In-Situ FTIR Versus Raman Monitoring Of Exchange Reactions During Reprocessing

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spectroscopic Monitoring Background and Objectives

Spectroscopic monitoring techniques have evolved significantly over the past decades, becoming essential tools for real-time analysis of chemical reactions in various industrial processes. In-situ Fourier Transform Infrared (FTIR) and Raman spectroscopy represent two of the most powerful analytical methods for monitoring exchange reactions during reprocessing operations, particularly in polymer recycling, catalytic conversions, and pharmaceutical manufacturing.

The historical development of these spectroscopic techniques dates back to the mid-20th century, with significant advancements occurring in the 1980s when computerization enabled more sophisticated data processing. The integration of fiber optics in the 1990s further revolutionized these technologies, allowing for remote sensing capabilities and true in-situ applications in challenging industrial environments.

Current technological trends indicate a growing preference for non-invasive monitoring solutions that can provide real-time data without disrupting the reaction process. This shift is driven by increasing demands for process efficiency, quality control, and regulatory compliance across industries. The ability to monitor exchange reactions during reprocessing has become particularly critical as circular economy initiatives gain momentum globally.

The primary objective of implementing spectroscopic monitoring in reprocessing operations is to enhance process understanding and control through real-time chemical information. Specifically, these technologies aim to identify reaction intermediates, determine reaction endpoints, monitor impurity formation, and optimize reaction conditions without sampling or process interruption.

Both FTIR and Raman spectroscopy offer unique advantages for monitoring exchange reactions. FTIR excels at identifying functional group transformations and quantifying concentration changes, while Raman provides superior performance in aqueous environments and offers better spatial resolution. The complementary nature of these techniques suggests potential benefits in combined or hybrid approaches.

This technical research aims to comprehensively evaluate the comparative advantages, limitations, and applications of in-situ FTIR versus Raman spectroscopy for monitoring exchange reactions during reprocessing. The assessment will consider factors such as sensitivity, selectivity, sampling interfaces, data processing requirements, and implementation challenges in industrial settings.

Furthermore, this investigation seeks to identify emerging technological innovations that may enhance the capabilities of these spectroscopic methods, including advances in miniaturization, multivariate data analysis, machine learning integration, and the development of more robust sampling interfaces for harsh processing environments.

The historical development of these spectroscopic techniques dates back to the mid-20th century, with significant advancements occurring in the 1980s when computerization enabled more sophisticated data processing. The integration of fiber optics in the 1990s further revolutionized these technologies, allowing for remote sensing capabilities and true in-situ applications in challenging industrial environments.

Current technological trends indicate a growing preference for non-invasive monitoring solutions that can provide real-time data without disrupting the reaction process. This shift is driven by increasing demands for process efficiency, quality control, and regulatory compliance across industries. The ability to monitor exchange reactions during reprocessing has become particularly critical as circular economy initiatives gain momentum globally.

The primary objective of implementing spectroscopic monitoring in reprocessing operations is to enhance process understanding and control through real-time chemical information. Specifically, these technologies aim to identify reaction intermediates, determine reaction endpoints, monitor impurity formation, and optimize reaction conditions without sampling or process interruption.

Both FTIR and Raman spectroscopy offer unique advantages for monitoring exchange reactions. FTIR excels at identifying functional group transformations and quantifying concentration changes, while Raman provides superior performance in aqueous environments and offers better spatial resolution. The complementary nature of these techniques suggests potential benefits in combined or hybrid approaches.

This technical research aims to comprehensively evaluate the comparative advantages, limitations, and applications of in-situ FTIR versus Raman spectroscopy for monitoring exchange reactions during reprocessing. The assessment will consider factors such as sensitivity, selectivity, sampling interfaces, data processing requirements, and implementation challenges in industrial settings.

Furthermore, this investigation seeks to identify emerging technological innovations that may enhance the capabilities of these spectroscopic methods, including advances in miniaturization, multivariate data analysis, machine learning integration, and the development of more robust sampling interfaces for harsh processing environments.

Market Analysis for Reprocessing Monitoring Technologies

The market for reprocessing monitoring technologies, particularly those utilizing in-situ FTIR and Raman spectroscopy, has experienced significant growth over the past decade. This expansion is primarily driven by increasing industrial demands for real-time process control and quality assurance in polymer recycling, chemical manufacturing, and pharmaceutical production.

Current market valuations place the global process analytical technology sector at approximately $3.5 billion, with spectroscopic monitoring technologies accounting for roughly 35% of this market. Within this segment, Raman and FTIR technologies collectively represent a market share of about 42%, demonstrating their critical importance in industrial applications.

The demand for in-situ monitoring technologies is particularly strong in regions with stringent environmental regulations, such as Western Europe and North America, where manufacturers face increasing pressure to optimize resource efficiency and minimize waste. The Asia-Pacific region, especially China and India, represents the fastest-growing market due to rapid industrialization and increasing adoption of advanced manufacturing technologies.

Key market drivers include the growing emphasis on circular economy principles, which necessitate efficient reprocessing technologies, and the increasing complexity of polymer formulations requiring precise monitoring during recycling processes. Additionally, regulatory requirements for product quality and process validation in pharmaceutical and chemical industries have significantly boosted demand for real-time analytical tools.

