Electrochemical hydrogel sensors for point-of-care testing

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Hydrogel Sensors Background and Objectives

Electrochemical hydrogel sensors represent a revolutionary advancement in biosensing technology, emerging from the convergence of electrochemistry, materials science, and biomedical engineering. The evolution of these sensors can be traced back to the early 2000s when researchers began exploring hydrogels as biocompatible matrices for biosensing applications. Over the past decade, significant progress has been made in enhancing the sensitivity, selectivity, and stability of these sensors, driven by the growing demand for rapid, accurate, and accessible diagnostic tools.

The technological trajectory of electrochemical hydrogel sensors has been characterized by continuous improvements in material composition, fabrication techniques, and signal transduction mechanisms. Early iterations primarily utilized conventional hydrogels with limited conductivity, whereas recent developments have incorporated nanomaterials, conductive polymers, and stimuli-responsive elements to achieve superior performance metrics.

Point-of-care testing (POCT) represents a paradigm shift in healthcare delivery, enabling diagnostic procedures to be performed at or near the patient location. This approach offers numerous advantages including reduced turnaround time, decreased sample volume requirements, and enhanced accessibility in resource-limited settings. Electrochemical hydrogel sensors are particularly well-suited for POCT applications due to their inherent flexibility, biocompatibility, and capacity for miniaturization.

The primary technical objectives for advancing electrochemical hydrogel sensors for POCT include: enhancing sensitivity to detect biomarkers at clinically relevant concentrations; improving selectivity to minimize interference from complex biological matrices; extending shelf-life and operational stability under ambient conditions; developing manufacturing processes amenable to mass production; and ensuring seamless integration with portable readout devices or smartphone-based platforms.

Current research trends indicate a growing focus on multifunctional hydrogel sensors capable of simultaneous detection of multiple analytes, self-calibrating systems that maintain accuracy over extended periods, and closed-loop platforms that combine sensing and therapeutic functionalities. Additionally, there is increasing emphasis on developing eco-friendly, biodegradable sensor components to address sustainability concerns.

The convergence of artificial intelligence with electrochemical hydrogel sensing technology represents an emerging frontier, with machine learning algorithms being employed to enhance signal processing, pattern recognition, and predictive analytics. This integration promises to further expand the capabilities and applications of these sensors in personalized medicine, remote patient monitoring, and epidemiological surveillance.

The ultimate goal of this technological evolution is to establish electrochemical hydrogel sensors as ubiquitous tools in healthcare settings worldwide, enabling rapid, accurate, and cost-effective diagnostic testing accessible to all populations, thereby contributing to improved health outcomes and more efficient healthcare delivery systems.

The technological trajectory of electrochemical hydrogel sensors has been characterized by continuous improvements in material composition, fabrication techniques, and signal transduction mechanisms. Early iterations primarily utilized conventional hydrogels with limited conductivity, whereas recent developments have incorporated nanomaterials, conductive polymers, and stimuli-responsive elements to achieve superior performance metrics.

Point-of-care testing (POCT) represents a paradigm shift in healthcare delivery, enabling diagnostic procedures to be performed at or near the patient location. This approach offers numerous advantages including reduced turnaround time, decreased sample volume requirements, and enhanced accessibility in resource-limited settings. Electrochemical hydrogel sensors are particularly well-suited for POCT applications due to their inherent flexibility, biocompatibility, and capacity for miniaturization.

The primary technical objectives for advancing electrochemical hydrogel sensors for POCT include: enhancing sensitivity to detect biomarkers at clinically relevant concentrations; improving selectivity to minimize interference from complex biological matrices; extending shelf-life and operational stability under ambient conditions; developing manufacturing processes amenable to mass production; and ensuring seamless integration with portable readout devices or smartphone-based platforms.

Current research trends indicate a growing focus on multifunctional hydrogel sensors capable of simultaneous detection of multiple analytes, self-calibrating systems that maintain accuracy over extended periods, and closed-loop platforms that combine sensing and therapeutic functionalities. Additionally, there is increasing emphasis on developing eco-friendly, biodegradable sensor components to address sustainability concerns.

