Ionically conductive hydrogels for motion detection

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ionically Conductive Hydrogels Background and Objectives

Ionically conductive hydrogels represent a significant advancement in the field of soft electronics and biomedical sensing technologies. These materials have evolved from conventional hydrogels through the incorporation of ionic conductors, enabling them to function as highly sensitive and flexible sensors for motion detection applications. The development trajectory of ionically conductive hydrogels spans several decades, beginning with basic hydrogel research in the 1960s and accelerating dramatically in the past decade with the emergence of stretchable electronics and wearable technology demands.

The technological evolution has progressed from simple water-retaining polymer networks to sophisticated multi-functional materials that combine mechanical robustness, biocompatibility, and excellent ionic conductivity. Key milestones include the development of double-network hydrogels in the early 2000s, the introduction of tough hydrogels with self-healing properties around 2012, and recent advancements in 3D printable ionically conductive hydrogels that maintain performance under mechanical deformation.

Current research focuses on enhancing the sensitivity, durability, and biocompatibility of these materials while maintaining their inherent flexibility and stretchability. The primary technical objectives include achieving stable ionic conductivity under repeated mechanical stress, minimizing hysteresis effects during cyclic loading, and developing manufacturing processes suitable for scalable production of hydrogel-based motion sensors.

Another critical objective is to improve the interface between ionically conductive hydrogels and electronic components, addressing challenges related to signal transduction and long-term stability in various environmental conditions. Researchers aim to develop hydrogels that maintain consistent performance across temperature fluctuations, humidity changes, and extended usage periods.

The integration of ionically conductive hydrogels with wireless communication technologies represents another important research direction, with the goal of creating autonomous sensing systems capable of real-time motion detection and data transmission. This includes efforts to minimize power consumption and develop self-powered sensing capabilities through integration with energy harvesting technologies.

From a materials science perspective, researchers are exploring various ionic species beyond traditional sodium and potassium salts, including organic ionic liquids and polyelectrolytes, to enhance conductivity while maintaining mechanical properties. Simultaneously, there is growing interest in environmentally sustainable and biodegradable formulations that maintain high performance standards while reducing environmental impact.

The ultimate technical objective is to develop a new generation of motion detection systems based on ionically conductive hydrogels that outperform traditional electronic sensors in terms of sensitivity, conformability, and biocompatibility, particularly for applications in healthcare monitoring, soft robotics, and human-machine interfaces.

The technological evolution has progressed from simple water-retaining polymer networks to sophisticated multi-functional materials that combine mechanical robustness, biocompatibility, and excellent ionic conductivity. Key milestones include the development of double-network hydrogels in the early 2000s, the introduction of tough hydrogels with self-healing properties around 2012, and recent advancements in 3D printable ionically conductive hydrogels that maintain performance under mechanical deformation.

Current research focuses on enhancing the sensitivity, durability, and biocompatibility of these materials while maintaining their inherent flexibility and stretchability. The primary technical objectives include achieving stable ionic conductivity under repeated mechanical stress, minimizing hysteresis effects during cyclic loading, and developing manufacturing processes suitable for scalable production of hydrogel-based motion sensors.

Another critical objective is to improve the interface between ionically conductive hydrogels and electronic components, addressing challenges related to signal transduction and long-term stability in various environmental conditions. Researchers aim to develop hydrogels that maintain consistent performance across temperature fluctuations, humidity changes, and extended usage periods.

The integration of ionically conductive hydrogels with wireless communication technologies represents another important research direction, with the goal of creating autonomous sensing systems capable of real-time motion detection and data transmission. This includes efforts to minimize power consumption and develop self-powered sensing capabilities through integration with energy harvesting technologies.

From a materials science perspective, researchers are exploring various ionic species beyond traditional sodium and potassium salts, including organic ionic liquids and polyelectrolytes, to enhance conductivity while maintaining mechanical properties. Simultaneously, there is growing interest in environmentally sustainable and biodegradable formulations that maintain high performance standards while reducing environmental impact.

The ultimate technical objective is to develop a new generation of motion detection systems based on ionically conductive hydrogels that outperform traditional electronic sensors in terms of sensitivity, conformability, and biocompatibility, particularly for applications in healthcare monitoring, soft robotics, and human-machine interfaces.

