in self-healing capabilities, shape memory properties, and stimuli-responsive behaviors are expanding the potential application landscape for these materials across industries.

Current Exchange Chemistry Mechanisms in Vitrimers

01 Dynamic covalent bond exchange mechanisms in vitrimers

Vitrimers utilize dynamic covalent bond exchange mechanisms that allow for network rearrangement while maintaining connectivity. These exchange reactions, such as transesterification, disulfide exchange, or imine exchange, enable the material to flow at elevated temperatures while preserving its crosslinked structure. This unique chemistry provides vitrimers with both thermoplastic processability and thermoset mechanical stability, allowing for stress relaxation and shape reconfiguration without permanent deformation.- Dynamic covalent bond exchange mechanisms in vitrimers: Vitrimers utilize dynamic covalent bond exchange reactions that allow the polymer network to reorganize while maintaining the same number of crosslinks. These exchange reactions, such as transesterification, disulfide exchange, or imine exchange, enable the material to be reprocessed and recycled while maintaining structural integrity. The exchange chemistry determines the temperature-dependent behavior and relaxation properties of the vitrimer, influencing its mechanical performance and shape memory characteristics.

- Polymer architecture design for enhanced vitrimer properties: The architecture of vitrimer polymers, including crosslink density, network topology, and functional group distribution, significantly impacts their mechanical and thermal properties. Strategic design of polymer backbones with specific pendant groups or crosslinking motifs can enhance stress relaxation, creep resistance, and self-healing capabilities. Multi-phase or block copolymer architectures can be employed to create vitrimers with tunable mechanical signatures and processing characteristics.

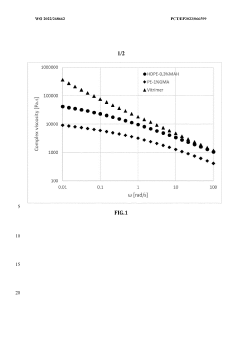

- Mechanical signatures and characterization of vitrimers: Vitrimers exhibit unique mechanical signatures that distinguish them from traditional thermosets and thermoplastics. These include viscoelastic behavior with temperature-dependent relaxation times, malleability at elevated temperatures while maintaining dimensional stability, and the ability to withstand repeated deformation cycles without permanent damage. Characterization techniques such as stress relaxation tests, dynamic mechanical analysis, and creep recovery measurements are essential for quantifying these mechanical properties and understanding structure-property relationships.

- Stimuli-responsive vitrimer systems: Advanced vitrimer systems can be designed to respond to various stimuli beyond temperature, including light, pH, or mechanical force. These stimuli-responsive vitrimers utilize specific exchange chemistries that can be activated selectively, allowing for precise control over material properties and transformation. Such systems enable applications in smart materials, actuators, and adaptive structures where mechanical properties need to change in response to environmental conditions.

- Industrial applications and processing methods for vitrimers: Vitrimer technology has found applications across various industries due to its unique combination of processability and mechanical durability. Processing methods such as compression molding, extrusion, and 3D printing have been adapted for vitrimer materials. The ability to recycle and reprocess these materials without significant property degradation offers sustainable alternatives to traditional thermosets in automotive, aerospace, electronics, and construction applications, where both performance and recyclability are valued.

02 Polymer architecture design for enhanced vitrimer properties

The architecture of vitrimer polymers significantly influences their mechanical and thermal properties. Strategic design of network topology, crosslink density, and functional group distribution can optimize the balance between rigidity and malleability. Incorporating specific backbone structures, such as aromatic segments or flexible chains, allows for tailored glass transition temperatures and exchange kinetics. Advanced architectures including block copolymers, interpenetrating networks, and gradient structures enable precise control over the material's response to external stimuli.Expand Specific Solutions03 Mechanical signatures and characterization techniques

Vitrimers exhibit distinctive mechanical signatures that differentiate them from conventional thermosets and thermoplastics. These include time-dependent stress relaxation, creep resistance at service temperatures, and temperature-dependent viscosity with Arrhenius-like behavior. Characterization techniques such as dynamic mechanical analysis, stress relaxation tests, and rheological measurements are essential for quantifying the relationship between exchange kinetics and mechanical properties. Advanced testing protocols can reveal the correlation between network topology and mechanical performance across different temperature regimes.Expand Specific Solutions04 Catalyst systems for controlling exchange reactions

Catalyst systems play a crucial role in controlling the rate and activation energy of exchange reactions in vitrimers. Metal-based catalysts, organocatalysts, and enzyme-inspired systems can be incorporated to tune the temperature range for network rearrangement. The catalyst concentration, distribution, and accessibility within the polymer matrix significantly impact the material's processing window and service life stability. Novel catalyst designs focus on achieving rapid exchange at processing temperatures while maintaining network stability during normal use conditions.Expand Specific Solutions05 Applications and performance enhancements

