Fracture Toughness Methods For Vitrimers: Test Selection And Data Interpretation

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vitrimer Fracture Toughness Testing Background and Objectives

Vitrimers represent a groundbreaking class of polymer materials that combine the processability of thermoplastics with the mechanical robustness of thermosets. First introduced by Leibler and colleagues in 2011, these materials feature dynamic covalent bonds that enable network rearrangement at elevated temperatures while maintaining structural integrity at service temperatures. This unique characteristic has positioned vitrimers as promising candidates for applications requiring both durability and recyclability, addressing the growing global demand for sustainable materials with extended lifecycles.

The evolution of vitrimer technology has progressed rapidly over the past decade, with significant advancements in chemistry, processing techniques, and property enhancement. Early vitrimers primarily utilized transesterification reactions, while contemporary systems incorporate diverse exchange mechanisms including disulfide metathesis, transamination, and boronic ester exchange. This chemical diversity has expanded the application landscape for vitrimers across automotive, aerospace, electronics, and medical industries.

Despite these advances, a critical gap exists in standardized methodologies for characterizing the fracture toughness of vitrimers. Fracture toughness—a material's resistance to crack propagation—is particularly complex in vitrimers due to their dynamic network structure, which can potentially self-heal and redistribute stress during fracture events. Traditional fracture mechanics approaches developed for conventional polymers may not fully capture these unique behaviors.

The primary objective of this technical research is to establish comprehensive guidelines for selecting appropriate fracture toughness testing methods for vitrimers and interpreting the resulting data. This includes evaluating the applicability of standard test protocols (ASTM, ISO) to vitrimer systems, identifying modifications necessary to account for their dynamic nature, and developing frameworks for meaningful data interpretation that considers temperature-dependent network rearrangement rates.

Secondary objectives include correlating fracture toughness measurements with vitrimer network architecture, exchange reaction kinetics, and processing history. Additionally, this research aims to explore how fracture toughness testing can be leveraged to inform vitrimer design principles, potentially enabling the development of materials with enhanced damage tolerance and predictable failure modes.

The significance of this research extends beyond academic interest, addressing industrial needs for reliable quality control metrics and design parameters. As vitrimers transition from laboratory curiosities to commercial products, standardized fracture characterization methodologies will become essential for material certification, regulatory approval, and widespread adoption across high-performance applications where mechanical reliability is paramount.

The evolution of vitrimer technology has progressed rapidly over the past decade, with significant advancements in chemistry, processing techniques, and property enhancement. Early vitrimers primarily utilized transesterification reactions, while contemporary systems incorporate diverse exchange mechanisms including disulfide metathesis, transamination, and boronic ester exchange. This chemical diversity has expanded the application landscape for vitrimers across automotive, aerospace, electronics, and medical industries.

Despite these advances, a critical gap exists in standardized methodologies for characterizing the fracture toughness of vitrimers. Fracture toughness—a material's resistance to crack propagation—is particularly complex in vitrimers due to their dynamic network structure, which can potentially self-heal and redistribute stress during fracture events. Traditional fracture mechanics approaches developed for conventional polymers may not fully capture these unique behaviors.

The primary objective of this technical research is to establish comprehensive guidelines for selecting appropriate fracture toughness testing methods for vitrimers and interpreting the resulting data. This includes evaluating the applicability of standard test protocols (ASTM, ISO) to vitrimer systems, identifying modifications necessary to account for their dynamic nature, and developing frameworks for meaningful data interpretation that considers temperature-dependent network rearrangement rates.

Secondary objectives include correlating fracture toughness measurements with vitrimer network architecture, exchange reaction kinetics, and processing history. Additionally, this research aims to explore how fracture toughness testing can be leveraged to inform vitrimer design principles, potentially enabling the development of materials with enhanced damage tolerance and predictable failure modes.

The significance of this research extends beyond academic interest, addressing industrial needs for reliable quality control metrics and design parameters. As vitrimers transition from laboratory curiosities to commercial products, standardized fracture characterization methodologies will become essential for material certification, regulatory approval, and widespread adoption across high-performance applications where mechanical reliability is paramount.