Market segmentation reveals that pharmaceutical applications currently dominate the use of these technologies at 38% market share, followed by polymer processing at 27%, and chemical manufacturing at 22%. The remaining 13% encompasses various applications including food processing and environmental monitoring.

Customer needs analysis indicates a strong preference for systems offering high sensitivity, reliability in challenging industrial environments, and seamless integration with existing production infrastructure. Price sensitivity varies significantly across sectors, with pharmaceutical companies willing to invest in premium solutions while polymer recycling operations typically seeking more cost-effective options.

The market forecast projects a compound annual growth rate of 8.7% for in-situ monitoring technologies over the next five years, with particularly strong growth in applications related to sustainable manufacturing and circular economy initiatives. This growth trajectory is supported by increasing investments in Industry 4.0 technologies and the integration of artificial intelligence with spectroscopic monitoring systems to enhance predictive capabilities and process optimization.

Current market valuations place the global process analytical technology sector at approximately $3.5 billion, with spectroscopic monitoring technologies accounting for roughly 35% of this market. Within this segment, Raman and FTIR technologies collectively represent a market share of about 42%, demonstrating their critical importance in industrial applications.

The demand for in-situ monitoring technologies is particularly strong in regions with stringent environmental regulations, such as Western Europe and North America, where manufacturers face increasing pressure to optimize resource efficiency and minimize waste. The Asia-Pacific region, especially China and India, represents the fastest-growing market due to rapid industrialization and increasing adoption of advanced manufacturing technologies.

Key market drivers include the growing emphasis on circular economy principles, which necessitate efficient reprocessing technologies, and the increasing complexity of polymer formulations requiring precise monitoring during recycling processes. Additionally, regulatory requirements for product quality and process validation in pharmaceutical and chemical industries have significantly boosted demand for real-time analytical tools.

Market segmentation reveals that pharmaceutical applications currently dominate the use of these technologies at 38% market share, followed by polymer processing at 27%, and chemical manufacturing at 22%. The remaining 13% encompasses various applications including food processing and environmental monitoring.

Customer needs analysis indicates a strong preference for systems offering high sensitivity, reliability in challenging industrial environments, and seamless integration with existing production infrastructure. Price sensitivity varies significantly across sectors, with pharmaceutical companies willing to invest in premium solutions while polymer recycling operations typically seeking more cost-effective options.

The market forecast projects a compound annual growth rate of 8.7% for in-situ monitoring technologies over the next five years, with particularly strong growth in applications related to sustainable manufacturing and circular economy initiatives. This growth trajectory is supported by increasing investments in Industry 4.0 technologies and the integration of artificial intelligence with spectroscopic monitoring systems to enhance predictive capabilities and process optimization.

Current Challenges in Exchange Reaction Monitoring

Exchange reaction monitoring during reprocessing presents several significant challenges that impede efficient and accurate analysis. The primary difficulty lies in the real-time tracking of dynamic chemical transformations occurring within complex reaction environments. Both In-Situ FTIR and Raman spectroscopy techniques, while powerful, encounter substantial obstacles when applied to these monitoring scenarios.

Signal interference represents a major challenge, particularly in industrial reprocessing environments where multiple chemical species coexist. Overlapping spectral bands frequently obscure critical reaction signatures, making precise quantification of exchange reaction progress problematic. This issue is especially pronounced in polymer reprocessing applications where similar functional groups produce comparable spectral features.

Temperature stability poses another considerable challenge. Exchange reactions often require elevated temperatures that can affect instrument performance and spectral quality. Thermal expansion of optical components in both FTIR and Raman systems can lead to signal drift and reduced measurement precision. Additionally, temperature gradients within reaction vessels create heterogeneous reaction environments that complicate representative sampling.

Sampling depth limitations present technical barriers specific to each monitoring method. FTIR typically provides surface-level information, while Raman can penetrate deeper into samples but suffers from fluorescence interference in certain materials. This creates a fundamental trade-off between measurement depth and signal quality that researchers must navigate based on specific reaction requirements.

Calibration complexity represents a persistent challenge, as exchange reactions often involve changing material properties throughout the reprocessing cycle. Developing robust calibration models that remain accurate across varying reaction conditions requires extensive reference data and sophisticated chemometric approaches. Current calibration methods often fail to account for the non-linear behavior exhibited during complex exchange reactions.

Time resolution constraints limit the ability to capture rapid reaction kinetics, particularly during critical transition phases. Most commercial systems struggle to achieve sub-second temporal resolution while maintaining adequate signal-to-noise ratios. This limitation becomes particularly problematic when monitoring reactions with multiple mechanistic steps occurring at different rates.

Data interpretation challenges stem from the massive datasets generated during continuous monitoring. Extracting meaningful reaction parameters from spectral time series requires advanced chemometric algorithms and domain expertise. Current automated analysis approaches often fail to distinguish between actual reaction events and instrumental artifacts, necessitating time-consuming manual verification.