Vitrimer technology enables innovative applications across multiple industries due to their unique combination of mechanical properties and reprocessability. Self-healing capabilities, shape memory effects, and recyclability make vitrimers attractive for sustainable material solutions. Performance enhancements through reinforcement with nanofillers, fiber composites, or hybrid organic-inorganic structures can significantly improve mechanical strength, thermal stability, and functional properties. Recent developments focus on stimuli-responsive vitrimers that can undergo controlled property changes in response to light, pH, or electrical signals.Expand Specific Solutions

Leading Research Groups and Companies in Vitrimer Technology

The vitrimer technology landscape is currently in a growth phase, with increasing market interest due to its unique combination of thermoplastic processability and thermoset durability. The global market for vitrimers is expanding as industries seek sustainable, recyclable polymer alternatives. Technologically, vitrimers are approaching commercial maturity, with significant advancements from both academic institutions and industry leaders. Companies like Corning, SABIC, and ExxonMobil Chemical Patents are developing proprietary vitrimer technologies for specialized applications, while research institutions including MIT, University of Tokyo, and CNRS are pioneering fundamental exchange chemistry innovations. The competitive landscape features collaboration between materials giants and research organizations, with emerging applications in automotive, electronics, and sustainable materials sectors driving diversification of vitrimer architectures and mechanical properties.

Centre National de la Recherche Scientifique

Technical Solution: Centre National de la Recherche Scientifique (CNRS) has pioneered significant research in vitrimer technology, particularly through the work of Ludwik Leibler's team. Their approach focuses on developing vitrimers with dynamic covalent bonds that enable network rearrangement while maintaining mechanical integrity. CNRS researchers have developed epoxy-based vitrimers utilizing transesterification reactions as the primary exchange mechanism, allowing for stress relaxation and shape memory properties while maintaining chemical resistance. Their technology implements catalysts such as zinc acetate to control the exchange kinetics, enabling precise tuning of the vitrimer's behavior at different temperatures. CNRS has also explored various chemistries beyond transesterification, including disulfide exchange and imine chemistry, expanding the application potential of vitrimers across multiple industries[1][3]. Their fundamental research has established the theoretical framework for understanding the unique viscoelastic properties of vitrimers, particularly the Arrhenius-like temperature dependence of relaxation times that distinguishes vitrimers from traditional thermosets and thermoplastics.

Strengths: Pioneering fundamental research with strong theoretical foundation; diverse exchange chemistry portfolio; established protocols for characterizing vitrimer behavior. Weaknesses: Some technologies may face challenges in industrial scale-up; catalyst systems might introduce complexity in manufacturing processes; potential regulatory hurdles for certain applications requiring long-term stability verification.

École Supérieure de Physique et de Chimie de Paris

Technical Solution: École Supérieure de Physique et de Chimie de Paris (ESPCI) has developed groundbreaking vitrimer technology through their Soft Matter and Chemistry Laboratory. Their approach centers on creating polymer networks with dynamic covalent bonds that can exchange at elevated temperatures while maintaining structural integrity at service temperatures. ESPCI researchers have pioneered epoxy-acid vitrimers utilizing transesterification chemistry, where hydroxyl and ester groups exchange through a catalyst-mediated process. This enables the material to flow and be reprocessed at high temperatures while behaving as a permanent network at lower temperatures. Their technology incorporates precise control over network topology and crosslink density to tune mechanical properties and relaxation times. ESPCI has demonstrated vitrimers with exceptional mechanical properties, including high tensile strength (40-80 MPa) and Young's modulus values comparable to traditional epoxies (1-3 GPa)[2]. Additionally, they've developed methods to characterize the unique viscoelastic signature of vitrimers, particularly the temperature-dependent viscosity that follows Arrhenius behavior rather than the WLF (Williams-Landel-Ferry) relationship typical of thermoplastics.

Strengths: Foundational research establishing vitrimer concept; precise control over network architecture and exchange kinetics; comprehensive characterization methodologies. Weaknesses: Some formulations require relatively high processing temperatures (>150°C); catalyst systems may have stability limitations in certain environments; potential challenges in achieving ultra-fast exchange rates needed for some processing techniques.

