Measuring Bond Exchange Rates In Vitrimers: Rheometry, Stress Relaxation, And Creep Protocols

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vitrimer Bond Exchange Fundamentals and Research Objectives

Vitrimers represent a groundbreaking class of polymer materials that combine the recyclability of thermoplastics with the mechanical robustness of thermosets. First introduced by Leibler and colleagues in 2011, these materials feature dynamic covalent bonds that enable network rearrangement while maintaining network integrity. The fundamental characteristic distinguishing vitrimers is their ability to undergo bond exchange reactions without changing the total number of crosslinks, preserving material integrity during reprocessing.

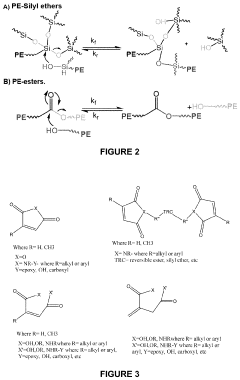

The evolution of vitrimer technology has progressed from early systems based on transesterification chemistry to more diverse exchange mechanisms including disulfide metathesis, imine exchange, and boronic ester exchange. Each mechanism offers distinct advantages in terms of activation energy, exchange kinetics, and environmental responsiveness, expanding the potential application landscape for these materials.

Bond exchange kinetics fundamentally govern vitrimer behavior, determining critical properties such as stress relaxation time, reprocessability window, and creep resistance. Understanding these kinetics is therefore essential for rational material design and performance prediction. However, standardized methodologies for quantifying exchange rates remain underdeveloped, creating significant challenges for comparative analysis across different vitrimer systems.

The primary technical objective of this research is to establish robust, reproducible protocols for measuring bond exchange rates in vitrimers using complementary rheological approaches. Specifically, we aim to correlate data from rheometry, stress relaxation, and creep measurements to develop a comprehensive understanding of exchange kinetics across diverse chemical systems and processing conditions.

Secondary objectives include identifying the relationship between molecular structure and exchange kinetics, determining activation energies for various exchange mechanisms, and establishing predictive models that connect microscopic exchange events to macroscopic material properties. These insights will enable more precise material design for specific application requirements.

The long-term technological goal is to develop a standardized framework for characterizing vitrimer materials that facilitates direct comparison between different systems. This standardization would accelerate material development cycles and enable more targeted design approaches for applications ranging from self-healing coatings to recyclable composites and dynamic adhesives.

Recent advances in analytical techniques, particularly in rheological methods with enhanced temperature control and sensitivity, provide new opportunities to probe exchange kinetics with unprecedented precision. By leveraging these technological developments, we aim to resolve current inconsistencies in reported exchange rates and establish more reliable structure-property relationships for this promising class of materials.

The evolution of vitrimer technology has progressed from early systems based on transesterification chemistry to more diverse exchange mechanisms including disulfide metathesis, imine exchange, and boronic ester exchange. Each mechanism offers distinct advantages in terms of activation energy, exchange kinetics, and environmental responsiveness, expanding the potential application landscape for these materials.

Bond exchange kinetics fundamentally govern vitrimer behavior, determining critical properties such as stress relaxation time, reprocessability window, and creep resistance. Understanding these kinetics is therefore essential for rational material design and performance prediction. However, standardized methodologies for quantifying exchange rates remain underdeveloped, creating significant challenges for comparative analysis across different vitrimer systems.

The primary technical objective of this research is to establish robust, reproducible protocols for measuring bond exchange rates in vitrimers using complementary rheological approaches. Specifically, we aim to correlate data from rheometry, stress relaxation, and creep measurements to develop a comprehensive understanding of exchange kinetics across diverse chemical systems and processing conditions.

Secondary objectives include identifying the relationship between molecular structure and exchange kinetics, determining activation energies for various exchange mechanisms, and establishing predictive models that connect microscopic exchange events to macroscopic material properties. These insights will enable more precise material design for specific application requirements.

The long-term technological goal is to develop a standardized framework for characterizing vitrimer materials that facilitates direct comparison between different systems. This standardization would accelerate material development cycles and enable more targeted design approaches for applications ranging from self-healing coatings to recyclable composites and dynamic adhesives.

