Hydrogel sensors for real-time biomedical monitoring

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Biosensors Background and Objectives

Hydrogel sensors have emerged as a revolutionary technology in the field of biomedical monitoring over the past decade. These innovative materials combine the properties of hydrophilic polymer networks with sensing capabilities, creating platforms that can interact with biological systems in ways previously unattainable. The evolution of hydrogel technology has progressed from simple water-absorbing materials to sophisticated smart systems capable of responding to multiple stimuli simultaneously while maintaining biocompatibility.

The technological trajectory of hydrogel sensors has been marked by significant milestones, including the development of conductive hydrogels in the early 2000s, followed by the integration of nanomaterials around 2010, and more recently, the creation of self-healing and 3D-printable formulations since 2015. Each advancement has expanded the potential applications and enhanced the performance metrics of these sensing platforms, particularly in sensitivity, response time, and stability under physiological conditions.

Current research is increasingly focused on addressing the persistent challenges of long-term stability in biological environments, signal drift compensation, and power requirements for continuous operation. The field is witnessing a convergence of materials science, electrical engineering, and biomedical expertise to overcome these limitations and push the boundaries of what hydrogel sensors can achieve in clinical settings.

The primary technical objectives for hydrogel sensor development include achieving sub-micromolar detection limits for key biomarkers, reducing response times to under 30 seconds, extending operational lifetimes to weeks rather than days, and miniaturizing systems for implantable or wearable form factors. Additionally, there is a growing emphasis on developing sensors capable of detecting multiple analytes simultaneously, moving beyond single-parameter monitoring to comprehensive physiological assessment.

Another critical goal is the seamless integration of these sensors with wireless communication technologies and data analytics platforms, enabling real-time data transmission and interpretation. This integration represents a crucial step toward closed-loop systems that can not only monitor but potentially respond to physiological changes automatically, such as drug delivery systems triggered by specific biomarker thresholds.

The ultimate vision driving hydrogel sensor research is the realization of continuous, non-invasive or minimally invasive monitoring solutions that can transform healthcare delivery models from reactive to preventative paradigms. By providing physicians and patients with real-time physiological data, these technologies hold promise for earlier disease detection, more personalized treatment regimens, and improved management of chronic conditions such as diabetes, cardiovascular disease, and neurological disorders.

The technological trajectory of hydrogel sensors has been marked by significant milestones, including the development of conductive hydrogels in the early 2000s, followed by the integration of nanomaterials around 2010, and more recently, the creation of self-healing and 3D-printable formulations since 2015. Each advancement has expanded the potential applications and enhanced the performance metrics of these sensing platforms, particularly in sensitivity, response time, and stability under physiological conditions.

Current research is increasingly focused on addressing the persistent challenges of long-term stability in biological environments, signal drift compensation, and power requirements for continuous operation. The field is witnessing a convergence of materials science, electrical engineering, and biomedical expertise to overcome these limitations and push the boundaries of what hydrogel sensors can achieve in clinical settings.

The primary technical objectives for hydrogel sensor development include achieving sub-micromolar detection limits for key biomarkers, reducing response times to under 30 seconds, extending operational lifetimes to weeks rather than days, and miniaturizing systems for implantable or wearable form factors. Additionally, there is a growing emphasis on developing sensors capable of detecting multiple analytes simultaneously, moving beyond single-parameter monitoring to comprehensive physiological assessment.

Another critical goal is the seamless integration of these sensors with wireless communication technologies and data analytics platforms, enabling real-time data transmission and interpretation. This integration represents a crucial step toward closed-loop systems that can not only monitor but potentially respond to physiological changes automatically, such as drug delivery systems triggered by specific biomarker thresholds.

The ultimate vision driving hydrogel sensor research is the realization of continuous, non-invasive or minimally invasive monitoring solutions that can transform healthcare delivery models from reactive to preventative paradigms. By providing physicians and patients with real-time physiological data, these technologies hold promise for earlier disease detection, more personalized treatment regimens, and improved management of chronic conditions such as diabetes, cardiovascular disease, and neurological disorders.

