Microphase Separation In Vitrimer Networks: SAXS/WAXS Characterization Approaches

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vitrimer Networks Microphase Separation Background and Objectives

Vitrimer networks represent a revolutionary class of polymer materials that combine the processability of thermoplastics with the mechanical robustness of thermosets. The concept was first introduced by Leibler and colleagues in 2011, marking a significant milestone in polymer science. These materials feature dynamic covalent bonds that enable network rearrangement while maintaining structural integrity, offering unprecedented opportunities for recyclable and self-healing materials.

Microphase separation within vitrimer networks has emerged as a critical phenomenon influencing their performance characteristics. This phenomenon occurs when chemically distinct segments within the polymer network segregate into nanoscale domains, creating heterogeneous morphologies that significantly impact mechanical, thermal, and optical properties. Understanding and controlling this separation process represents a frontier in advanced materials development.

The evolution of vitrimer technology has accelerated over the past decade, with research expanding from simple proof-of-concept systems to complex architectures with tailored functionalities. This progression has been driven by increasing demands for sustainable materials with enhanced performance profiles across industries including automotive, aerospace, electronics, and healthcare sectors.

X-ray scattering techniques, particularly Small-Angle X-ray Scattering (SAXS) and Wide-Angle X-ray Scattering (WAXS), have emerged as indispensable tools for characterizing microphase separation in these complex networks. These non-destructive methods provide critical insights into domain sizes, shapes, orientations, and spatial arrangements across multiple length scales, from angstroms to hundreds of nanometers.

The primary objective of this technical investigation is to comprehensively evaluate current SAXS/WAXS methodologies for characterizing microphase separation in vitrimer networks. We aim to identify optimal experimental protocols, data analysis approaches, and interpretation frameworks that yield reliable structural information across diverse vitrimer compositions and processing conditions.

Additionally, this research seeks to establish correlations between microphase morphology and macroscopic properties, potentially enabling predictive capabilities for rational material design. By mapping the relationship between network chemistry, processing parameters, and resultant microphase structures, we anticipate developing design principles for next-generation vitrimers with precisely engineered performance profiles.

Furthermore, this investigation aims to identify technological gaps in current characterization approaches and propose innovative solutions to address these limitations. This includes exploring complementary techniques, developing new sample preparation methods, and advancing data analysis algorithms specifically optimized for vitrimer systems.

Microphase separation within vitrimer networks has emerged as a critical phenomenon influencing their performance characteristics. This phenomenon occurs when chemically distinct segments within the polymer network segregate into nanoscale domains, creating heterogeneous morphologies that significantly impact mechanical, thermal, and optical properties. Understanding and controlling this separation process represents a frontier in advanced materials development.

The evolution of vitrimer technology has accelerated over the past decade, with research expanding from simple proof-of-concept systems to complex architectures with tailored functionalities. This progression has been driven by increasing demands for sustainable materials with enhanced performance profiles across industries including automotive, aerospace, electronics, and healthcare sectors.

X-ray scattering techniques, particularly Small-Angle X-ray Scattering (SAXS) and Wide-Angle X-ray Scattering (WAXS), have emerged as indispensable tools for characterizing microphase separation in these complex networks. These non-destructive methods provide critical insights into domain sizes, shapes, orientations, and spatial arrangements across multiple length scales, from angstroms to hundreds of nanometers.

The primary objective of this technical investigation is to comprehensively evaluate current SAXS/WAXS methodologies for characterizing microphase separation in vitrimer networks. We aim to identify optimal experimental protocols, data analysis approaches, and interpretation frameworks that yield reliable structural information across diverse vitrimer compositions and processing conditions.

Additionally, this research seeks to establish correlations between microphase morphology and macroscopic properties, potentially enabling predictive capabilities for rational material design. By mapping the relationship between network chemistry, processing parameters, and resultant microphase structures, we anticipate developing design principles for next-generation vitrimers with precisely engineered performance profiles.