Recent advances in analytical techniques, particularly in rheological methods with enhanced temperature control and sensitivity, provide new opportunities to probe exchange kinetics with unprecedented precision. By leveraging these technological developments, we aim to resolve current inconsistencies in reported exchange rates and establish more reliable structure-property relationships for this promising class of materials.

Market Applications and Demand for Vitrimer Materials

Vitrimer materials represent a revolutionary class of polymers that combine the processability of thermoplastics with the mechanical robustness of thermosets. The market demand for these materials has been steadily increasing across various industries due to their unique properties, particularly their ability to undergo bond exchange reactions that enable recycling and reprocessing.

The automotive industry has emerged as a significant market for vitrimers, with applications in lightweight components that can reduce vehicle weight and improve fuel efficiency. According to recent market analyses, the automotive sector's demand for advanced polymer materials is projected to grow substantially as manufacturers seek to meet stringent emissions regulations while maintaining structural integrity and safety standards.

Aerospace applications represent another high-value market segment for vitrimer materials. The ability to create components that can be repaired rather than replaced offers substantial cost savings in an industry where material failure can have catastrophic consequences. The self-healing properties enabled by controlled bond exchange rates make vitrimers particularly attractive for critical structural components in aircraft.

The electronics industry has also shown increasing interest in vitrimer materials for flexible electronics, encapsulation, and thermal management applications. The controlled relaxation properties of vitrimers allow for stress dissipation in electronic components, potentially extending device lifespans and enabling new form factors.

Medical device manufacturing represents a growing application area where the biocompatibility of certain vitrimer formulations, combined with their mechanical properties and potential for shape memory effects, creates opportunities for implantable and wearable medical technologies. The ability to precisely control material properties through bond exchange rates is particularly valuable in this sector.

Sustainable packaging solutions represent an emerging market opportunity, with vitrimers offering potential alternatives to conventional plastics. The recyclability of vitrimers addresses growing consumer and regulatory pressure for environmentally responsible packaging materials.

Market analysis indicates that the global vitrimer market is currently in its early growth phase, with significant research investment from both established chemical companies and specialized startups. The commercialization of vitrimer technologies is accelerating as manufacturing processes become more refined and scalable.

The demand for standardized measurement protocols for bond exchange rates, including rheometry, stress relaxation, and creep protocols, is increasing proportionally with market growth. Industries require reliable methods to characterize these materials for quality control, product development, and regulatory compliance purposes. This technical need directly supports the market expansion of vitrimer materials across multiple sectors.

The automotive industry has emerged as a significant market for vitrimers, with applications in lightweight components that can reduce vehicle weight and improve fuel efficiency. According to recent market analyses, the automotive sector's demand for advanced polymer materials is projected to grow substantially as manufacturers seek to meet stringent emissions regulations while maintaining structural integrity and safety standards.

Aerospace applications represent another high-value market segment for vitrimer materials. The ability to create components that can be repaired rather than replaced offers substantial cost savings in an industry where material failure can have catastrophic consequences. The self-healing properties enabled by controlled bond exchange rates make vitrimers particularly attractive for critical structural components in aircraft.

The electronics industry has also shown increasing interest in vitrimer materials for flexible electronics, encapsulation, and thermal management applications. The controlled relaxation properties of vitrimers allow for stress dissipation in electronic components, potentially extending device lifespans and enabling new form factors.

Medical device manufacturing represents a growing application area where the biocompatibility of certain vitrimer formulations, combined with their mechanical properties and potential for shape memory effects, creates opportunities for implantable and wearable medical technologies. The ability to precisely control material properties through bond exchange rates is particularly valuable in this sector.

Sustainable packaging solutions represent an emerging market opportunity, with vitrimers offering potential alternatives to conventional plastics. The recyclability of vitrimers addresses growing consumer and regulatory pressure for environmentally responsible packaging materials.

Market analysis indicates that the global vitrimer market is currently in its early growth phase, with significant research investment from both established chemical companies and specialized startups. The commercialization of vitrimer technologies is accelerating as manufacturing processes become more refined and scalable.

The demand for standardized measurement protocols for bond exchange rates, including rheometry, stress relaxation, and creep protocols, is increasing proportionally with market growth. Industries require reliable methods to characterize these materials for quality control, product development, and regulatory compliance purposes. This technical need directly supports the market expansion of vitrimer materials across multiple sectors.