Market Analysis for Real-time Biomedical Monitoring

The global market for real-time biomedical monitoring is experiencing unprecedented growth, driven by increasing healthcare costs, aging populations, and the rising prevalence of chronic diseases. Hydrogel sensors represent a significant innovation in this space, offering continuous, non-invasive monitoring capabilities that address critical healthcare needs. The market for these advanced biosensing technologies is projected to reach $25 billion by 2028, with a compound annual growth rate of 18.7% from 2023 to 2028.

Consumer demand for personalized healthcare solutions has created substantial market opportunities for hydrogel-based monitoring systems. Patients with chronic conditions such as diabetes, cardiovascular diseases, and neurological disorders represent primary market segments, collectively accounting for approximately 60% of the current demand. Healthcare providers constitute another significant market segment, seeking solutions that reduce hospitalization rates and enable remote patient monitoring.

Geographically, North America dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth due to improving healthcare infrastructure, increasing healthcare expenditure, and growing awareness about preventive healthcare.

The wearable medical device sector, where hydrogel sensors play a crucial role, has seen investment growth of 215% over the past five years. Venture capital funding in biosensor technologies reached $3.8 billion in 2022, with hydrogel-specific innovations capturing nearly $780 million of this investment.

Market analysis reveals several key trends driving adoption: increasing demand for continuous glucose monitoring systems, growing preference for non-invasive monitoring technologies, rising adoption of telehealth services, and expanding applications in sports medicine and performance monitoring. The COVID-19 pandemic has accelerated these trends, with remote patient monitoring adoption increasing by 64% since 2020.

Reimbursement policies are evolving favorably, with major insurance providers now covering various forms of continuous monitoring devices. This shift in payment models has expanded the addressable market by making these technologies more accessible to broader patient populations.

Consumer surveys indicate strong willingness to adopt wearable hydrogel sensors, with 78% of chronic disease patients expressing interest in technologies that could reduce hospital visits. Healthcare providers report 40% reduction in readmission rates when utilizing continuous monitoring solutions, creating strong economic incentives for adoption across healthcare systems.

Consumer demand for personalized healthcare solutions has created substantial market opportunities for hydrogel-based monitoring systems. Patients with chronic conditions such as diabetes, cardiovascular diseases, and neurological disorders represent primary market segments, collectively accounting for approximately 60% of the current demand. Healthcare providers constitute another significant market segment, seeking solutions that reduce hospitalization rates and enable remote patient monitoring.

Geographically, North America dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth due to improving healthcare infrastructure, increasing healthcare expenditure, and growing awareness about preventive healthcare.

The wearable medical device sector, where hydrogel sensors play a crucial role, has seen investment growth of 215% over the past five years. Venture capital funding in biosensor technologies reached $3.8 billion in 2022, with hydrogel-specific innovations capturing nearly $780 million of this investment.

Market analysis reveals several key trends driving adoption: increasing demand for continuous glucose monitoring systems, growing preference for non-invasive monitoring technologies, rising adoption of telehealth services, and expanding applications in sports medicine and performance monitoring. The COVID-19 pandemic has accelerated these trends, with remote patient monitoring adoption increasing by 64% since 2020.

Reimbursement policies are evolving favorably, with major insurance providers now covering various forms of continuous monitoring devices. This shift in payment models has expanded the addressable market by making these technologies more accessible to broader patient populations.

Consumer surveys indicate strong willingness to adopt wearable hydrogel sensors, with 78% of chronic disease patients expressing interest in technologies that could reduce hospital visits. Healthcare providers report 40% reduction in readmission rates when utilizing continuous monitoring solutions, creating strong economic incentives for adoption across healthcare systems.

Current Hydrogel Sensor Technology Landscape

The hydrogel sensor landscape for real-time biomedical monitoring has evolved significantly in recent years, with several distinct technological approaches emerging. Current hydrogel sensors primarily utilize physical, chemical, or electrical property changes to detect biological signals, with each approach offering unique advantages for specific monitoring applications.

