Interface Engineering Between Vitrimer Matrix And Reinforcements: Adhesion And Interphase Studies

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vitrimer-Reinforcement Interface Engineering Background and Objectives

Vitrimers represent a groundbreaking class of polymer materials that combine the processability of thermoplastics with the mechanical robustness of thermosets. Since their introduction by Leibler and colleagues in 2011, these materials have garnered significant attention due to their unique ability to undergo dynamic bond exchange reactions while maintaining network integrity. This characteristic enables vitrimers to be reshaped, repaired, and recycled without compromising their structural properties, addressing critical sustainability challenges in polymer science.

The interface between vitrimer matrices and reinforcement materials constitutes a critical domain for advancing composite technology. Historically, composite materials have faced persistent challenges related to interfacial adhesion, stress transfer efficiency, and long-term durability. The evolution of interface engineering has progressed from simple mechanical interlocking mechanisms to sophisticated chemical bonding strategies, with recent developments focusing on dynamic and responsive interfaces that can adapt to environmental stimuli.

Current technological trajectories indicate growing interest in exploiting the dynamic bond exchange capabilities of vitrimers to create "living interfaces" that can heal, reconfigure, and strengthen in response to external triggers. This represents a paradigm shift from static to dynamic interface design principles, potentially revolutionizing composite performance across multiple industries including aerospace, automotive, and renewable energy sectors.

The primary objective of vitrimer-reinforcement interface engineering research is to develop fundamental understanding and practical methodologies for creating robust, adaptive interfaces that maximize load transfer efficiency while enabling recyclability and repairability. Specific technical goals include: characterizing the molecular mechanisms governing adhesion at vitrimer-reinforcement interfaces; developing novel coupling agents and surface modification techniques specifically designed for dynamic networks; and establishing quantitative relationships between processing parameters, interfacial chemistry, and mechanical performance.

Additionally, this research aims to explore the unique opportunities presented by the dynamic nature of vitrimers for creating self-healing interfaces that can restore performance after damage events. The potential for controlled bond exchange reactions at interfaces offers unprecedented possibilities for designing composites with extended service life and improved sustainability profiles.

The technological evolution in this field is increasingly influenced by computational modeling approaches that enable prediction of interfacial behavior across multiple length scales, from molecular interactions to macroscopic mechanical properties. These predictive capabilities, combined with advanced characterization techniques such as in-situ spectroscopy and nanomechanical testing, are accelerating the development of next-generation interface engineering solutions for vitrimer-based composites.

The interface between vitrimer matrices and reinforcement materials constitutes a critical domain for advancing composite technology. Historically, composite materials have faced persistent challenges related to interfacial adhesion, stress transfer efficiency, and long-term durability. The evolution of interface engineering has progressed from simple mechanical interlocking mechanisms to sophisticated chemical bonding strategies, with recent developments focusing on dynamic and responsive interfaces that can adapt to environmental stimuli.

Current technological trajectories indicate growing interest in exploiting the dynamic bond exchange capabilities of vitrimers to create "living interfaces" that can heal, reconfigure, and strengthen in response to external triggers. This represents a paradigm shift from static to dynamic interface design principles, potentially revolutionizing composite performance across multiple industries including aerospace, automotive, and renewable energy sectors.

The primary objective of vitrimer-reinforcement interface engineering research is to develop fundamental understanding and practical methodologies for creating robust, adaptive interfaces that maximize load transfer efficiency while enabling recyclability and repairability. Specific technical goals include: characterizing the molecular mechanisms governing adhesion at vitrimer-reinforcement interfaces; developing novel coupling agents and surface modification techniques specifically designed for dynamic networks; and establishing quantitative relationships between processing parameters, interfacial chemistry, and mechanical performance.

Additionally, this research aims to explore the unique opportunities presented by the dynamic nature of vitrimers for creating self-healing interfaces that can restore performance after damage events. The potential for controlled bond exchange reactions at interfaces offers unprecedented possibilities for designing composites with extended service life and improved sustainability profiles.