Market Analysis for Motion Detection Applications

The motion detection market is experiencing robust growth, driven by increasing applications across multiple sectors including healthcare, sports science, robotics, and consumer electronics. The global motion detection market was valued at approximately 6.2 billion USD in 2022 and is projected to reach 12.8 billion USD by 2028, representing a compound annual growth rate (CAGR) of 12.8%. This growth trajectory is particularly significant for ionically conductive hydrogels, which are emerging as next-generation sensing materials for precise motion detection applications.

Healthcare represents the largest market segment for motion detection technologies, accounting for nearly 32% of the total market share. Within this sector, rehabilitation monitoring, gait analysis, and patient activity tracking are key application areas where hydrogel-based sensors show particular promise due to their biocompatibility and conformability to human skin. The aging global population and increasing prevalence of mobility disorders are further expanding this market segment.

The sports and fitness industry constitutes another rapidly growing sector, with a market size of approximately 1.8 billion USD specifically for motion detection technologies. Professional sports teams, athletic training facilities, and consumer fitness products increasingly incorporate advanced motion sensors to analyze performance metrics and prevent injuries. Hydrogel-based wearable sensors offer advantages in this space due to their flexibility, durability during physical activity, and potential for real-time data collection.

Consumer electronics represents the fastest-growing segment with a CAGR of 15.3%, driven by virtual reality, gaming interfaces, and smart home applications. The demand for more intuitive human-machine interfaces is creating significant opportunities for hydrogel-based motion detection systems that can offer enhanced sensitivity and user comfort compared to traditional rigid sensors.

Geographically, North America leads the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, primarily due to increasing technological adoption in countries like China, Japan, and South Korea, along with growing manufacturing capabilities for advanced materials including specialized hydrogels.

Key market challenges include price sensitivity in consumer applications, durability concerns for hydrogel-based sensors, and integration complexities with existing electronic systems. Despite these challenges, the market outlook remains highly positive as technological advancements continue to address these limitations and expand the application scope of ionically conductive hydrogels in motion detection.

Healthcare represents the largest market segment for motion detection technologies, accounting for nearly 32% of the total market share. Within this sector, rehabilitation monitoring, gait analysis, and patient activity tracking are key application areas where hydrogel-based sensors show particular promise due to their biocompatibility and conformability to human skin. The aging global population and increasing prevalence of mobility disorders are further expanding this market segment.

The sports and fitness industry constitutes another rapidly growing sector, with a market size of approximately 1.8 billion USD specifically for motion detection technologies. Professional sports teams, athletic training facilities, and consumer fitness products increasingly incorporate advanced motion sensors to analyze performance metrics and prevent injuries. Hydrogel-based wearable sensors offer advantages in this space due to their flexibility, durability during physical activity, and potential for real-time data collection.

Consumer electronics represents the fastest-growing segment with a CAGR of 15.3%, driven by virtual reality, gaming interfaces, and smart home applications. The demand for more intuitive human-machine interfaces is creating significant opportunities for hydrogel-based motion detection systems that can offer enhanced sensitivity and user comfort compared to traditional rigid sensors.

Geographically, North America leads the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, primarily due to increasing technological adoption in countries like China, Japan, and South Korea, along with growing manufacturing capabilities for advanced materials including specialized hydrogels.

Key market challenges include price sensitivity in consumer applications, durability concerns for hydrogel-based sensors, and integration complexities with existing electronic systems. Despite these challenges, the market outlook remains highly positive as technological advancements continue to address these limitations and expand the application scope of ionically conductive hydrogels in motion detection.

Current Status and Technical Challenges in Hydrogel Sensors

The current landscape of hydrogel-based sensors for motion detection reveals significant advancements alongside persistent technical challenges. Globally, research institutions and companies have developed various ionically conductive hydrogels with promising properties for flexible electronics and wearable devices. These materials combine high stretchability, self-healing capabilities, and excellent ionic conductivity, making them suitable for detecting human movements with high sensitivity.

Despite these advancements, several technical hurdles remain unresolved. The long-term stability of hydrogel sensors presents a major challenge, as these materials tend to dehydrate over time, leading to performance degradation. Environmental factors such as temperature fluctuations and humidity changes significantly impact sensor reliability, limiting their practical applications in diverse settings.