The convergence of artificial intelligence with electrochemical hydrogel sensing technology represents an emerging frontier, with machine learning algorithms being employed to enhance signal processing, pattern recognition, and predictive analytics. This integration promises to further expand the capabilities and applications of these sensors in personalized medicine, remote patient monitoring, and epidemiological surveillance.

The ultimate goal of this technological evolution is to establish electrochemical hydrogel sensors as ubiquitous tools in healthcare settings worldwide, enabling rapid, accurate, and cost-effective diagnostic testing accessible to all populations, thereby contributing to improved health outcomes and more efficient healthcare delivery systems.

Point-of-Care Testing Market Analysis

The global Point-of-Care Testing (POCT) market has experienced substantial growth in recent years, valued at approximately $29.5 billion in 2020 and projected to reach $50.6 billion by 2025, representing a compound annual growth rate (CAGR) of 11.4%. This growth is primarily driven by the increasing prevalence of chronic and infectious diseases, the aging population, and the growing demand for rapid diagnostic solutions.

Electrochemical hydrogel sensors have emerged as a promising technology within the POCT market due to their high sensitivity, specificity, and ability to provide real-time results. The market for these sensors is expected to grow at a CAGR of 13.2% from 2021 to 2026, outpacing the overall POCT market growth.

Geographically, North America currently dominates the POCT market with approximately 40% market share, followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is anticipated to witness the highest growth rate due to improving healthcare infrastructure, increasing healthcare expenditure, and growing awareness about early disease diagnosis.

By application segment, infectious disease testing represents the largest market share (35%), followed by cardiac markers (20%), glucose monitoring (15%), and coagulation testing (10%). Electrochemical hydrogel sensors are particularly gaining traction in infectious disease and cardiac marker testing segments due to their enhanced performance characteristics.

The end-user landscape is dominated by hospitals and clinics (45%), followed by diagnostic laboratories (25%), home care settings (20%), and others (10%). The home care segment is expected to witness the fastest growth, driven by the increasing focus on patient-centric care and the development of user-friendly POCT devices incorporating electrochemical hydrogel sensors.

Key market drivers include the growing need for rapid diagnosis, increasing prevalence of lifestyle-related diseases, technological advancements in sensor technology, and the shift toward decentralized healthcare. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of rapid, accessible diagnostic solutions.

Challenges facing the market include stringent regulatory requirements, reimbursement issues, and quality concerns. However, opportunities exist in emerging markets, technological innovations, and integration with digital health platforms. The development of multiplexed electrochemical hydrogel sensors capable of detecting multiple analytes simultaneously represents a particularly promising growth avenue.

Consumer trends indicate increasing preference for non-invasive or minimally invasive testing methods, personalized healthcare solutions, and connectivity features that enable data sharing with healthcare providers, all of which align well with the capabilities of advanced electrochemical hydrogel sensor technologies.

Electrochemical hydrogel sensors have emerged as a promising technology within the POCT market due to their high sensitivity, specificity, and ability to provide real-time results. The market for these sensors is expected to grow at a CAGR of 13.2% from 2021 to 2026, outpacing the overall POCT market growth.

Geographically, North America currently dominates the POCT market with approximately 40% market share, followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is anticipated to witness the highest growth rate due to improving healthcare infrastructure, increasing healthcare expenditure, and growing awareness about early disease diagnosis.

By application segment, infectious disease testing represents the largest market share (35%), followed by cardiac markers (20%), glucose monitoring (15%), and coagulation testing (10%). Electrochemical hydrogel sensors are particularly gaining traction in infectious disease and cardiac marker testing segments due to their enhanced performance characteristics.

The end-user landscape is dominated by hospitals and clinics (45%), followed by diagnostic laboratories (25%), home care settings (20%), and others (10%). The home care segment is expected to witness the fastest growth, driven by the increasing focus on patient-centric care and the development of user-friendly POCT devices incorporating electrochemical hydrogel sensors.

Key market drivers include the growing need for rapid diagnosis, increasing prevalence of lifestyle-related diseases, technological advancements in sensor technology, and the shift toward decentralized healthcare. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of rapid, accessible diagnostic solutions.