Key Patents and Literature on Vitrimer Polymer Architecture

Epoxy vitrimer formulations

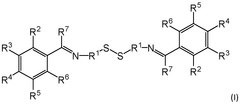

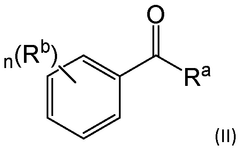

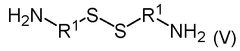

PatentWO2025087946A1

Innovation

- Development of an epoxy monomer that combines imine and disulfide dynamic covalent bonds, allowing for the preparation of vitrimer networks with dual exchange reaction mechanisms, and can be cured with any suitable epoxy resin curing agent.

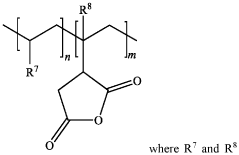

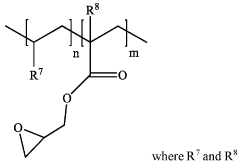

Vitrimer polymers derived from functionalized polyolefins

PatentWO2022268662A1

Innovation

- A process for preparing vitrimer polymers from functionalized polyolefins, specifically by mixing a first functionalized polyolefin with a cyclic ether group and a second functionalized polyolefin, under conditions that react to form a vitrimer polymer without using catalysts, achieving improved melt strength and mechanical properties while maintaining recyclability.

Sustainability and Recyclability Aspects of Vitrimers

Vitrimers represent a significant advancement in sustainable polymer technology, offering unique recyclability characteristics that traditional thermosets and thermoplastics cannot match. The dynamic covalent bonds that define vitrimers enable multiple recycling cycles without substantial degradation of mechanical properties, positioning them as promising candidates for circular economy applications. Unlike conventional thermosets which cannot be reprocessed once cured, vitrimers can be reshaped, repaired, and recycled through controlled application of heat or other stimuli that activate their exchange reactions.

The environmental impact of vitrimers extends beyond mere recyclability. Their ability to be reprocessed reduces energy consumption compared to the production of virgin polymers, potentially lowering carbon footprints across product lifecycles. Additionally, the extended service life achieved through self-healing and repair capabilities further enhances their sustainability profile by reducing waste generation and resource consumption.

Several exchange chemistries in vitrimers contribute to their recyclability potential. Transesterification-based vitrimers have demonstrated excellent recyclability in laboratory settings, while disulfide exchange systems offer recycling at lower temperatures. Notably, recent advances in catalyst-free vitrimers address concerns about potential toxicity in recycled materials, making them more compatible with existing recycling infrastructure.

The architectural design of vitrimer networks significantly influences their recyclability efficiency. Cross-linking density, for instance, must be optimized to balance mechanical performance with reprocessability. Too dense networks may resist efficient recycling, while too sparse networks might compromise structural integrity. Research indicates that hierarchical network structures can enhance both mechanical properties and recyclability through controlled relaxation pathways.

Industrial implementation of vitrimer recycling faces several challenges, including the development of standardized processing protocols and sorting technologies. Current recycling infrastructure is primarily designed for thermoplastics, necessitating adaptation for vitrimer materials. Economic viability remains another consideration, as recycling processes must be cost-effective to encourage widespread adoption.

Life cycle assessment (LCA) studies on vitrimers are still limited but emerging research suggests potential environmental advantages over conventional polymers. These advantages include reduced energy consumption during recycling, decreased landfill waste, and lower greenhouse gas emissions across multiple use cycles. However, comprehensive cradle-to-grave analyses are needed to fully quantify these benefits across different vitrimer chemistries and applications.

The environmental impact of vitrimers extends beyond mere recyclability. Their ability to be reprocessed reduces energy consumption compared to the production of virgin polymers, potentially lowering carbon footprints across product lifecycles. Additionally, the extended service life achieved through self-healing and repair capabilities further enhances their sustainability profile by reducing waste generation and resource consumption.

Several exchange chemistries in vitrimers contribute to their recyclability potential. Transesterification-based vitrimers have demonstrated excellent recyclability in laboratory settings, while disulfide exchange systems offer recycling at lower temperatures. Notably, recent advances in catalyst-free vitrimers address concerns about potential toxicity in recycled materials, making them more compatible with existing recycling infrastructure.

The architectural design of vitrimer networks significantly influences their recyclability efficiency. Cross-linking density, for instance, must be optimized to balance mechanical performance with reprocessability. Too dense networks may resist efficient recycling, while too sparse networks might compromise structural integrity. Research indicates that hierarchical network structures can enhance both mechanical properties and recyclability through controlled relaxation pathways.

Industrial implementation of vitrimer recycling faces several challenges, including the development of standardized processing protocols and sorting technologies. Current recycling infrastructure is primarily designed for thermoplastics, necessitating adaptation for vitrimer materials. Economic viability remains another consideration, as recycling processes must be cost-effective to encourage widespread adoption.