Current Methodologies and Challenges in Bond Exchange Rate Measurement

The current landscape of bond exchange rate measurement in vitrimers encompasses several established methodologies, each with specific advantages and limitations. Rheometry stands as the most widely adopted technique, utilizing small-amplitude oscillatory shear tests to determine the characteristic relaxation time (τ*) through time-temperature superposition principles. This approach provides valuable insights into material behavior across different temperature ranges but often struggles with precision at extreme temperatures and may not fully capture the complexity of multiple relaxation mechanisms occurring simultaneously.

Stress relaxation testing represents another fundamental approach, wherein a constant strain is applied to a vitrimer sample and the stress decay is monitored over time. The resulting relaxation curves can be fitted to various models (Maxwell, stretched exponential, etc.) to extract exchange kinetics parameters. While this method offers direct observation of relaxation phenomena, it faces challenges in distinguishing between different relaxation mechanisms and requires careful control of environmental conditions to ensure reproducibility.

Creep compliance measurements, involving the application of constant stress and observation of strain evolution, provide complementary data to stress relaxation tests. This methodology is particularly valuable for characterizing long-term material behavior but demands extended testing periods and sophisticated equipment for accurate measurements at varying temperatures and stress levels.

Dynamic mechanical analysis (DMA) has emerged as a versatile technique for characterizing viscoelastic properties across frequency and temperature domains. However, interpreting DMA data specifically for bond exchange kinetics requires complex mathematical models and assumptions about network topology that may not hold true for all vitrimer systems.

Recent advances in specialized techniques include dielectric spectroscopy for monitoring polar bond exchanges and solid-state NMR for direct observation of exchange events at the molecular level. These methods offer unprecedented molecular insights but remain limited by accessibility, cost, and expertise requirements.

A significant challenge across all methodologies is the difficulty in decoupling various relaxation mechanisms. Vitrimers undergo multiple simultaneous processes including bond exchange, physical relaxation, and potential degradation, making it challenging to isolate the specific contribution of chemical bond exchange to the observed mechanical response.

Standardization represents another critical challenge, as variations in sample preparation, testing protocols, and data analysis methods lead to inconsistent results across research groups. The field currently lacks universally accepted benchmarks and reference materials that would enable meaningful comparison between different studies and material systems.

Stress relaxation testing represents another fundamental approach, wherein a constant strain is applied to a vitrimer sample and the stress decay is monitored over time. The resulting relaxation curves can be fitted to various models (Maxwell, stretched exponential, etc.) to extract exchange kinetics parameters. While this method offers direct observation of relaxation phenomena, it faces challenges in distinguishing between different relaxation mechanisms and requires careful control of environmental conditions to ensure reproducibility.

Creep compliance measurements, involving the application of constant stress and observation of strain evolution, provide complementary data to stress relaxation tests. This methodology is particularly valuable for characterizing long-term material behavior but demands extended testing periods and sophisticated equipment for accurate measurements at varying temperatures and stress levels.

Dynamic mechanical analysis (DMA) has emerged as a versatile technique for characterizing viscoelastic properties across frequency and temperature domains. However, interpreting DMA data specifically for bond exchange kinetics requires complex mathematical models and assumptions about network topology that may not hold true for all vitrimer systems.

Recent advances in specialized techniques include dielectric spectroscopy for monitoring polar bond exchanges and solid-state NMR for direct observation of exchange events at the molecular level. These methods offer unprecedented molecular insights but remain limited by accessibility, cost, and expertise requirements.

A significant challenge across all methodologies is the difficulty in decoupling various relaxation mechanisms. Vitrimers undergo multiple simultaneous processes including bond exchange, physical relaxation, and potential degradation, making it challenging to isolate the specific contribution of chemical bond exchange to the observed mechanical response.

Standardization represents another critical challenge, as variations in sample preparation, testing protocols, and data analysis methods lead to inconsistent results across research groups. The field currently lacks universally accepted benchmarks and reference materials that would enable meaningful comparison between different studies and material systems.