Market Applications and Demand for Vitrimer Materials

Vitrimer materials represent a revolutionary class of polymers that combine the recyclability of thermoplastics with the mechanical strength and chemical resistance of thermosets. The global market for advanced polymers is experiencing significant growth, with vitrimers positioned as a key innovation driver. Current market analysis indicates that the self-healing materials market, which includes vitrimers, is projected to reach $4.1 billion by 2027, growing at a compound annual growth rate of 27.4%.

The automotive industry has emerged as a primary adopter of vitrimer technology, seeking lightweight yet durable materials to improve fuel efficiency while maintaining safety standards. Fracture toughness testing is particularly critical in this sector, as components must withstand impact forces during collisions. Major automotive manufacturers have begun incorporating vitrimer composites in non-structural parts, with plans to expand to semi-structural applications pending further validation of long-term performance metrics.

Aerospace applications represent another high-value market for vitrimers, where the combination of repairability and high-performance characteristics addresses the industry's stringent safety requirements. Boeing and Airbus have initiated research programs exploring vitrimer composites for interior components, with potential future applications in more critical structures. The ability to accurately measure and predict fracture toughness is essential for certification in this highly regulated industry.

The electronics sector has shown increasing interest in vitrimers for flexible displays and device housings. As consumer electronics trend toward foldable and more durable designs, manufacturers require materials with predictable fracture behavior under repeated stress. Companies like Samsung and LG have invested in vitrimer research for next-generation display technologies, where precise fracture toughness data interpretation is crucial for product development.

Medical device manufacturing represents an emerging application area with significant growth potential. The biocompatibility of certain vitrimer formulations, combined with their ability to be sterilized repeatedly without degradation, makes them attractive for implantable and external medical devices. The market for bioresorbable medical polymers alone is expected to reach $1.7 billion by 2025, with vitrimers potentially capturing a significant portion of this growth.

Construction and infrastructure sectors are exploring vitrimers for applications requiring durability under environmental stress. Self-healing capabilities could significantly extend the service life of coatings, sealants, and composite structural elements. The ability to accurately measure fracture toughness under various environmental conditions is particularly valuable for these outdoor applications, where materials face temperature fluctuations, moisture, and UV exposure.

The circular economy initiatives and increasingly stringent environmental regulations worldwide are creating additional market pull for recyclable high-performance materials like vitrimers. Companies facing extended producer responsibility requirements are particularly interested in materials that can be reprocessed multiple times without significant property degradation.

The automotive industry has emerged as a primary adopter of vitrimer technology, seeking lightweight yet durable materials to improve fuel efficiency while maintaining safety standards. Fracture toughness testing is particularly critical in this sector, as components must withstand impact forces during collisions. Major automotive manufacturers have begun incorporating vitrimer composites in non-structural parts, with plans to expand to semi-structural applications pending further validation of long-term performance metrics.

Aerospace applications represent another high-value market for vitrimers, where the combination of repairability and high-performance characteristics addresses the industry's stringent safety requirements. Boeing and Airbus have initiated research programs exploring vitrimer composites for interior components, with potential future applications in more critical structures. The ability to accurately measure and predict fracture toughness is essential for certification in this highly regulated industry.

The electronics sector has shown increasing interest in vitrimers for flexible displays and device housings. As consumer electronics trend toward foldable and more durable designs, manufacturers require materials with predictable fracture behavior under repeated stress. Companies like Samsung and LG have invested in vitrimer research for next-generation display technologies, where precise fracture toughness data interpretation is crucial for product development.

Medical device manufacturing represents an emerging application area with significant growth potential. The biocompatibility of certain vitrimer formulations, combined with their ability to be sterilized repeatedly without degradation, makes them attractive for implantable and external medical devices. The market for bioresorbable medical polymers alone is expected to reach $1.7 billion by 2025, with vitrimers potentially capturing a significant portion of this growth.