Life cycle assessment (LCA) studies on vitrimers are still limited but emerging research suggests potential environmental advantages over conventional polymers. These advantages include reduced energy consumption during recycling, decreased landfill waste, and lower greenhouse gas emissions across multiple use cycles. However, comprehensive cradle-to-grave analyses are needed to fully quantify these benefits across different vitrimer chemistries and applications.

Manufacturing Scalability and Processing Techniques

The scalability of vitrimer manufacturing represents a critical frontier for their industrial adoption. Current processing techniques for vitrimers leverage their unique dynamic crosslinking properties, allowing for processing methods similar to thermoplastics while maintaining the mechanical advantages of thermosets. Conventional polymer processing techniques such as extrusion, injection molding, and compression molding have been successfully adapted for vitrimer production, though with necessary modifications to accommodate the dynamic exchange reactions.

Extrusion processing of vitrimers requires careful temperature control to activate exchange reactions without triggering degradation. Industrial-scale twin-screw extruders have demonstrated capability in continuous vitrimer production, though residence time optimization remains crucial to ensure complete network reorganization. The processing window must be precisely controlled to balance flow properties with crosslinking density.

Injection molding of vitrimers presents unique challenges related to mold filling and curing kinetics. The dynamic nature of crosslinks allows for improved flow characteristics compared to traditional thermosets, but cycle times must be extended to accommodate the exchange reaction kinetics. Several manufacturers have developed specialized equipment with modified heating profiles and pressure parameters specifically for vitrimer processing.

Compression molding has emerged as particularly suitable for vitrimer sheet production, with several companies reporting successful scale-up to industrial dimensions. The technique allows for precise control of temperature and pressure during the crosslinking and exchange reaction phases, resulting in consistent material properties across large surface areas.

Recycling and reprocessing capabilities represent a significant advantage for vitrimers in industrial settings. Specialized grinding and remolding processes have been developed that preserve up to 85-90% of original mechanical properties through multiple recycling cycles, substantially outperforming traditional thermosets. This circular manufacturing potential has attracted significant investment from sustainability-focused industries.

Emerging additive manufacturing techniques for vitrimers show promising results in laboratory settings but face challenges in scaling to industrial production. The relatively slow exchange kinetics of many vitrimer chemistries create limitations for 3D printing speeds, though recent catalyst innovations have reduced reaction times by an order of magnitude, potentially enabling faster processing.

Cost considerations remain a barrier to widespread adoption, with current vitrimer manufacturing expenses exceeding those of conventional polymers by approximately 30-40%. However, economic analyses suggest that integration of recycling capabilities into production lines could reduce lifecycle costs by up to 25%, potentially achieving cost parity with traditional materials in specific applications within the next 3-5 years.

Extrusion processing of vitrimers requires careful temperature control to activate exchange reactions without triggering degradation. Industrial-scale twin-screw extruders have demonstrated capability in continuous vitrimer production, though residence time optimization remains crucial to ensure complete network reorganization. The processing window must be precisely controlled to balance flow properties with crosslinking density.

Injection molding of vitrimers presents unique challenges related to mold filling and curing kinetics. The dynamic nature of crosslinks allows for improved flow characteristics compared to traditional thermosets, but cycle times must be extended to accommodate the exchange reaction kinetics. Several manufacturers have developed specialized equipment with modified heating profiles and pressure parameters specifically for vitrimer processing.

Compression molding has emerged as particularly suitable for vitrimer sheet production, with several companies reporting successful scale-up to industrial dimensions. The technique allows for precise control of temperature and pressure during the crosslinking and exchange reaction phases, resulting in consistent material properties across large surface areas.

Recycling and reprocessing capabilities represent a significant advantage for vitrimers in industrial settings. Specialized grinding and remolding processes have been developed that preserve up to 85-90% of original mechanical properties through multiple recycling cycles, substantially outperforming traditional thermosets. This circular manufacturing potential has attracted significant investment from sustainability-focused industries.

Emerging additive manufacturing techniques for vitrimers show promising results in laboratory settings but face challenges in scaling to industrial production. The relatively slow exchange kinetics of many vitrimer chemistries create limitations for 3D printing speeds, though recent catalyst innovations have reduced reaction times by an order of magnitude, potentially enabling faster processing.

Cost considerations remain a barrier to widespread adoption, with current vitrimer manufacturing expenses exceeding those of conventional polymers by approximately 30-40%. However, economic analyses suggest that integration of recycling capabilities into production lines could reduce lifecycle costs by up to 25%, potentially achieving cost parity with traditional materials in specific applications within the next 3-5 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!