Biocompatibility and toxicity concerns persist, particularly for sensors designed for direct skin contact or implantable applications. The leaching of potentially harmful components from hydrogels during prolonged use raises safety questions that require further investigation and regulatory consideration.

Manufacturing scalability represents another significant obstacle. Current laboratory-scale production methods for high-performance ionically conductive hydrogels often involve complex synthesis procedures that are difficult to scale up for mass production. This manufacturing gap hinders commercial viability and widespread adoption.

Signal processing and noise reduction remain technically challenging. The soft and compliant nature of hydrogels, while beneficial for wearability, introduces signal artifacts during motion. Developing robust algorithms to filter movement artifacts from actual sensing signals requires sophisticated computational approaches not yet fully realized.

Power requirements pose additional limitations. Most current hydrogel sensor systems require external power sources, restricting their portability and continuous operation capabilities. Research into self-powered hydrogel sensors integrated with energy harvesting technologies is still in nascent stages.

The integration of hydrogel sensors with conventional electronic components presents interface challenges due to the fundamental differences between soft, water-containing hydrogels and rigid electronic components. This mechanical and chemical mismatch often leads to connection failures and reduced system reliability.

Standardization across the field is notably lacking, with researchers using diverse testing protocols and performance metrics, making direct comparisons between different hydrogel sensor technologies difficult. This fragmentation impedes knowledge transfer and slows overall progress in the field.

Despite these advancements, several technical hurdles remain unresolved. The long-term stability of hydrogel sensors presents a major challenge, as these materials tend to dehydrate over time, leading to performance degradation. Environmental factors such as temperature fluctuations and humidity changes significantly impact sensor reliability, limiting their practical applications in diverse settings.

Biocompatibility and toxicity concerns persist, particularly for sensors designed for direct skin contact or implantable applications. The leaching of potentially harmful components from hydrogels during prolonged use raises safety questions that require further investigation and regulatory consideration.

Manufacturing scalability represents another significant obstacle. Current laboratory-scale production methods for high-performance ionically conductive hydrogels often involve complex synthesis procedures that are difficult to scale up for mass production. This manufacturing gap hinders commercial viability and widespread adoption.

Signal processing and noise reduction remain technically challenging. The soft and compliant nature of hydrogels, while beneficial for wearability, introduces signal artifacts during motion. Developing robust algorithms to filter movement artifacts from actual sensing signals requires sophisticated computational approaches not yet fully realized.

Power requirements pose additional limitations. Most current hydrogel sensor systems require external power sources, restricting their portability and continuous operation capabilities. Research into self-powered hydrogel sensors integrated with energy harvesting technologies is still in nascent stages.

The integration of hydrogel sensors with conventional electronic components presents interface challenges due to the fundamental differences between soft, water-containing hydrogels and rigid electronic components. This mechanical and chemical mismatch often leads to connection failures and reduced system reliability.

Standardization across the field is notably lacking, with researchers using diverse testing protocols and performance metrics, making direct comparisons between different hydrogel sensor technologies difficult. This fragmentation impedes knowledge transfer and slows overall progress in the field.

Current Technical Solutions for Hydrogel-Based Motion Sensing

01 Ionic hydrogels with enhanced conductivity through salt incorporation

Incorporating various salts into hydrogel matrices significantly enhances ionic conductivity. These salts, including lithium salts, sodium salts, and other ionic compounds, dissociate within the hydrogel network to provide mobile charge carriers. The concentration and type of salt directly influence the conductivity level, with higher salt concentrations generally yielding higher conductivity. These ionically conductive hydrogels find applications in flexible electronics, sensors, and energy storage devices.- Polymer-based ionically conductive hydrogels: Polymer-based ionically conductive hydrogels utilize various polymer matrices to enhance ionic conductivity. These hydrogels incorporate polymers such as polyacrylamide, polyvinyl alcohol, or polyethylene oxide as structural frameworks that can hold electrolyte solutions. The polymer networks provide mechanical stability while allowing ion movement through their hydrated structure. These materials often achieve high conductivity through optimized cross-linking density and water content, making them suitable for applications in flexible electronics, sensors, and biomedical devices.

