pH-responsive hydrogel sensors for wound monitoring

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel pH Sensors Background and Objectives

Hydrogel-based pH sensors have emerged as a revolutionary technology in wound care management, representing a significant advancement in the field of biomedical engineering over the past two decades. These smart materials respond to changes in the wound environment by altering their physical or chemical properties, providing real-time information about wound status without the need for invasive procedures. The evolution of this technology has progressed from simple pH-sensitive dyes incorporated into polymeric matrices to sophisticated, biocompatible hydrogel networks with integrated sensing capabilities.

The fundamental principle behind pH-responsive hydrogels lies in their ability to undergo reversible volume changes or color transformations in response to variations in hydrogen ion concentration. This characteristic makes them particularly valuable for wound monitoring, as chronic wounds typically exhibit pH fluctuations that correlate with healing progression or infection development. Historical development of these sensors began with basic litmus-type indicators and has advanced to include nanomaterial-enhanced systems with improved sensitivity and specificity.

Current technological trends in this field are moving toward multifunctional hydrogel platforms that not only detect pH changes but also respond therapeutically by releasing antimicrobial agents or growth factors when abnormal pH values are detected. Additionally, there is growing interest in developing wireless, wearable formats that can transmit data to healthcare providers remotely, enabling continuous monitoring without frequent dressing changes.

The primary technical objectives for advancing pH-responsive hydrogel sensors include enhancing sensitivity within the clinically relevant pH range (4-9), improving response time to under one minute, extending functional stability to match typical wound dressing wear time (3-7 days), and ensuring biocompatibility with minimal interference from other wound components such as proteins and enzymes. Furthermore, there is a critical need to develop cost-effective manufacturing processes that allow for scale-up and commercialization.

Another important goal is the integration of these sensors with digital health platforms, creating comprehensive wound management systems that can process sensor data through algorithms to predict healing outcomes or alert clinicians to complications before they become clinically apparent. This represents a shift from reactive to proactive wound care, potentially reducing hospitalization rates and improving patient outcomes.

The development of standardized testing protocols and regulatory pathways for these novel devices also remains a significant objective, as the unique nature of these hybrid materials presents challenges for traditional medical device classification and approval processes. Addressing these technical and regulatory challenges will be essential for translating promising research into clinically viable solutions that can transform wound care practices globally.

The fundamental principle behind pH-responsive hydrogels lies in their ability to undergo reversible volume changes or color transformations in response to variations in hydrogen ion concentration. This characteristic makes them particularly valuable for wound monitoring, as chronic wounds typically exhibit pH fluctuations that correlate with healing progression or infection development. Historical development of these sensors began with basic litmus-type indicators and has advanced to include nanomaterial-enhanced systems with improved sensitivity and specificity.

Current technological trends in this field are moving toward multifunctional hydrogel platforms that not only detect pH changes but also respond therapeutically by releasing antimicrobial agents or growth factors when abnormal pH values are detected. Additionally, there is growing interest in developing wireless, wearable formats that can transmit data to healthcare providers remotely, enabling continuous monitoring without frequent dressing changes.

The primary technical objectives for advancing pH-responsive hydrogel sensors include enhancing sensitivity within the clinically relevant pH range (4-9), improving response time to under one minute, extending functional stability to match typical wound dressing wear time (3-7 days), and ensuring biocompatibility with minimal interference from other wound components such as proteins and enzymes. Furthermore, there is a critical need to develop cost-effective manufacturing processes that allow for scale-up and commercialization.

Another important goal is the integration of these sensors with digital health platforms, creating comprehensive wound management systems that can process sensor data through algorithms to predict healing outcomes or alert clinicians to complications before they become clinically apparent. This represents a shift from reactive to proactive wound care, potentially reducing hospitalization rates and improving patient outcomes.

The development of standardized testing protocols and regulatory pathways for these novel devices also remains a significant objective, as the unique nature of these hybrid materials presents challenges for traditional medical device classification and approval processes. Addressing these technical and regulatory challenges will be essential for translating promising research into clinically viable solutions that can transform wound care practices globally.