Construction and infrastructure sectors are exploring vitrimers for applications requiring durability under environmental stress. Self-healing capabilities could significantly extend the service life of coatings, sealants, and composite structural elements. The ability to accurately measure fracture toughness under various environmental conditions is particularly valuable for these outdoor applications, where materials face temperature fluctuations, moisture, and UV exposure.

The circular economy initiatives and increasingly stringent environmental regulations worldwide are creating additional market pull for recyclable high-performance materials like vitrimers. Companies facing extended producer responsibility requirements are particularly interested in materials that can be reprocessed multiple times without significant property degradation.

Current Fracture Toughness Testing Methods and Challenges

The field of fracture toughness testing for vitrimers currently employs several established methodologies, each with distinct advantages and limitations. Linear elastic fracture mechanics (LEFM) tests, including the Single Edge Notched Bending (SENB) and Compact Tension (CT) tests, remain the gold standard for many rigid materials. However, these methods face significant challenges when applied to vitrimers due to their unique viscoelastic properties and dynamic bond rearrangement capabilities.

Essential Single Edge Notch Tension (ESENT) and Double Cantilever Beam (DCB) tests have gained popularity for vitrimer testing, as they can better accommodate the time-dependent mechanical responses characteristic of these materials. Nevertheless, these methods often struggle with issues of crack tip blunting and stress relaxation during testing, which can lead to inaccurate toughness measurements.

J-integral and crack-tip opening displacement (CTOD) approaches offer more comprehensive frameworks for evaluating fracture behavior beyond the linear elastic regime. These methods can capture the elastic-plastic deformation and energy dissipation mechanisms in vitrimers, but require sophisticated instrumentation and complex data analysis protocols that are not yet standardized for these dynamic polymer networks.

A significant challenge in current testing methodologies is the temperature and rate dependence of vitrimer mechanical properties. Standard testing conditions may not accurately reflect the material's behavior across its operational temperature range, particularly near the topology freezing transition temperature (Tv) where bond exchange kinetics dramatically change. This necessitates the development of temperature-controlled testing environments with precise control capabilities.

Data interpretation presents another major hurdle, as conventional fracture mechanics equations assume time-independent material properties. The dynamic nature of vitrimers, with their ability to rearrange covalent bonds under stress, introduces time-dependent healing phenomena that can confound traditional analysis methods. Researchers currently lack standardized protocols for separating intrinsic toughness from apparent toughness enhanced by self-healing during testing.

Miniaturized testing methods, such as microindentation and small-punch tests, are emerging as potential solutions for rapid screening of vitrimer formulations. However, these techniques require further validation and correlation with macroscale properties before widespread adoption. Additionally, in-situ characterization techniques combining mechanical testing with spectroscopic or imaging methods are being developed to directly observe bond exchange processes during fracture events.

The scientific community has yet to reach consensus on which testing methodologies most accurately characterize vitrimer fracture behavior, particularly for comparing materials across different chemical compositions and network architectures. This lack of standardization hampers material development efforts and complicates the translation of laboratory findings to industrial applications.

Essential Single Edge Notch Tension (ESENT) and Double Cantilever Beam (DCB) tests have gained popularity for vitrimer testing, as they can better accommodate the time-dependent mechanical responses characteristic of these materials. Nevertheless, these methods often struggle with issues of crack tip blunting and stress relaxation during testing, which can lead to inaccurate toughness measurements.

J-integral and crack-tip opening displacement (CTOD) approaches offer more comprehensive frameworks for evaluating fracture behavior beyond the linear elastic regime. These methods can capture the elastic-plastic deformation and energy dissipation mechanisms in vitrimers, but require sophisticated instrumentation and complex data analysis protocols that are not yet standardized for these dynamic polymer networks.

A significant challenge in current testing methodologies is the temperature and rate dependence of vitrimer mechanical properties. Standard testing conditions may not accurately reflect the material's behavior across its operational temperature range, particularly near the topology freezing transition temperature (Tv) where bond exchange kinetics dramatically change. This necessitates the development of temperature-controlled testing environments with precise control capabilities.