Signal interference represents a major challenge, particularly in industrial reprocessing environments where multiple chemical species coexist. Overlapping spectral bands frequently obscure critical reaction signatures, making precise quantification of exchange reaction progress problematic. This issue is especially pronounced in polymer reprocessing applications where similar functional groups produce comparable spectral features.

Temperature stability poses another considerable challenge. Exchange reactions often require elevated temperatures that can affect instrument performance and spectral quality. Thermal expansion of optical components in both FTIR and Raman systems can lead to signal drift and reduced measurement precision. Additionally, temperature gradients within reaction vessels create heterogeneous reaction environments that complicate representative sampling.

Sampling depth limitations present technical barriers specific to each monitoring method. FTIR typically provides surface-level information, while Raman can penetrate deeper into samples but suffers from fluorescence interference in certain materials. This creates a fundamental trade-off between measurement depth and signal quality that researchers must navigate based on specific reaction requirements.

Calibration complexity represents a persistent challenge, as exchange reactions often involve changing material properties throughout the reprocessing cycle. Developing robust calibration models that remain accurate across varying reaction conditions requires extensive reference data and sophisticated chemometric approaches. Current calibration methods often fail to account for the non-linear behavior exhibited during complex exchange reactions.

Time resolution constraints limit the ability to capture rapid reaction kinetics, particularly during critical transition phases. Most commercial systems struggle to achieve sub-second temporal resolution while maintaining adequate signal-to-noise ratios. This limitation becomes particularly problematic when monitoring reactions with multiple mechanistic steps occurring at different rates.

Data interpretation challenges stem from the massive datasets generated during continuous monitoring. Extracting meaningful reaction parameters from spectral time series requires advanced chemometric algorithms and domain expertise. Current automated analysis approaches often fail to distinguish between actual reaction events and instrumental artifacts, necessitating time-consuming manual verification.

Comparative Analysis of FTIR and Raman Technologies

01 In-situ FTIR and Raman spectroscopy for reaction monitoring

In-situ FTIR and Raman spectroscopy techniques are used for real-time monitoring of chemical reactions, allowing researchers to observe changes in molecular structures and reaction kinetics without sampling. These spectroscopic methods provide valuable insights into reaction mechanisms, intermediates, and endpoints, enabling better process control and optimization in various chemical processes.- In-situ FTIR and Raman spectroscopy for reaction monitoring: In-situ FTIR and Raman spectroscopy techniques are used for real-time monitoring of chemical reactions, allowing researchers to observe changes in molecular structures during reaction processes. These spectroscopic methods provide valuable information about reaction kinetics, intermediates, and mechanisms without disturbing the reaction environment. The integration of these techniques enables comprehensive analysis of complex chemical transformations and helps optimize reaction conditions.

- Combined spectroscopic systems for enhanced process monitoring: Combined spectroscopic systems that integrate FTIR and Raman technologies offer complementary analytical capabilities for comprehensive process monitoring. These hybrid systems provide more complete molecular information than either technique alone, enabling simultaneous detection of various chemical species and physical parameters. Such integrated approaches are particularly valuable in industrial settings where multiple process variables need to be monitored simultaneously for quality control and process optimization.

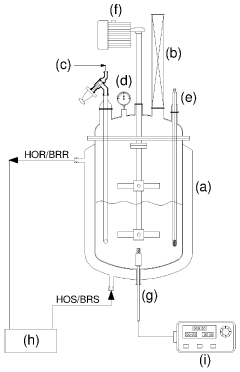

- Probe designs for in-situ spectroscopic measurements: Specialized probe designs enable effective in-situ FTIR and Raman spectroscopic measurements in challenging environments. These probes feature optimized optical configurations, robust materials for harsh conditions, and innovative sampling interfaces. Advanced probe technologies allow for non-invasive monitoring in high-pressure, high-temperature, or chemically aggressive environments while maintaining measurement accuracy and reliability.

- Real-time process control using spectroscopic data: Real-time process control systems utilize data from in-situ FTIR and Raman spectroscopy to enable automated adjustments of process parameters. These systems incorporate advanced algorithms for spectral analysis, feature extraction, and multivariate statistical methods to convert spectroscopic signals into actionable process information. The integration of spectroscopic monitoring with control systems allows for rapid detection of deviations and immediate corrective actions, improving product quality and process efficiency.

- Applications in pharmaceutical and biomedical monitoring: In-situ FTIR and Raman spectroscopy techniques are increasingly applied in pharmaceutical manufacturing and biomedical monitoring. These methods enable real-time analysis of drug formulation processes, crystallization monitoring, polymorph detection, and quality control. In biomedical applications, these spectroscopic techniques provide non-invasive monitoring of biological processes, tissue characterization, and disease diagnostics through molecular fingerprinting of biological samples.

