UV-curable hydrogels for optical sensor applications

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV-Curable Hydrogels Background and Objectives

UV-curable hydrogels represent a significant advancement in materials science that has evolved considerably over the past three decades. These specialized polymer networks are formed through photopolymerization processes triggered by ultraviolet light, creating three-dimensional structures capable of absorbing and retaining substantial amounts of water while maintaining their structural integrity. The evolution of these materials began in the 1990s with simple acrylic-based formulations and has progressed to sophisticated multi-component systems with precisely tunable properties.

The technological trajectory of UV-curable hydrogels has been characterized by continuous improvements in mechanical strength, optical clarity, biocompatibility, and response sensitivity. Early applications were primarily focused on biomedical uses such as wound dressings and drug delivery systems. However, the unique combination of optical transparency, stimuli-responsiveness, and customizable mechanical properties has increasingly positioned these materials as ideal candidates for optical sensing applications.

Current research objectives in this field center on developing UV-curable hydrogel formulations that exhibit enhanced sensitivity to specific analytes while maintaining excellent optical properties. The primary goal is to create materials that can translate chemical or biological interactions into measurable optical signals with high fidelity and reproducibility. This includes optimizing the crosslinking density, incorporating functional monomers with specific recognition elements, and engineering the network architecture to maximize signal transduction efficiency.

Another critical objective involves improving the long-term stability of these hydrogels in various environmental conditions, addressing challenges such as photobleaching, mechanical degradation, and biofouling that can compromise sensor performance over time. Researchers are exploring novel photoinitiator systems, stabilizing additives, and surface modification strategies to enhance durability while preserving sensing capabilities.

The integration of UV-curable hydrogels with existing optical sensing platforms represents another important technical goal. This includes developing fabrication methods compatible with microfluidic systems, fiber optic technologies, and plasmonic structures to create next-generation sensing devices. Miniaturization and multiplexing capabilities are particularly emphasized to enable simultaneous detection of multiple analytes in complex samples.

From an application perspective, the field is moving toward specialized hydrogel formulations tailored for specific sensing environments, ranging from physiological conditions for medical diagnostics to harsh industrial settings for environmental monitoring. The ultimate objective is to establish UV-curable hydrogels as a versatile platform technology that can be readily adapted to address diverse sensing challenges across healthcare, environmental science, food safety, and industrial process control.

The technological trajectory of UV-curable hydrogels has been characterized by continuous improvements in mechanical strength, optical clarity, biocompatibility, and response sensitivity. Early applications were primarily focused on biomedical uses such as wound dressings and drug delivery systems. However, the unique combination of optical transparency, stimuli-responsiveness, and customizable mechanical properties has increasingly positioned these materials as ideal candidates for optical sensing applications.

Current research objectives in this field center on developing UV-curable hydrogel formulations that exhibit enhanced sensitivity to specific analytes while maintaining excellent optical properties. The primary goal is to create materials that can translate chemical or biological interactions into measurable optical signals with high fidelity and reproducibility. This includes optimizing the crosslinking density, incorporating functional monomers with specific recognition elements, and engineering the network architecture to maximize signal transduction efficiency.

Another critical objective involves improving the long-term stability of these hydrogels in various environmental conditions, addressing challenges such as photobleaching, mechanical degradation, and biofouling that can compromise sensor performance over time. Researchers are exploring novel photoinitiator systems, stabilizing additives, and surface modification strategies to enhance durability while preserving sensing capabilities.

The integration of UV-curable hydrogels with existing optical sensing platforms represents another important technical goal. This includes developing fabrication methods compatible with microfluidic systems, fiber optic technologies, and plasmonic structures to create next-generation sensing devices. Miniaturization and multiplexing capabilities are particularly emphasized to enable simultaneous detection of multiple analytes in complex samples.

From an application perspective, the field is moving toward specialized hydrogel formulations tailored for specific sensing environments, ranging from physiological conditions for medical diagnostics to harsh industrial settings for environmental monitoring. The ultimate objective is to establish UV-curable hydrogels as a versatile platform technology that can be readily adapted to address diverse sensing challenges across healthcare, environmental science, food safety, and industrial process control.

Market Analysis for Optical Sensor Hydrogels

The optical sensor market utilizing UV-curable hydrogels is experiencing robust growth, driven by increasing demand across healthcare, environmental monitoring, and industrial applications. The global optical sensor market was valued at $22.3 billion in 2021 and is projected to reach $39.8 billion by 2028, representing a compound annual growth rate (CAGR) of 8.7%. Within this broader market, hydrogel-based optical sensors are emerging as a high-growth segment due to their unique properties and versatility.