Data interpretation presents another major hurdle, as conventional fracture mechanics equations assume time-independent material properties. The dynamic nature of vitrimers, with their ability to rearrange covalent bonds under stress, introduces time-dependent healing phenomena that can confound traditional analysis methods. Researchers currently lack standardized protocols for separating intrinsic toughness from apparent toughness enhanced by self-healing during testing.

Miniaturized testing methods, such as microindentation and small-punch tests, are emerging as potential solutions for rapid screening of vitrimer formulations. However, these techniques require further validation and correlation with macroscale properties before widespread adoption. Additionally, in-situ characterization techniques combining mechanical testing with spectroscopic or imaging methods are being developed to directly observe bond exchange processes during fracture events.

The scientific community has yet to reach consensus on which testing methodologies most accurately characterize vitrimer fracture behavior, particularly for comparing materials across different chemical compositions and network architectures. This lack of standardization hampers material development efforts and complicates the translation of laboratory findings to industrial applications.

Established Fracture Toughness Test Protocols for Vitrimers

01 Vitrimer compositions with enhanced fracture toughness

Vitrimers can be formulated with specific compositions to enhance their fracture toughness properties. These compositions typically include dynamic covalent bonds that allow for stress relaxation while maintaining structural integrity. By carefully selecting the chemical components and their ratios, researchers have developed vitrimers with significantly improved resistance to crack propagation and mechanical failure under stress conditions.- Vitrimer compositions with enhanced fracture toughness: Specific vitrimer compositions can be engineered to exhibit enhanced fracture toughness properties. These materials incorporate dynamic covalent bonds that allow for stress relaxation while maintaining structural integrity. The compositions typically include crosslinked polymer networks with exchangeable bonds that can rearrange under stress, preventing catastrophic failure and improving overall toughness. These formulations often balance network density with mobility to optimize mechanical properties.

- Testing methods for vitrimer fracture toughness: Various specialized testing methodologies have been developed to accurately measure and characterize the fracture toughness of vitrimers. These include modified fracture mechanics tests that account for the unique viscoelastic and self-healing properties of vitrimers. Testing protocols often involve controlled temperature and strain rate conditions to properly evaluate the material's response under different environmental conditions. These methods help quantify how vitrimers resist crack propagation compared to traditional thermosets.

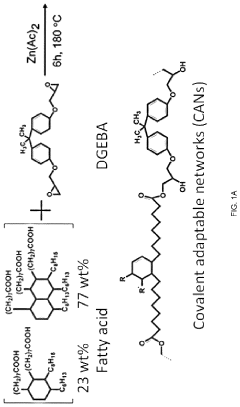

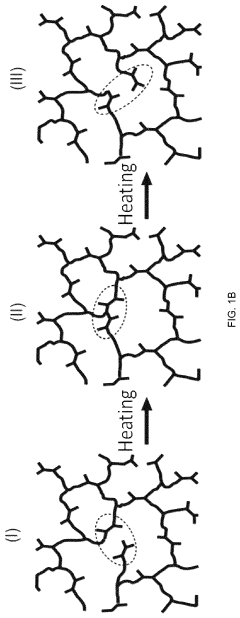

- Self-healing mechanisms improving fracture resistance: Vitrimers exhibit self-healing capabilities that significantly contribute to their fracture toughness. The dynamic bond exchange reactions allow for autonomous repair of microcracks before they propagate into larger fractures. This mechanism is particularly effective at elevated temperatures where bond exchange kinetics are accelerated. The self-healing property enables vitrimers to recover mechanical strength after damage, extending their service life and improving overall fracture resistance compared to conventional polymers.

- Processing techniques affecting fracture properties: The processing methods used in vitrimer manufacturing significantly impact their fracture toughness characteristics. Techniques such as controlled curing protocols, thermal annealing, and processing under specific pressure conditions can optimize the network architecture and bond exchange dynamics. Post-processing treatments can also be employed to enhance fracture resistance by relieving internal stresses and promoting favorable molecular arrangements. These processing variables allow for tailoring fracture properties for specific applications.