Physically responsive hydrogels represent a major category, where mechanical deformation, swelling, or structural changes occur in response to stimuli. These sensors typically employ photonic crystals, diffraction gratings, or microstructured surfaces that change color or optical properties when exposed to target analytes. Companies like Medtronic and Abbott have commercialized systems using this principle for continuous glucose monitoring, achieving detection limits in the micromolar range with response times under 5 minutes.

Electrochemical hydrogel sensors constitute another significant segment, incorporating conductive polymers or nanomaterials within the hydrogel matrix. These sensors transduce biological signals into measurable electrical outputs through mechanisms including amperometric, potentiometric, or impedimetric detection. Recent advances by research groups at MIT and Stanford have demonstrated electrochemical hydrogel sensors capable of detecting multiple biomarkers simultaneously with sub-nanomolar sensitivity.

Smart hydrogels with stimuli-responsive properties have gained substantial attention, particularly those responding to pH, temperature, or specific biomolecules. These materials undergo reversible volume phase transitions or property changes when exposed to target analytes. Notable examples include phenylboronic acid-containing hydrogels for glucose sensing and temperature-responsive poly(N-isopropylacrylamide) hydrogels for protein detection.

Nanocomposite hydrogels represent the cutting edge of current technology, incorporating nanomaterials such as quantum dots, carbon nanotubes, or metallic nanoparticles to enhance sensitivity and introduce novel detection mechanisms. These materials often exhibit improved mechanical properties and electrical conductivity compared to conventional hydrogels. Research from Harvard and UC Berkeley has demonstrated nanocomposite hydrogel sensors with detection limits in the picomolar range and response times under 30 seconds.

Wireless and wearable hydrogel sensor platforms have emerged as a rapidly growing segment, with companies like Dexcom and Verily developing fully integrated systems. These platforms typically combine flexible substrates, wireless power transfer, and data transmission capabilities with hydrogel sensing elements. Current commercial systems can operate continuously for 7-14 days before replacement, though laboratory prototypes have demonstrated extended lifetimes of up to 30 days.

Manufacturing scalability remains a challenge, with most advanced hydrogel sensors still produced using laboratory-scale techniques. However, companies including 3M and Johnson & Johnson have begun implementing roll-to-roll processing and automated dispensing systems to increase production volumes while maintaining sensor performance and reliability.

Physically responsive hydrogels represent a major category, where mechanical deformation, swelling, or structural changes occur in response to stimuli. These sensors typically employ photonic crystals, diffraction gratings, or microstructured surfaces that change color or optical properties when exposed to target analytes. Companies like Medtronic and Abbott have commercialized systems using this principle for continuous glucose monitoring, achieving detection limits in the micromolar range with response times under 5 minutes.

Electrochemical hydrogel sensors constitute another significant segment, incorporating conductive polymers or nanomaterials within the hydrogel matrix. These sensors transduce biological signals into measurable electrical outputs through mechanisms including amperometric, potentiometric, or impedimetric detection. Recent advances by research groups at MIT and Stanford have demonstrated electrochemical hydrogel sensors capable of detecting multiple biomarkers simultaneously with sub-nanomolar sensitivity.

Smart hydrogels with stimuli-responsive properties have gained substantial attention, particularly those responding to pH, temperature, or specific biomolecules. These materials undergo reversible volume phase transitions or property changes when exposed to target analytes. Notable examples include phenylboronic acid-containing hydrogels for glucose sensing and temperature-responsive poly(N-isopropylacrylamide) hydrogels for protein detection.

Nanocomposite hydrogels represent the cutting edge of current technology, incorporating nanomaterials such as quantum dots, carbon nanotubes, or metallic nanoparticles to enhance sensitivity and introduce novel detection mechanisms. These materials often exhibit improved mechanical properties and electrical conductivity compared to conventional hydrogels. Research from Harvard and UC Berkeley has demonstrated nanocomposite hydrogel sensors with detection limits in the picomolar range and response times under 30 seconds.