- Ionic liquid-incorporated hydrogels for enhanced conductivity: Incorporating ionic liquids into hydrogel matrices significantly improves their ionic conductivity. These room-temperature molten salts provide abundant mobile ions while maintaining low volatility and high thermal stability. The integration of ionic liquids with hydrogel networks creates materials with conductivity values often exceeding traditional aqueous electrolyte systems. These advanced hydrogels maintain conductivity even under varying environmental conditions and can be designed with self-healing properties, making them valuable for energy storage applications and electrochemical devices.

- Nanocomposite hydrogels with enhanced ionic conductivity: Nanocomposite hydrogels incorporate nanomaterials such as graphene, carbon nanotubes, or metal oxide nanoparticles to enhance ionic conductivity. These nanomaterials create additional conductive pathways within the hydrogel structure, reducing ion transport resistance. The synergistic effect between the nanofillers and polymer matrix often results in conductivity values significantly higher than conventional hydrogels. These materials also frequently exhibit improved mechanical properties and stability, making them suitable for applications in flexible electronics, supercapacitors, and bioelectronics.

- Stimuli-responsive conductive hydrogels: Stimuli-responsive conductive hydrogels can change their ionic conductivity in response to external triggers such as temperature, pH, light, or electrical fields. These smart materials utilize reversible cross-linking mechanisms or conformational changes in their polymer structure to modulate ion transport pathways. The ability to control conductivity through external stimuli makes these hydrogels particularly valuable for applications in controlled drug delivery, soft robotics, and adaptive electronics. Some formulations combine multiple responsive elements to create multi-stimuli responsive systems with precisely tunable conductivity properties.

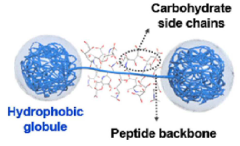

- Hydrogels with biomimetic ionic channels for high conductivity: Biomimetic hydrogels incorporate structures inspired by natural ion channels to achieve exceptional ionic conductivity. These materials often feature precisely engineered nanopores or channels that facilitate rapid and selective ion transport. By mimicking biological ion transport mechanisms, these hydrogels can achieve conductivity values approaching those of natural systems while maintaining biocompatibility. The biomimetic approach allows for the development of hydrogels with both high conductivity and selectivity for specific ions, making them particularly valuable for applications in biosensing, artificial tissues, and bioelectronic interfaces.

02 Polymer network design for improved ionic conductivity

The structure and composition of the polymer network significantly impact the ionic conductivity of hydrogels. Cross-linking density, polymer chain flexibility, and functional group selection all play crucial roles in facilitating ion transport. Hydrogels with optimized polymer networks featuring controlled mesh sizes and hydrophilic domains create efficient ion transport channels. Advanced polymer designs incorporate specific functional groups that interact favorably with ions to enhance mobility throughout the hydrogel matrix.Expand Specific Solutions03 Nanocomposite hydrogels for enhanced conductivity

Incorporating nanomaterials such as carbon nanotubes, graphene, metal nanoparticles, or conductive polymers into hydrogels creates nanocomposite structures with significantly improved ionic conductivity. These nanomaterials provide additional conductive pathways and can interact with the polymer network to enhance ion mobility. The synergistic effect between the nanomaterials and the hydrogel matrix results in conductivity values that exceed those of conventional hydrogels, making these materials suitable for advanced applications in bioelectronics and energy storage.Expand Specific Solutions04 Stimuli-responsive conductive hydrogels

Hydrogels that change their conductivity in response to external stimuli such as temperature, pH, light, or mechanical stress offer dynamic control over ionic conductivity. These smart materials incorporate responsive elements that can trigger structural changes in the hydrogel network, altering ion mobility pathways. Applications include sensors, controlled drug delivery systems, and adaptive electronics where conductivity modulation is required based on environmental conditions or user input.Expand Specific Solutions05 Hydrogel electrolytes for energy storage applications

Specially formulated ionically conductive hydrogels serve as solid or quasi-solid electrolytes in batteries, supercapacitors, and other energy storage devices. These hydrogels combine high ionic conductivity with mechanical stability and safety advantages over liquid electrolytes. The hydrogel structure prevents electrolyte leakage while maintaining efficient ion transport between electrodes. Advanced formulations incorporate flame-retardant components and self-healing properties to enhance the safety and durability of energy storage devices.Expand Specific Solutions

