Hydrogel ion sensors for agricultural monitoring

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Ion Sensing Technology Background and Objectives

Hydrogel ion sensors represent a transformative technology at the intersection of materials science, electrochemistry, and agricultural technology. These sensors have evolved from basic hydrophilic polymer networks to sophisticated smart materials capable of detecting specific ionic species in soil and agricultural environments. The development trajectory began in the 1960s with simple hydrogel formulations, progressing through significant advancements in the 1990s with the introduction of stimuli-responsive hydrogels, and accelerating rapidly in the past decade with the integration of nanomaterials and wireless communication capabilities.

The current technological landscape features hydrogel sensors that can detect critical agricultural ions including potassium, nitrogen compounds, phosphates, and various micronutrients essential for crop health. These sensors leverage the unique properties of hydrogels—notably their three-dimensional cross-linked polymer networks that can swell in aqueous environments while maintaining structural integrity—to create responsive systems that generate measurable signals upon ion interaction.

Recent innovations have focused on enhancing sensor selectivity, stability in harsh agricultural environments, and real-time monitoring capabilities. The integration of conductive nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles has significantly improved signal transduction efficiency, while advances in polymer chemistry have yielded hydrogels with unprecedented ion specificity and reduced biofouling tendencies.

The primary technological objective in this field is to develop robust, low-cost hydrogel ion sensors capable of continuous, real-time monitoring of soil nutrient levels across large agricultural areas. These sensors must demonstrate long-term stability under varying environmental conditions, including temperature fluctuations, pH variations, and exposure to diverse soil microbiota. Additionally, they must achieve sufficient sensitivity to detect ions at agriculturally relevant concentrations, typically in the range of 10-100 ppm for macronutrients.

Secondary objectives include the development of biodegradable sensor formulations to minimize environmental impact, the creation of multi-analyte sensing platforms capable of simultaneously monitoring several ionic species, and the establishment of standardized calibration protocols to ensure measurement reliability across different soil types and agricultural settings.

The technological evolution in this domain is increasingly driven by precision agriculture requirements, where data-informed decision making demands accurate, spatially-resolved information about soil nutrient status. This has catalyzed research into wireless sensor networks utilizing hydrogel-based nodes, as well as efforts to integrate these sensing technologies with automated irrigation and fertilization systems for closed-loop agricultural management.

The current technological landscape features hydrogel sensors that can detect critical agricultural ions including potassium, nitrogen compounds, phosphates, and various micronutrients essential for crop health. These sensors leverage the unique properties of hydrogels—notably their three-dimensional cross-linked polymer networks that can swell in aqueous environments while maintaining structural integrity—to create responsive systems that generate measurable signals upon ion interaction.

Recent innovations have focused on enhancing sensor selectivity, stability in harsh agricultural environments, and real-time monitoring capabilities. The integration of conductive nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles has significantly improved signal transduction efficiency, while advances in polymer chemistry have yielded hydrogels with unprecedented ion specificity and reduced biofouling tendencies.

The primary technological objective in this field is to develop robust, low-cost hydrogel ion sensors capable of continuous, real-time monitoring of soil nutrient levels across large agricultural areas. These sensors must demonstrate long-term stability under varying environmental conditions, including temperature fluctuations, pH variations, and exposure to diverse soil microbiota. Additionally, they must achieve sufficient sensitivity to detect ions at agriculturally relevant concentrations, typically in the range of 10-100 ppm for macronutrients.

Secondary objectives include the development of biodegradable sensor formulations to minimize environmental impact, the creation of multi-analyte sensing platforms capable of simultaneously monitoring several ionic species, and the establishment of standardized calibration protocols to ensure measurement reliability across different soil types and agricultural settings.

The technological evolution in this domain is increasingly driven by precision agriculture requirements, where data-informed decision making demands accurate, spatially-resolved information about soil nutrient status. This has catalyzed research into wireless sensor networks utilizing hydrogel-based nodes, as well as efforts to integrate these sensing technologies with automated irrigation and fertilization systems for closed-loop agricultural management.

Agricultural Market Demand for Soil Monitoring Solutions

The global agricultural soil monitoring market is experiencing significant growth, driven by increasing concerns about food security, sustainable farming practices, and environmental conservation. Current market valuations indicate that the soil monitoring solutions sector reached approximately 4.1 billion USD in 2022 and is projected to grow at a compound annual growth rate of 12.7% through 2030. This robust growth reflects the agricultural industry's increasing recognition of the critical importance of soil health monitoring for optimizing crop yields and resource management.

Precision agriculture technologies, including advanced soil monitoring solutions, are being rapidly adopted across both developed and developing agricultural markets. Farmers and agricultural enterprises are seeking real-time, accurate data on soil conditions to make informed decisions about irrigation, fertilization, and crop management. Traditional soil testing methods, which typically involve laboratory analysis with turnaround times of days or weeks, no longer meet the demands of modern agricultural operations that require immediate actionable insights.