Healthcare applications currently dominate the market for UV-curable hydrogel optical sensors, accounting for approximately 45% of the total market share. This is primarily attributed to the rising prevalence of chronic diseases requiring continuous monitoring, growing adoption of point-of-care diagnostics, and increasing investment in telemedicine infrastructure. The biosensor segment, particularly glucose monitoring for diabetes management, represents the largest application area with significant commercial traction.

Environmental monitoring applications constitute the second-largest market segment at 28%, driven by stringent regulations regarding water quality assessment, air pollution monitoring, and food safety. Industrial process control applications account for 18% of the market, while consumer electronics and other applications make up the remaining 9%.

Regionally, North America leads the market with a 38% share, followed by Europe (29%), Asia-Pacific (24%), and the rest of the world (9%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to increasing healthcare expenditure, rapid industrialization, and growing environmental concerns in countries like China, Japan, and India.

Key market drivers include technological advancements in hydrogel formulations that enhance sensitivity, selectivity, and stability; miniaturization trends enabling integration into wearable and implantable devices; and growing demand for real-time, continuous monitoring solutions across various industries. The shift toward personalized healthcare and remote patient monitoring has further accelerated market growth, particularly following the COVID-19 pandemic.

Market challenges include high development costs, complex regulatory approval processes for medical applications, and technical limitations related to long-term stability and calibration of hydrogel-based sensors. Additionally, competition from alternative sensing technologies and materials presents ongoing market pressure.

Customer segments show distinct preferences: healthcare providers prioritize accuracy and reliability; environmental agencies focus on durability and cost-effectiveness; while industrial users emphasize integration capabilities and response time. This market segmentation necessitates tailored product development strategies to address specific end-user requirements.

Healthcare applications currently dominate the market for UV-curable hydrogel optical sensors, accounting for approximately 45% of the total market share. This is primarily attributed to the rising prevalence of chronic diseases requiring continuous monitoring, growing adoption of point-of-care diagnostics, and increasing investment in telemedicine infrastructure. The biosensor segment, particularly glucose monitoring for diabetes management, represents the largest application area with significant commercial traction.

Environmental monitoring applications constitute the second-largest market segment at 28%, driven by stringent regulations regarding water quality assessment, air pollution monitoring, and food safety. Industrial process control applications account for 18% of the market, while consumer electronics and other applications make up the remaining 9%.

Regionally, North America leads the market with a 38% share, followed by Europe (29%), Asia-Pacific (24%), and the rest of the world (9%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to increasing healthcare expenditure, rapid industrialization, and growing environmental concerns in countries like China, Japan, and India.

Key market drivers include technological advancements in hydrogel formulations that enhance sensitivity, selectivity, and stability; miniaturization trends enabling integration into wearable and implantable devices; and growing demand for real-time, continuous monitoring solutions across various industries. The shift toward personalized healthcare and remote patient monitoring has further accelerated market growth, particularly following the COVID-19 pandemic.

Market challenges include high development costs, complex regulatory approval processes for medical applications, and technical limitations related to long-term stability and calibration of hydrogel-based sensors. Additionally, competition from alternative sensing technologies and materials presents ongoing market pressure.

Customer segments show distinct preferences: healthcare providers prioritize accuracy and reliability; environmental agencies focus on durability and cost-effectiveness; while industrial users emphasize integration capabilities and response time. This market segmentation necessitates tailored product development strategies to address specific end-user requirements.

Technical Challenges in UV-Curable Hydrogel Development

Despite significant advancements in UV-curable hydrogel technology, several critical technical challenges persist in developing these materials for optical sensor applications. The primary challenge lies in achieving optimal mechanical properties while maintaining optical clarity. Current UV-curable hydrogels often exhibit a trade-off between mechanical strength and transparency, with increased crosslinking density improving durability but potentially reducing light transmission capabilities essential for sensor functionality.

Material stability presents another significant hurdle, particularly in diverse environmental conditions. UV-curable hydrogels tend to experience performance degradation when exposed to varying temperatures, pH levels, and ionic strengths. This instability manifests as dimensional changes, altered mechanical properties, or decreased optical performance, severely limiting their practical deployment in real-world sensing applications.