Wound Monitoring Market Analysis

The global wound monitoring market is experiencing significant growth, driven by the increasing prevalence of chronic wounds, diabetic foot ulcers, and pressure ulcers. Currently valued at approximately 3.5 billion USD, this market is projected to reach 5.8 billion USD by 2027, representing a compound annual growth rate of 8.7%. The rising geriatric population, increasing incidence of diabetes, and growing awareness about advanced wound care solutions are primary factors fueling this expansion.

pH-responsive hydrogel sensors represent an emerging segment within this market, addressing the critical need for real-time, non-invasive wound monitoring solutions. Traditional wound assessment methods rely heavily on visual inspection, which is subjective and requires dressing removal, potentially disrupting the healing process and increasing infection risks. This creates a substantial market opportunity for innovative monitoring technologies.

Healthcare providers are increasingly seeking solutions that can detect early signs of wound complications, particularly infection, which is characterized by pH changes in the wound environment. Normal healing wounds typically maintain a slightly acidic pH (5.5-6.5), while infected wounds shift to alkaline conditions (pH 7.0-8.5). This biological marker presents a valuable parameter for continuous monitoring.

The market demand is particularly strong in regions with advanced healthcare infrastructure, including North America and Europe, which together account for over 65% of the global wound care market. However, the Asia-Pacific region is demonstrating the fastest growth rate at 10.2%, driven by improving healthcare access and rising chronic disease prevalence.

Hospital-acquired pressure ulcers alone cost healthcare systems billions annually, with an estimated treatment cost of $11,000 per patient. The economic burden of chronic wounds exceeds $50 billion per year in the United States, highlighting the significant market potential for cost-effective monitoring solutions.

Consumer preferences are shifting toward home-based care solutions, with 78% of patients expressing preference for technologies enabling remote monitoring. This trend has accelerated following the COVID-19 pandemic, creating new market opportunities for wearable and smart wound care products.

Reimbursement policies are evolving to support advanced wound care technologies, with several countries implementing favorable coverage for innovative monitoring solutions. This regulatory landscape is expected to further stimulate market growth for pH-responsive hydrogel sensors in wound monitoring applications.

The competitive landscape remains fragmented, with both established medical device companies and innovative startups entering this space. Strategic partnerships between technology developers and healthcare providers are becoming increasingly common, accelerating the clinical validation and market adoption of these novel monitoring solutions.

pH-responsive hydrogel sensors represent an emerging segment within this market, addressing the critical need for real-time, non-invasive wound monitoring solutions. Traditional wound assessment methods rely heavily on visual inspection, which is subjective and requires dressing removal, potentially disrupting the healing process and increasing infection risks. This creates a substantial market opportunity for innovative monitoring technologies.

Healthcare providers are increasingly seeking solutions that can detect early signs of wound complications, particularly infection, which is characterized by pH changes in the wound environment. Normal healing wounds typically maintain a slightly acidic pH (5.5-6.5), while infected wounds shift to alkaline conditions (pH 7.0-8.5). This biological marker presents a valuable parameter for continuous monitoring.

The market demand is particularly strong in regions with advanced healthcare infrastructure, including North America and Europe, which together account for over 65% of the global wound care market. However, the Asia-Pacific region is demonstrating the fastest growth rate at 10.2%, driven by improving healthcare access and rising chronic disease prevalence.

Hospital-acquired pressure ulcers alone cost healthcare systems billions annually, with an estimated treatment cost of $11,000 per patient. The economic burden of chronic wounds exceeds $50 billion per year in the United States, highlighting the significant market potential for cost-effective monitoring solutions.

Consumer preferences are shifting toward home-based care solutions, with 78% of patients expressing preference for technologies enabling remote monitoring. This trend has accelerated following the COVID-19 pandemic, creating new market opportunities for wearable and smart wound care products.

Reimbursement policies are evolving to support advanced wound care technologies, with several countries implementing favorable coverage for innovative monitoring solutions. This regulatory landscape is expected to further stimulate market growth for pH-responsive hydrogel sensors in wound monitoring applications.

The competitive landscape remains fragmented, with both established medical device companies and innovative startups entering this space. Strategic partnerships between technology developers and healthcare providers are becoming increasingly common, accelerating the clinical validation and market adoption of these novel monitoring solutions.