The technological evolution in this field is increasingly influenced by computational modeling approaches that enable prediction of interfacial behavior across multiple length scales, from molecular interactions to macroscopic mechanical properties. These predictive capabilities, combined with advanced characterization techniques such as in-situ spectroscopy and nanomechanical testing, are accelerating the development of next-generation interface engineering solutions for vitrimer-based composites.

Market Analysis for Advanced Composite Materials

The advanced composite materials market is experiencing robust growth, driven by increasing demand across aerospace, automotive, wind energy, and construction sectors. The global market value for advanced composites reached $36.7 billion in 2022 and is projected to grow at a CAGR of 7.9% through 2030, potentially reaching $69.5 billion. This growth trajectory is particularly significant for vitrimer-based composites, which represent an emerging segment within the broader advanced materials landscape.

Vitrimer matrix composites address critical market needs for recyclable yet high-performance materials, positioning them favorably against traditional thermosets and thermoplastics. The market demand is primarily driven by sustainability regulations, particularly in Europe and North America, where end-of-life recycling requirements are becoming increasingly stringent for composite materials.

The interface engineering segment within advanced composites represents approximately 15% of research and development expenditure, highlighting its importance in overall composite performance. Industries are willing to pay premium prices for composites with enhanced interfacial properties, as these directly translate to longer service life and improved mechanical performance.

Aerospace remains the highest value market for advanced interface-engineered composites, with an estimated market share of 32%, followed by automotive (28%), wind energy (18%), and sporting goods (12%). The aerospace sector particularly values the self-healing and recyclability aspects of vitrimer-based composites, which can significantly reduce maintenance costs and extend component lifespans.

Regional analysis shows North America leading the market with 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China, Japan, and South Korea, where government initiatives are actively promoting advanced materials development.

Customer requirements analysis reveals that interfacial strength, durability under environmental exposure, and recyclability are the top three priorities for end-users. The market is increasingly demanding quantifiable improvements in interlaminar shear strength and resistance to delamination, with benchmark requirements typically exceeding 20% improvement over conventional composites.

Competitive analysis indicates that major chemical companies and composite manufacturers are investing heavily in vitrimer technology, with over 250 patents filed in the last five years specifically addressing interface engineering between vitrimer matrices and various reinforcements. This patent activity suggests strong commercial interest and anticipates market entry of multiple vitrimer-based products within the next 2-3 years.

Vitrimer matrix composites address critical market needs for recyclable yet high-performance materials, positioning them favorably against traditional thermosets and thermoplastics. The market demand is primarily driven by sustainability regulations, particularly in Europe and North America, where end-of-life recycling requirements are becoming increasingly stringent for composite materials.

The interface engineering segment within advanced composites represents approximately 15% of research and development expenditure, highlighting its importance in overall composite performance. Industries are willing to pay premium prices for composites with enhanced interfacial properties, as these directly translate to longer service life and improved mechanical performance.

Aerospace remains the highest value market for advanced interface-engineered composites, with an estimated market share of 32%, followed by automotive (28%), wind energy (18%), and sporting goods (12%). The aerospace sector particularly values the self-healing and recyclability aspects of vitrimer-based composites, which can significantly reduce maintenance costs and extend component lifespans.

Regional analysis shows North America leading the market with 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China, Japan, and South Korea, where government initiatives are actively promoting advanced materials development.

Customer requirements analysis reveals that interfacial strength, durability under environmental exposure, and recyclability are the top three priorities for end-users. The market is increasingly demanding quantifiable improvements in interlaminar shear strength and resistance to delamination, with benchmark requirements typically exceeding 20% improvement over conventional composites.

Competitive analysis indicates that major chemical companies and composite manufacturers are investing heavily in vitrimer technology, with over 250 patents filed in the last five years specifically addressing interface engineering between vitrimer matrices and various reinforcements. This patent activity suggests strong commercial interest and anticipates market entry of multiple vitrimer-based products within the next 2-3 years.