02 Combined spectroscopic techniques for enhanced monitoring capabilities

The integration of multiple spectroscopic techniques, particularly combining FTIR with Raman spectroscopy, creates complementary analytical capabilities for comprehensive in-situ monitoring. This approach provides more complete molecular information as FTIR detects polar bond vibrations while Raman is sensitive to symmetric vibrations, allowing for more accurate characterization of complex systems and reaction environments.Expand Specific Solutions03 In-situ spectroscopy for industrial process monitoring and control

In-situ FTIR and Raman spectroscopy systems are implemented in industrial settings for continuous process monitoring and quality control. These technologies enable real-time analysis of manufacturing processes, allowing for immediate detection of deviations, optimization of production parameters, and ensuring consistent product quality across various industries including pharmaceuticals, polymers, and petrochemicals.Expand Specific Solutions04 Advanced probe designs and sampling interfaces for in-situ spectroscopy

Specialized probe designs and sampling interfaces have been developed to facilitate in-situ spectroscopic measurements in challenging environments. These innovations include fiber-optic probes, flow cells, high-pressure/high-temperature sampling systems, and immersion probes that can withstand harsh conditions while maintaining optical performance for accurate spectroscopic monitoring of reactions and processes.Expand Specific Solutions05 Data analysis and chemometric methods for spectroscopic monitoring

Advanced data analysis techniques and chemometric methods are applied to in-situ FTIR and Raman spectroscopic data to extract meaningful information from complex spectra. These approaches include multivariate analysis, machine learning algorithms, and automated pattern recognition that enable quantitative analysis, component identification, and prediction of reaction endpoints from spectroscopic measurements in real-time monitoring applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The in-situ FTIR versus Raman monitoring of exchange reactions during reprocessing represents an emerging technological field currently in its growth phase. The market is expanding steadily with an estimated global value of $300-400 million, driven by increasing demand for real-time analytical techniques in chemical processing. While both technologies are maturing, they remain specialized with varying adoption rates across industries. Leading companies like BASF Corp. and Amgen demonstrate advanced implementation in pharmaceutical and chemical manufacturing, while academic institutions including Xiamen University and Monash University are pushing research boundaries. Technological development is being accelerated through collaborations between industry players such as Shell Oil Co. and Dow Global Technologies with research institutions like Dalian Institute of Chemical Physics, creating a competitive landscape where specialized expertise and proprietary methodologies determine market positioning.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: Dalian Institute of Chemical Physics (DICP) has developed advanced in-situ FTIR and Raman spectroscopy systems specifically designed for monitoring exchange reactions during polymer reprocessing. Their approach combines operando spectroscopy with microfluidic reactors to enable real-time monitoring of chemical transformations at the molecular level. DICP's technology utilizes temperature-controlled reaction cells with diamond ATR crystals for FTIR and specialized probe designs for Raman that can withstand harsh chemical environments. Their system incorporates multivariate data analysis algorithms to deconvolute complex spectral information, allowing researchers to track reaction kinetics, identify intermediates, and optimize reprocessing conditions. The institute has demonstrated particular success in monitoring transesterification reactions in polyesters and dynamic covalent exchange in vitrimers, achieving detection sensitivity down to 0.1% concentration changes in functional groups.

Strengths: Superior temporal resolution for capturing fast reaction dynamics; excellent chemical resistance for monitoring corrosive environments; integrated data processing capabilities for real-time analysis. Weaknesses: Higher implementation cost compared to offline methods; requires specialized expertise for operation and data interpretation; limited spatial resolution compared to some imaging techniques.

Pendar Technologies, LLC

Technical Solution: Pendar Technologies has developed a revolutionary approach to monitoring exchange reactions during polymer reprocessing through their proprietary Molecular Property Spectrometer (MPS) platform. This technology integrates both FTIR and Raman capabilities into a single, compact instrument specifically designed for in-situ monitoring of chemical transformations. Their system employs quantum cascade laser (QCL) technology for mid-IR spectroscopy, providing significantly higher signal-to-noise ratios compared to conventional FTIR systems, while simultaneously collecting Raman data using a specialized excitation source that minimizes fluorescence interference. The MPS platform features a unique sampling interface that can be directly integrated into extruders and reactors, allowing for real-time monitoring without disrupting the reprocessing operation. Pendar's system incorporates advanced machine learning algorithms that can identify subtle spectral changes indicative of exchange reactions, even in complex polymer matrices with overlapping signals. The technology has demonstrated particular success in monitoring transesterification reactions in polyesters and dynamic covalent exchange in vitrimers, providing crucial insights into reaction kinetics and mechanisms.

Strengths: Exceptional sensitivity for detecting low-concentration species; compact design allows for easy integration into existing equipment; advanced data processing capabilities for complex reaction monitoring. Weaknesses: Higher initial cost compared to single-technique systems; requires periodic recalibration for optimal performance; limited track record in certain polymer systems compared to established techniques.

Key Patents and Innovations in Spectroscopic Monitoring

An improved process for the manufacture of aromatic ketones

PatentActiveIN201611025819A

Innovation

- A process utilizing acetyl fluoride as an acylating agent in the presence of anhydrous hydrofluoric acid as a catalyst, with real-time monitoring by FTIR to achieve high purity aromatic ketones, employing mild conditions and continuous stirring, and using dispersants like stearic acid to enhance reaction efficiency and selectivity.