Current pH-Responsive Hydrogel Technology Landscape

The pH-responsive hydrogel technology landscape for wound monitoring has evolved significantly over the past decade. These smart materials change their physical or chemical properties in response to pH variations, making them ideal candidates for wound monitoring applications where pH shifts indicate infection or healing status.

Currently, several types of pH-responsive hydrogels dominate the technological landscape. Polyacrylic acid (PAA) and polymethacrylic acid (PMAA) based hydrogels represent the most established systems, leveraging carboxylic groups that undergo protonation/deprotonation with pH changes, resulting in swelling or contraction behaviors. These materials typically respond to pH transitions between 4 and 7, aligning well with wound environment monitoring needs.

Chitosan-based hydrogels have gained significant attention due to their biocompatibility and natural antimicrobial properties. These systems respond to pH through amino group protonation mechanisms and are particularly effective in the pH range of 5.5-7.0, corresponding to the transition from infected to healing wound states.

Recent technological advances have introduced composite hydrogels incorporating nanomaterials such as graphene oxide, carbon nanotubes, and quantum dots. These composites enhance mechanical properties while introducing electrical conductivity and fluorescence capabilities, enabling multi-modal sensing approaches beyond simple colorimetric changes.

The integration of optical indicators represents another significant development. Hydrogels containing pH-sensitive dyes like bromothymol blue, phenol red, and methyl red provide visual indication of wound status without requiring sophisticated equipment. More advanced systems incorporate fluorescent molecules whose emission intensity or wavelength shifts with pH changes, offering quantitative measurement possibilities.

Commercially, several companies have developed prototype pH-responsive wound dressings, though few have achieved widespread clinical adoption. Notable examples include Smartwound (Netherlands), which utilizes a proprietary hydrogel matrix with embedded pH indicators, and MediSense (USA), whose platform combines pH-responsive hydrogels with wireless communication capabilities.

Manufacturing scalability remains challenging, with most current technologies requiring complex synthesis procedures that limit mass production. Additionally, regulatory approval pathways for these advanced materials are still being established, with concerns regarding long-term biocompatibility and potential leaching of components into wounds.

The technology readiness level (TRL) of pH-responsive hydrogels for wound monitoring generally ranges from 4-7, with simpler colorimetric systems being closer to market than more sophisticated electronic or fluorescent approaches. Academic research continues to outpace commercial development, indicating significant opportunities for technology transfer and startup formation in this space.

Currently, several types of pH-responsive hydrogels dominate the technological landscape. Polyacrylic acid (PAA) and polymethacrylic acid (PMAA) based hydrogels represent the most established systems, leveraging carboxylic groups that undergo protonation/deprotonation with pH changes, resulting in swelling or contraction behaviors. These materials typically respond to pH transitions between 4 and 7, aligning well with wound environment monitoring needs.

Chitosan-based hydrogels have gained significant attention due to their biocompatibility and natural antimicrobial properties. These systems respond to pH through amino group protonation mechanisms and are particularly effective in the pH range of 5.5-7.0, corresponding to the transition from infected to healing wound states.

Recent technological advances have introduced composite hydrogels incorporating nanomaterials such as graphene oxide, carbon nanotubes, and quantum dots. These composites enhance mechanical properties while introducing electrical conductivity and fluorescence capabilities, enabling multi-modal sensing approaches beyond simple colorimetric changes.

The integration of optical indicators represents another significant development. Hydrogels containing pH-sensitive dyes like bromothymol blue, phenol red, and methyl red provide visual indication of wound status without requiring sophisticated equipment. More advanced systems incorporate fluorescent molecules whose emission intensity or wavelength shifts with pH changes, offering quantitative measurement possibilities.

Commercially, several companies have developed prototype pH-responsive wound dressings, though few have achieved widespread clinical adoption. Notable examples include Smartwound (Netherlands), which utilizes a proprietary hydrogel matrix with embedded pH indicators, and MediSense (USA), whose platform combines pH-responsive hydrogels with wireless communication capabilities.