Wireless and wearable hydrogel sensor platforms have emerged as a rapidly growing segment, with companies like Dexcom and Verily developing fully integrated systems. These platforms typically combine flexible substrates, wireless power transfer, and data transmission capabilities with hydrogel sensing elements. Current commercial systems can operate continuously for 7-14 days before replacement, though laboratory prototypes have demonstrated extended lifetimes of up to 30 days.

Manufacturing scalability remains a challenge, with most advanced hydrogel sensors still produced using laboratory-scale techniques. However, companies including 3M and Johnson & Johnson have begun implementing roll-to-roll processing and automated dispensing systems to increase production volumes while maintaining sensor performance and reliability.

Existing Hydrogel Sensing Mechanisms

01 Biomedical applications of hydrogel sensors

Hydrogel sensors are widely used in biomedical applications for monitoring physiological parameters. These sensors can be designed to detect various biomarkers, glucose levels, pH changes, and other health indicators in the human body. The biocompatible nature of hydrogels makes them suitable for implantable and wearable medical devices, allowing for continuous health monitoring with minimal invasiveness. These sensors can be integrated into medical devices for real-time patient monitoring and diagnostics.- Biomedical hydrogel sensors for health monitoring: Hydrogel sensors designed for biomedical applications can monitor various physiological parameters in real-time. These sensors utilize responsive hydrogel materials that can detect changes in the body's biochemical environment, such as glucose levels, pH, or specific biomarkers. The hydrogels are engineered to be biocompatible and can be integrated into wearable devices or implantable systems for continuous health monitoring, providing valuable data for disease management and personalized healthcare.

- Conductive hydrogel materials for enhanced sensing capabilities: Conductive hydrogels incorporate electrically conductive materials such as carbon nanotubes, graphene, or conductive polymers into the hydrogel matrix. These materials enhance the electrical properties of the hydrogel, enabling improved signal transduction and sensitivity in sensor applications. The conductive networks within the hydrogel structure facilitate rapid response to stimuli and allow for the detection of subtle changes in the surrounding environment, making them particularly useful for applications requiring high precision and reliability.

- Stimuli-responsive hydrogel sensors: Stimuli-responsive hydrogel sensors are designed to undergo physical or chemical changes in response to specific environmental triggers such as temperature, pH, light, or specific molecules. These smart hydrogels can swell, shrink, change color, or alter their electrical properties when exposed to target stimuli. The responsive nature of these hydrogels enables the development of sensors that can provide visual or electrical signals without requiring complex electronics, making them suitable for point-of-care diagnostics and environmental monitoring applications.

- Fabrication methods for hydrogel-based sensing platforms: Advanced fabrication techniques for hydrogel sensors include 3D printing, photolithography, microfluidic patterning, and electrospinning. These methods enable precise control over the sensor architecture, porosity, and functional group distribution within the hydrogel matrix. By optimizing the fabrication process, researchers can create hydrogel sensors with improved sensitivity, selectivity, and mechanical stability. The development of scalable manufacturing approaches also facilitates the transition from laboratory prototypes to commercial sensing devices.

- Hydrogel sensors for environmental and industrial applications: Hydrogel sensors are increasingly being utilized for environmental monitoring and industrial process control. These sensors can detect pollutants, heavy metals, or specific chemicals in water and soil samples. In industrial settings, hydrogel sensors can monitor parameters such as humidity, pressure, or the presence of volatile organic compounds. The adaptability of hydrogel chemistry allows for the development of specialized sensors tailored to specific environmental or industrial challenges, providing cost-effective solutions for real-time monitoring and early warning systems.