Comparative Analysis of Rheometry, Stress Relaxation and Creep Protocols

01 Catalyst effects on vitrimer bond exchange rates

Catalysts play a crucial role in controlling the bond exchange rates in vitrimers. Different types of catalysts can accelerate or decelerate the dynamic covalent bond exchanges that are characteristic of vitrimers. The selection of appropriate catalysts can be tailored to achieve specific exchange kinetics, which directly impacts the material's processability, self-healing properties, and thermal responsiveness. Optimization of catalyst concentration and type allows for precise control over the vitrimer's behavior at different temperatures.- Catalyst effects on vitrimer bond exchange rates: Catalysts play a crucial role in controlling the bond exchange rates in vitrimers. Different types of catalysts can accelerate or decelerate the dynamic covalent bond exchanges that are characteristic of vitrimers. The selection of appropriate catalysts can tune the reprocessability, self-healing properties, and overall performance of vitrimer materials. Temperature-dependent catalyst activity can also provide control over when and how quickly bond exchanges occur in the polymer network.

- Temperature dependence of bond exchange kinetics: The rate of bond exchange in vitrimers shows significant temperature dependence, following Arrhenius-type behavior. At elevated temperatures, the exchange reactions accelerate, allowing the material to flow and be reprocessed, while at lower temperatures, the exchanges slow down, maintaining the material's dimensional stability. This temperature-responsive behavior enables vitrimers to combine the processability of thermoplastics with the mechanical properties of thermosets.

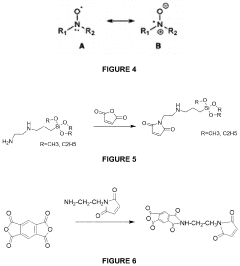

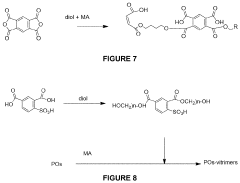

- Chemical structure influence on exchange dynamics: The chemical structure of the polymer backbone and the exchangeable bonds significantly influences the bond exchange rates in vitrimers. Factors such as steric hindrance, electronic effects, and the nature of the dynamic covalent bonds (e.g., disulfide, transesterification, or imine bonds) determine how readily these bonds can exchange. Modifying these structural elements allows for tailoring the viscoelastic properties and relaxation times of vitrimer materials.

- Measurement and characterization techniques: Various analytical techniques are employed to measure and characterize bond exchange rates in vitrimers. These include rheological measurements, stress relaxation tests, dynamic mechanical analysis, and spectroscopic methods. These techniques help quantify parameters such as relaxation times, activation energies, and exchange kinetics, which are essential for understanding and predicting vitrimer behavior under different conditions and for different applications.

- Network topology effects on exchange rates: The network topology of vitrimers, including crosslink density, network heterogeneity, and chain mobility, significantly affects bond exchange rates. Higher crosslink density typically slows down exchange processes due to increased steric constraints, while more flexible network segments can facilitate faster exchanges. Understanding and controlling these topological factors enables the design of vitrimers with tailored relaxation behaviors for specific applications.

02 Temperature-dependent bond exchange mechanisms

The bond exchange rates in vitrimers exhibit strong temperature dependence, which is fundamental to their unique properties. At elevated temperatures, the exchange reactions accelerate, allowing the material to flow and be reprocessed while maintaining network integrity. This temperature-responsive behavior follows Arrhenius-type kinetics, with activation energies that can be engineered through molecular design. Understanding these temperature-dependent mechanisms is essential for developing vitrimers with predictable processing windows and mechanical properties.Expand Specific Solutions03 Chemical structure influence on exchange kinetics

The chemical structure of the vitrimer network significantly influences bond exchange rates. Factors such as crosslink density, backbone flexibility, and the nature of the exchangeable bonds (e.g., disulfide, transesterification, or imine exchange) determine the kinetics of the bond exchange processes. Molecular architecture can be designed to facilitate or hinder bond accessibility, thereby controlling exchange rates. Strategic placement of functional groups can create local environments that promote faster exchange without compromising the overall material stability.Expand Specific Solutions04 Measurement and characterization techniques