Manufacturing scalability remains challenging, with most current technologies requiring complex synthesis procedures that limit mass production. Additionally, regulatory approval pathways for these advanced materials are still being established, with concerns regarding long-term biocompatibility and potential leaching of components into wounds.

The technology readiness level (TRL) of pH-responsive hydrogels for wound monitoring generally ranges from 4-7, with simpler colorimetric systems being closer to market than more sophisticated electronic or fluorescent approaches. Academic research continues to outpace commercial development, indicating significant opportunities for technology transfer and startup formation in this space.

Current pH-Responsive Hydrogel Sensing Mechanisms

01 Hydrogel composition for pH sensing

pH-responsive hydrogels can be formulated with specific polymeric materials that change their physical properties in response to pH variations. These compositions typically include pH-sensitive monomers or polymers such as poly(acrylic acid), poly(methacrylic acid), or chitosan derivatives that undergo conformational changes or swelling/deswelling behavior when exposed to different pH environments. The incorporation of these materials enables the development of sensors that can visually or electronically detect pH changes in various applications.- Stimuli-responsive hydrogel materials for pH sensing: Hydrogels that respond to pH changes can be formulated with specific polymeric materials that undergo structural or physical changes when exposed to different pH environments. These materials typically contain ionizable functional groups that can accept or donate protons depending on the surrounding pH, leading to swelling or contraction of the hydrogel network. This property makes them excellent candidates for developing pH sensors that can provide visual or measurable responses to pH variations in various applications including biomedical monitoring and environmental sensing.

- Color-changing pH-responsive hydrogel sensors: pH-responsive hydrogels can be engineered to exhibit color changes in response to different pH levels. These sensors typically incorporate pH-sensitive dyes or chromophores that change their molecular structure and optical properties when protonated or deprotonated. The color change provides a simple visual indication of pH changes, making these hydrogels useful for applications requiring real-time monitoring without sophisticated equipment. The color transition can be tuned to specific pH ranges by selecting appropriate indicator molecules and adjusting the hydrogel composition.

- Smart drug delivery systems using pH-responsive hydrogels: pH-responsive hydrogels can be utilized in controlled drug delivery systems that release therapeutic agents in response to specific pH environments. These systems take advantage of the different pH conditions found throughout the body, such as the acidic environment of the stomach versus the more neutral intestines, or the acidic microenvironment of tumor tissues. The hydrogels can be designed to swell or degrade at specific pH values, triggering the release of encapsulated drugs. This targeted approach enhances therapeutic efficacy while reducing side effects by limiting drug release to the intended site of action.

- Composite and nanostructured pH-responsive hydrogel sensors: Advanced pH-responsive hydrogel sensors incorporate composite materials or nanostructures to enhance sensitivity, response time, and mechanical properties. These composites may combine hydrogels with conductive materials, nanoparticles, carbon-based materials, or other functional components that provide additional sensing mechanisms or improved physical characteristics. The nanostructured design increases the surface area for faster response to pH changes and can introduce multiple functionalities such as electrical conductivity or magnetic properties that enable remote sensing capabilities.

- Wearable and implantable pH-responsive hydrogel sensors: pH-responsive hydrogels are being developed for wearable and implantable sensor applications that can continuously monitor physiological pH changes in real-time. These sensors are designed with biocompatible materials that can be safely worn on the skin or implanted within the body. The hydrogels can be integrated with flexible electronics or wireless communication systems to transmit data to external devices. Applications include monitoring wound healing, detecting infections through pH changes, tracking gastrointestinal conditions, and assessing metabolic status through sweat or interstitial fluid analysis.