02 Conductive hydrogel compositions for sensing applications

Conductive hydrogels incorporate electrically conductive materials such as carbon nanotubes, graphene, or conductive polymers to create responsive sensing materials. These compositions enable the development of sensors that can detect mechanical deformation, pressure, or chemical changes through variations in electrical properties. The combination of hydrogel flexibility with electrical conductivity creates versatile sensing platforms that can be used in various applications including wearable electronics, soft robotics, and environmental monitoring systems.Expand Specific Solutions03 Stimuli-responsive hydrogel sensor systems

Stimuli-responsive hydrogels change their properties in response to environmental triggers such as temperature, pH, light, or specific chemical compounds. These smart materials can be engineered to swell, shrink, change color, or alter their electrical properties when exposed to target stimuli. This responsive behavior forms the basis for sensing applications where the hydrogel acts as both the recognition element and the transducer. These systems can be designed with high specificity for particular analytes, making them valuable for environmental monitoring and diagnostic applications.Expand Specific Solutions04 Fabrication methods for hydrogel-based sensors

Various fabrication techniques are employed to create hydrogel sensors with specific architectures and functionalities. These methods include 3D printing, photolithography, microfluidic approaches, and electrospinning. Advanced manufacturing processes allow for precise control over the sensor geometry, porosity, and incorporation of functional components. These fabrication methods enable the development of miniaturized sensors, sensor arrays, and integrated sensing platforms with enhanced performance characteristics such as sensitivity, response time, and durability.Expand Specific Solutions05 Hydrogel sensors for environmental and industrial monitoring

Hydrogel sensors are deployed for detecting environmental pollutants, monitoring industrial processes, and ensuring food safety. These sensors can be designed to respond to specific contaminants in water, soil, or air, providing visual or electrical signals upon detection. The versatility of hydrogels allows for customization to detect various analytes including heavy metals, pesticides, and microbial contamination. Their relatively low cost and potential for large-scale deployment make them attractive for distributed sensing networks in environmental monitoring applications.Expand Specific Solutions

Leading Companies in Hydrogel Biosensor Industry

Hydrogel sensors for real-time biomedical monitoring are advancing rapidly in a growing market estimated to reach significant value by 2030. The technology is transitioning from early development to commercialization, with varying maturity levels across applications. Leading players include established medical technology companies like Koninklijke Philips and Edwards Lifesciences, alongside innovative startups such as GrollTex and Applied Biosensors. Academic institutions, particularly Sichuan University, KAIST, and the University of California, are driving fundamental research. The competitive landscape features a mix of commercial entities focusing on product development and research institutions advancing core technologies, with increasing collaboration between sectors to accelerate clinical translation and market adoption.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced hydrogel-based biosensors for continuous health monitoring applications. Their technology integrates conductive hydrogels with flexible electronics to create wearable sensors that can monitor multiple biomarkers simultaneously. The platform uses specialized hydrogel matrices embedded with nanomaterials (such as graphene and silver nanoparticles) to enhance conductivity and sensing capabilities. These sensors can detect physiological parameters including glucose levels, electrolytes, pH, and various metabolites in bodily fluids like sweat and interstitial fluid. Philips' approach focuses on creating biocompatible hydrogels with self-healing properties that maintain sensor functionality over extended periods while minimizing tissue irritation. Their sensors incorporate wireless data transmission capabilities for seamless integration with healthcare monitoring systems, enabling real-time data collection and analysis for both hospital and home-based patient monitoring.

Strengths: Strong integration with existing medical device ecosystem; extensive clinical validation capabilities; advanced manufacturing infrastructure for scaling production. Weaknesses: Higher cost compared to academic solutions; potentially slower innovation cycle due to regulatory compliance requirements; system complexity may limit some point-of-care applications.

Edwards Lifesciences Corp.