Various analytical methods have been developed to measure and characterize bond exchange rates in vitrimers. These include rheological measurements to track stress relaxation, dynamic mechanical analysis to observe the viscoelastic response, and specialized spectroscopic techniques to monitor bond exchange events in real-time. Advanced characterization approaches combine multiple techniques to correlate macroscopic properties with molecular-level exchange processes, providing comprehensive insights into vitrimer behavior under different conditions.Expand Specific Solutions05 Applications leveraging controlled exchange rates

Controlled bond exchange rates in vitrimers enable a wide range of applications across multiple industries. Materials with fast exchange rates at specific temperatures can be used for rapid processing and manufacturing, while those with slower exchange rates provide enhanced stability during use. Applications include self-healing coatings, recyclable composites, adaptive adhesives, and shape-memory materials. By precisely engineering the exchange kinetics, vitrimers can be tailored for specific performance requirements in automotive, aerospace, electronics, and medical device industries.Expand Specific Solutions

Leading Research Groups and Industrial Players in Vitrimer Technology

Vitrimer bond exchange rate measurement technology is currently in an early growth phase, with the market expanding as industries recognize its potential for developing advanced materials with self-healing and recyclable properties. The global market for vitrimers is projected to grow significantly as applications in automotive, aerospace, and consumer goods industries increase. Technologically, rheometry, stress relaxation, and creep protocols are evolving rapidly, with key players demonstrating varying levels of expertise. Dow Global Technologies and Dow Silicones lead industrial applications, while L'Oréal and Unilever focus on consumer product implementations. Academic institutions like MIT and South China University of Technology are advancing fundamental research, while companies like Goodyear and Robert Bosch are exploring automotive applications, creating a diverse competitive landscape balancing academic innovation with industrial implementation.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed comprehensive protocols for measuring bond exchange rates in vitrimers using advanced rheometry techniques. Their approach combines traditional stress relaxation measurements with dynamic mechanical analysis (DMA) to characterize the complex viscoelastic behavior of vitrimer materials. The company has pioneered a multi-temperature testing methodology that enables the extraction of activation energies associated with bond exchange reactions, allowing for precise determination of relaxation time constants across different temperature regimes. Their proprietary analysis software correlates rheological data with chemical structure to establish structure-property relationships in vitrimer systems. Dow has also implemented specialized creep compliance measurements under controlled environmental conditions to simulate real-world performance of vitrimer materials in various applications, particularly focusing on silicone-based vitrimers with tunable exchange kinetics.

Strengths: Extensive materials science expertise and analytical capabilities allow for comprehensive characterization across multiple vitrimer chemistries. Their industrial-scale testing facilities enable translation from laboratory findings to commercial applications. Weaknesses: Their methodologies may be optimized primarily for silicone-based systems, potentially limiting applicability to other vitrimer chemistries without significant adaptation.

University of Rennes

Technical Solution: The University of Rennes has developed sophisticated protocols for measuring bond exchange kinetics in vitrimers through a combination of rheological techniques and molecular modeling. Their methodology employs temperature-sweep stress relaxation tests to establish the characteristic relaxation times at different temperatures, enabling the calculation of activation energies for the exchange reactions. The research team has pioneered the use of time-temperature superposition principles specifically adapted for vitrimer materials, allowing for the construction of master curves that predict long-term behavior from short-term measurements. Their approach incorporates specialized sample preparation techniques to ensure consistent network topology before testing, and they have developed correction factors to account for the influence of crosslink density on measured relaxation parameters. The Rennes protocol includes complementary creep measurements under constant load to validate the stress relaxation findings and provide insights into the material's resistance to permanent deformation under sustained loading conditions.

Strengths: Strong theoretical foundation combining polymer physics and chemistry principles, enabling fundamental understanding of exchange mechanisms. Their methods have been validated across multiple vitrimer chemistries including epoxy, polyester, and polyurethane systems. Weaknesses: Some of their more advanced characterization techniques require specialized equipment not commonly available in industrial settings, potentially limiting widespread adoption.

Key Scientific Advances in Bond Exchange Kinetics Measurement

Thermally reversibile crosslinked polyolefins and related polymers, and related methods

PatentActiveUS20220162402A1

Innovation

- Development of thermally reversibly crosslinked polyolefins (TRC-PO) through reactive melt-processing using a mixture of polyolefins, initiators, and reversible crosslinkers with unsaturated cyclic anhydrides, imides, and nitroxides, which form dynamic covalent bonds allowing for repeatable melt-processing and recycling.