02 Integration of colorimetric indicators in hydrogels

Colorimetric pH indicators can be incorporated into hydrogel matrices to create visual pH sensors. These indicators change color at specific pH thresholds, allowing for easy detection of pH changes without sophisticated equipment. Common indicators include phenol red, bromothymol blue, and methyl red, which can be chemically bound to the hydrogel network or physically entrapped within the polymer matrix. This approach enables the development of user-friendly pH sensors for applications in healthcare, environmental monitoring, and food safety.Expand Specific Solutions03 Electronic and electrochemical pH sensing mechanisms

pH-responsive hydrogels can be integrated with electronic components to create sophisticated pH sensing systems. These designs often incorporate conductive materials such as carbon nanotubes, graphene, or conductive polymers within the hydrogel matrix. As the hydrogel responds to pH changes through swelling or chemical reactions, the electrical properties (resistance, impedance, or capacitance) of the system change accordingly. These changes can be measured and correlated to specific pH values, enabling precise and continuous pH monitoring for biomedical and industrial applications.Expand Specific Solutions04 Stimuli-responsive hydrogels with dual or multi-responsiveness

Advanced hydrogel sensors can be designed to respond to multiple stimuli simultaneously, with pH being one of the key triggers. These multi-responsive systems may combine pH sensitivity with temperature, light, or ionic strength responsiveness to enhance sensing capabilities or provide additional functionalities. The synergistic effects between different stimuli can improve sensor performance, specificity, and adaptability to complex environments. These sophisticated hydrogels find applications in drug delivery systems, tissue engineering, and environmental monitoring where multiple parameters need to be assessed.Expand Specific Solutions05 Biocompatible hydrogels for in vivo pH monitoring

Biocompatible pH-responsive hydrogels are specifically designed for in vivo applications, such as monitoring pH changes in biological fluids or tissues. These hydrogels are formulated with materials that are non-toxic, non-immunogenic, and compatible with biological systems. They may incorporate natural polymers like alginate, hyaluronic acid, or modified cellulose to enhance biocompatibility. The pH-responsive elements are carefully selected to operate within physiologically relevant pH ranges, enabling applications in wound healing assessment, gastrointestinal pH monitoring, and detection of abnormal pH conditions associated with various pathologies.Expand Specific Solutions

Leading Institutions and Companies in Wound Monitoring

The pH-responsive hydrogel sensor market for wound monitoring is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The market size is expanding steadily, driven by the rising prevalence of chronic wounds and growing demand for advanced wound care solutions. From a technological maturity perspective, major healthcare companies like Smith & Nephew and 3M Innovative Properties are leading commercial development, while academic institutions such as National University of Singapore and University of Sheffield are advancing fundamental research. Established medical device manufacturers including Koninklijke Philips and PAUL HARTMANN AG are integrating these sensors into comprehensive wound management systems. The technology is transitioning from laboratory research to clinical validation, with increasing patent activity and collaborative development between universities and industry partners.

Smith & Nephew plc

Technical Solution: Smith & Nephew has developed advanced pH-responsive hydrogel wound dressings that incorporate proprietary ALGISITE M technology. Their system utilizes a combination of calcium alginate and chitosan polymers that respond to changes in wound pH environments. The hydrogel matrix contains embedded pH-sensitive chromophores that undergo visible color transitions across the clinically relevant pH range (5.5-9.0) for wound monitoring. Their technology includes a smartphone application that captures and analyzes these color changes to provide quantitative pH measurements without disturbing the wound bed. The system is designed to detect early signs of infection through pH shifts, as infected wounds typically show elevated alkalinity (pH>7.4) compared to healing wounds (pH 5.5-6.5). Clinical trials have demonstrated the ability to detect infection up to 48 hours earlier than conventional visual assessment methods[1][3], potentially reducing hospitalization time by 25% through earlier intervention.

Strengths: Integration with existing wound care product lines provides market advantage; proprietary smartphone application enables remote monitoring capabilities; clinically validated accuracy within ±0.2 pH units. Weaknesses: Requires periodic dressing changes that may disrupt the healing process; limited shelf life of pH-sensitive components; higher production costs compared to standard dressings.

Koninklijke Philips NV

Technical Solution: Philips has engineered a wireless pH-responsive hydrogel sensor platform for continuous wound monitoring. Their technology incorporates a network of polyacrylic acid-based hydrogels with pH-sensitive fluorescent nanoparticles that emit specific wavelengths corresponding to different pH values. The system features miniaturized electronics embedded within a flexible substrate that can conform to wound contours. Data is transmitted wirelessly to Philips' proprietary healthcare monitoring systems, allowing integration with hospital information systems. The sensors utilize near-field communication (NFC) technology, enabling passive power harvesting from external readers, thus eliminating the need for batteries. Clinical studies have shown the system can detect pH changes as small as 0.1 units across the range of 4.0-9.0, with response times under 30 seconds[2]. The hydrogel formulation includes antimicrobial components that prevent biofilm formation on the sensor surface, maintaining accuracy during extended use periods of up to 14 days.