Leading Research Groups and Companies in Hydrogel Technology

The ionically conductive hydrogels for motion detection market is currently in an early growth phase, characterized by intensive research and development activities. The global market size is estimated to be expanding at a CAGR of 15-20%, driven by increasing applications in wearable electronics, healthcare monitoring, and soft robotics. From a technological maturity perspective, the field remains in development with significant innovation potential. Leading academic institutions like South China University of Technology, Sichuan University, and University of British Columbia are pioneering fundamental research, while companies including Hitachi, NXP Semiconductors, and Mitsubishi Electric are focusing on commercial applications. National research organizations such as the National Research Council of Canada and Centre National de la Recherche Scientifique provide critical infrastructure supporting cross-sector collaboration to advance this emerging technology toward market readiness.

Sichuan University

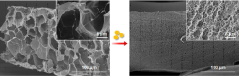

Technical Solution: Sichuan University has developed innovative ionically conductive hydrogels for motion detection based on a multi-component system incorporating zwitterionic polymers. Their proprietary technology creates hydrogels with exceptional freeze-resistance and temperature stability (-40°C to 60°C), addressing a critical limitation in conventional hydrogel sensors[2]. The university's research team has engineered hydrogels with a unique microstructure featuring ionic channels that facilitate rapid ion transport while maintaining structural integrity during deformation. Their approach includes incorporating graphene oxide nanosheets into the hydrogel matrix, creating a hierarchical structure that enhances both mechanical properties and electrical conductivity[4]. Sichuan University has also pioneered adhesive hydrogels that can firmly attach to various surfaces including human skin without additional adhesives, enabling direct integration into wearable motion detection systems with minimal signal interference[5].

Strengths: Exceptional temperature stability allowing operation in extreme environments; superior adhesion properties enabling direct skin application without additional adhesives; excellent biocompatibility with minimal skin irritation. Weaknesses: Higher production costs compared to conventional sensors; limited long-term stability in high-humidity environments; challenges in achieving consistent performance across large-scale manufacturing.

Ulsan National Institute of Science & Technology

Technical Solution: Ulsan National Institute of Science & Technology (UNIST) has developed advanced ionically conductive hydrogels for motion detection using a unique dual-network structure. Their approach combines a rigid polymer network providing mechanical stability with an interpenetrating ionic network that ensures excellent conductivity. The hydrogels incorporate specific ionic compounds (typically lithium salts) that maintain high ionic mobility even under deformation. UNIST researchers have pioneered self-healing hydrogels that can recover their properties after damage, crucial for wearable sensing applications[1]. Their technology includes strain-sensitive hydrogels that change electrical resistance proportionally to applied strain, enabling precise motion tracking. The institute has also developed transparent hydrogels with tunable optical properties while maintaining ionic conductivity, making them suitable for integration with display technologies[3].

Strengths: Exceptional self-healing capabilities allowing for extended device lifespan; superior biocompatibility making them ideal for on-skin applications; excellent mechanical durability with strain tolerance exceeding 400%. Weaknesses: Temperature sensitivity affecting performance in extreme conditions; relatively slow response time compared to electronic sensors; challenges in mass production scalability.

Key Patents and Research Breakthroughs in Ionic Conductivity

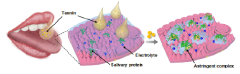

Ion-conductive hydrogels for astringency perception methods for their preparation and uses thereof

PatentActiveKR1020210112810A

Innovation

- An ion conductive hydrogel is developed using acrylamide monomer, mucin, lithium chloride, and a crosslinking agent to create a microporous structure that forms hierarchical micro/nanopores upon interaction with polyphenolic compounds, mimicking the human tongue's astringency perception mechanism.

Ionic conducting gels, preparation method thereof and use of same

PatentWO2005007746A1

Innovation

- A method involving the sol-gel process to create ion-conductive gels (ionogels) by mixing ionic liquids with sol-gel precursors in the presence of carboxylic acids, forming a continuous solid skeleton that encapsulates the ionic liquid, allowing for a single-step synthesis of transparent, monolithic, and stable ionic conductors capable of withstanding temperatures up to 350°C.