Furthermore, this investigation aims to identify technological gaps in current characterization approaches and propose innovative solutions to address these limitations. This includes exploring complementary techniques, developing new sample preparation methods, and advancing data analysis algorithms specifically optimized for vitrimer systems.

Market Applications and Demand for Vitrimer Materials

Vitrimer materials represent a revolutionary class of polymers that combine the processability of thermoplastics with the mechanical robustness of thermosets, creating significant market opportunities across multiple industries. The ability to understand and control microphase separation in these networks through advanced characterization techniques like SAXS/WAXS is driving increased commercial interest.

The automotive sector shows substantial demand for vitrimer materials, particularly in lightweight components that can reduce vehicle weight and improve fuel efficiency. Market analysts project that vitrimers could replace up to 15% of conventional automotive plastics in the next decade, especially in applications requiring both heat resistance and recyclability. The self-healing properties enabled by controlled microphase separation make these materials particularly valuable for parts exposed to repeated stress and environmental factors.

Aerospace applications represent another high-value market, where the temperature-resistant properties and structural integrity of vitrimers offer significant advantages. The ability to precisely engineer microphase separation allows for customized mechanical responses under different conditions, critical for components experiencing extreme temperature variations and mechanical stresses during flight operations.

The electronics industry is increasingly adopting vitrimer materials for flexible electronics, circuit boards, and protective casings. The controlled microphase separation provides unique combinations of electrical insulation, thermal management, and mechanical flexibility. This market segment is experiencing rapid growth as consumer electronics continue to demand more durable yet lightweight materials.

Medical device manufacturing represents an emerging application area with stringent requirements for biocompatibility and sterilization resistance. Vitrimers with well-characterized microphase separation can be engineered to provide specific biological responses while maintaining structural integrity through multiple sterilization cycles. The market for medical-grade vitrimers is expected to grow significantly as regulatory pathways become established.

Sustainable packaging solutions represent a volume-driven market opportunity, where the recyclability of vitrimers addresses growing consumer and regulatory pressure for environmentally responsible materials. Companies developing food-contact approved vitrimers with controlled microphase separation are positioning themselves to capture market share from conventional single-use plastics.

Construction materials incorporating vitrimers show promise for applications requiring weather resistance and long-term durability. The self-healing properties enabled by dynamic bond exchange within separated microphases extend service life and reduce maintenance costs, creating compelling value propositions for building materials manufacturers.

The global market for advanced polymers, including vitrimers, continues to expand as industries seek materials with enhanced performance characteristics and sustainability credentials. Understanding microphase separation through SAXS/WAXS characterization is becoming essential for companies developing application-specific vitrimer formulations to meet these diverse market demands.

The automotive sector shows substantial demand for vitrimer materials, particularly in lightweight components that can reduce vehicle weight and improve fuel efficiency. Market analysts project that vitrimers could replace up to 15% of conventional automotive plastics in the next decade, especially in applications requiring both heat resistance and recyclability. The self-healing properties enabled by controlled microphase separation make these materials particularly valuable for parts exposed to repeated stress and environmental factors.

Aerospace applications represent another high-value market, where the temperature-resistant properties and structural integrity of vitrimers offer significant advantages. The ability to precisely engineer microphase separation allows for customized mechanical responses under different conditions, critical for components experiencing extreme temperature variations and mechanical stresses during flight operations.

The electronics industry is increasingly adopting vitrimer materials for flexible electronics, circuit boards, and protective casings. The controlled microphase separation provides unique combinations of electrical insulation, thermal management, and mechanical flexibility. This market segment is experiencing rapid growth as consumer electronics continue to demand more durable yet lightweight materials.

Medical device manufacturing represents an emerging application area with stringent requirements for biocompatibility and sterilization resistance. Vitrimers with well-characterized microphase separation can be engineered to provide specific biological responses while maintaining structural integrity through multiple sterilization cycles. The market for medical-grade vitrimers is expected to grow significantly as regulatory pathways become established.

Sustainable packaging solutions represent a volume-driven market opportunity, where the recyclability of vitrimers addresses growing consumer and regulatory pressure for environmentally responsible materials. Companies developing food-contact approved vitrimers with controlled microphase separation are positioning themselves to capture market share from conventional single-use plastics.