Technical Solution: Edwards Lifesciences has pioneered hydrogel-based sensing technology specifically optimized for cardiovascular monitoring applications. Their platform utilizes specialized hydrogels with embedded optical and electrochemical sensing elements designed to detect critical cardiac biomarkers and hemodynamic parameters. The company's approach incorporates biocompatible hydrogel matrices that can be deployed via minimally invasive catheters, allowing for direct monitoring within blood vessels or cardiac chambers. These sensors employ advanced signal processing algorithms to filter physiological noise and provide high-fidelity measurements of parameters such as oxygen saturation, pressure gradients, and specific cardiac biomarkers. Edwards' technology includes hydrogels engineered with anti-fouling properties to resist protein adhesion and maintain long-term stability in blood-contacting environments. Their systems integrate with existing clinical monitoring platforms, providing seamless data integration for critical care and surgical settings where real-time cardiovascular monitoring is essential.

Strengths: Exceptional expertise in cardiovascular applications; established clinical adoption pathways; strong intellectual property portfolio in implantable sensing. Weaknesses: Narrow focus primarily on cardiovascular applications limits broader biomedical monitoring applications; higher invasiveness compared to fully external monitoring solutions; significant regulatory hurdles for implantable sensors.

Key Patents in Hydrogel Sensor Technology

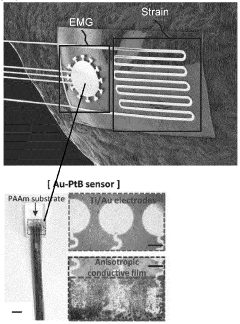

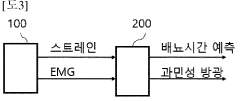

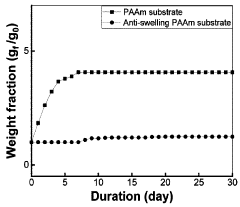

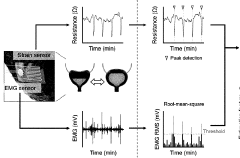

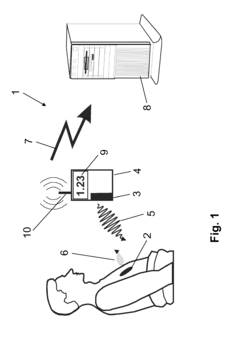

Real-time bladder sensing system through bio-implantable sensor element

PatentWO2024106697A1

Innovation

- A real-time bladder sensing system using a bio-implantable sensor element with a hydrogel substrate and anti-swelling coating, integrating EMG and strain sensors to predict urination timing and detect overactive bladder, while minimizing mechanical impact and maintaining high adhesive strength to bladder tissue.

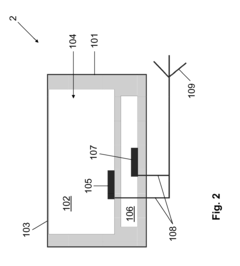

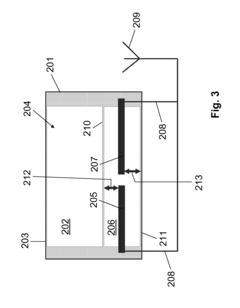

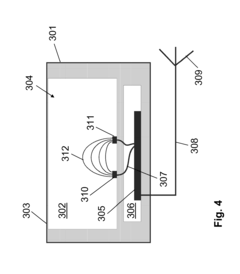

Implantable biosensor and sensor assembly

PatentActiveEP2158840A2

Innovation

- An implantable, wireless biosensor using a hydrogel-based measuring chamber with a semi-permeable membrane and microacoustic SAW sensors to detect changes in analyte concentrations without the need for batteries or active telemetry, enabling continuous, passive monitoring of glucose and other analytes.

Biocompatibility and Safety Considerations

Biocompatibility represents a critical consideration in the development of hydrogel sensors for real-time biomedical monitoring. These sensors, which interface directly with biological tissues and fluids, must demonstrate minimal adverse reactions when implanted or attached to the human body. Current research indicates that hydrogel materials composed of natural polymers such as alginate, collagen, and hyaluronic acid generally exhibit superior biocompatibility compared to their synthetic counterparts. However, even natural hydrogels may trigger foreign body responses depending on their specific formulation and the individual patient's immunological profile.