Biocompatibility concerns emerge when these hydrogels are intended for biomedical sensing applications. The photoinitiators and unreacted monomers can exhibit cytotoxicity, while the UV curing process itself may generate free radicals that compromise biocompatibility. Developing formulations that balance efficient curing with minimal biological impact remains technically challenging.

Response time optimization represents a critical technical barrier. Many current UV-curable hydrogel sensors exhibit slow response to analytes due to diffusion limitations within the polymer network. This delayed response restricts their utility in applications requiring real-time monitoring, such as continuous glucose sensing or environmental pollutant detection.

Manufacturing scalability poses significant technical difficulties. Achieving uniform curing throughout the hydrogel structure, especially in complex geometries or larger dimensions, remains problematic. Inconsistent crosslinking can create internal stress gradients that compromise both mechanical integrity and optical performance, leading to unpredictable sensor behavior.

Signal transduction mechanisms present sophisticated engineering challenges. Converting the hydrogel's physical or chemical response to an optical signal with sufficient sensitivity and specificity requires precise control over material properties. Current systems often struggle with signal-to-noise ratios that limit detection thresholds and measurement accuracy.

Long-term stability issues further complicate development efforts. UV-cured hydrogels frequently exhibit performance drift over time due to continued polymerization, hydrolytic degradation, or photobleaching of incorporated chromophores. This instability compromises sensor calibration and reliability, particularly problematic for implantable or environmental monitoring applications requiring extended operational lifetimes.

Addressing these interconnected technical challenges requires interdisciplinary approaches combining polymer chemistry, photophysics, materials engineering, and sensing technologies to develop next-generation UV-curable hydrogels suitable for advanced optical sensing applications.

Material stability presents another significant hurdle, particularly in diverse environmental conditions. UV-curable hydrogels tend to experience performance degradation when exposed to varying temperatures, pH levels, and ionic strengths. This instability manifests as dimensional changes, altered mechanical properties, or decreased optical performance, severely limiting their practical deployment in real-world sensing applications.

Biocompatibility concerns emerge when these hydrogels are intended for biomedical sensing applications. The photoinitiators and unreacted monomers can exhibit cytotoxicity, while the UV curing process itself may generate free radicals that compromise biocompatibility. Developing formulations that balance efficient curing with minimal biological impact remains technically challenging.

Response time optimization represents a critical technical barrier. Many current UV-curable hydrogel sensors exhibit slow response to analytes due to diffusion limitations within the polymer network. This delayed response restricts their utility in applications requiring real-time monitoring, such as continuous glucose sensing or environmental pollutant detection.

Manufacturing scalability poses significant technical difficulties. Achieving uniform curing throughout the hydrogel structure, especially in complex geometries or larger dimensions, remains problematic. Inconsistent crosslinking can create internal stress gradients that compromise both mechanical integrity and optical performance, leading to unpredictable sensor behavior.

Signal transduction mechanisms present sophisticated engineering challenges. Converting the hydrogel's physical or chemical response to an optical signal with sufficient sensitivity and specificity requires precise control over material properties. Current systems often struggle with signal-to-noise ratios that limit detection thresholds and measurement accuracy.

Long-term stability issues further complicate development efforts. UV-cured hydrogels frequently exhibit performance drift over time due to continued polymerization, hydrolytic degradation, or photobleaching of incorporated chromophores. This instability compromises sensor calibration and reliability, particularly problematic for implantable or environmental monitoring applications requiring extended operational lifetimes.

Addressing these interconnected technical challenges requires interdisciplinary approaches combining polymer chemistry, photophysics, materials engineering, and sensing technologies to develop next-generation UV-curable hydrogels suitable for advanced optical sensing applications.

Current UV-Curable Hydrogel Formulation Solutions

01 Composition and formulation of UV-curable hydrogels

UV-curable hydrogels can be formulated using various polymeric materials that undergo crosslinking upon exposure to ultraviolet light. These formulations typically include photoinitiators that trigger the polymerization reaction when exposed to specific wavelengths of UV light. The composition may include water-soluble polymers, monomers with functional groups capable of crosslinking, and additives that enhance the properties of the resulting hydrogel. The careful selection of these components determines the physical properties, biocompatibility, and application-specific characteristics of the final hydrogel.- Composition and formulation of UV-curable hydrogels: UV-curable hydrogels can be formulated using various polymeric materials that undergo crosslinking upon exposure to ultraviolet light. These formulations typically include photoinitiators that trigger the polymerization reaction when exposed to UV radiation. The composition may include water-soluble polymers, monomers with functional groups capable of crosslinking, and additives to enhance specific properties. The resulting hydrogels exhibit controlled swelling behavior and mechanical properties that can be tailored for specific applications.