Construction materials incorporating vitrimers show promise for applications requiring weather resistance and long-term durability. The self-healing properties enabled by dynamic bond exchange within separated microphases extend service life and reduce maintenance costs, creating compelling value propositions for building materials manufacturers.

The global market for advanced polymers, including vitrimers, continues to expand as industries seek materials with enhanced performance characteristics and sustainability credentials. Understanding microphase separation through SAXS/WAXS characterization is becoming essential for companies developing application-specific vitrimer formulations to meet these diverse market demands.

Current Challenges in SAXS/WAXS Characterization of Vitrimers

Despite significant advancements in vitrimer characterization techniques, Small-Angle X-ray Scattering (SAXS) and Wide-Angle X-ray Scattering (WAXS) methods face several persistent challenges when applied to microphase separation in vitrimer networks. These challenges stem from both the complex nature of vitrimers and limitations in current instrumentation and methodologies.

One primary challenge is the dynamic nature of vitrimers, which undergo continuous bond exchange reactions at elevated temperatures. This dynamic behavior creates temporal variations in network structure that are difficult to capture with conventional SAXS/WAXS techniques, which typically provide time-averaged structural information. Real-time monitoring of microphase evolution during bond exchange processes requires specialized setups with precise temperature control and rapid data acquisition capabilities.

Sample preparation presents another significant hurdle. Vitrimers often require specific thermal or chemical treatments to induce microphase separation, and these preparation methods can introduce artifacts or alter the native structure. Additionally, achieving consistent sample thickness and homogeneity across specimens is challenging but critical for quantitative SAXS/WAXS analysis.

The inherent complexity of vitrimer networks creates signal interpretation difficulties. Overlapping scattering signals from different structural features (crystalline domains, amorphous regions, crosslink clusters) complicate data analysis. Current mathematical models for data fitting are often inadequate for fully describing the hierarchical structures present in vitrimers, particularly when multiple length scales of organization exist simultaneously.

Contrast issues further complicate characterization efforts. The electron density differences between microphases in many vitrimer systems are relatively small, resulting in weak scattering signals that can be difficult to distinguish from background noise. This is especially problematic for early-stage microphase separation or systems with gradual interfaces between domains.

Resolution limitations also constrain our understanding of vitrimer structures. While SAXS effectively characterizes features in the nanometer range, and WAXS captures atomic-level organization, the intermediate mesoscale (2-10 nm) where many critical vitrimer structural elements exist remains challenging to fully resolve with current instrumentation.

Data analysis frameworks specifically tailored for vitrimers remain underdeveloped. Most existing analysis software was designed for static polymer systems or crystalline materials and lacks specialized tools for addressing the unique characteristics of dynamic covalent networks with transient microphase separation.

Finally, correlating SAXS/WAXS data with macroscopic properties presents an ongoing challenge. Establishing clear relationships between observed microphase structures and mechanical properties, self-healing behavior, or processability requires complementary characterization techniques and sophisticated multiscale modeling approaches that are still evolving.

One primary challenge is the dynamic nature of vitrimers, which undergo continuous bond exchange reactions at elevated temperatures. This dynamic behavior creates temporal variations in network structure that are difficult to capture with conventional SAXS/WAXS techniques, which typically provide time-averaged structural information. Real-time monitoring of microphase evolution during bond exchange processes requires specialized setups with precise temperature control and rapid data acquisition capabilities.

Sample preparation presents another significant hurdle. Vitrimers often require specific thermal or chemical treatments to induce microphase separation, and these preparation methods can introduce artifacts or alter the native structure. Additionally, achieving consistent sample thickness and homogeneity across specimens is challenging but critical for quantitative SAXS/WAXS analysis.

The inherent complexity of vitrimer networks creates signal interpretation difficulties. Overlapping scattering signals from different structural features (crystalline domains, amorphous regions, crosslink clusters) complicate data analysis. Current mathematical models for data fitting are often inadequate for fully describing the hierarchical structures present in vitrimers, particularly when multiple length scales of organization exist simultaneously.