Current Challenges in Vitrimer-Reinforcement Adhesion

Despite the promising properties of vitrimers as a matrix material for composites, significant challenges persist in achieving optimal adhesion between vitrimer matrices and various reinforcement materials. The primary challenge stems from the dynamic nature of vitrimers, which undergo continuous bond exchange reactions. This dynamic behavior, while beneficial for reprocessability and self-healing, creates difficulties in establishing stable and durable interfaces with reinforcement materials that typically have static surface chemistries.

Surface compatibility issues represent another major challenge. Many reinforcement materials, particularly carbon fibers and inorganic fillers, possess surface chemistries that are not naturally compatible with the dynamic covalent networks of vitrimers. This incompatibility leads to weak interfacial bonding, resulting in premature failure under mechanical stress and compromised overall composite performance.

The processing temperature window presents a complex challenge unique to vitrimer composites. Vitrimers require specific temperature conditions to activate their dynamic exchange reactions, but these temperatures must be carefully balanced against the thermal stability limits of reinforcement materials and the processing requirements for achieving good wetting and adhesion. This narrow processing window complicates manufacturing and can lead to suboptimal interface formation.

Stress concentration at interfaces during thermal cycling poses another significant challenge. The dynamic nature of vitrimers means they can undergo dimensional changes during temperature fluctuations, creating mechanical stresses at the interface with more dimensionally stable reinforcements. Over time, these cyclic stresses can lead to interface degradation and composite failure.

Water and environmental stability at the interface region remains problematic. Many dynamic covalent bonds in vitrimers are susceptible to hydrolysis or other environmental degradation mechanisms. When moisture penetrates the interface region, it can accelerate bond exchange or even break covalent bonds, weakening the interface integrity over time.

Characterization difficulties further complicate interface engineering efforts. Traditional composite interface characterization techniques are often inadequate for capturing the dynamic nature of vitrimer interfaces. Researchers struggle to develop methods that can effectively monitor bond exchange reactions at interfaces and correlate these dynamics with mechanical performance.

Lastly, the lack of standardized testing protocols specifically designed for vitrimer composites hinders progress in interface engineering. Without standardized methods to evaluate interface quality and durability under conditions relevant to the dynamic nature of vitrimers, comparing different interface engineering approaches becomes challenging, slowing advancement in the field.

Surface compatibility issues represent another major challenge. Many reinforcement materials, particularly carbon fibers and inorganic fillers, possess surface chemistries that are not naturally compatible with the dynamic covalent networks of vitrimers. This incompatibility leads to weak interfacial bonding, resulting in premature failure under mechanical stress and compromised overall composite performance.

The processing temperature window presents a complex challenge unique to vitrimer composites. Vitrimers require specific temperature conditions to activate their dynamic exchange reactions, but these temperatures must be carefully balanced against the thermal stability limits of reinforcement materials and the processing requirements for achieving good wetting and adhesion. This narrow processing window complicates manufacturing and can lead to suboptimal interface formation.

Stress concentration at interfaces during thermal cycling poses another significant challenge. The dynamic nature of vitrimers means they can undergo dimensional changes during temperature fluctuations, creating mechanical stresses at the interface with more dimensionally stable reinforcements. Over time, these cyclic stresses can lead to interface degradation and composite failure.

Water and environmental stability at the interface region remains problematic. Many dynamic covalent bonds in vitrimers are susceptible to hydrolysis or other environmental degradation mechanisms. When moisture penetrates the interface region, it can accelerate bond exchange or even break covalent bonds, weakening the interface integrity over time.

Characterization difficulties further complicate interface engineering efforts. Traditional composite interface characterization techniques are often inadequate for capturing the dynamic nature of vitrimer interfaces. Researchers struggle to develop methods that can effectively monitor bond exchange reactions at interfaces and correlate these dynamics with mechanical performance.