- Composite vitrimer systems with reinforced toughness: Incorporating reinforcement materials into vitrimer matrices creates composite systems with substantially improved fracture toughness. These composites combine the dynamic bond exchange capabilities of vitrimers with the reinforcing effects of fillers such as fibers, nanoparticles, or secondary polymer phases. The resulting hierarchical structures can effectively dissipate energy through multiple mechanisms, including crack deflection, bridging, and localized bond exchange. These composite approaches provide pathways to achieve exceptional toughness while maintaining the reprocessability advantages of vitrimers.

02 Testing methods for vitrimer fracture toughness

Various specialized testing methodologies have been developed to accurately measure and characterize the fracture toughness of vitrimers. These methods include modified fracture mechanics tests, dynamic mechanical analysis, and specialized impact resistance measurements that account for the unique viscoelastic and self-healing properties of vitrimers. These testing approaches help quantify how vitrimers respond to mechanical stress and predict their performance in real-world applications.Expand Specific Solutions03 Self-healing mechanisms in vitrimers affecting fracture toughness

The self-healing capabilities of vitrimers significantly contribute to their fracture toughness properties. Through dynamic bond exchange reactions that occur at elevated temperatures or under specific conditions, vitrimers can repair microcracks and damage, preventing catastrophic failure. This self-healing mechanism allows for the redistribution of stress and the reformation of bonds across crack interfaces, effectively increasing the material's overall fracture toughness and extending its service life.Expand Specific Solutions04 Reinforcement strategies for improving vitrimer fracture resistance

Various reinforcement strategies have been employed to enhance the fracture toughness of vitrimers. These include the incorporation of nanofillers, fiber reinforcements, and the development of multi-phase systems with engineered interfaces. By creating composite structures that can dissipate energy through multiple mechanisms, these reinforced vitrimers demonstrate superior resistance to crack initiation and propagation while maintaining their reprocessability and recyclability advantages.Expand Specific Solutions05 Structure-property relationships in vitrimer fracture behavior

Research has established important correlations between the molecular structure of vitrimers and their fracture toughness properties. Factors such as crosslink density, exchange reaction kinetics, and network topology significantly influence how vitrimers respond to mechanical stress. By understanding these structure-property relationships, scientists can design vitrimers with tailored fracture toughness characteristics for specific applications, balancing properties like strength, toughness, and processability.Expand Specific Solutions

Leading Research Groups and Industrial Players in Vitrimer Technology

The fracture toughness testing market for vitrimers is in an emerging growth phase, with increasing interest driven by the unique self-healing and recyclable properties of these materials. The global market size remains relatively modest but is expanding rapidly as vitrimers find applications in automotive, electronics, and aerospace industries. Technologically, the field is transitioning from early development to commercial application, with varying levels of maturity across testing methodologies. Leading players include Corning and Mitsubishi Heavy Industries, who are developing standardized testing protocols, while academic institutions like Xi'an Jiaotong University and California Institute of Technology are advancing fundamental research. Companies such as SCHOTT Glass, Toshiba, and SABIC are integrating vitrimer technology into commercial applications, focusing on establishing reliable fracture toughness measurement techniques for these dynamic polymer networks.

Corning, Inc.

Technical Solution: Corning has developed specialized fracture toughness testing methodologies specifically tailored for vitrimer materials, which combine glass-like and polymer-like properties. Their approach utilizes modified compact tension (CT) specimens with precise notch geometries to account for the dynamic crosslinking nature of vitrimers. Corning's testing protocol incorporates temperature-dependent measurements that capture the unique behavior of vitrimers across their glass transition temperature range, allowing for comprehensive characterization of fracture properties during both glassy and rubbery states. Their methodology includes specialized sample preparation techniques that maintain the integrity of the dynamic covalent networks during testing, and employs digital image correlation (DIC) to track crack propagation patterns unique to vitrimers. Corning has also pioneered the development of standardized data interpretation frameworks that account for the time-dependent mechanical response of vitrimers, enabling more accurate prediction of long-term material performance.