- Biomedical applications of UV-curable hydrogels: UV-curable hydrogels have significant applications in biomedical fields due to their biocompatibility and tunable properties. These materials can be used for tissue engineering scaffolds, wound dressings, drug delivery systems, and as matrices for cell encapsulation. The ability to cure these hydrogels in situ using UV light allows for minimally invasive placement in the body. Their high water content and structural similarity to natural extracellular matrices make them particularly suitable for biomedical applications requiring interaction with biological tissues.

- Optical and electronic applications of UV-curable hydrogels: UV-curable hydrogels have found applications in optical and electronic devices due to their transparency and ability to be precisely patterned. These materials can be used in the fabrication of optical components, displays, sensors, and flexible electronics. The photopolymerization process allows for high-resolution patterning and the creation of complex three-dimensional structures. Additionally, these hydrogels can be formulated to have specific optical properties such as refractive index, light transmission, and diffraction characteristics.

- Advanced manufacturing techniques for UV-curable hydrogels: Various advanced manufacturing techniques can be employed for processing UV-curable hydrogels, including 3D printing, photolithography, and microfluidic fabrication. These techniques leverage the photopolymerization mechanism to create complex structures with precise geometries. The spatial and temporal control offered by UV curing enables the fabrication of hydrogels with gradient properties, patterned surfaces, and intricate internal architectures. These manufacturing approaches allow for customization of hydrogel structures for specific applications.

- Functional additives and modifications for UV-curable hydrogels: UV-curable hydrogels can be enhanced with various functional additives and chemical modifications to improve their performance characteristics. These may include reinforcing nanoparticles, antimicrobial agents, stimuli-responsive components, and biomolecules. Such additives can impart properties like improved mechanical strength, self-healing capabilities, controlled degradation, and specific biological functions. The incorporation of functional groups can also enable post-curing modifications through click chemistry or other reactions, expanding the versatility of these materials.

02 Biomedical applications of UV-curable hydrogels

UV-curable hydrogels have significant applications in the biomedical field due to their tunable properties and ability to be formed in situ. These materials can be used for tissue engineering scaffolds, drug delivery systems, wound dressings, and as matrices for cell encapsulation. The ability to cure these hydrogels using UV light allows for precise spatial and temporal control during application, making them suitable for minimally invasive medical procedures. Their biocompatibility and ability to mimic natural tissue environments make them valuable for regenerative medicine applications.Expand Specific Solutions03 Optical and electronic applications of UV-curable hydrogels

UV-curable hydrogels have found applications in optical and electronic devices due to their transparency, flexibility, and controllable refractive properties. These materials can be used in the fabrication of optical components, displays, sensors, and electronic devices. The ability to pattern these hydrogels using UV light enables the creation of complex microstructures with specific optical or electronic properties. Additionally, these hydrogels can be functionalized with conductive materials to create soft electronics or responsive optical systems.Expand Specific Solutions04 Mechanical properties and stability enhancement of UV-curable hydrogels

Improving the mechanical properties and stability of UV-curable hydrogels is crucial for their practical applications. Various approaches have been developed to enhance their strength, elasticity, and durability, including the incorporation of reinforcing agents, optimization of crosslinking density, and development of interpenetrating polymer networks. Additionally, methods to improve their resistance to degradation, dehydration, and mechanical stress have been explored. These enhancements expand the range of applications and increase the longevity of UV-curable hydrogel products.Expand Specific Solutions05 Smart and responsive UV-curable hydrogels

Smart UV-curable hydrogels that respond to environmental stimuli such as temperature, pH, light, or specific biomolecules have been developed for advanced applications. These responsive materials can undergo reversible changes in their properties, such as swelling/deswelling, optical characteristics, or mechanical behavior in response to external triggers. Such smart hydrogels are valuable for creating sensors, actuators, controlled release systems, and adaptive materials. The UV-curing process allows for the precise incorporation of responsive elements while maintaining the desired network structure.Expand Specific Solutions