Challenges facing the market include stringent regulatory requirements, reimbursement issues, and quality concerns. However, opportunities exist in emerging markets, technological innovations, and integration with digital health platforms. The development of multiplexed electrochemical hydrogel sensors capable of detecting multiple analytes simultaneously represents a particularly promising growth avenue.

Consumer trends indicate increasing preference for non-invasive or minimally invasive testing methods, personalized healthcare solutions, and connectivity features that enable data sharing with healthcare providers, all of which align well with the capabilities of advanced electrochemical hydrogel sensor technologies.

Current Status and Challenges in Hydrogel Sensor Technology

Electrochemical hydrogel sensors have emerged as promising platforms for point-of-care testing due to their unique properties combining hydrophilicity, flexibility, and biocompatibility. Currently, these sensors have reached significant development milestones, with various commercial applications beginning to emerge in glucose monitoring, wound healing assessment, and sweat analysis.

The global landscape shows uneven development, with North America and Europe leading in research output and patent filings. Asian countries, particularly China, Japan, and South Korea, are rapidly closing this gap with increased R&D investments. Academic-industrial collaborations have accelerated technology transfer, though regulatory approval remains a significant bottleneck in many regions.

Despite progress, several technical challenges persist in hydrogel sensor technology. Stability issues remain paramount, as many hydrogel matrices experience performance degradation over time due to dehydration, biofouling, and mechanical stress. Long-term functionality beyond 14 days remains difficult to achieve in real-world applications, limiting continuous monitoring capabilities.

Sensitivity and selectivity challenges are particularly evident in complex biological fluids where multiple analytes and interferents coexist. Cross-reactivity problems and signal drift in the presence of proteins and other biomolecules continue to hamper reliable measurements in clinical settings. The signal-to-noise ratio deteriorates significantly in samples with low analyte concentrations, affecting detection limits.

Manufacturing scalability presents another major hurdle. Current fabrication methods often involve complex, multi-step processes that are difficult to standardize for mass production. Batch-to-batch variability remains high, affecting sensor reproducibility and reliability. The integration of electrochemical components with hydrogel matrices requires precise control that current manufacturing technologies struggle to maintain consistently.

Power requirements and data transmission capabilities limit the practical deployment of these sensors. While some progress has been made in developing self-powered systems using biofuel cells, most current designs still require external power sources or frequent recharging, restricting true point-of-care applications in resource-limited settings.

Biocompatibility and toxicity concerns persist despite hydrogels' generally favorable biological profiles. Long-term implantation studies have revealed inflammatory responses in some cases, while leaching of unreacted monomers or crosslinking agents remains problematic. Regulatory bodies have expressed concerns about the long-term safety profiles of novel hydrogel formulations, particularly those incorporating nanomaterials.

Cost-effectiveness represents another significant barrier, with current manufacturing expenses making widespread adoption economically challenging, especially in developing regions where point-of-care testing could provide the greatest impact on healthcare outcomes.

The global landscape shows uneven development, with North America and Europe leading in research output and patent filings. Asian countries, particularly China, Japan, and South Korea, are rapidly closing this gap with increased R&D investments. Academic-industrial collaborations have accelerated technology transfer, though regulatory approval remains a significant bottleneck in many regions.

Despite progress, several technical challenges persist in hydrogel sensor technology. Stability issues remain paramount, as many hydrogel matrices experience performance degradation over time due to dehydration, biofouling, and mechanical stress. Long-term functionality beyond 14 days remains difficult to achieve in real-world applications, limiting continuous monitoring capabilities.

Sensitivity and selectivity challenges are particularly evident in complex biological fluids where multiple analytes and interferents coexist. Cross-reactivity problems and signal drift in the presence of proteins and other biomolecules continue to hamper reliable measurements in clinical settings. The signal-to-noise ratio deteriorates significantly in samples with low analyte concentrations, affecting detection limits.

Manufacturing scalability presents another major hurdle. Current fabrication methods often involve complex, multi-step processes that are difficult to standardize for mass production. Batch-to-batch variability remains high, affecting sensor reproducibility and reliability. The integration of electrochemical components with hydrogel matrices requires precise control that current manufacturing technologies struggle to maintain consistently.