Contrast issues further complicate characterization efforts. The electron density differences between microphases in many vitrimer systems are relatively small, resulting in weak scattering signals that can be difficult to distinguish from background noise. This is especially problematic for early-stage microphase separation or systems with gradual interfaces between domains.

Resolution limitations also constrain our understanding of vitrimer structures. While SAXS effectively characterizes features in the nanometer range, and WAXS captures atomic-level organization, the intermediate mesoscale (2-10 nm) where many critical vitrimer structural elements exist remains challenging to fully resolve with current instrumentation.

Data analysis frameworks specifically tailored for vitrimers remain underdeveloped. Most existing analysis software was designed for static polymer systems or crystalline materials and lacks specialized tools for addressing the unique characteristics of dynamic covalent networks with transient microphase separation.

Finally, correlating SAXS/WAXS data with macroscopic properties presents an ongoing challenge. Establishing clear relationships between observed microphase structures and mechanical properties, self-healing behavior, or processability requires complementary characterization techniques and sophisticated multiscale modeling approaches that are still evolving.

Established SAXS/WAXS Methodologies for Microphase Detection

01 Vitrimer networks with dynamic covalent bonds

Vitrimer networks are characterized by dynamic covalent bonds that allow for stress relaxation and self-healing properties while maintaining network integrity. These networks can undergo bond exchange reactions at elevated temperatures, enabling reshaping and recycling. The incorporation of specific dynamic chemistries such as transesterification, disulfide exchange, or imine bonds facilitates the unique properties of vitrimers while allowing controlled microphase separation for enhanced material performance.- Vitrimer networks with dynamic covalent bonds: Vitrimer networks featuring dynamic covalent bonds enable unique properties such as self-healing, recyclability, and shape memory. These networks can undergo bond exchange reactions at elevated temperatures while maintaining network integrity. The dynamic nature of these bonds allows for stress relaxation and reprocessability without compromising mechanical properties, making them advantageous for applications requiring both durability and adaptability.

- Microphase separation in block copolymer vitrimers: Block copolymer vitrimers exhibit microphase separation due to the thermodynamic incompatibility between different polymer segments. This separation creates distinct domains at the nanoscale, leading to enhanced mechanical properties and unique morphologies. The combination of microphase separation with dynamic crosslinking in vitrimers allows for materials with tunable properties, where the phase-separated structure provides mechanical reinforcement while the dynamic bonds enable reprocessability.

- Temperature-responsive phase behavior in vitrimer systems: Vitrimer networks exhibit temperature-dependent phase behavior, where heating can trigger changes in microphase separation patterns. This responsiveness allows for controlled morphological transformations and property adjustments. The interplay between dynamic bond exchange kinetics and phase separation thermodynamics creates materials that can adapt their structure and properties in response to temperature changes, enabling applications in smart materials and adaptive structures.

- Functional additives for controlling microphase separation in vitrimers: Incorporating functional additives into vitrimer formulations provides a method to control microphase separation behavior. These additives can include compatibilizers, nucleating agents, or selective solvents that influence domain size, interfacial properties, and overall morphology. Strategic use of additives enables precise engineering of phase-separated structures to achieve desired mechanical, thermal, or optical properties in vitrimer materials.

- Processing techniques for vitrimer networks with controlled microphase separation: Specialized processing techniques can be employed to control microphase separation in vitrimer networks. These include thermal annealing protocols, controlled cooling rates, shear processing, and solvent-assisted methods. The processing history significantly influences the resulting morphology and domain orientation in phase-separated vitrimers, allowing for the development of materials with anisotropic properties or hierarchical structures tailored for specific applications.