Key Industry Players in UV-Curable Hydrogel Technology

The UV-curable hydrogels market for optical sensor applications is in a growth phase, characterized by increasing adoption across biomedical and environmental monitoring sectors. The market size is expanding rapidly, projected to reach significant value due to rising demand for real-time sensing technologies. Technologically, the field shows moderate maturity with ongoing innovations in material formulations. Key players demonstrate varying levels of expertise: established chemical corporations like DuPont, Dow Toray, and Shin-Etsu Chemical lead with advanced polymer technologies; specialized materials companies such as Namics Corp and Momentive Performance Materials focus on application-specific formulations; while academic institutions including Tiangong University and University of Glasgow drive fundamental research. The competitive landscape features collaboration between industry and academia to overcome challenges in biocompatibility and long-term stability.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced UV-curable hydrogel systems specifically engineered for optical sensing applications. Their proprietary technology combines acrylic-based monomers with specialized photoinitiators that enable rapid polymerization under UV exposure. The resulting hydrogels feature precisely controlled water content (typically 30-70%) and optical transparency exceeding 95% in the visible spectrum. DuPont's formulations incorporate functional groups that can be tailored to detect specific analytes through mechanisms such as fluorescence quenching or refractive index changes. Their manufacturing process employs photolithography techniques allowing for microscale patterning with resolution down to 10 μm, enabling the creation of complex sensor arrays on a single substrate. These materials demonstrate exceptional stability with less than 5% performance degradation over 12 months in typical operating conditions.

Strengths: Superior optical clarity and customizable chemical functionality allow for highly sensitive detection systems. Established manufacturing infrastructure enables consistent quality and scalability. Weaknesses: Higher production costs compared to conventional hydrogels, and some formulations may require specialized handling due to oxygen sensitivity during curing.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu has pioneered silicone-based UV-curable hydrogels for optical sensing that offer exceptional environmental stability. Their technology utilizes modified silicone macromers with pendant methacrylate groups that form interpenetrating networks when exposed to UV radiation in the presence of their proprietary photoinitiator system. These hydrogels maintain optical clarity (>92% transmission) across a wide temperature range (-20°C to 150°C) while exhibiting minimal swelling variation (<3%) in diverse pH environments. Shin-Etsu's formulations incorporate silicone-organic hybrid structures that provide both hydrophilic domains for analyte interaction and hydrophobic regions that enhance mechanical durability. Their manufacturing process employs injection molding followed by UV exposure, allowing for complex three-dimensional sensor geometries with high reproducibility. The resulting materials show remarkable resistance to biofouling, making them particularly suitable for implantable or long-term environmental monitoring applications.

Strengths: Exceptional thermal and chemical stability compared to conventional hydrogels, with superior resistance to protein adsorption and bacterial adhesion. Weaknesses: Higher initial material costs and more complex processing requirements than acrylic-based alternatives, with somewhat lower water content limiting diffusion rates for some analytes.

Critical Patents and Literature in Hydrogel Optical Sensors

Method for making UV-absorbing ophthalmic lenses

PatentActiveEP3052534A1

Innovation

- A method involving a pre-polymerization mixture with a germanium-based Norrish Type I photoinitiator and specific UV-absorbing vinylic monomers, which allows for rapid curing under visible light, minimizing internal stress and reducing production time and costs, while maintaining high lens edge quality.

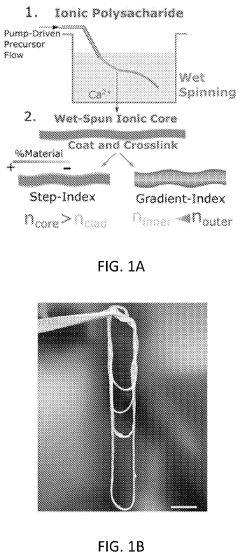

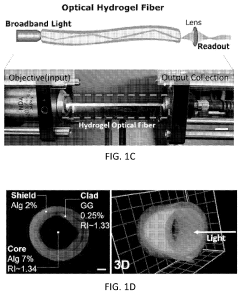

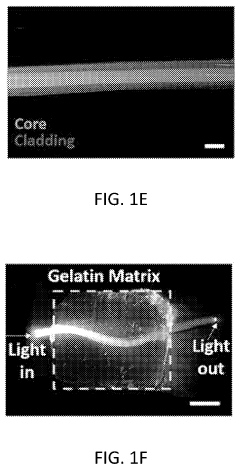

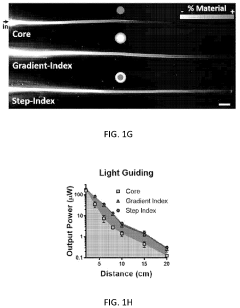

Polysaccharide hydrogel optical fibers and their fabrication and use

PatentPendingUS20240184016A1

Innovation

- Development of optical fibers with wet-spun multi-layer hydrogel cladding using ionic-crosslinked polysaccharides, allowing for step- or gradient-index architectures, fusion splicing, and incorporation of plasmonic nanoparticles for biosensor applications, enabling rapid detection of pathogens like SARS-CoV-2 and integration with medical swabs.