Standardization Efforts for Vitrimer Testing Protocols

The field of vitrimers has experienced rapid growth since their introduction in 2011, yet the lack of standardized testing protocols has hindered consistent comparison of materials across research groups. Recognizing this challenge, several international organizations have initiated efforts to establish standardized methods for measuring bond exchange rates in vitrimers.

The International Union of Pure and Applied Chemistry (IUPAC) formed a working group in 2018 dedicated to developing standardized rheometry protocols for dynamic polymer networks. Their recommendations, published in 2020, provide detailed guidelines for sample preparation, instrument calibration, and data analysis specifically tailored to vitrimer materials.

Similarly, the American Society for Testing and Materials (ASTM) has established committee D30.10 focused on developing standard test methods for stress relaxation measurements in vitrimers. Their proposed standard, ASTM D8394, outlines specific temperature ranges, applied strains, and data collection intervals to ensure reproducibility across different laboratories.

The European Committee for Standardization (CEN) has complemented these efforts through Technical Committee 249, which addresses creep protocol standardization for vitrimers. Their technical specification CEN/TS 17627 provides comprehensive guidance on experimental setup, environmental controls, and mathematical models for extracting activation energies from creep data.

Collaborative initiatives between academic institutions and industry partners have also contributed significantly to standardization efforts. The Vitrimer Consortium, comprising 15 universities and 23 industrial partners across North America, Europe, and Asia, has established an open-access database of benchmark materials with well-characterized bond exchange kinetics, serving as reference standards for new testing protocols.

International round-robin testing programs have been instrumental in validating these standardization efforts. A notable example is the 2022 interlaboratory study coordinated by the National Institute of Standards and Technology (NIST), which involved 27 laboratories testing identical vitrimer samples using proposed standard protocols, revealing critical factors affecting measurement reproducibility.

Despite these advances, challenges remain in harmonizing protocols across different measurement techniques. Current standardization efforts are working to establish clear correlations between rheometry, stress relaxation, and creep measurements, with particular focus on developing conversion factors that allow direct comparison of results obtained through different methods.

The International Union of Pure and Applied Chemistry (IUPAC) formed a working group in 2018 dedicated to developing standardized rheometry protocols for dynamic polymer networks. Their recommendations, published in 2020, provide detailed guidelines for sample preparation, instrument calibration, and data analysis specifically tailored to vitrimer materials.

Similarly, the American Society for Testing and Materials (ASTM) has established committee D30.10 focused on developing standard test methods for stress relaxation measurements in vitrimers. Their proposed standard, ASTM D8394, outlines specific temperature ranges, applied strains, and data collection intervals to ensure reproducibility across different laboratories.

The European Committee for Standardization (CEN) has complemented these efforts through Technical Committee 249, which addresses creep protocol standardization for vitrimers. Their technical specification CEN/TS 17627 provides comprehensive guidance on experimental setup, environmental controls, and mathematical models for extracting activation energies from creep data.

Collaborative initiatives between academic institutions and industry partners have also contributed significantly to standardization efforts. The Vitrimer Consortium, comprising 15 universities and 23 industrial partners across North America, Europe, and Asia, has established an open-access database of benchmark materials with well-characterized bond exchange kinetics, serving as reference standards for new testing protocols.

International round-robin testing programs have been instrumental in validating these standardization efforts. A notable example is the 2022 interlaboratory study coordinated by the National Institute of Standards and Technology (NIST), which involved 27 laboratories testing identical vitrimer samples using proposed standard protocols, revealing critical factors affecting measurement reproducibility.

Despite these advances, challenges remain in harmonizing protocols across different measurement techniques. Current standardization efforts are working to establish clear correlations between rheometry, stress relaxation, and creep measurements, with particular focus on developing conversion factors that allow direct comparison of results obtained through different methods.

Environmental Impact and Sustainability of Vitrimer Materials

Vitrimer materials represent a significant advancement in sustainable polymer technology due to their unique ability to combine the recyclability of thermoplastics with the mechanical strength of thermosets. The environmental impact of vitrimers is particularly noteworthy when considering their bond exchange mechanisms, which enable multiple recycling cycles without significant property degradation.