Power requirements and data transmission capabilities limit the practical deployment of these sensors. While some progress has been made in developing self-powered systems using biofuel cells, most current designs still require external power sources or frequent recharging, restricting true point-of-care applications in resource-limited settings.

Biocompatibility and toxicity concerns persist despite hydrogels' generally favorable biological profiles. Long-term implantation studies have revealed inflammatory responses in some cases, while leaching of unreacted monomers or crosslinking agents remains problematic. Regulatory bodies have expressed concerns about the long-term safety profiles of novel hydrogel formulations, particularly those incorporating nanomaterials.

Cost-effectiveness represents another significant barrier, with current manufacturing expenses making widespread adoption economically challenging, especially in developing regions where point-of-care testing could provide the greatest impact on healthcare outcomes.

Current Electrochemical Hydrogel Sensing Methodologies

01 Conductive polymer-based hydrogel sensors

Electrochemical hydrogel sensors incorporating conductive polymers offer enhanced electrical conductivity and sensitivity for biosensing applications. These polymers, such as polyaniline, polypyrrole, and PEDOT, create a conductive network within the hydrogel matrix, facilitating electron transfer between analytes and electrodes. The combination of hydrogel's biocompatibility with conductive polymers' electrical properties enables real-time monitoring of various biomarkers with improved signal transduction and stability in physiological environments.- Conductive hydrogel compositions for electrochemical sensing: Conductive hydrogels combine the properties of hydrogels with electrical conductivity, making them ideal for electrochemical sensing applications. These materials typically incorporate conductive polymers or nanomaterials within a hydrogel matrix to create flexible, biocompatible sensors. The hydrogel structure provides a moist environment that facilitates ion transport while maintaining good mechanical properties, and the conductive elements enable efficient signal transduction for detecting various analytes.

- Hydrogel-based wearable electrochemical sensors: Wearable electrochemical sensors utilizing hydrogels offer continuous monitoring capabilities with enhanced comfort and conformability to the human body. These sensors can be designed as patches, textiles, or flexible devices that adhere to the skin and monitor various physiological parameters or biomarkers in bodily fluids such as sweat or interstitial fluid. The hydrogel component provides excellent skin contact, reduces motion artifacts, and improves sensor stability during movement while maintaining electrochemical functionality.

- Stimuli-responsive hydrogel sensors for targeted detection: Stimuli-responsive hydrogels change their properties in response to specific environmental triggers, enabling targeted electrochemical detection capabilities. These smart materials can be engineered to respond to changes in pH, temperature, specific ions, or biomolecules by altering their swelling behavior, permeability, or electrical properties. This responsiveness enhances the selectivity and sensitivity of electrochemical sensors, allowing for precise detection of analytes in complex biological environments.

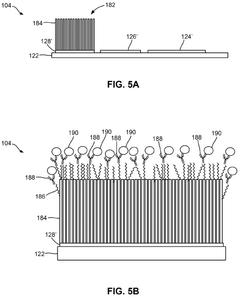

- Nanocomposite hydrogels for enhanced sensing performance: Nanocomposite hydrogels incorporate various nanomaterials such as carbon nanotubes, graphene, metal nanoparticles, or quantum dots to enhance the electrochemical sensing capabilities. These nanomaterials improve electrical conductivity, increase surface area for electrochemical reactions, and provide additional functional groups for analyte binding. The resulting nanocomposite sensors exhibit improved sensitivity, lower detection limits, faster response times, and greater stability compared to conventional hydrogel sensors.

- Biocompatible hydrogel interfaces for in vivo electrochemical sensing: Biocompatible hydrogel interfaces are designed specifically for in vivo electrochemical sensing applications, where direct contact with biological tissues is required. These materials minimize foreign body responses, reduce biofouling, and maintain sensor functionality in complex biological environments. The hydrogel composition can be tailored to match the mechanical properties of surrounding tissues while incorporating antimicrobial components or anti-inflammatory agents to improve long-term biocompatibility and sensor longevity for continuous monitoring applications.