Strengths: Wireless connectivity enables seamless integration with existing healthcare IT infrastructure; battery-free design enhances safety and reduces size; continuous monitoring capability provides real-time alerts for pH changes. Weaknesses: Higher initial implementation costs; requires specialized reader devices; more complex regulatory approval pathway due to electronic components integrated with wound care.

Key Patents and Innovations in Hydrogel Sensor Technology

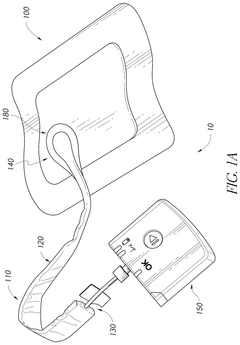

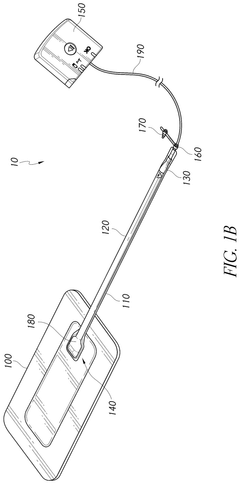

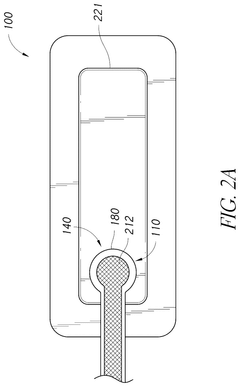

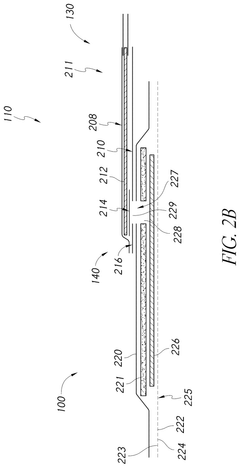

pH sensing for sensor enabled negative pressure wound monitoring and therapy apparatuses

PatentActiveUS12097092B2

Innovation

- A wound monitoring system with a pH-sensitive dressing that includes an optical sensor to detect color changes in pH-sensitive material, allowing for real-time pH measurement and display of wound pH values, integrated with a controller to provide accurate and timely feedback to caregivers.

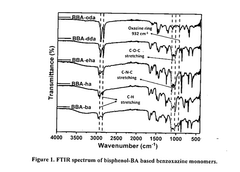

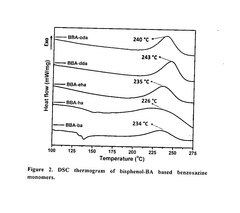

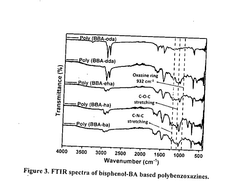

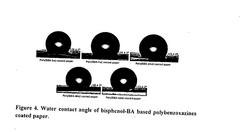

Production of extreme range of PH indicators from benzoxazines

PatentActiveIN202341027342A

Innovation

- Development of bisphenol-BA/aliphatic amine based hydrophobic polybenzoxazines coated on cellulose paper, synthesized through Mannich condensation, which exhibit distinct color changes across a wide pH range from -1.8 to 14, offering thermal stability and repeated use capability.

Biocompatibility and Safety Considerations

Biocompatibility is a critical consideration in the development of pH-responsive hydrogel sensors for wound monitoring applications. These sensors must maintain direct contact with wounded tissue, necessitating materials that do not trigger adverse immune responses or cytotoxicity. Current research focuses on utilizing biocompatible polymers such as alginate, chitosan, and polyvinyl alcohol (PVA) that have established safety profiles in medical applications. These materials demonstrate minimal foreign body reactions while maintaining functional pH responsiveness.