The safety profile of hydrogel sensors encompasses multiple dimensions beyond mere biocompatibility. Mechanical properties must be carefully engineered to prevent tissue damage through friction or pressure. Particularly for long-term implantable sensors, the hydrogel matrix should possess mechanical characteristics that closely mimic surrounding tissues, thereby minimizing physical irritation and inflammatory responses. Recent advancements have focused on developing ultra-soft hydrogels with elastic moduli comparable to soft tissues (1-100 kPa), significantly reducing mechanical mismatch issues.

Chemical leaching presents another significant safety concern. Unreacted monomers, crosslinking agents, or degradation products from hydrogel matrices may potentially cause local or systemic toxicity. Rigorous leaching tests and cytotoxicity assessments have become standard protocols in the development pipeline. The FDA and international regulatory bodies have established specific guidelines for acceptable leaching levels, typically requiring less than 10 ppm of potentially harmful compounds.

Degradation kinetics of hydrogel sensors must be precisely controlled, especially for biodegradable formulations. Premature degradation can lead to sensor failure and release of embedded electronic components, while excessively slow degradation may necessitate surgical removal. Current research trends favor hydrogels with programmable degradation rates that align with the intended monitoring duration, ranging from days to months depending on the clinical application.

Sterilization compatibility represents a frequently overlooked yet crucial safety consideration. Traditional sterilization methods such as ethylene oxide treatment, gamma irradiation, or autoclave processing can significantly alter hydrogel properties, potentially compromising both sensor functionality and biocompatibility. Recent innovations have focused on developing hydrogel formulations that maintain structural and functional integrity following industry-standard sterilization procedures.

Long-term biological effects of implanted hydrogel sensors remain an active area of investigation. Chronic inflammation, fibrotic encapsulation, and potential carcinogenicity must be thoroughly evaluated through extended in vivo studies. The scientific community has increasingly adopted standardized protocols for evaluating these long-term effects, including histopathological analysis and biomarker monitoring over periods exceeding six months in appropriate animal models.

The safety profile of hydrogel sensors encompasses multiple dimensions beyond mere biocompatibility. Mechanical properties must be carefully engineered to prevent tissue damage through friction or pressure. Particularly for long-term implantable sensors, the hydrogel matrix should possess mechanical characteristics that closely mimic surrounding tissues, thereby minimizing physical irritation and inflammatory responses. Recent advancements have focused on developing ultra-soft hydrogels with elastic moduli comparable to soft tissues (1-100 kPa), significantly reducing mechanical mismatch issues.

Chemical leaching presents another significant safety concern. Unreacted monomers, crosslinking agents, or degradation products from hydrogel matrices may potentially cause local or systemic toxicity. Rigorous leaching tests and cytotoxicity assessments have become standard protocols in the development pipeline. The FDA and international regulatory bodies have established specific guidelines for acceptable leaching levels, typically requiring less than 10 ppm of potentially harmful compounds.

Degradation kinetics of hydrogel sensors must be precisely controlled, especially for biodegradable formulations. Premature degradation can lead to sensor failure and release of embedded electronic components, while excessively slow degradation may necessitate surgical removal. Current research trends favor hydrogels with programmable degradation rates that align with the intended monitoring duration, ranging from days to months depending on the clinical application.

Sterilization compatibility represents a frequently overlooked yet crucial safety consideration. Traditional sterilization methods such as ethylene oxide treatment, gamma irradiation, or autoclave processing can significantly alter hydrogel properties, potentially compromising both sensor functionality and biocompatibility. Recent innovations have focused on developing hydrogel formulations that maintain structural and functional integrity following industry-standard sterilization procedures.

Long-term biological effects of implanted hydrogel sensors remain an active area of investigation. Chronic inflammation, fibrotic encapsulation, and potential carcinogenicity must be thoroughly evaluated through extended in vivo studies. The scientific community has increasingly adopted standardized protocols for evaluating these long-term effects, including histopathological analysis and biomarker monitoring over periods exceeding six months in appropriate animal models.