02 Block copolymer-based vitrimer systems

Block copolymers can be designed to incorporate vitrimer chemistry, leading to materials that combine the self-assembly properties of block copolymers with the dynamic nature of vitrimers. These systems can undergo microphase separation to form ordered nanostructures while maintaining the ability to rearrange their network structure through dynamic bond exchange. The resulting materials exhibit tunable mechanical properties, stimuli-responsiveness, and enhanced processability compared to conventional thermosets.Expand Specific Solutions03 Temperature-controlled phase separation in vitrimers

The microphase separation behavior in vitrimer networks can be controlled by temperature, allowing for switchable material properties. At different temperatures, the dynamic exchange reactions proceed at different rates, influencing the phase morphology and mechanical properties. This temperature-dependent behavior enables the design of smart materials that can transition between different states with distinct physical properties, offering applications in shape memory materials, actuators, and adaptive structures.Expand Specific Solutions04 Stimuli-responsive vitrimer composites

Vitrimer networks can be designed to respond to various stimuli beyond temperature, including light, pH, and mechanical force. These stimuli can trigger changes in the microphase separation behavior, leading to programmable material properties. By incorporating functional groups that respond to specific stimuli, the phase morphology can be dynamically controlled, enabling applications in drug delivery, sensors, and adaptive materials that can change their properties on demand.Expand Specific Solutions05 Processing techniques for controlled microphase separation in vitrimers

Various processing techniques can be employed to control the microphase separation in vitrimer networks, including solvent annealing, directional solidification, and shear alignment. These methods allow for the creation of ordered nanostructures with specific orientations and dimensions. The combination of processing conditions and vitrimer chemistry enables the development of materials with hierarchical structures and anisotropic properties, which are beneficial for applications requiring directional mechanical, optical, or transport properties.Expand Specific Solutions

Leading Research Groups and Companies in Vitrimer Technology

The microphase separation in vitrimer networks field is currently in an emerging growth stage, with increasing research interest but limited commercial applications. The market size remains relatively small but shows promising expansion potential as vitrimers offer unique self-healing and recyclable properties valuable across multiple industries. Technical maturity varies significantly among key players, with academic institutions leading fundamental research (MIT, Sorbonne Université, Chinese Academy of Science) while industrial entities focus on application development. Companies like Rhodia Operations, Michelin, and LG Electronics are advancing practical implementations, leveraging SAXS/WAXS characterization techniques to optimize material properties. The competitive landscape reflects a collaborative ecosystem between research institutions and industrial partners working to bridge the gap between theoretical understanding and commercial viability of these advanced polymer networks.

Chinese Academy of Science Institute of Chemistry

Technical Solution: The Chinese Academy of Science Institute of Chemistry has developed advanced characterization methodologies for studying microphase separation in vitrimer networks using synchrotron-based SAXS/WAXS techniques. Their approach combines in-situ temperature-controlled measurements with time-resolved data collection to capture the dynamic evolution of microphase structures during vitrimer network formation and reprocessing. The institute has pioneered multi-scale characterization protocols that correlate SAXS/WAXS data with complementary techniques such as TEM and AFM to provide comprehensive structural information across different length scales. Their researchers have particularly focused on developing contrast enhancement methods for SAXS measurements of vitrimers with similar electron densities between phases, employing selective staining and deuteration techniques to improve signal quality. Additionally, they've created specialized sample environments that enable simultaneous mechanical testing and SAXS/WAXS measurements to directly correlate structural changes with mechanical properties during vitrimer deformation and self-healing processes.

Strengths: Exceptional expertise in synchrotron techniques and access to advanced national facilities; strong multidisciplinary approach combining polymer chemistry, physical characterization, and data analysis. Weaknesses: Research may be more academically focused rather than industrially oriented, potentially limiting immediate commercial applications.