Biocompatibility and Safety Considerations

The integration of UV-curable hydrogels into optical sensing applications necessitates rigorous evaluation of biocompatibility and safety profiles, particularly when these materials interface with biological systems. UV-curable hydrogels present unique safety considerations due to their synthesis method involving photoinitiators and UV radiation, which can potentially leave residual compounds in the final material.

Primary biocompatibility concerns include cytotoxicity of unreacted monomers, photoinitiators, and degradation products. Studies have demonstrated that certain photoinitiators like Irgacure 2959 exhibit acceptable cytotoxicity profiles at concentrations typically used for hydrogel formation, while others may induce cellular damage. The complete polymerization process is critical, as residual monomers can leach into surrounding tissues or fluids, potentially causing adverse reactions.

Inflammatory responses represent another significant consideration. UV-cured hydrogels must undergo thorough evaluation to ensure they do not trigger chronic inflammation when deployed in vivo. Recent research has focused on developing hydrogel formulations with anti-inflammatory properties, incorporating bioactive molecules that actively suppress inflammatory cascades while maintaining optical clarity essential for sensing applications.

Long-term stability and degradation characteristics directly impact safety profiles. Hydrogels that undergo uncontrolled degradation may release potentially harmful byproducts or compromise sensor functionality. Controlled biodegradation rates must be engineered to match the intended application duration while ensuring degradation products remain non-toxic.

Sterilization compatibility presents unique challenges for optical sensor applications. Traditional sterilization methods like autoclaving can alter the mechanical and optical properties of hydrogels. Alternative approaches such as ethylene oxide treatment or gamma irradiation must be validated to ensure they effectively sterilize without compromising material performance or introducing new safety concerns.

Regulatory frameworks governing UV-curable hydrogels vary significantly based on application context. Medical-grade optical sensors face stringent requirements under FDA and EMA guidelines, necessitating comprehensive biocompatibility testing according to ISO 10993 standards. Environmental sensing applications may require additional ecotoxicity assessments to evaluate potential impacts on aquatic organisms and ecosystems.

Recent advances in "green chemistry" approaches have yielded promising developments in safer UV-curable hydrogel formulations. These include water-based systems that eliminate organic solvents, naturally derived photoinitiators with improved safety profiles, and biobased monomers that reduce dependence on petroleum derivatives while enhancing biocompatibility.

Primary biocompatibility concerns include cytotoxicity of unreacted monomers, photoinitiators, and degradation products. Studies have demonstrated that certain photoinitiators like Irgacure 2959 exhibit acceptable cytotoxicity profiles at concentrations typically used for hydrogel formation, while others may induce cellular damage. The complete polymerization process is critical, as residual monomers can leach into surrounding tissues or fluids, potentially causing adverse reactions.

Inflammatory responses represent another significant consideration. UV-cured hydrogels must undergo thorough evaluation to ensure they do not trigger chronic inflammation when deployed in vivo. Recent research has focused on developing hydrogel formulations with anti-inflammatory properties, incorporating bioactive molecules that actively suppress inflammatory cascades while maintaining optical clarity essential for sensing applications.

Long-term stability and degradation characteristics directly impact safety profiles. Hydrogels that undergo uncontrolled degradation may release potentially harmful byproducts or compromise sensor functionality. Controlled biodegradation rates must be engineered to match the intended application duration while ensuring degradation products remain non-toxic.

Sterilization compatibility presents unique challenges for optical sensor applications. Traditional sterilization methods like autoclaving can alter the mechanical and optical properties of hydrogels. Alternative approaches such as ethylene oxide treatment or gamma irradiation must be validated to ensure they effectively sterilize without compromising material performance or introducing new safety concerns.