Lastly, the lack of standardized testing protocols specifically designed for vitrimer composites hinders progress in interface engineering. Without standardized methods to evaluate interface quality and durability under conditions relevant to the dynamic nature of vitrimers, comparing different interface engineering approaches becomes challenging, slowing advancement in the field.

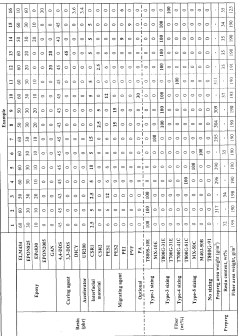

Current Methodologies for Vitrimer-Reinforcement Interface Enhancement

01 Vitrimer matrix composition and synthesis methods

Vitrimer matrices can be engineered with specific chemical compositions to enhance their interfacial properties with reinforcements. These matrices typically contain dynamic covalent bonds that allow for reconfiguration while maintaining network integrity. Synthesis methods include incorporating functional groups that can participate in exchange reactions, enabling self-healing and recyclability while maintaining strong adhesion to reinforcements. The chemical structure of the vitrimer matrix significantly influences the quality of the interphase region and overall composite performance.- Chemical modification of vitrimer interfaces: Chemical modification techniques can be applied to vitrimer matrix interfaces to enhance adhesion with reinforcements. These modifications typically involve introducing functional groups that can form dynamic covalent bonds with both the vitrimer matrix and reinforcement materials. This approach creates a strong interphase region with adaptable bonds that can rearrange under stress while maintaining structural integrity. The modified interface exhibits improved load transfer capabilities and resistance to delamination under mechanical stress.

- Dynamic bond engineering at reinforcement interfaces: Engineering dynamic covalent bonds at the interface between vitrimer matrices and reinforcements creates adaptive interphases that can undergo bond exchange reactions. This approach allows for stress redistribution, self-healing capabilities, and improved interfacial adhesion. By carefully selecting the chemistry of these dynamic bonds, the interface can be designed to respond to specific stimuli such as temperature, pH, or mechanical stress, providing tailored performance characteristics for different applications.

- Surface treatment of reinforcement materials: Surface treatments can be applied to reinforcement materials to enhance their compatibility with vitrimer matrices. These treatments may include plasma processing, chemical etching, or application of coupling agents that create reactive sites on the reinforcement surface. By modifying the surface chemistry and topography of reinforcements, these treatments increase the available bonding sites for interaction with the vitrimer matrix, resulting in stronger adhesion and a more robust interphase region.

- Nanoparticle-mediated interface enhancement: Incorporating functionalized nanoparticles at the interface between vitrimer matrices and reinforcements can significantly improve adhesion and interphase properties. These nanoparticles act as bridges between the matrix and reinforcements, creating additional bonding sites and increasing the effective surface area for interaction. The nanoparticles can be designed with specific functional groups that participate in the dynamic exchange reactions characteristic of vitrimers, further enhancing the adaptive nature of the interface.

- Processing techniques for optimized interphase formation: Specialized processing techniques can be employed to optimize the formation of the interphase region between vitrimer matrices and reinforcements. These techniques include controlled curing protocols, gradient polymerization approaches, and in-situ polymerization methods that promote interpenetration of polymer chains across the interface. By carefully managing processing parameters such as temperature, pressure, and cure time, the interphase region can be engineered to have a gradual transition in properties, minimizing stress concentrations and enhancing overall composite performance.