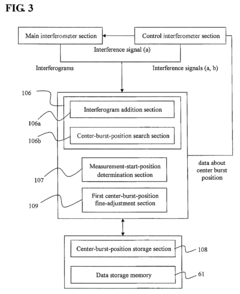

Fourier transform infrared spectrophotometer

PatentInactiveUS7535004B2

Innovation

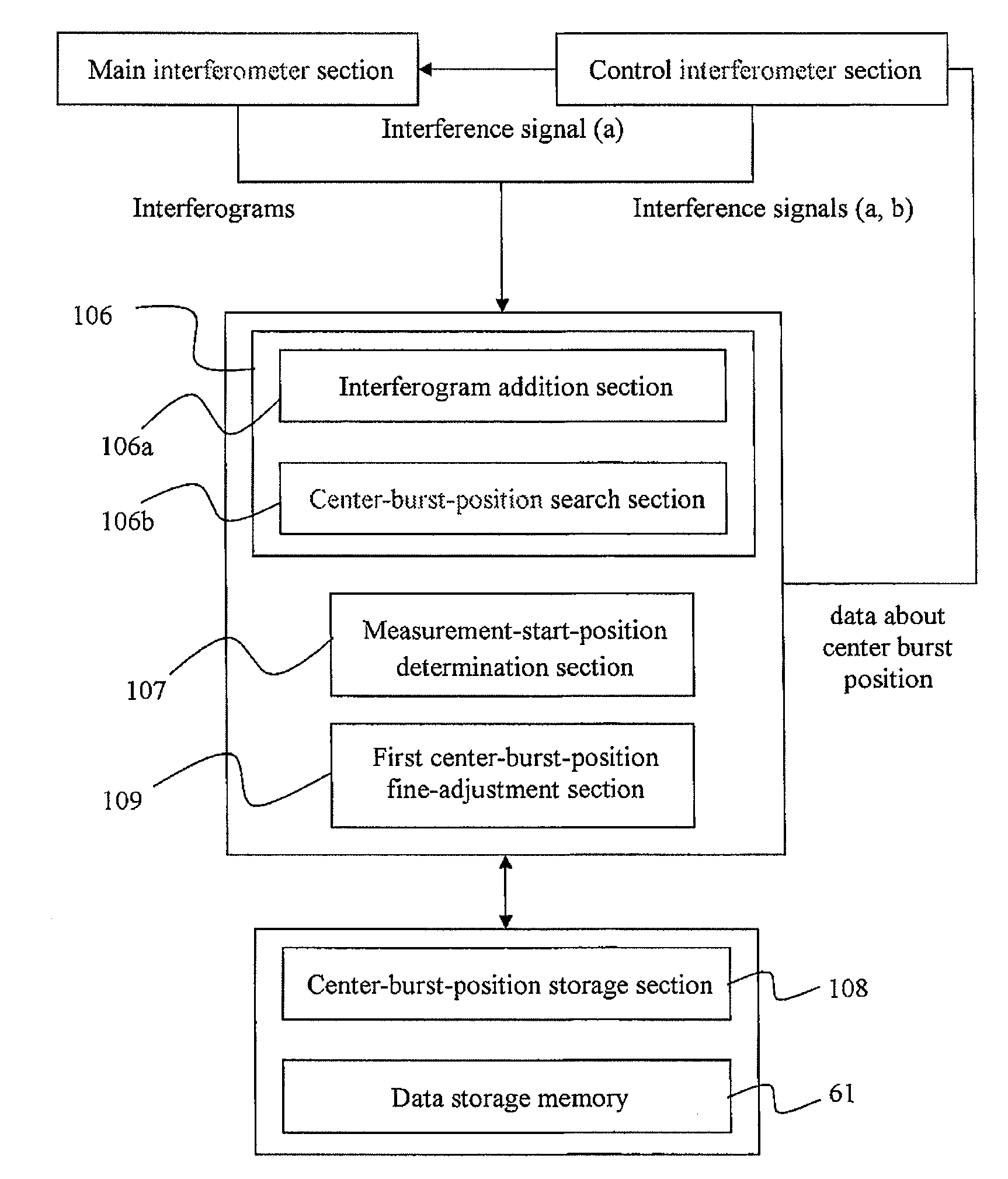

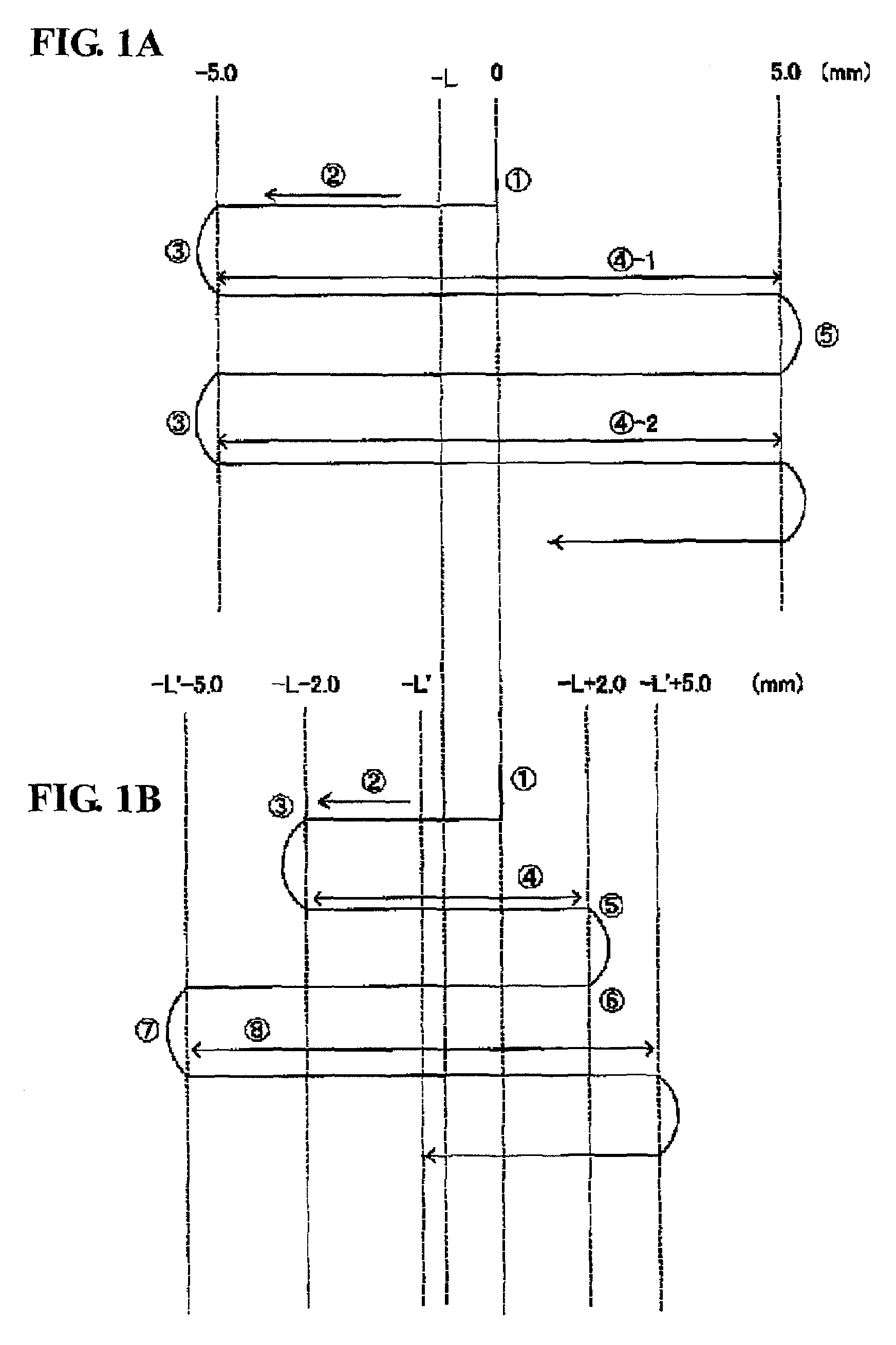

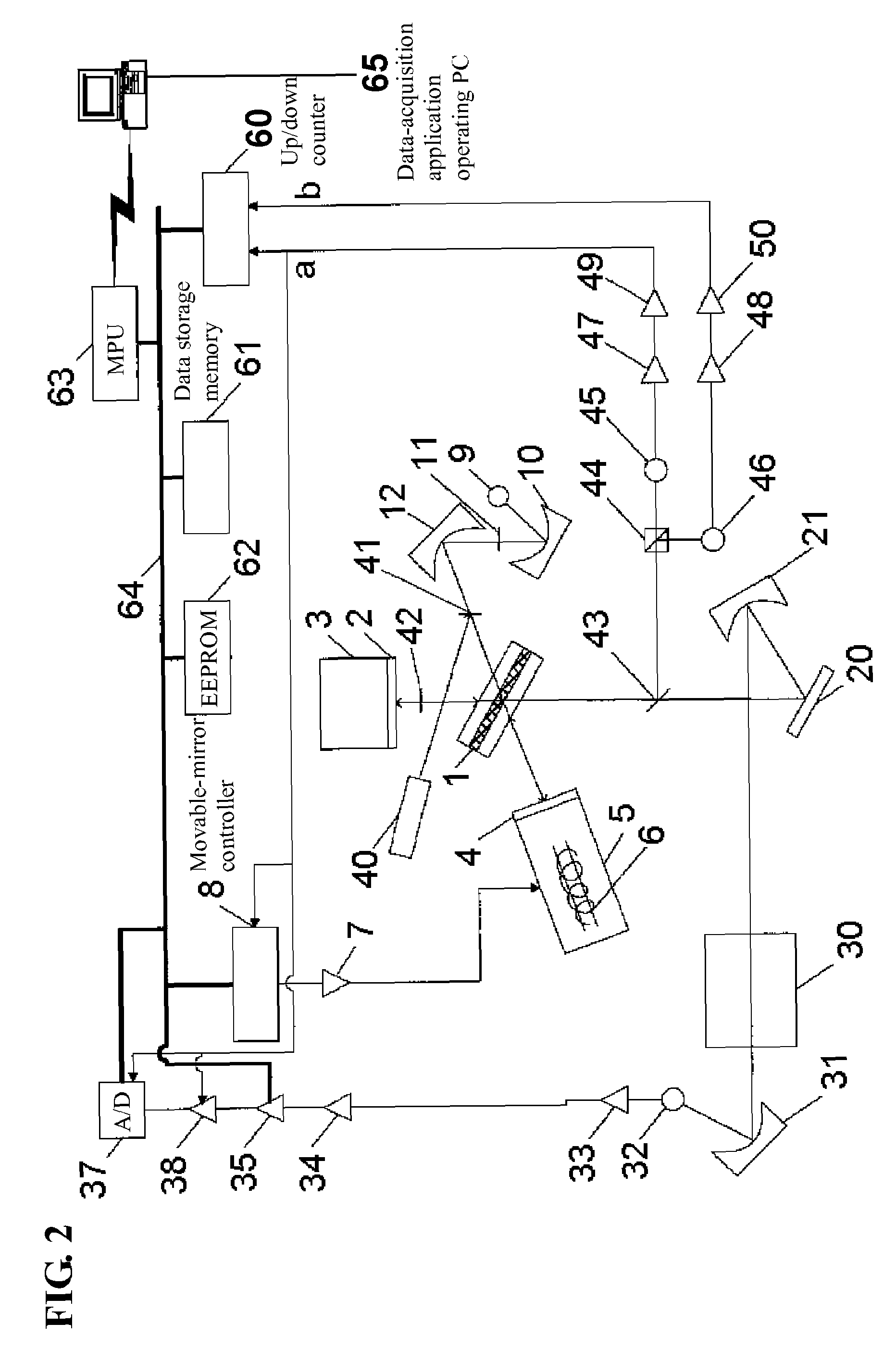

- The implementation of a center-burst-position detection section that performs addition processing on interferogram intensities to produce a cumulative interferogram, correcting positional deviations and enhancing the detection of the center burst position by increasing the intensity of true peaks while canceling out noise peaks, thereby ensuring accurate detection even under low light conditions.

Environmental Impact and Sustainability Considerations

The environmental impact of analytical techniques used in reprocessing exchange reactions represents a critical consideration in sustainable chemistry practices. In-situ FTIR and Raman monitoring technologies offer significant advantages over traditional analytical methods by reducing waste generation and energy consumption. These spectroscopic techniques enable real-time analysis without requiring sample extraction or preparation, thereby eliminating the need for solvents and reagents typically associated with conventional analytical procedures.

When comparing the environmental footprints of FTIR and Raman technologies, several factors merit consideration. FTIR systems generally consume more energy due to their requirement for continuous infrared source operation and temperature control mechanisms. Conversely, Raman systems utilizing laser technology have become increasingly energy-efficient with the development of low-power diode lasers, though older systems with high-powered lasers may still present higher energy demands.