Regulatory frameworks governing UV-curable hydrogels vary significantly based on application context. Medical-grade optical sensors face stringent requirements under FDA and EMA guidelines, necessitating comprehensive biocompatibility testing according to ISO 10993 standards. Environmental sensing applications may require additional ecotoxicity assessments to evaluate potential impacts on aquatic organisms and ecosystems.

Recent advances in "green chemistry" approaches have yielded promising developments in safer UV-curable hydrogel formulations. These include water-based systems that eliminate organic solvents, naturally derived photoinitiators with improved safety profiles, and biobased monomers that reduce dependence on petroleum derivatives while enhancing biocompatibility.

Environmental Impact and Sustainability Assessment

The environmental impact of UV-curable hydrogels for optical sensor applications requires thorough assessment as these materials gain prominence in sensing technologies. Traditional sensor materials often involve energy-intensive manufacturing processes and hazardous chemicals, whereas UV-curable hydrogels offer potential advantages in terms of reduced energy consumption during production. The UV-curing process typically operates at ambient temperatures and requires significantly less energy compared to thermal curing methods, potentially reducing the carbon footprint of sensor manufacturing.

Material composition analysis reveals that many UV-curable hydrogels utilize water as a primary component, reducing dependence on petroleum-based resources. However, certain photoinitiators and monomers used in these formulations may present environmental concerns if released into ecosystems. Recent advancements have focused on developing bio-based alternatives to synthetic components, with research showing promising results for photoinitiators derived from lignin and other natural sources.

End-of-life considerations for optical sensors based on UV-curable hydrogels present both challenges and opportunities. The biodegradability of these materials varies significantly depending on their specific chemical composition. Studies indicate that hydrogels containing natural polymers such as alginate or cellulose derivatives demonstrate superior biodegradation profiles compared to those based on synthetic polymers. This biodegradability can substantially reduce waste accumulation in landfills when sensors reach end-of-life.

Water consumption during manufacturing represents another critical environmental factor. UV-curable hydrogels generally require less water in production compared to conventional sensor materials, though the exact reduction depends on specific formulations and manufacturing protocols. Research indicates potential water savings of 30-45% when implementing optimized UV-curable hydrogel production methods.

Life cycle assessment (LCA) studies comparing UV-curable hydrogel sensors with traditional alternatives demonstrate varying results across impact categories. While these materials typically show reduced global warming potential and energy demand, certain formulations may score less favorably in categories such as ecotoxicity or resource depletion, depending on specific chemical constituents.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced materials. The European Union's REACH regulations and similar initiatives in other regions are driving manufacturers toward greener formulations with reduced environmental persistence. This regulatory landscape is accelerating innovation in environmentally benign UV-curable hydrogels, with several companies developing formulations specifically designed to meet stringent sustainability criteria while maintaining optimal optical sensing performance.

Material composition analysis reveals that many UV-curable hydrogels utilize water as a primary component, reducing dependence on petroleum-based resources. However, certain photoinitiators and monomers used in these formulations may present environmental concerns if released into ecosystems. Recent advancements have focused on developing bio-based alternatives to synthetic components, with research showing promising results for photoinitiators derived from lignin and other natural sources.

End-of-life considerations for optical sensors based on UV-curable hydrogels present both challenges and opportunities. The biodegradability of these materials varies significantly depending on their specific chemical composition. Studies indicate that hydrogels containing natural polymers such as alginate or cellulose derivatives demonstrate superior biodegradation profiles compared to those based on synthetic polymers. This biodegradability can substantially reduce waste accumulation in landfills when sensors reach end-of-life.

Water consumption during manufacturing represents another critical environmental factor. UV-curable hydrogels generally require less water in production compared to conventional sensor materials, though the exact reduction depends on specific formulations and manufacturing protocols. Research indicates potential water savings of 30-45% when implementing optimized UV-curable hydrogel production methods.

Life cycle assessment (LCA) studies comparing UV-curable hydrogel sensors with traditional alternatives demonstrate varying results across impact categories. While these materials typically show reduced global warming potential and energy demand, certain formulations may score less favorably in categories such as ecotoxicity or resource depletion, depending on specific chemical constituents.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced materials. The European Union's REACH regulations and similar initiatives in other regions are driving manufacturers toward greener formulations with reduced environmental persistence. This regulatory landscape is accelerating innovation in environmentally benign UV-curable hydrogels, with several companies developing formulations specifically designed to meet stringent sustainability criteria while maintaining optimal optical sensing performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!