Strengths: Comprehensive testing methodology that accounts for the unique temperature-dependent behavior of vitrimers; advanced imaging techniques for precise crack propagation analysis; established correlation between molecular structure and fracture properties. Weaknesses: Testing protocols may require specialized equipment not widely available; methodology may be optimized for specific vitrimer chemistries in Corning's portfolio rather than all vitrimer types.

SCHOTT Glass Technologies (Suzhou) Co. Ltd.

Technical Solution: SCHOTT has developed a multi-scale approach to vitrimer fracture toughness testing that bridges molecular dynamics with macroscopic mechanical properties. Their methodology incorporates modified Essential Work of Fracture (EWF) tests specifically calibrated for vitrimers' dynamic network structure. SCHOTT's testing protocol includes specialized sample preparation techniques that control the degree of crosslinking and exchange reactions prior to testing, ensuring reproducible results. They employ high-resolution thermal imaging during fracture tests to monitor the heat generation and dissipation associated with bond exchange reactions during crack propagation. This allows for real-time correlation between mechanical loading and chemical network rearrangement. SCHOTT has also pioneered the use of time-temperature superposition principles adapted specifically for vitrimer materials, enabling the prediction of long-term fracture behavior from short-term tests. Their data interpretation framework incorporates both traditional fracture mechanics parameters and vitrimer-specific metrics that quantify the contribution of dynamic covalent bonds to crack resistance.

Strengths: Integration of thermal analysis with mechanical testing provides unique insights into bond exchange dynamics during fracture; specialized sample preparation methods ensure consistent network architecture; comprehensive data interpretation framework. Weaknesses: Complex testing setup requires significant expertise and specialized equipment; methodology may be less applicable to vitrimers with very slow exchange kinetics.

Critical Analysis of Vitrimer-Specific Test Standards

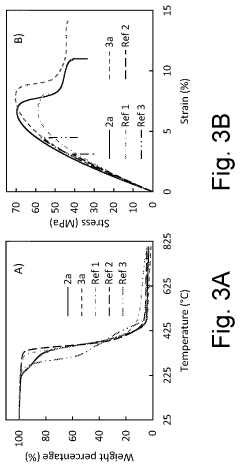

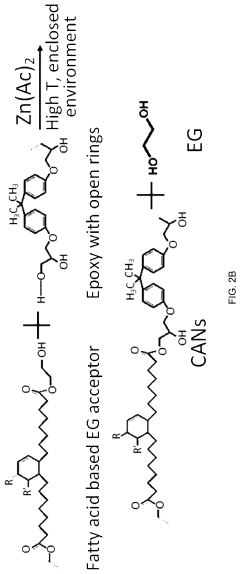

Epoxy-derived covalent adaptable networks and methods of their production

PatentPendingUS20230067778A1

Innovation

- Development of epoxy-derived covalent adaptable networks (CANs) utilizing a combination of vinylogous urethane, urea, or amide functions with free amines, enabling bond-exchange without catalysts, with low relaxation times and broad applicability across various monomers and monomer ratios, resulting in transparent or translucent materials with reduced discoloration upon heating.

Methods of recycling and reshaping thermosetting polymers and composites thereof

PatentActiveUS11932734B2

Innovation

- The use of small molecule alcohols, thiols, or amines as solvents to dissolve and re-polymerize thermoset polymers, allowing for the recovery of both the polymer matrix and carbon fibers through bond exchange reactions, which can be catalyzed at elevated temperatures without the need for mechanical pressure or harsh chemicals, enabling recycling and reshaping of thermosetting polymers and composites.

Standardization Efforts for Vitrimer Mechanical Testing

The standardization of mechanical testing protocols for vitrimers represents a critical frontier in materials science, with significant implications for industrial adoption and quality control. Currently, there exists a notable gap in standardized testing methodologies specifically tailored to vitrimers' unique dynamic behavior, which differs substantially from traditional thermosets and thermoplastics.

Several international standards organizations, including ASTM International, ISO, and ESIS (European Structural Integrity Society), have begun preliminary discussions on developing vitrimer-specific testing protocols. These efforts primarily focus on adapting existing fracture toughness testing methods to account for the time-temperature dependence of vitrimer mechanical properties.