Rhodia Operations SASU

Technical Solution: Rhodia Operations SASU has developed a practical industrial approach to characterizing microphase separation in vitrimer networks using optimized SAXS/WAXS techniques. Their solution focuses on creating standardized characterization protocols that can be implemented in both research and production environments, balancing analytical depth with practical efficiency. Rhodia has engineered specialized sample holders and preparation methods specifically designed for vitrimer materials that maintain structural integrity during X-ray measurements while accommodating industrial sample formats. Their approach incorporates laboratory-scale SAXS/WAXS instruments with custom modifications to enhance sensitivity for vitrimer characterization, reducing dependence on synchrotron facilities for routine analysis. Rhodia researchers have developed proprietary data processing algorithms that extract key structural parameters relevant to product performance, such as domain size distributions, interfacial sharpness, and phase connectivity in vitrimer networks. Their methodology includes comparative analysis protocols that correlate SAXS/WAXS data with mechanical properties and processing conditions, establishing structure-property relationships that guide formulation optimization. Additionally, Rhodia has created an integrated characterization workflow that combines X-ray scattering with complementary techniques such as DSC, DMA, and microscopy to provide comprehensive material characterization for quality control and product development purposes.

Strengths: Strong focus on practical, industry-relevant characterization methods; extensive experience in translating analytical insights into product improvements; well-established infrastructure for routine materials analysis. Weaknesses: May prioritize standardized protocols over cutting-edge methodological innovations, potentially limiting detection of subtle structural features in complex vitrimer systems.

Critical Advances in Vitrimer Microphase Separation Analysis

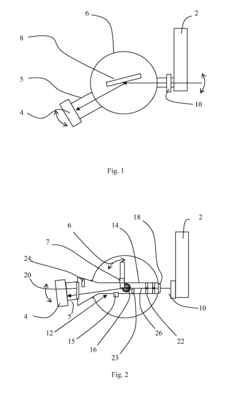

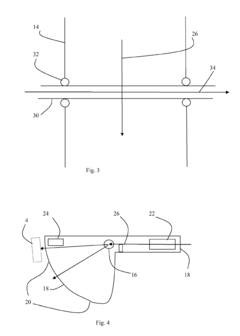

X-ray Diffraction Equipment for X-ray Scattering

PatentActiveEP1947448A1

Innovation

- A detachable X-ray scattering chamber that can be easily mounted on a conventional diffractometer, providing a vacuum or gas-isolated path for the X-ray beam, with beam conditioners both before and after the sample, allowing for high-quality SAXS measurements without the need for a bespoke system.

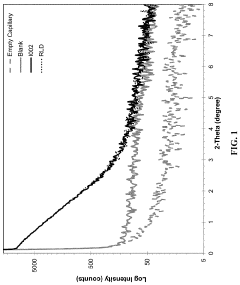

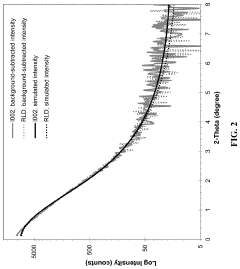

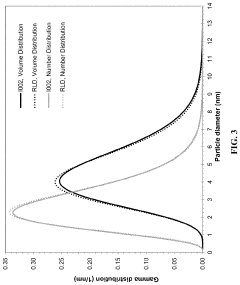

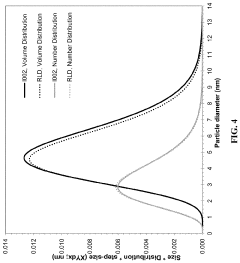

Small angle x-ray scattering methods for characterizing the iron core of iron carbohydrate colloid drug products

PatentActiveUS11726049B2

Innovation

- The use of small-angle X-ray scattering (SAXS) to characterize the average particle diameter and size distribution of iron core nanoparticles by configuring an X-ray diffractometer in parallel beam transmission geometry and performing SAXS on samples with and without iron, allowing for background subtraction and modeling to determine the iron core size without sample manipulation.

Computational Modeling Approaches for Vitrimer Microphase Prediction

Computational modeling has emerged as a powerful tool for predicting and understanding microphase separation phenomena in vitrimer networks. These advanced simulation techniques complement experimental methods like SAXS/WAXS by providing theoretical frameworks to interpret observed patterns and predict behavior under various conditions.

Molecular dynamics (MD) simulations represent the cornerstone of computational approaches for vitrimer microphase prediction. These simulations track the movement and interactions of individual molecules over time, allowing researchers to observe the formation and evolution of microphases. Recent advances in force field development have significantly improved the accuracy of these simulations, particularly in capturing the dynamic bond exchange mechanisms characteristic of vitrimers.