02 Surface modification of reinforcements for improved adhesion

Surface treatments and modifications of reinforcement materials can significantly enhance the adhesion between vitrimer matrices and reinforcements. These modifications typically involve introducing functional groups on the reinforcement surface that can chemically interact with the vitrimer network. Techniques include plasma treatment, chemical grafting, and application of coupling agents that create covalent bonds across the interface. Such modifications improve stress transfer efficiency and prevent delamination under mechanical loading, resulting in composites with superior mechanical properties.Expand Specific Solutions03 Interphase engineering and characterization techniques

The interphase region between vitrimer matrices and reinforcements plays a crucial role in determining composite properties. Engineering this region involves controlling the gradient of properties from the bulk matrix to the reinforcement surface. Advanced characterization techniques such as nano-indentation, atomic force microscopy, and spectroscopic methods are employed to understand the structure-property relationships at the interphase. This knowledge enables the design of composites with tailored interfacial properties that can respond to external stimuli while maintaining structural integrity.Expand Specific Solutions04 Dynamic bond exchange mechanisms at interfaces

The unique property of vitrimers to undergo bond exchange reactions can be leveraged at the interface with reinforcements. These dynamic mechanisms allow for stress relaxation, self-healing, and reconfiguration at the interface without compromising the overall structural integrity. By controlling the kinetics of these exchange reactions, the interface can be engineered to respond to external stimuli such as temperature, pH, or light. This approach enables the development of smart composites with adaptive interfaces that can enhance durability and extend service life.Expand Specific Solutions05 Processing techniques for optimized interface formation

Specialized processing techniques can significantly influence the quality of interfaces between vitrimer matrices and reinforcements. These include controlled curing protocols, application of pressure during composite formation, and temperature management strategies that promote optimal crosslinking at the interface. Advanced manufacturing methods such as resin transfer molding with modified parameters, hot pressing with specific temperature profiles, and in-situ polymerization around reinforcements can be employed to create composites with superior interfacial properties. These techniques ensure uniform distribution of stress across the interface and minimize the formation of defects.Expand Specific Solutions

Leading Research Groups and Industrial Players

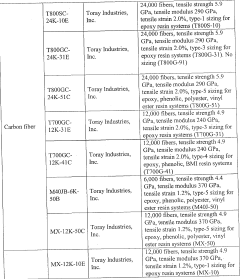

The vitrimer matrix-reinforcement interface engineering field is currently in a growth phase, with increasing market interest driven by demands for high-performance composite materials. The global market is expanding rapidly, estimated at several billion dollars, as industries seek sustainable, durable composites with enhanced mechanical properties. Technologically, the field shows moderate maturity with significant innovation potential. Leading players include established materials companies like Toray Industries and Arkema developing proprietary vitrimer technologies, alongside automotive manufacturers (Mercedes-Benz) seeking lightweight composite applications. Research institutions (University of Delaware, Harbin Institute of Technology) are advancing fundamental understanding of interface chemistry, while specialized composite manufacturers (Changzhou Rongxin) focus on commercial applications. The competitive landscape features both vertical integration by large corporations and specialized innovation from smaller technical players, with increasing cross-sector collaboration accelerating development.

Toray Industries, Inc.

Technical Solution: Toray has pioneered innovative interface engineering solutions for vitrimer composites through their T-FUSION™ technology platform. This approach utilizes specially designed coupling agents containing both dynamic covalent networks and fiber-reactive functional groups to create adaptive interfaces between carbon fiber reinforcements and vitrimer matrices. Their proprietary surface treatment technology modifies carbon fiber surfaces with nano-scale silica particles functionalized with dynamic exchange groups that participate in bond exchange reactions with the vitrimer matrix. This creates a gradient interphase region with controlled mobility and stress transfer characteristics. Toray has demonstrated that these engineered interfaces can improve interlaminar shear strength by up to 40% while maintaining the recyclability benefits of vitrimers. Their recent advancements include the development of hybrid sizing systems that combine conventional sizing components with dynamic exchange catalysts, accelerating the bond exchange reactions at the interface region during thermal recycling processes while preserving fiber integrity.

Strengths: Exceptional interfacial adhesion with carbon fiber reinforcements; maintains fiber properties during recycling processes; creates gradient interphase regions for optimal stress transfer. Weaknesses: Technology primarily optimized for carbon fiber systems with less development for glass or natural fiber reinforcements; requires precise control of processing conditions; higher cost compared to conventional sizing treatments.