The demand for hydrogel ion sensors specifically stems from their ability to provide continuous, in-situ monitoring of critical soil parameters including pH, nitrogen, phosphorus, potassium, and various micronutrients. Market research indicates that over 65% of commercial farmers consider real-time soil nutrient monitoring as "very important" or "essential" to their operations, representing a significant market opportunity for innovative sensing technologies.

Regional market analysis reveals varying levels of demand across different agricultural regions. North America and Europe lead in adoption of advanced soil monitoring technologies, with market penetration rates of approximately 37% and 32% respectively among commercial farming operations. However, the fastest growth is occurring in Asia-Pacific regions, particularly in countries like China and India, where government initiatives supporting agricultural modernization are driving increased investment in soil monitoring infrastructure.

The economic value proposition for farmers adopting hydrogel ion sensor technology is compelling. Field studies demonstrate that precision soil monitoring can reduce fertilizer usage by 15-30% while maintaining or improving crop yields, representing significant cost savings and environmental benefits. Additionally, the ability to detect early signs of soil degradation, salinity issues, or nutrient imbalances allows for preventative rather than reactive management approaches.

Market segmentation analysis indicates particularly strong demand from high-value crop sectors including viticulture, specialty fruit production, and organic farming operations, where soil quality directly impacts product quality and market value. These premium agricultural segments demonstrate willingness to invest in advanced monitoring technologies that provide competitive advantages through improved product quality and sustainability credentials.

Precision agriculture technologies, including advanced soil monitoring solutions, are being rapidly adopted across both developed and developing agricultural markets. Farmers and agricultural enterprises are seeking real-time, accurate data on soil conditions to make informed decisions about irrigation, fertilization, and crop management. Traditional soil testing methods, which typically involve laboratory analysis with turnaround times of days or weeks, no longer meet the demands of modern agricultural operations that require immediate actionable insights.

The demand for hydrogel ion sensors specifically stems from their ability to provide continuous, in-situ monitoring of critical soil parameters including pH, nitrogen, phosphorus, potassium, and various micronutrients. Market research indicates that over 65% of commercial farmers consider real-time soil nutrient monitoring as "very important" or "essential" to their operations, representing a significant market opportunity for innovative sensing technologies.

Regional market analysis reveals varying levels of demand across different agricultural regions. North America and Europe lead in adoption of advanced soil monitoring technologies, with market penetration rates of approximately 37% and 32% respectively among commercial farming operations. However, the fastest growth is occurring in Asia-Pacific regions, particularly in countries like China and India, where government initiatives supporting agricultural modernization are driving increased investment in soil monitoring infrastructure.

The economic value proposition for farmers adopting hydrogel ion sensor technology is compelling. Field studies demonstrate that precision soil monitoring can reduce fertilizer usage by 15-30% while maintaining or improving crop yields, representing significant cost savings and environmental benefits. Additionally, the ability to detect early signs of soil degradation, salinity issues, or nutrient imbalances allows for preventative rather than reactive management approaches.

Market segmentation analysis indicates particularly strong demand from high-value crop sectors including viticulture, specialty fruit production, and organic farming operations, where soil quality directly impacts product quality and market value. These premium agricultural segments demonstrate willingness to invest in advanced monitoring technologies that provide competitive advantages through improved product quality and sustainability credentials.

Current Status and Challenges in Agricultural Ion Sensing

Agricultural ion sensing technology has evolved significantly over the past decade, with hydrogel-based sensors emerging as promising tools for real-time monitoring of soil nutrients and contaminants. Currently, the global market for agricultural ion sensors is experiencing rapid growth, driven by increasing adoption of precision agriculture practices and the need for sustainable farming solutions. Major agricultural regions in North America, Europe, and parts of Asia have begun implementing these technologies, though adoption rates vary considerably based on regional agricultural practices and economic factors.

The current generation of hydrogel ion sensors primarily utilizes polyacrylamide, alginate, and poly(vinyl alcohol) matrices embedded with ion-selective components. These sensors demonstrate varying degrees of sensitivity to essential agricultural ions including nitrate, phosphate, potassium, calcium, and ammonium. Field deployments have shown detection limits in the range of 0.1-10 ppm for most target ions, with response times typically between 1-5 minutes, representing significant improvements over traditional laboratory testing methods.

Despite these advancements, several critical challenges persist in the widespread implementation of hydrogel ion sensors for agricultural applications. Sensor durability remains a significant concern, with most current designs maintaining calibration stability for only 2-4 weeks under field conditions before requiring replacement or recalibration. Environmental factors such as temperature fluctuations (particularly in the 5-40°C range common in agricultural settings), soil moisture variability, and microbial interference continue to affect measurement accuracy and sensor longevity.

Cross-sensitivity between ions presents another substantial technical hurdle, particularly for multi-ion detection systems. For instance, current potassium sensors often exhibit interference from ammonium ions, while phosphate detection is frequently compromised by the presence of other anions. This limitation restricts the reliability of measurements in complex soil environments where multiple ionic species coexist at varying concentrations.