The ASTM D30 Committee on Composite Materials has established a working group dedicated to dynamic covalent networks, with a subcommittee specifically addressing standardized mechanical testing procedures for vitrimers. Their initial focus has been on modifying ASTM D5045 (Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials) to incorporate considerations for bond exchange kinetics.

ISO Technical Committee 61 on Plastics has similarly initiated a project to develop guidelines for characterizing the mechanical properties of dynamic polymer networks, with particular emphasis on fracture toughness evaluation across different temperature regimes and loading rates.

A significant challenge in these standardization efforts is establishing consistent specimen preparation protocols that account for the processing history of vitrimers, which substantially affects network topology and subsequent mechanical behavior. Current draft guidelines recommend detailed documentation of thermal history, catalyst concentration, and curing conditions to ensure reproducibility.

Interlaboratory studies coordinated by the European Vitrimer Network have begun comparing fracture toughness results across different testing facilities, aiming to identify key variables affecting measurement consistency. Preliminary findings suggest that strain rate and environmental temperature control represent critical parameters requiring strict standardization.

The Materials Research Society has established a task force to develop recommended practices for reporting vitrimer mechanical properties, emphasizing the importance of specifying bond exchange kinetics parameters alongside traditional fracture toughness values to facilitate meaningful material comparisons.

These standardization initiatives, while still in developmental stages, represent crucial steps toward establishing a unified framework for vitrimer mechanical characterization, ultimately facilitating broader industrial implementation and enabling more reliable material selection processes for engineering applications.

Several international standards organizations, including ASTM International, ISO, and ESIS (European Structural Integrity Society), have begun preliminary discussions on developing vitrimer-specific testing protocols. These efforts primarily focus on adapting existing fracture toughness testing methods to account for the time-temperature dependence of vitrimer mechanical properties.

The ASTM D30 Committee on Composite Materials has established a working group dedicated to dynamic covalent networks, with a subcommittee specifically addressing standardized mechanical testing procedures for vitrimers. Their initial focus has been on modifying ASTM D5045 (Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials) to incorporate considerations for bond exchange kinetics.

ISO Technical Committee 61 on Plastics has similarly initiated a project to develop guidelines for characterizing the mechanical properties of dynamic polymer networks, with particular emphasis on fracture toughness evaluation across different temperature regimes and loading rates.

A significant challenge in these standardization efforts is establishing consistent specimen preparation protocols that account for the processing history of vitrimers, which substantially affects network topology and subsequent mechanical behavior. Current draft guidelines recommend detailed documentation of thermal history, catalyst concentration, and curing conditions to ensure reproducibility.

Interlaboratory studies coordinated by the European Vitrimer Network have begun comparing fracture toughness results across different testing facilities, aiming to identify key variables affecting measurement consistency. Preliminary findings suggest that strain rate and environmental temperature control represent critical parameters requiring strict standardization.

The Materials Research Society has established a task force to develop recommended practices for reporting vitrimer mechanical properties, emphasizing the importance of specifying bond exchange kinetics parameters alongside traditional fracture toughness values to facilitate meaningful material comparisons.

These standardization initiatives, while still in developmental stages, represent crucial steps toward establishing a unified framework for vitrimer mechanical characterization, ultimately facilitating broader industrial implementation and enabling more reliable material selection processes for engineering applications.

Environmental Factors Affecting Vitrimer Fracture Performance

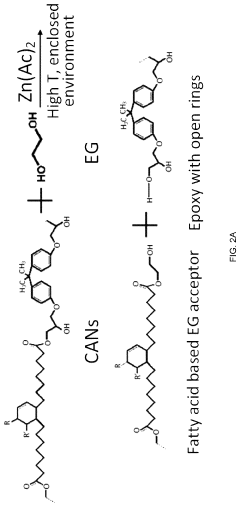

Environmental conditions significantly influence the fracture performance of vitrimers, creating a complex relationship that must be thoroughly understood for accurate test selection and data interpretation. Temperature represents the most critical environmental factor, as vitrimers exhibit distinct mechanical behaviors across different thermal regimes. Below their glass transition temperature (Tg), vitrimers behave similarly to thermosets with relatively brittle fracture characteristics. However, near and above Tg, the dynamic bond exchange mechanisms activate, leading to viscoelastic behavior that dramatically alters fracture toughness measurements.