The lifecycle assessment of both technologies reveals important sustainability differences. FTIR components, particularly infrared sources and optical elements, often contain rare earth materials with significant extraction impacts. Raman systems, while requiring specialized optical components and detector assemblies, generally incorporate fewer environmentally problematic materials. Both technologies, however, represent substantial improvements over traditional analytical methods requiring extensive chemical usage.

Maintenance requirements also factor into environmental considerations. FTIR systems typically require more frequent replacement of desiccants and purge gases to maintain optical path integrity, while Raman systems generally demand less consumable replacement but may require periodic laser source replacement. The extended operational lifetime of modern spectroscopic equipment mitigates manufacturing impacts through reduced replacement frequency.

Integration of these monitoring technologies into reprocessing workflows delivers substantial sustainability benefits through process optimization. Real-time monitoring enables precise reaction endpoint determination, reducing energy consumption from unnecessary heating or mixing operations. Additionally, the ability to detect side reactions or impurities early prevents batch failures that would otherwise generate significant waste streams requiring disposal.

Recent innovations have further enhanced the environmental profile of both technologies. Miniaturized systems with reduced material requirements, fiber-optic probes allowing single-instrument monitoring of multiple reaction vessels, and integration with automated control systems for optimized resource utilization represent significant advances. These developments align with green chemistry principles by minimizing resource consumption while maximizing information yield from chemical processes.

When comparing the environmental footprints of FTIR and Raman technologies, several factors merit consideration. FTIR systems generally consume more energy due to their requirement for continuous infrared source operation and temperature control mechanisms. Conversely, Raman systems utilizing laser technology have become increasingly energy-efficient with the development of low-power diode lasers, though older systems with high-powered lasers may still present higher energy demands.

The lifecycle assessment of both technologies reveals important sustainability differences. FTIR components, particularly infrared sources and optical elements, often contain rare earth materials with significant extraction impacts. Raman systems, while requiring specialized optical components and detector assemblies, generally incorporate fewer environmentally problematic materials. Both technologies, however, represent substantial improvements over traditional analytical methods requiring extensive chemical usage.