University of Delaware

Technical Solution: The University of Delaware's Center for Composite Materials has developed a comprehensive approach to vitrimer-reinforcement interface engineering through their Tailored Interphase Technology (TIT) program. Their research focuses on creating controlled interphase regions between vitrimer matrices and various reinforcement types through molecular design and surface modification techniques. The university's approach involves grafting dynamic exchange catalysts directly onto fiber surfaces using plasma treatment followed by chemical vapor deposition of catalyst-containing silanes. This creates localized regions of enhanced exchange reaction rates at the fiber-matrix interface, allowing for preferential stress relaxation and improved damage tolerance. Their studies have demonstrated that controlling the catalyst concentration gradient at the interphase can create materials with position-dependent relaxation times, enabling directional properties. Recent publications have shown that their engineered interfaces can improve composite toughness by up to 65% while maintaining full recyclability through transesterification reactions at the fiber-matrix boundary.

Strengths: Highly customizable interface properties through precise catalyst placement; applicable to multiple fiber types including carbon, glass, and natural fibers; excellent balance of mechanical properties and recyclability. Weaknesses: Laboratory-scale process that may face challenges in industrial scaling; requires specialized equipment for surface treatments; potential long-term stability issues with catalyst-modified surfaces.

Key Innovations in Interphase Control and Characterization

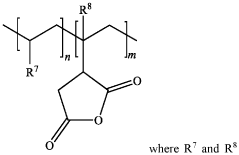

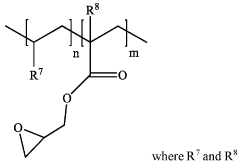

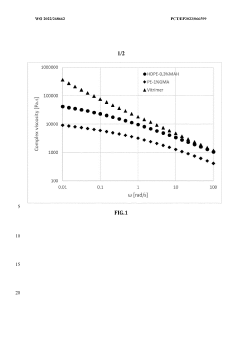

Vitrimer polymers derived from functionalized polyolefins

PatentWO2022268662A1

Innovation

- A process for preparing vitrimer polymers from functionalized polyolefins, specifically by mixing a first functionalized polyolefin with a cyclic ether group and a second functionalized polyolefin, under conditions that react to form a vitrimer polymer without using catalysts, achieving improved melt strength and mechanical properties while maintaining recyclability.

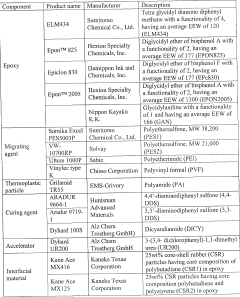

Reinforced interphase and bonded structures thereof

PatentWO2012116261A1

Innovation

- A thermosetting resin-based adhesive composition with a migrating agent, interfacial material, and toughener is used, which concentrates the interfacial material in a thick interphase between the adherend and adhesive, enhancing both tensile strength and fracture toughness by forming a multilayered interphase with improved stress relief and transfer capabilities.

Sustainability Aspects of Vitrimer Composite Materials

Sustainability has emerged as a critical consideration in materials science, with vitrimer composite materials offering significant advantages over traditional thermosets and thermoplastics. The dynamic covalent bonds in vitrimers enable recycling and reprocessing capabilities while maintaining structural integrity, positioning these materials as promising candidates for circular economy applications.

The environmental impact of vitrimer composites must be evaluated through comprehensive life cycle assessments. Current research indicates that the energy required for reprocessing vitrimers is substantially lower than that needed for producing virgin materials, resulting in reduced carbon footprints. Additionally, the ability to repair and recycle these composites extends their service life, minimizing waste generation and resource consumption.

Interface engineering between vitrimer matrices and reinforcements plays a pivotal role in sustainability. Enhanced adhesion at these interfaces improves durability and damage resistance, directly contributing to longer product lifespans. Studies have demonstrated that properly engineered interfaces can withstand multiple recycling cycles without significant degradation of mechanical properties, preserving the value of embedded reinforcements.