02 Nanocomposite hydrogel sensors for enhanced sensitivity

Incorporating nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles into hydrogel matrices creates nanocomposite sensors with significantly improved electrochemical performance. These nanomaterials enhance electron transfer rates, increase surface area for analyte interaction, and improve mechanical properties of the hydrogel. The resulting nanocomposite sensors demonstrate higher sensitivity, lower detection limits, and faster response times for detecting various analytes including glucose, heavy metals, and biomarkers in complex biological samples.Expand Specific Solutions03 Stimuli-responsive hydrogel sensors

Stimuli-responsive hydrogel sensors change their properties in response to environmental triggers such as pH, temperature, or specific biomolecules. These smart hydrogels undergo reversible volume changes or alterations in their electrochemical properties when exposed to target analytes, generating measurable electrical signals. The responsive nature enables selective detection of specific biomarkers while minimizing interference from other substances. Applications include continuous glucose monitoring, detection of disease biomarkers, and environmental pollutant sensing with high specificity and adaptability to different sensing environments.Expand Specific Solutions04 Wearable and flexible electrochemical hydrogel sensors

Flexible and stretchable hydrogel-based electrochemical sensors are designed for wearable health monitoring applications. These sensors combine soft hydrogel materials with flexible electrodes to create conformable devices that maintain functionality during movement and deformation. The hydrogel matrix provides a stable interface between the skin and sensing elements, enabling continuous monitoring of physiological parameters such as glucose levels, electrolytes, and metabolites. Advanced fabrication techniques including 3D printing and microfabrication allow for customized sensor designs that can be integrated into various wearable platforms.Expand Specific Solutions05 Enzyme-immobilized hydrogel biosensors

Enzyme-immobilized hydrogel biosensors incorporate specific enzymes within the hydrogel matrix to catalyze reactions with target analytes, generating electrochemical signals. The three-dimensional hydrogel structure provides an ideal microenvironment for maintaining enzyme stability and activity while allowing diffusion of analytes. These biosensors offer high selectivity for specific biomolecules such as glucose, lactate, and cholesterol. Various immobilization techniques including physical entrapment, covalent binding, and cross-linking are employed to optimize enzyme retention and activity, resulting in sensors with extended operational lifetimes and improved analytical performance.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

Electrochemical hydrogel sensors for point-of-care testing are advancing through early commercialization stages, with the market expected to reach significant growth due to increasing demand for rapid, accessible healthcare diagnostics. The technology combines the benefits of hydrogels with electrochemical sensing to enable real-time, sensitive detection at the point of care. Major players include established medical device companies like Abbott Point of Care and Roche Diagnostics, who leverage their extensive distribution networks, alongside innovative research from academic institutions such as The University of California and Technical University of Denmark. Nova Biomedical and Ascensia Diabetes Care are focusing on specialized applications, particularly in blood glucose monitoring, while emerging collaborations between universities and industry partners are accelerating technology maturation and clinical validation.

Abbott Point of Care, Inc.

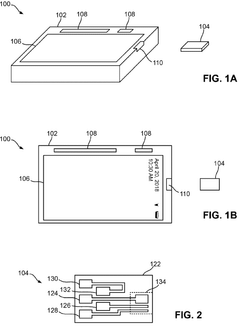

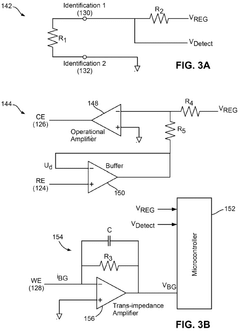

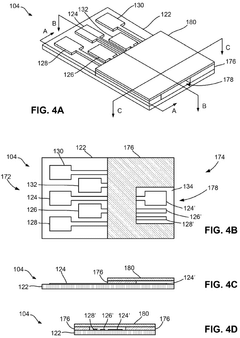

Technical Solution: Abbott Point of Care has developed advanced electrochemical hydrogel sensor platforms specifically designed for point-of-care testing applications. Their i-STAT system utilizes specialized hydrogel matrices embedded with electrochemical sensors that enable rapid analysis of blood samples. The technology incorporates conductive hydrogels with tailored porosity that allows for selective analyte diffusion while maintaining sensor stability. Abbott's approach combines multi-layered hydrogel structures with integrated microelectrodes to create disposable test cartridges capable of measuring multiple parameters simultaneously. The hydrogel composition includes biocompatible polymers modified with redox-active components that enhance signal transduction and improve detection limits. Their proprietary manufacturing process ensures consistent sensor performance across production batches, with integrated quality control mechanisms that verify sensor functionality before patient use[1][3].