The sustainability profile of vitrimers is enhanced by their extended lifecycle compared to conventional polymers. When bond exchange rates are optimized through proper measurement protocols such as rheometry, stress relaxation, and creep testing, vitrimers can be designed to maintain structural integrity through multiple reprocessing cycles. This directly reduces waste generation and resource consumption associated with traditional single-use polymers.

Energy consumption during vitrimer recycling presents another critical environmental consideration. The dynamic covalent bonds that characterize vitrimers typically require less energy for reprocessing compared to mechanical recycling of conventional thermoplastics or the energy-intensive breakdown of thermosets. Precise measurement of activation energies for bond exchange reactions through temperature-dependent rheological studies enables the development of more energy-efficient recycling protocols.

Carbon footprint analyses of vitrimer materials indicate potential reductions in greenhouse gas emissions when compared to traditional polymer life cycles. This advantage stems from both reduced production requirements for virgin materials and lower energy demands during reprocessing. The quantification of stress relaxation times at various temperatures provides valuable data for optimizing processing conditions to minimize environmental impact.

Water usage and chemical emissions during vitrimer production and recycling must also be considered in comprehensive environmental assessments. Current research indicates that many vitrimer systems require fewer hazardous solvents during recycling compared to chemical recycling approaches for conventional polymers. The measurement protocols for bond exchange rates can be adapted to evaluate the environmental persistence of any catalysts or additives used in vitrimer formulations.

Biodegradability remains a challenge for most vitrimer materials, as the robust covalent network, even with dynamic bonds, typically resists environmental degradation. However, emerging research incorporating bio-based precursors and environmentally responsive bond exchange mechanisms shows promise for developing vitrimers with controlled end-of-life scenarios. Creep protocols are particularly valuable for predicting long-term environmental stability and potential microplastic formation.

The integration of vitrimers into circular economy frameworks represents perhaps their greatest sustainability contribution. By enabling multiple use cycles without the property degradation typical of recycled conventional polymers, vitrimers could significantly reduce the environmental burden of polymer materials across numerous industries.

The sustainability profile of vitrimers is enhanced by their extended lifecycle compared to conventional polymers. When bond exchange rates are optimized through proper measurement protocols such as rheometry, stress relaxation, and creep testing, vitrimers can be designed to maintain structural integrity through multiple reprocessing cycles. This directly reduces waste generation and resource consumption associated with traditional single-use polymers.

Energy consumption during vitrimer recycling presents another critical environmental consideration. The dynamic covalent bonds that characterize vitrimers typically require less energy for reprocessing compared to mechanical recycling of conventional thermoplastics or the energy-intensive breakdown of thermosets. Precise measurement of activation energies for bond exchange reactions through temperature-dependent rheological studies enables the development of more energy-efficient recycling protocols.

Carbon footprint analyses of vitrimer materials indicate potential reductions in greenhouse gas emissions when compared to traditional polymer life cycles. This advantage stems from both reduced production requirements for virgin materials and lower energy demands during reprocessing. The quantification of stress relaxation times at various temperatures provides valuable data for optimizing processing conditions to minimize environmental impact.

Water usage and chemical emissions during vitrimer production and recycling must also be considered in comprehensive environmental assessments. Current research indicates that many vitrimer systems require fewer hazardous solvents during recycling compared to chemical recycling approaches for conventional polymers. The measurement protocols for bond exchange rates can be adapted to evaluate the environmental persistence of any catalysts or additives used in vitrimer formulations.

Biodegradability remains a challenge for most vitrimer materials, as the robust covalent network, even with dynamic bonds, typically resists environmental degradation. However, emerging research incorporating bio-based precursors and environmentally responsive bond exchange mechanisms shows promise for developing vitrimers with controlled end-of-life scenarios. Creep protocols are particularly valuable for predicting long-term environmental stability and potential microplastic formation.

The integration of vitrimers into circular economy frameworks represents perhaps their greatest sustainability contribution. By enabling multiple use cycles without the property degradation typical of recycled conventional polymers, vitrimers could significantly reduce the environmental burden of polymer materials across numerous industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!