Maintenance requirements also factor into environmental considerations. FTIR systems typically require more frequent replacement of desiccants and purge gases to maintain optical path integrity, while Raman systems generally demand less consumable replacement but may require periodic laser source replacement. The extended operational lifetime of modern spectroscopic equipment mitigates manufacturing impacts through reduced replacement frequency.

Integration of these monitoring technologies into reprocessing workflows delivers substantial sustainability benefits through process optimization. Real-time monitoring enables precise reaction endpoint determination, reducing energy consumption from unnecessary heating or mixing operations. Additionally, the ability to detect side reactions or impurities early prevents batch failures that would otherwise generate significant waste streams requiring disposal.

Recent innovations have further enhanced the environmental profile of both technologies. Miniaturized systems with reduced material requirements, fiber-optic probes allowing single-instrument monitoring of multiple reaction vessels, and integration with automated control systems for optimized resource utilization represent significant advances. These developments align with green chemistry principles by minimizing resource consumption while maximizing information yield from chemical processes.

Data Processing and Machine Learning Applications

The integration of advanced data processing and machine learning techniques has revolutionized the analysis of spectroscopic data obtained from in-situ FTIR and Raman monitoring during reprocessing exchange reactions. Traditional spectral analysis methods often struggle with the complexity and volume of data generated during these dynamic chemical processes, creating a significant bottleneck in real-time monitoring applications.

Machine learning algorithms, particularly those based on multivariate analysis such as Principal Component Analysis (PCA) and Partial Least Squares (PLS), have demonstrated remarkable efficiency in extracting meaningful patterns from spectroscopic data. These techniques enable the identification of subtle spectral changes that might be imperceptible through conventional analysis methods, thereby enhancing the detection sensitivity of reaction intermediates and transition states during exchange reactions.

Deep learning approaches, including Convolutional Neural Networks (CNNs) and Recurrent Neural Networks (RNNs), have shown particular promise in processing time-resolved spectral data. These models can effectively capture the temporal evolution of spectral features during reprocessing, providing insights into reaction kinetics and mechanisms with unprecedented detail. The ability to predict reaction outcomes based on early spectral signatures represents a significant advancement in process optimization.

Automated baseline correction and noise reduction algorithms have substantially improved the quality of spectral data obtained from both FTIR and Raman techniques. These preprocessing steps are crucial for ensuring the reliability of subsequent machine learning analyses, particularly in industrial environments where signal-to-noise ratios may be compromised by various factors.

Transfer learning methodologies have emerged as valuable tools for addressing the challenge of limited training data in specialized chemical processes. By leveraging models pre-trained on large spectroscopic datasets, researchers can develop effective analytical tools with relatively small amounts of process-specific data, accelerating the deployment of monitoring solutions in new reprocessing applications.

Real-time data processing frameworks that combine edge computing with cloud-based analytics have enabled the implementation of in-line monitoring systems capable of providing immediate feedback during reprocessing operations. These systems can trigger automated process adjustments based on spectral indicators, moving beyond passive monitoring to active process control.

The integration of chemometric methods with physical models has created hybrid analytical approaches that balance data-driven insights with fundamental chemical principles. This synergistic combination enhances the interpretability of machine learning outputs, addressing the "black box" concerns often associated with pure data-driven methods in critical chemical manufacturing processes.

Machine learning algorithms, particularly those based on multivariate analysis such as Principal Component Analysis (PCA) and Partial Least Squares (PLS), have demonstrated remarkable efficiency in extracting meaningful patterns from spectroscopic data. These techniques enable the identification of subtle spectral changes that might be imperceptible through conventional analysis methods, thereby enhancing the detection sensitivity of reaction intermediates and transition states during exchange reactions.

Deep learning approaches, including Convolutional Neural Networks (CNNs) and Recurrent Neural Networks (RNNs), have shown particular promise in processing time-resolved spectral data. These models can effectively capture the temporal evolution of spectral features during reprocessing, providing insights into reaction kinetics and mechanisms with unprecedented detail. The ability to predict reaction outcomes based on early spectral signatures represents a significant advancement in process optimization.

Automated baseline correction and noise reduction algorithms have substantially improved the quality of spectral data obtained from both FTIR and Raman techniques. These preprocessing steps are crucial for ensuring the reliability of subsequent machine learning analyses, particularly in industrial environments where signal-to-noise ratios may be compromised by various factors.

Transfer learning methodologies have emerged as valuable tools for addressing the challenge of limited training data in specialized chemical processes. By leveraging models pre-trained on large spectroscopic datasets, researchers can develop effective analytical tools with relatively small amounts of process-specific data, accelerating the deployment of monitoring solutions in new reprocessing applications.

Real-time data processing frameworks that combine edge computing with cloud-based analytics have enabled the implementation of in-line monitoring systems capable of providing immediate feedback during reprocessing operations. These systems can trigger automated process adjustments based on spectral indicators, moving beyond passive monitoring to active process control.

The integration of chemometric methods with physical models has created hybrid analytical approaches that balance data-driven insights with fundamental chemical principles. This synergistic combination enhances the interpretability of machine learning outputs, addressing the "black box" concerns often associated with pure data-driven methods in critical chemical manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!