Strengths: Highly integrated system with established clinical validation and regulatory approvals; extensive market presence with widespread adoption in hospital settings; robust manufacturing capabilities ensuring product consistency. Weaknesses: Relatively higher cost per test compared to traditional laboratory methods; limited shelf life of hydrogel sensors requiring controlled storage conditions; system requires proprietary hardware limiting flexibility.

F. Hoffmann-La Roche Ltd.

Technical Solution: Roche has pioneered electrochemical hydrogel sensor technology for point-of-care diagnostics through their Accu-Chek and cobas systems. Their approach utilizes specially formulated hydrogels containing cross-linked networks of hydrophilic polymers integrated with electrochemical detection elements. The company has developed proprietary hydrogel formulations that incorporate enzyme-stabilizing components, extending sensor lifetime and improving accuracy in biological fluids. Their technology employs multi-layer sensor designs where each layer serves specific functions: selective membranes for interference rejection, enzyme-containing hydrogels for analyte recognition, and electrode structures for signal transduction. Roche's sensors feature temperature compensation algorithms and automatic calibration systems that adjust for environmental variations. The company has also developed manufacturing techniques for mass-producing these complex sensor structures with high reproducibility, enabling widespread deployment in clinical settings worldwide[2][5].

Strengths: Extensive experience in commercializing diagnostic technologies with established global distribution networks; sophisticated manufacturing capabilities ensuring high-volume production with consistent quality; comprehensive clinical validation data supporting performance claims. Weaknesses: Higher initial investment costs for implementing their systems; proprietary consumables creating customer lock-in; some systems require more frequent calibration compared to newer technologies.

Key Patents and Scientific Breakthroughs in Hydrogel Sensors

Electrochemical Sensor System

PatentInactiveUS20200362158A1

Innovation

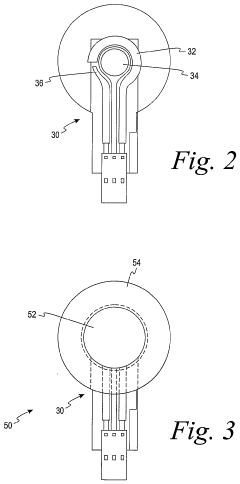

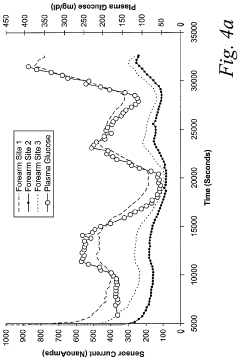

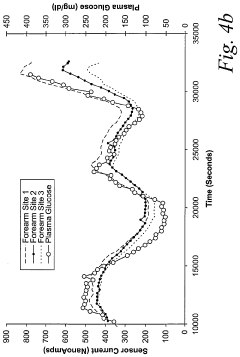

- A hydrogel composition comprising specific monomers, cross-linking agents, and solvents, forming a copolymeric network that provides mechanical and thermal stability, allowing for the extraction of interstitial fluid for analyte concentration determination using an electrochemical sensor system.

Portable electrochemical-sensor system for analyzing user health conditions and method thereof

PatentActiveUS12117435B2

Innovation

- A portable electrochemical-sensor system with a point-of-care (PoC) device and disposable electrochemical-sensor structures that can detect multiple biomarkers in small bodily fluid samples, integrated with geospatial health care features for emergency communication.

Regulatory Framework for Medical Diagnostic Devices

The regulatory landscape for electrochemical hydrogel sensors in point-of-care testing (POCT) is complex and multifaceted, requiring careful navigation by manufacturers and healthcare providers. These innovative diagnostic tools must comply with stringent frameworks established by various international regulatory bodies to ensure safety, efficacy, and reliability.