Biocompatibility and Safety Considerations

The integration of ionically conductive hydrogels into motion detection systems necessitates rigorous evaluation of biocompatibility and safety profiles, particularly for applications involving direct contact with human skin or implantation within biological tissues. These hydrogels, while promising for their electrical conductivity and mechanical properties, must meet stringent biocompatibility standards to ensure user safety and regulatory compliance.

Primary biocompatibility considerations include cytotoxicity assessment, where hydrogel materials must demonstrate minimal adverse effects on cellular viability and proliferation. Recent studies have shown that hydrogels based on natural polymers such as alginate, chitosan, and hyaluronic acid generally exhibit favorable biocompatibility profiles compared to synthetic alternatives. However, the ionic components incorporated to enhance conductivity—typically lithium, sodium, or potassium salts—require careful evaluation for potential systemic toxicity.

Immunogenicity represents another critical safety parameter, as foreign materials can trigger inflammatory responses or allergic reactions. Research indicates that hydrogel matrix composition significantly influences immune recognition, with highly purified materials showing reduced immunogenic potential. Cross-linking agents used in hydrogel synthesis, particularly glutaraldehyde and formaldehyde derivatives, have been identified as potential sources of adverse reactions and require substitution with biocompatible alternatives such as genipin or enzymatic cross-linking methods.

Long-term stability and degradation characteristics must be thoroughly investigated, as leaching of ionic components or degradation products could pose toxicological concerns. Studies have demonstrated that controlled degradation profiles can be engineered through polymer selection and cross-linking density optimization, allowing for predictable material performance throughout the intended application lifetime.

For wearable motion detection applications, skin sensitization and irritation testing becomes paramount. Hydrogels with neutral pH values (6.5-7.5) and osmolarity similar to physiological conditions have shown superior dermal compatibility. Additionally, antimicrobial properties may be incorporated through the integration of silver nanoparticles or quaternary ammonium compounds, though these additives introduce additional safety considerations requiring balanced assessment.

Regulatory pathways for ionically conductive hydrogels vary depending on application classification, with medical devices facing more stringent requirements than consumer electronics. ISO 10993 standards provide a framework for biological evaluation, including tests for sensitization, irritation, and systemic toxicity. Manufacturers must navigate these regulatory landscapes while maintaining the functional properties necessary for effective motion detection.

Environmental considerations also factor into comprehensive safety assessments, with biodegradability and ecological impact gaining importance as sustainability becomes a market differentiator. Hydrogels derived from renewable resources with controlled end-of-life characteristics represent a promising direction for environmentally conscious development.

Primary biocompatibility considerations include cytotoxicity assessment, where hydrogel materials must demonstrate minimal adverse effects on cellular viability and proliferation. Recent studies have shown that hydrogels based on natural polymers such as alginate, chitosan, and hyaluronic acid generally exhibit favorable biocompatibility profiles compared to synthetic alternatives. However, the ionic components incorporated to enhance conductivity—typically lithium, sodium, or potassium salts—require careful evaluation for potential systemic toxicity.

Immunogenicity represents another critical safety parameter, as foreign materials can trigger inflammatory responses or allergic reactions. Research indicates that hydrogel matrix composition significantly influences immune recognition, with highly purified materials showing reduced immunogenic potential. Cross-linking agents used in hydrogel synthesis, particularly glutaraldehyde and formaldehyde derivatives, have been identified as potential sources of adverse reactions and require substitution with biocompatible alternatives such as genipin or enzymatic cross-linking methods.

Long-term stability and degradation characteristics must be thoroughly investigated, as leaching of ionic components or degradation products could pose toxicological concerns. Studies have demonstrated that controlled degradation profiles can be engineered through polymer selection and cross-linking density optimization, allowing for predictable material performance throughout the intended application lifetime.

For wearable motion detection applications, skin sensitization and irritation testing becomes paramount. Hydrogels with neutral pH values (6.5-7.5) and osmolarity similar to physiological conditions have shown superior dermal compatibility. Additionally, antimicrobial properties may be incorporated through the integration of silver nanoparticles or quaternary ammonium compounds, though these additives introduce additional safety considerations requiring balanced assessment.

Regulatory pathways for ionically conductive hydrogels vary depending on application classification, with medical devices facing more stringent requirements than consumer electronics. ISO 10993 standards provide a framework for biological evaluation, including tests for sensitization, irritation, and systemic toxicity. Manufacturers must navigate these regulatory landscapes while maintaining the functional properties necessary for effective motion detection.