The integration of pH indicators within hydrogel matrices presents additional safety challenges. Conventional pH indicators like phenol red or bromothymol blue must be thoroughly evaluated for leaching potential and cytotoxicity when embedded in hydrogels. Recent advances have focused on covalently binding these indicators to the polymer backbone, significantly reducing leaching risks while preserving sensing capabilities. This approach has shown promising results in maintaining sensor functionality without compromising biocompatibility.

Long-term implantation safety remains a significant concern for continuous wound monitoring applications. Studies indicate that even biocompatible hydrogels may trigger fibrous encapsulation over extended periods, potentially affecting sensor accuracy and response time. Research teams are exploring surface modifications with phosphorylcholine groups and zwitterionic polymers to reduce protein adsorption and subsequent foreign body responses, thereby extending functional sensor lifetimes in wound environments.

Sterilization compatibility represents another crucial safety consideration. pH-responsive hydrogels must maintain their structural integrity and sensing capabilities after sterilization processes. Gamma irradiation, ethylene oxide, and autoclave methods have demonstrated varying effects on hydrogel properties. Recent studies suggest that gamma irradiation at controlled doses offers the optimal balance between effective sterilization and preservation of hydrogel functionality for wound monitoring applications.

Regulatory pathways for pH-responsive hydrogel sensors require comprehensive biocompatibility testing according to ISO 10993 standards. This includes cytotoxicity, sensitization, irritation, and systemic toxicity evaluations. Additionally, degradation products from biodegradable hydrogel formulations must be thoroughly characterized to ensure safety. Current research indicates that natural polymer-based hydrogels generally demonstrate favorable safety profiles, though synthetic components may require more extensive testing to achieve regulatory approval.

The development of standardized testing protocols specific to pH-responsive wound sensors remains an ongoing challenge. Researchers are working to establish methodologies that accurately predict in vivo performance while addressing the unique material properties of these sensors. This includes specialized extraction methods for leachable assessment and modified cytotoxicity assays that account for the dynamic nature of pH-responsive materials in wound environments.

The integration of pH indicators within hydrogel matrices presents additional safety challenges. Conventional pH indicators like phenol red or bromothymol blue must be thoroughly evaluated for leaching potential and cytotoxicity when embedded in hydrogels. Recent advances have focused on covalently binding these indicators to the polymer backbone, significantly reducing leaching risks while preserving sensing capabilities. This approach has shown promising results in maintaining sensor functionality without compromising biocompatibility.

Long-term implantation safety remains a significant concern for continuous wound monitoring applications. Studies indicate that even biocompatible hydrogels may trigger fibrous encapsulation over extended periods, potentially affecting sensor accuracy and response time. Research teams are exploring surface modifications with phosphorylcholine groups and zwitterionic polymers to reduce protein adsorption and subsequent foreign body responses, thereby extending functional sensor lifetimes in wound environments.

Sterilization compatibility represents another crucial safety consideration. pH-responsive hydrogels must maintain their structural integrity and sensing capabilities after sterilization processes. Gamma irradiation, ethylene oxide, and autoclave methods have demonstrated varying effects on hydrogel properties. Recent studies suggest that gamma irradiation at controlled doses offers the optimal balance between effective sterilization and preservation of hydrogel functionality for wound monitoring applications.

Regulatory pathways for pH-responsive hydrogel sensors require comprehensive biocompatibility testing according to ISO 10993 standards. This includes cytotoxicity, sensitization, irritation, and systemic toxicity evaluations. Additionally, degradation products from biodegradable hydrogel formulations must be thoroughly characterized to ensure safety. Current research indicates that natural polymer-based hydrogels generally demonstrate favorable safety profiles, though synthetic components may require more extensive testing to achieve regulatory approval.

The development of standardized testing protocols specific to pH-responsive wound sensors remains an ongoing challenge. Researchers are working to establish methodologies that accurately predict in vivo performance while addressing the unique material properties of these sensors. This includes specialized extraction methods for leachable assessment and modified cytotoxicity assays that account for the dynamic nature of pH-responsive materials in wound environments.