In the United States, the Food and Drug Administration (FDA) classifies most electrochemical hydrogel sensors as Class II medical devices, requiring 510(k) premarket notification unless they qualify for the Clinical Laboratory Improvement Amendments (CLIA) waived test status. The FDA's approach emphasizes analytical and clinical validation, with particular attention to sensitivity, specificity, and reproducibility of results in diverse clinical settings.

The European Union has implemented the In Vitro Diagnostic Regulation (IVDR 2017/746), which replaced the previous In Vitro Diagnostic Directive (IVDD) with a transition period ending in 2022. This regulation introduces more rigorous requirements for clinical evidence, post-market surveillance, and risk classification. Electrochemical hydrogel sensors typically fall under Class B or C, depending on their intended use and associated risks.

In Asia, regulatory frameworks vary significantly. Japan's Pharmaceuticals and Medical Devices Agency (PMDA) requires thorough clinical validation and quality management system certification. China's National Medical Products Administration (NMPA) has recently strengthened its regulatory oversight, implementing a classification-based system similar to the FDA's approach but with unique documentation requirements.

International standards play a crucial role in harmonizing these diverse regulatory requirements. ISO 13485 for quality management systems and IEC 61010 for safety requirements are fundamental for manufacturers. Additionally, ISO 15197 specifically addresses requirements for blood glucose monitoring systems, which share technological similarities with many electrochemical hydrogel sensors.

Regulatory considerations extend beyond initial approval to encompass the entire product lifecycle. Post-market surveillance, adverse event reporting, and quality system regulations must be continuously maintained. For electrochemical hydrogel sensors used in POCT, data security and privacy regulations such as HIPAA in the US and GDPR in Europe add another layer of compliance requirements, particularly for devices with wireless connectivity or cloud-based data management.

Emerging regulatory trends indicate a shift toward more adaptive frameworks that can accommodate rapid technological innovation while maintaining safety standards. The FDA's Digital Health Software Precertification Program and the EU's MDCG guidance on software as a medical device exemplify this evolution, potentially streamlining pathways for novel electrochemical sensing technologies that incorporate artificial intelligence or machine learning components.

In the United States, the Food and Drug Administration (FDA) classifies most electrochemical hydrogel sensors as Class II medical devices, requiring 510(k) premarket notification unless they qualify for the Clinical Laboratory Improvement Amendments (CLIA) waived test status. The FDA's approach emphasizes analytical and clinical validation, with particular attention to sensitivity, specificity, and reproducibility of results in diverse clinical settings.

The European Union has implemented the In Vitro Diagnostic Regulation (IVDR 2017/746), which replaced the previous In Vitro Diagnostic Directive (IVDD) with a transition period ending in 2022. This regulation introduces more rigorous requirements for clinical evidence, post-market surveillance, and risk classification. Electrochemical hydrogel sensors typically fall under Class B or C, depending on their intended use and associated risks.

In Asia, regulatory frameworks vary significantly. Japan's Pharmaceuticals and Medical Devices Agency (PMDA) requires thorough clinical validation and quality management system certification. China's National Medical Products Administration (NMPA) has recently strengthened its regulatory oversight, implementing a classification-based system similar to the FDA's approach but with unique documentation requirements.

International standards play a crucial role in harmonizing these diverse regulatory requirements. ISO 13485 for quality management systems and IEC 61010 for safety requirements are fundamental for manufacturers. Additionally, ISO 15197 specifically addresses requirements for blood glucose monitoring systems, which share technological similarities with many electrochemical hydrogel sensors.

Regulatory considerations extend beyond initial approval to encompass the entire product lifecycle. Post-market surveillance, adverse event reporting, and quality system regulations must be continuously maintained. For electrochemical hydrogel sensors used in POCT, data security and privacy regulations such as HIPAA in the US and GDPR in Europe add another layer of compliance requirements, particularly for devices with wireless connectivity or cloud-based data management.

Emerging regulatory trends indicate a shift toward more adaptive frameworks that can accommodate rapid technological innovation while maintaining safety standards. The FDA's Digital Health Software Precertification Program and the EU's MDCG guidance on software as a medical device exemplify this evolution, potentially streamlining pathways for novel electrochemical sensing technologies that incorporate artificial intelligence or machine learning components.