Commercialization Challenges and Opportunities

The commercialization of hydrogel sensors for real-time biomedical monitoring faces significant challenges despite their promising potential. Manufacturing scalability remains a primary hurdle, as current production methods are predominantly laboratory-based and difficult to translate to industrial-scale manufacturing. The intricate nature of these sensors, often requiring precise control of material properties and incorporation of sensing elements, complicates mass production efforts and increases unit costs.

Regulatory approval presents another substantial barrier, particularly for implantable or long-term wearable hydrogel sensors. The path through FDA or equivalent international regulatory bodies requires extensive clinical validation, biocompatibility testing, and demonstration of long-term safety. This process typically demands significant time and financial investment, creating a challenging environment for startups and smaller companies.

Market adoption faces resistance from established healthcare systems that are often slow to integrate new monitoring technologies. The conservative nature of medical practice, combined with reimbursement uncertainties from insurance providers, creates additional friction in the commercialization pathway. Healthcare providers require compelling evidence of both clinical efficacy and cost-effectiveness before widely adopting new monitoring solutions.

Despite these challenges, substantial opportunities exist in this emerging field. The growing trend toward personalized medicine and remote patient monitoring creates a favorable environment for hydrogel sensor technologies. The global market for wearable medical devices is projected to reach $85.6 billion by 2027, with biosensors representing a significant portion of this growth.

Strategic partnerships between academic institutions, where much of the foundational research occurs, and established medical device manufacturers offer a promising commercialization pathway. These collaborations can leverage complementary expertise in sensor development and manufacturing scale-up while providing access to established distribution channels and regulatory experience.

Specialized applications in high-value medical niches present attractive initial market entry points. Continuous glucose monitoring for diabetes management, wound healing assessment, and monitoring of post-surgical recovery represent areas where hydrogel sensors offer distinct advantages over current solutions. These focused applications can generate revenue while broader platform technologies continue development.

The integration of hydrogel sensors with digital health platforms and artificial intelligence for data analysis represents another significant opportunity. This combination can create comprehensive health monitoring ecosystems that deliver actionable insights to both patients and healthcare providers, potentially commanding premium pricing and establishing stronger market positions.

Regulatory approval presents another substantial barrier, particularly for implantable or long-term wearable hydrogel sensors. The path through FDA or equivalent international regulatory bodies requires extensive clinical validation, biocompatibility testing, and demonstration of long-term safety. This process typically demands significant time and financial investment, creating a challenging environment for startups and smaller companies.

Market adoption faces resistance from established healthcare systems that are often slow to integrate new monitoring technologies. The conservative nature of medical practice, combined with reimbursement uncertainties from insurance providers, creates additional friction in the commercialization pathway. Healthcare providers require compelling evidence of both clinical efficacy and cost-effectiveness before widely adopting new monitoring solutions.

Despite these challenges, substantial opportunities exist in this emerging field. The growing trend toward personalized medicine and remote patient monitoring creates a favorable environment for hydrogel sensor technologies. The global market for wearable medical devices is projected to reach $85.6 billion by 2027, with biosensors representing a significant portion of this growth.

Strategic partnerships between academic institutions, where much of the foundational research occurs, and established medical device manufacturers offer a promising commercialization pathway. These collaborations can leverage complementary expertise in sensor development and manufacturing scale-up while providing access to established distribution channels and regulatory experience.

Specialized applications in high-value medical niches present attractive initial market entry points. Continuous glucose monitoring for diabetes management, wound healing assessment, and monitoring of post-surgical recovery represent areas where hydrogel sensors offer distinct advantages over current solutions. These focused applications can generate revenue while broader platform technologies continue development.

The integration of hydrogel sensors with digital health platforms and artificial intelligence for data analysis represents another significant opportunity. This combination can create comprehensive health monitoring ecosystems that deliver actionable insights to both patients and healthcare providers, potentially commanding premium pricing and establishing stronger market positions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!