The chemical exchange reactions that characterize vitrimers offer unique opportunities for designing self-healing capabilities at the interface regions. This self-healing functionality reduces maintenance requirements and prevents premature failure, further enhancing sustainability through extended service life and reduced replacement frequency.

Recent advances in bio-based vitrimers derived from renewable resources represent another sustainability dimension. These materials incorporate plant-based precursors for both the matrix and coupling agents at interfaces, reducing dependence on petroleum-based feedstocks. Research indicates that bio-based vitrimers can achieve comparable interfacial properties to their synthetic counterparts while offering improved end-of-life biodegradability.

Regulatory frameworks increasingly emphasize materials that support circular economy principles. Vitrimer composites with well-engineered interfaces align with these emerging regulations, potentially offering manufacturers compliance advantages and market differentiation. The recyclability of these materials addresses growing concerns about composite waste management, particularly in industries like automotive and aerospace where composite usage continues to expand.

Economic sustainability also benefits from interface engineering in vitrimer composites. The ability to disassemble and recover valuable reinforcements such as carbon fibers represents significant cost savings. Studies estimate that reclaimed carbon fibers from vitrimer composites retain up to 90% of their original mechanical properties when interface chemistry is optimized for reversibility during recycling processes.

The environmental impact of vitrimer composites must be evaluated through comprehensive life cycle assessments. Current research indicates that the energy required for reprocessing vitrimers is substantially lower than that needed for producing virgin materials, resulting in reduced carbon footprints. Additionally, the ability to repair and recycle these composites extends their service life, minimizing waste generation and resource consumption.

Interface engineering between vitrimer matrices and reinforcements plays a pivotal role in sustainability. Enhanced adhesion at these interfaces improves durability and damage resistance, directly contributing to longer product lifespans. Studies have demonstrated that properly engineered interfaces can withstand multiple recycling cycles without significant degradation of mechanical properties, preserving the value of embedded reinforcements.

The chemical exchange reactions that characterize vitrimers offer unique opportunities for designing self-healing capabilities at the interface regions. This self-healing functionality reduces maintenance requirements and prevents premature failure, further enhancing sustainability through extended service life and reduced replacement frequency.

Recent advances in bio-based vitrimers derived from renewable resources represent another sustainability dimension. These materials incorporate plant-based precursors for both the matrix and coupling agents at interfaces, reducing dependence on petroleum-based feedstocks. Research indicates that bio-based vitrimers can achieve comparable interfacial properties to their synthetic counterparts while offering improved end-of-life biodegradability.

Regulatory frameworks increasingly emphasize materials that support circular economy principles. Vitrimer composites with well-engineered interfaces align with these emerging regulations, potentially offering manufacturers compliance advantages and market differentiation. The recyclability of these materials addresses growing concerns about composite waste management, particularly in industries like automotive and aerospace where composite usage continues to expand.

Economic sustainability also benefits from interface engineering in vitrimer composites. The ability to disassemble and recover valuable reinforcements such as carbon fibers represents significant cost savings. Studies estimate that reclaimed carbon fibers from vitrimer composites retain up to 90% of their original mechanical properties when interface chemistry is optimized for reversibility during recycling processes.

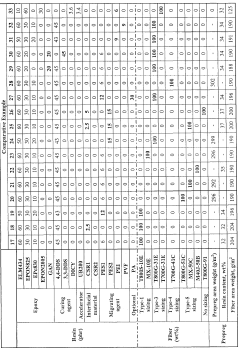

Performance Testing Standards for Vitrimer Composites

The development of standardized testing protocols for vitrimer composites represents a critical challenge in the advancement of these materials for industrial applications. Current performance testing standards for vitrimer composites must address their unique dynamic behavior, which differs significantly from traditional thermosets and thermoplastics. These standards need to evaluate both the static mechanical properties and the dynamic reconfiguration capabilities that make vitrimers valuable.