Biocompatibility and Material Safety Considerations

Biocompatibility is a critical consideration in the development of electrochemical hydrogel sensors for point-of-care testing applications. These sensors, which often interface directly with biological fluids or tissues, must demonstrate minimal adverse reactions when in contact with the human body. The hydrogel matrices used in these sensors typically consist of polymeric networks that can absorb significant amounts of water while maintaining their structural integrity, providing an ideal environment for electrochemical sensing.

Material selection for these sensors requires careful evaluation of potential cytotoxicity, immunogenicity, and inflammatory responses. Common biocompatible hydrogel materials include polyethylene glycol (PEG), polyvinyl alcohol (PVA), alginate, and chitosan, which have established safety profiles in medical applications. Recent advancements have focused on developing naturally derived hydrogels that offer enhanced biocompatibility while maintaining the necessary mechanical and electrochemical properties for sensing applications.

The incorporation of electrochemical components, including electrodes and conductive elements, presents additional biocompatibility challenges. Noble metals such as gold and platinum are frequently utilized due to their excellent biocompatibility and electrochemical stability. However, the integration of these materials with hydrogels must be carefully engineered to prevent leaching of potentially harmful components into the biological environment.

Regulatory considerations for these sensors are governed by standards such as ISO 10993 for biological evaluation of medical devices. Comprehensive testing protocols include cytotoxicity assays, sensitization tests, irritation studies, and systemic toxicity evaluations. For point-of-care applications, where sensors may be used by non-specialists in diverse environments, material stability and degradation characteristics must be thoroughly assessed to ensure safety throughout the product lifecycle.

Long-term exposure effects represent another critical aspect of material safety. Hydrogel sensors designed for continuous monitoring applications must maintain their biocompatibility over extended periods, resisting degradation that could release harmful byproducts. Recent research has focused on developing self-healing hydrogels that can maintain their integrity during prolonged use, thereby enhancing both safety and sensor longevity.

Sterilization compatibility is essential for clinical applications, as sensors must withstand sterilization processes without compromising their biocompatibility or sensing capabilities. Common sterilization methods include ethylene oxide treatment, gamma irradiation, and autoclave processing, each presenting unique challenges for hydrogel-based sensors. Material selection must account for these sterilization requirements to ensure both safety and functionality in clinical settings.

Material selection for these sensors requires careful evaluation of potential cytotoxicity, immunogenicity, and inflammatory responses. Common biocompatible hydrogel materials include polyethylene glycol (PEG), polyvinyl alcohol (PVA), alginate, and chitosan, which have established safety profiles in medical applications. Recent advancements have focused on developing naturally derived hydrogels that offer enhanced biocompatibility while maintaining the necessary mechanical and electrochemical properties for sensing applications.

The incorporation of electrochemical components, including electrodes and conductive elements, presents additional biocompatibility challenges. Noble metals such as gold and platinum are frequently utilized due to their excellent biocompatibility and electrochemical stability. However, the integration of these materials with hydrogels must be carefully engineered to prevent leaching of potentially harmful components into the biological environment.

Regulatory considerations for these sensors are governed by standards such as ISO 10993 for biological evaluation of medical devices. Comprehensive testing protocols include cytotoxicity assays, sensitization tests, irritation studies, and systemic toxicity evaluations. For point-of-care applications, where sensors may be used by non-specialists in diverse environments, material stability and degradation characteristics must be thoroughly assessed to ensure safety throughout the product lifecycle.

Long-term exposure effects represent another critical aspect of material safety. Hydrogel sensors designed for continuous monitoring applications must maintain their biocompatibility over extended periods, resisting degradation that could release harmful byproducts. Recent research has focused on developing self-healing hydrogels that can maintain their integrity during prolonged use, thereby enhancing both safety and sensor longevity.

Sterilization compatibility is essential for clinical applications, as sensors must withstand sterilization processes without compromising their biocompatibility or sensing capabilities. Common sterilization methods include ethylene oxide treatment, gamma irradiation, and autoclave processing, each presenting unique challenges for hydrogel-based sensors. Material selection must account for these sterilization requirements to ensure both safety and functionality in clinical settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!