Environmental considerations also factor into comprehensive safety assessments, with biodegradability and ecological impact gaining importance as sustainability becomes a market differentiator. Hydrogels derived from renewable resources with controlled end-of-life characteristics represent a promising direction for environmentally conscious development.

Sustainability and Environmental Impact Assessment

The sustainability profile of ionically conductive hydrogels represents a critical dimension in their development for motion detection applications. These materials offer significant environmental advantages compared to traditional electronic sensors, primarily due to their biodegradable nature and reduced reliance on rare earth elements. Many hydrogel formulations utilize naturally derived polymers such as alginate, cellulose, and chitosan, which can be sourced from renewable resources and potentially decompose without harmful residues.

The life cycle assessment of ionically conductive hydrogels reveals promising characteristics in terms of energy consumption during manufacturing. Unlike conventional electronic components that require energy-intensive clean room facilities and high-temperature processing, many hydrogels can be synthesized at ambient or near-ambient conditions, substantially reducing the carbon footprint associated with production. Water-based processing further minimizes the use of harmful organic solvents that typically plague electronic manufacturing.

Resource efficiency constitutes another environmental advantage of these materials. The primary components—water, ionic compounds, and polymeric networks—are generally abundant and can be derived from sustainable sources. This contrasts sharply with traditional motion sensors that depend on scarce metals and semiconductor materials with geopolitically complicated supply chains.

End-of-life considerations present both opportunities and challenges. While the biodegradability of many hydrogel components offers a pathway to reduced electronic waste, the presence of certain crosslinking agents or synthetic polymers may compromise complete environmental decomposition. Research into green chemistry approaches for hydrogel synthesis has shown promising results, with developments in enzyme-mediated crosslinking and naturally derived ionic conductors potentially eliminating persistent pollutants from the material lifecycle.

The scalability of environmentally friendly production methods remains a significant challenge. Current laboratory-scale synthesis procedures often employ techniques that may not translate efficiently to industrial production without substantial environmental costs. Addressing this scale-up challenge requires dedicated research into green manufacturing protocols specifically tailored to ionically conductive hydrogels.

Water consumption during both production and operation presents another environmental consideration. While hydrogels inherently require water for their functionality, strategies for water conservation and recycling within manufacturing processes need further development. Additionally, the potential for water loss during operation in variable humidity environments necessitates research into encapsulation technologies that maintain hydrogel performance while minimizing resource consumption.

The life cycle assessment of ionically conductive hydrogels reveals promising characteristics in terms of energy consumption during manufacturing. Unlike conventional electronic components that require energy-intensive clean room facilities and high-temperature processing, many hydrogels can be synthesized at ambient or near-ambient conditions, substantially reducing the carbon footprint associated with production. Water-based processing further minimizes the use of harmful organic solvents that typically plague electronic manufacturing.

Resource efficiency constitutes another environmental advantage of these materials. The primary components—water, ionic compounds, and polymeric networks—are generally abundant and can be derived from sustainable sources. This contrasts sharply with traditional motion sensors that depend on scarce metals and semiconductor materials with geopolitically complicated supply chains.

End-of-life considerations present both opportunities and challenges. While the biodegradability of many hydrogel components offers a pathway to reduced electronic waste, the presence of certain crosslinking agents or synthetic polymers may compromise complete environmental decomposition. Research into green chemistry approaches for hydrogel synthesis has shown promising results, with developments in enzyme-mediated crosslinking and naturally derived ionic conductors potentially eliminating persistent pollutants from the material lifecycle.

The scalability of environmentally friendly production methods remains a significant challenge. Current laboratory-scale synthesis procedures often employ techniques that may not translate efficiently to industrial production without substantial environmental costs. Addressing this scale-up challenge requires dedicated research into green manufacturing protocols specifically tailored to ionically conductive hydrogels.

Water consumption during both production and operation presents another environmental consideration. While hydrogels inherently require water for their functionality, strategies for water conservation and recycling within manufacturing processes need further development. Additionally, the potential for water loss during operation in variable humidity environments necessitates research into encapsulation technologies that maintain hydrogel performance while minimizing resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!