Mechanical performance testing standards for vitrimer composites typically include tensile, compression, flexural, and impact resistance tests following modified versions of ASTM D3039, D695, D790, and D7136 respectively. However, these standards require adaptation to account for the temperature and time-dependent behavior of vitrimers, particularly around their topology freezing transition temperature (Tv).

Interfacial adhesion testing between vitrimer matrices and reinforcements presents unique challenges due to the dynamic nature of the interface. Modified versions of the single fiber pull-out test (ASTM D3379) and short beam shear test (ASTM D2344) have been developed to characterize the interfacial strength under various temperature conditions. These tests must be conducted both below and above Tv to fully understand the interface behavior.

Durability testing standards for vitrimer composites include accelerated aging protocols that assess the material's response to environmental factors such as humidity, UV exposure, and thermal cycling. ASTM D5229 for moisture absorption and ASTM G154 for UV resistance have been adapted for vitrimer systems, with particular attention to how these factors affect the dynamic bond exchange mechanisms.

Reprocessability assessment represents a unique testing requirement for vitrimer composites. Standards are emerging to quantify healing efficiency, reprocessing cycles, and property retention after multiple recycling events. These include measurements of shape memory recovery ratio, stress relaxation time at various temperatures, and mechanical property retention after multiple reprocessing cycles.

Thermal performance testing standards include dynamic mechanical analysis (DMA) following ASTM D7028, differential scanning calorimetry (DSC) according to ASTM E1356, and rheological characterization using ASTM D4440. These tests are crucial for determining the topology freezing transition temperature (Tv) and the temperature-dependent viscoelastic behavior that defines vitrimer performance.

Standardized methods for characterizing the interphase region between vitrimer matrices and reinforcements are still evolving. Techniques such as nanoindentation mapping (ISO 14577), atomic force microscopy (AFM), and Raman spectroscopy are being standardized to quantify interphase thickness, gradient properties, and chemical composition at the interface, providing critical insights into interface engineering effectiveness.

Mechanical performance testing standards for vitrimer composites typically include tensile, compression, flexural, and impact resistance tests following modified versions of ASTM D3039, D695, D790, and D7136 respectively. However, these standards require adaptation to account for the temperature and time-dependent behavior of vitrimers, particularly around their topology freezing transition temperature (Tv).

Interfacial adhesion testing between vitrimer matrices and reinforcements presents unique challenges due to the dynamic nature of the interface. Modified versions of the single fiber pull-out test (ASTM D3379) and short beam shear test (ASTM D2344) have been developed to characterize the interfacial strength under various temperature conditions. These tests must be conducted both below and above Tv to fully understand the interface behavior.

Durability testing standards for vitrimer composites include accelerated aging protocols that assess the material's response to environmental factors such as humidity, UV exposure, and thermal cycling. ASTM D5229 for moisture absorption and ASTM G154 for UV resistance have been adapted for vitrimer systems, with particular attention to how these factors affect the dynamic bond exchange mechanisms.

Reprocessability assessment represents a unique testing requirement for vitrimer composites. Standards are emerging to quantify healing efficiency, reprocessing cycles, and property retention after multiple recycling events. These include measurements of shape memory recovery ratio, stress relaxation time at various temperatures, and mechanical property retention after multiple reprocessing cycles.

Thermal performance testing standards include dynamic mechanical analysis (DMA) following ASTM D7028, differential scanning calorimetry (DSC) according to ASTM E1356, and rheological characterization using ASTM D4440. These tests are crucial for determining the topology freezing transition temperature (Tv) and the temperature-dependent viscoelastic behavior that defines vitrimer performance.

Standardized methods for characterizing the interphase region between vitrimer matrices and reinforcements are still evolving. Techniques such as nanoindentation mapping (ISO 14577), atomic force microscopy (AFM), and Raman spectroscopy are being standardized to quantify interphase thickness, gradient properties, and chemical composition at the interface, providing critical insights into interface engineering effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!