Humidity and moisture exposure constitute another crucial environmental consideration. Vitrimers containing hydrolyzable bonds, particularly those based on transesterification or transamidation chemistry, may experience accelerated bond exchange rates in humid environments. This acceleration can lead to premature stress relaxation during fracture testing, potentially yielding misleading toughness values. Studies have demonstrated that moisture absorption can reduce the apparent fracture toughness by up to 30% in certain vitrimer systems, necessitating controlled humidity conditions during testing.

Chemical exposure presents additional complexities for vitrimer fracture performance. Solvents and reactive media can penetrate the vitrimer network, causing swelling or participating in exchange reactions that fundamentally alter the material's mechanical properties. For instance, acidic or basic environments may catalyze dynamic bond exchanges, effectively lowering the activation energy for network rearrangement and consequently affecting fracture behavior.

UV radiation and oxidative conditions represent significant environmental stressors for vitrimers in outdoor applications. Prolonged exposure to these conditions can degrade the dynamic bonds responsible for the vitrimer's unique properties, potentially converting the material to a conventional thermoset with diminished toughness. This degradation pathway necessitates specialized testing protocols that incorporate accelerated aging to predict long-term fracture performance.

Mechanical pre-conditioning, while not strictly environmental, interacts with environmental factors to influence fracture behavior. Cyclic loading under varying temperature conditions can induce bond exchange and network reorganization, effectively "training" the vitrimer network and altering subsequent fracture response. This phenomenon, termed thermo-mechanical memory, must be accounted for when interpreting fracture toughness data.

Strain rate sensitivity represents another critical consideration that varies with environmental conditions. At elevated temperatures where bond exchange is active, vitrimers exhibit pronounced strain rate dependence in fracture tests. This behavior necessitates standardized testing speeds calibrated to the specific environmental conditions to ensure reproducible and meaningful fracture toughness measurements.

Humidity and moisture exposure constitute another crucial environmental consideration. Vitrimers containing hydrolyzable bonds, particularly those based on transesterification or transamidation chemistry, may experience accelerated bond exchange rates in humid environments. This acceleration can lead to premature stress relaxation during fracture testing, potentially yielding misleading toughness values. Studies have demonstrated that moisture absorption can reduce the apparent fracture toughness by up to 30% in certain vitrimer systems, necessitating controlled humidity conditions during testing.

Chemical exposure presents additional complexities for vitrimer fracture performance. Solvents and reactive media can penetrate the vitrimer network, causing swelling or participating in exchange reactions that fundamentally alter the material's mechanical properties. For instance, acidic or basic environments may catalyze dynamic bond exchanges, effectively lowering the activation energy for network rearrangement and consequently affecting fracture behavior.

UV radiation and oxidative conditions represent significant environmental stressors for vitrimers in outdoor applications. Prolonged exposure to these conditions can degrade the dynamic bonds responsible for the vitrimer's unique properties, potentially converting the material to a conventional thermoset with diminished toughness. This degradation pathway necessitates specialized testing protocols that incorporate accelerated aging to predict long-term fracture performance.

Mechanical pre-conditioning, while not strictly environmental, interacts with environmental factors to influence fracture behavior. Cyclic loading under varying temperature conditions can induce bond exchange and network reorganization, effectively "training" the vitrimer network and altering subsequent fracture response. This phenomenon, termed thermo-mechanical memory, must be accounted for when interpreting fracture toughness data.

Strain rate sensitivity represents another critical consideration that varies with environmental conditions. At elevated temperatures where bond exchange is active, vitrimers exhibit pronounced strain rate dependence in fracture tests. This behavior necessitates standardized testing speeds calibrated to the specific environmental conditions to ensure reproducible and meaningful fracture toughness measurements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!