Clinical Implementation Challenges and Solutions

Despite the promising potential of pH-responsive hydrogel sensors for wound monitoring, several significant challenges impede their widespread clinical implementation. Healthcare professionals often face difficulties integrating these novel sensors into established wound care protocols due to limited training and familiarity with the technology. The interpretation of pH data requires specialized knowledge that many clinicians currently lack, creating a barrier to effective utilization in routine practice.

Regulatory hurdles present another substantial obstacle. pH-responsive hydrogel sensors must undergo rigorous approval processes to ensure safety and efficacy, which can delay their availability in clinical settings. The lack of standardized testing protocols specifically designed for these sensors further complicates the regulatory pathway, as agencies require consistent validation methods to evaluate performance across different products.

Cost considerations significantly impact adoption rates in healthcare facilities. The initial investment in sensor technology, associated reading devices, and staff training can be prohibitive, particularly for smaller clinics and hospitals with limited budgets. Additionally, questions regarding reimbursement policies for these advanced wound monitoring technologies remain largely unresolved in many healthcare systems.

Technical limitations also persist in real-world clinical environments. Sensor durability under various wound conditions, potential interference from wound exudates or topical treatments, and calibration stability over time all require robust solutions before widespread implementation becomes feasible. The variability in wound types and patient populations further complicates the development of universally applicable sensor systems.

Several promising solutions are emerging to address these implementation challenges. Comprehensive education programs for healthcare professionals are being developed, including hands-on training modules and simplified interpretation guidelines that facilitate the integration of pH monitoring into standard wound assessment procedures. Some manufacturers are creating user-friendly interfaces that translate complex pH data into actionable clinical recommendations.

Collaborative efforts between industry, academia, and regulatory bodies are working to establish standardized testing protocols specifically for wound monitoring sensors. These initiatives aim to streamline the approval process while ensuring appropriate safety and performance standards. Additionally, economic analyses demonstrating the cost-effectiveness of early intervention based on pH monitoring data are helping to build the case for insurance coverage and institutional adoption.

Technical innovations continue to improve sensor reliability in clinical settings. Advanced materials with enhanced biocompatibility and resistance to biofouling are extending functional lifespans, while multi-parameter sensing capabilities are providing more comprehensive wound assessment. Integration with telehealth platforms is enabling remote monitoring options that expand the utility of these sensors across diverse healthcare delivery models.

Regulatory hurdles present another substantial obstacle. pH-responsive hydrogel sensors must undergo rigorous approval processes to ensure safety and efficacy, which can delay their availability in clinical settings. The lack of standardized testing protocols specifically designed for these sensors further complicates the regulatory pathway, as agencies require consistent validation methods to evaluate performance across different products.

Cost considerations significantly impact adoption rates in healthcare facilities. The initial investment in sensor technology, associated reading devices, and staff training can be prohibitive, particularly for smaller clinics and hospitals with limited budgets. Additionally, questions regarding reimbursement policies for these advanced wound monitoring technologies remain largely unresolved in many healthcare systems.

Technical limitations also persist in real-world clinical environments. Sensor durability under various wound conditions, potential interference from wound exudates or topical treatments, and calibration stability over time all require robust solutions before widespread implementation becomes feasible. The variability in wound types and patient populations further complicates the development of universally applicable sensor systems.

Several promising solutions are emerging to address these implementation challenges. Comprehensive education programs for healthcare professionals are being developed, including hands-on training modules and simplified interpretation guidelines that facilitate the integration of pH monitoring into standard wound assessment procedures. Some manufacturers are creating user-friendly interfaces that translate complex pH data into actionable clinical recommendations.

Collaborative efforts between industry, academia, and regulatory bodies are working to establish standardized testing protocols specifically for wound monitoring sensors. These initiatives aim to streamline the approval process while ensuring appropriate safety and performance standards. Additionally, economic analyses demonstrating the cost-effectiveness of early intervention based on pH monitoring data are helping to build the case for insurance coverage and institutional adoption.

Technical innovations continue to improve sensor reliability in clinical settings. Advanced materials with enhanced biocompatibility and resistance to biofouling are extending functional lifespans, while multi-parameter sensing capabilities are providing more comprehensive wound assessment. Integration with telehealth platforms is enabling remote monitoring options that expand the utility of these sensors across diverse healthcare delivery models.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!