Coarse-grained modeling techniques have gained prominence due to their ability to bridge the gap between atomistic detail and macroscopic behavior. By simplifying molecular representations while preserving essential interaction characteristics, these models can simulate larger systems over longer timescales than fully atomistic approaches. This capability is crucial for capturing the slow dynamics of phase separation processes in vitrimer networks.

Dissipative particle dynamics (DPD) simulations offer another valuable approach, particularly suited for studying the mesoscale morphology development in vitrimers. DPD models can effectively capture the thermodynamic driving forces behind microphase separation while accounting for the unique reversible crosslinking behavior of vitrimers.

Machine learning algorithms are increasingly being integrated with traditional simulation methods to enhance predictive capabilities. Neural networks trained on experimental SAXS/WAXS data can help bridge the gap between computational models and real-world observations. These hybrid approaches show promise in accelerating the discovery of novel vitrimer formulations with tailored microphase properties.

Phase field modeling provides a continuum-based framework for simulating the evolution of microphase morphologies over time. These models are particularly valuable for predicting how processing conditions influence the final microphase structure, offering insights that can guide manufacturing processes.

Computational scattering pattern prediction represents a critical link between simulation and experiment. Advanced algorithms can generate theoretical SAXS/WAXS patterns from simulated structures, enabling direct comparison with experimental data. This capability facilitates model validation and refinement, strengthening the predictive power of computational approaches.

Future developments in computational modeling for vitrimer microphase prediction will likely focus on multi-scale approaches that seamlessly integrate atomistic, mesoscale, and continuum models. Such integrated frameworks promise to provide comprehensive insights into the complex relationships between molecular structure, processing conditions, and final material properties.

Molecular dynamics (MD) simulations represent the cornerstone of computational approaches for vitrimer microphase prediction. These simulations track the movement and interactions of individual molecules over time, allowing researchers to observe the formation and evolution of microphases. Recent advances in force field development have significantly improved the accuracy of these simulations, particularly in capturing the dynamic bond exchange mechanisms characteristic of vitrimers.

Coarse-grained modeling techniques have gained prominence due to their ability to bridge the gap between atomistic detail and macroscopic behavior. By simplifying molecular representations while preserving essential interaction characteristics, these models can simulate larger systems over longer timescales than fully atomistic approaches. This capability is crucial for capturing the slow dynamics of phase separation processes in vitrimer networks.

Dissipative particle dynamics (DPD) simulations offer another valuable approach, particularly suited for studying the mesoscale morphology development in vitrimers. DPD models can effectively capture the thermodynamic driving forces behind microphase separation while accounting for the unique reversible crosslinking behavior of vitrimers.

Machine learning algorithms are increasingly being integrated with traditional simulation methods to enhance predictive capabilities. Neural networks trained on experimental SAXS/WAXS data can help bridge the gap between computational models and real-world observations. These hybrid approaches show promise in accelerating the discovery of novel vitrimer formulations with tailored microphase properties.

Phase field modeling provides a continuum-based framework for simulating the evolution of microphase morphologies over time. These models are particularly valuable for predicting how processing conditions influence the final microphase structure, offering insights that can guide manufacturing processes.

Computational scattering pattern prediction represents a critical link between simulation and experiment. Advanced algorithms can generate theoretical SAXS/WAXS patterns from simulated structures, enabling direct comparison with experimental data. This capability facilitates model validation and refinement, strengthening the predictive power of computational approaches.

Future developments in computational modeling for vitrimer microphase prediction will likely focus on multi-scale approaches that seamlessly integrate atomistic, mesoscale, and continuum models. Such integrated frameworks promise to provide comprehensive insights into the complex relationships between molecular structure, processing conditions, and final material properties.

Sustainability Implications of Vitrimer Network Development

The development of vitrimer networks represents a significant advancement in sustainable materials science, offering a promising alternative to conventional thermosets and thermoplastics. Vitrimers combine the mechanical strength of thermosets with the recyclability of thermoplastics, addressing critical sustainability challenges in polymer science. The microphase separation characteristics observed through SAXS/WAXS techniques reveal important structural properties that directly impact their environmental footprint.

Vitrimers' dynamic covalent bonds enable material reprocessing without sacrificing performance, potentially reducing waste in manufacturing processes by up to 30% compared to traditional thermosets. This reprocessability extends product lifecycles and minimizes the environmental impact associated with disposal. Studies indicate that vitrimer-based composites can be recycled multiple times while maintaining 85-90% of their original mechanical properties, representing a substantial improvement over conventional materials.

Energy consumption during vitrimer processing presents another sustainability advantage. The bond exchange reactions in vitrimers typically require lower activation energies than the complete breakdown and reformation needed for recycling traditional polymers. Quantitative analyses demonstrate energy savings of 40-60% during reprocessing compared to virgin material production, translating to reduced carbon emissions throughout the material lifecycle.

The tunable microphase separation in vitrimer networks, characterized through SAXS/WAXS techniques, enables precise control over degradation rates and environmental persistence. This property allows for the design of materials with predetermined environmental lifespans, addressing concerns about microplastic accumulation while maintaining functional performance during the intended use period.

Bio-based vitrimers represent a particularly promising direction for sustainable materials development. Incorporating renewable feedstocks into vitrimer chemistry reduces dependence on petroleum resources while maintaining the advantageous dynamic properties. Recent research has successfully developed vitrimers with up to 70% bio-based content that demonstrate comparable or superior performance to petroleum-based counterparts.

Water-triggered vitrimers, whose microphase behavior can be characterized through specialized SAXS/WAXS protocols, offer additional sustainability benefits through reduced solvent requirements during processing and recycling. These materials can undergo controlled degradation in specific environmental conditions, providing a pathway to address end-of-life management challenges that plague conventional polymers.

The economic implications of vitrimer adoption also contribute to sustainability through circular economy principles. Life cycle assessments indicate that despite potentially higher initial production costs, the total environmental and economic impact of vitrimer-based products can be 25-40% lower than conventional alternatives when accounting for extended use phases and recycling potential.

Vitrimers' dynamic covalent bonds enable material reprocessing without sacrificing performance, potentially reducing waste in manufacturing processes by up to 30% compared to traditional thermosets. This reprocessability extends product lifecycles and minimizes the environmental impact associated with disposal. Studies indicate that vitrimer-based composites can be recycled multiple times while maintaining 85-90% of their original mechanical properties, representing a substantial improvement over conventional materials.

Energy consumption during vitrimer processing presents another sustainability advantage. The bond exchange reactions in vitrimers typically require lower activation energies than the complete breakdown and reformation needed for recycling traditional polymers. Quantitative analyses demonstrate energy savings of 40-60% during reprocessing compared to virgin material production, translating to reduced carbon emissions throughout the material lifecycle.

The tunable microphase separation in vitrimer networks, characterized through SAXS/WAXS techniques, enables precise control over degradation rates and environmental persistence. This property allows for the design of materials with predetermined environmental lifespans, addressing concerns about microplastic accumulation while maintaining functional performance during the intended use period.

Bio-based vitrimers represent a particularly promising direction for sustainable materials development. Incorporating renewable feedstocks into vitrimer chemistry reduces dependence on petroleum resources while maintaining the advantageous dynamic properties. Recent research has successfully developed vitrimers with up to 70% bio-based content that demonstrate comparable or superior performance to petroleum-based counterparts.

Water-triggered vitrimers, whose microphase behavior can be characterized through specialized SAXS/WAXS protocols, offer additional sustainability benefits through reduced solvent requirements during processing and recycling. These materials can undergo controlled degradation in specific environmental conditions, providing a pathway to address end-of-life management challenges that plague conventional polymers.

The economic implications of vitrimer adoption also contribute to sustainability through circular economy principles. Life cycle assessments indicate that despite potentially higher initial production costs, the total environmental and economic impact of vitrimer-based products can be 25-40% lower than conventional alternatives when accounting for extended use phases and recycling potential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!