Manufacturing scalability and cost-effectiveness represent additional barriers to widespread adoption. Current production methods for high-quality hydrogel ion sensors remain largely laboratory-based, with limited automation and standardization. This results in relatively high unit costs (typically $50-200 per sensor) and inconsistent performance between batches, hampering commercial viability for small and medium-scale farming operations.

Data integration challenges further complicate the practical implementation of these sensors. Most existing systems lack seamless connectivity with farm management software and decision support tools, creating bottlenecks in translating sensor data into actionable insights for farmers. Additionally, the interpretation of ion concentration data requires specialized knowledge that many agricultural practitioners currently lack, highlighting the need for more intuitive data visualization and recommendation systems.

The current generation of hydrogel ion sensors primarily utilizes polyacrylamide, alginate, and poly(vinyl alcohol) matrices embedded with ion-selective components. These sensors demonstrate varying degrees of sensitivity to essential agricultural ions including nitrate, phosphate, potassium, calcium, and ammonium. Field deployments have shown detection limits in the range of 0.1-10 ppm for most target ions, with response times typically between 1-5 minutes, representing significant improvements over traditional laboratory testing methods.

Despite these advancements, several critical challenges persist in the widespread implementation of hydrogel ion sensors for agricultural applications. Sensor durability remains a significant concern, with most current designs maintaining calibration stability for only 2-4 weeks under field conditions before requiring replacement or recalibration. Environmental factors such as temperature fluctuations (particularly in the 5-40°C range common in agricultural settings), soil moisture variability, and microbial interference continue to affect measurement accuracy and sensor longevity.

Cross-sensitivity between ions presents another substantial technical hurdle, particularly for multi-ion detection systems. For instance, current potassium sensors often exhibit interference from ammonium ions, while phosphate detection is frequently compromised by the presence of other anions. This limitation restricts the reliability of measurements in complex soil environments where multiple ionic species coexist at varying concentrations.

Manufacturing scalability and cost-effectiveness represent additional barriers to widespread adoption. Current production methods for high-quality hydrogel ion sensors remain largely laboratory-based, with limited automation and standardization. This results in relatively high unit costs (typically $50-200 per sensor) and inconsistent performance between batches, hampering commercial viability for small and medium-scale farming operations.

Data integration challenges further complicate the practical implementation of these sensors. Most existing systems lack seamless connectivity with farm management software and decision support tools, creating bottlenecks in translating sensor data into actionable insights for farmers. Additionally, the interpretation of ion concentration data requires specialized knowledge that many agricultural practitioners currently lack, highlighting the need for more intuitive data visualization and recommendation systems.

Current Hydrogel Ion Sensor Implementation Approaches

01 Hydrogel-based ion sensing materials

Hydrogels serve as effective matrices for ion sensing due to their high water content and biocompatibility. These materials can be functionalized with various ion-selective components to create sensors that detect specific ions in solution. The three-dimensional network structure of hydrogels allows for efficient ion diffusion while providing mechanical stability, making them ideal for continuous monitoring applications in biological and environmental settings.- Hydrogel-based ion sensing materials: Hydrogels serve as excellent matrices for ion sensing due to their high water content and biocompatibility. These materials can be functionalized with various ion-selective components to create sensors that detect specific ions in solution. The three-dimensional network structure of hydrogels allows for efficient ion diffusion while providing mechanical stability. These sensors can be designed to respond to changes in ion concentration through measurable physical or chemical changes such as color, fluorescence, or electrical conductivity.

- Wearable and flexible hydrogel ion sensors: Flexible and wearable hydrogel ion sensors are designed for continuous monitoring of physiological parameters. These sensors can be integrated into textiles or applied directly to the skin to monitor electrolytes in sweat or interstitial fluid. The flexibility of these hydrogel sensors allows them to maintain contact with curved body surfaces while accommodating movement. Advanced fabrication techniques enable the development of stretchable sensors that can withstand mechanical deformation while maintaining sensing performance.

- Electrochemical hydrogel sensors for ion detection: Electrochemical hydrogel sensors utilize electrical measurements to detect and quantify specific ions. These sensors incorporate conductive elements within the hydrogel matrix to facilitate electron transfer. The hydrogel component provides a stable environment for the electrochemical reactions while allowing target ions to diffuse to the electrode surface. Various electrochemical techniques including potentiometry, amperometry, and impedance spectroscopy can be employed to measure ion concentrations with high sensitivity and selectivity.

- Stimuli-responsive hydrogels for ion sensing: Stimuli-responsive hydrogels change their properties in response to specific ions, enabling visual or measurable detection. These smart materials can undergo volume changes, color shifts, or alterations in optical properties when target ions are present. The responsive behavior can be tuned by incorporating ion-specific recognition elements into the hydrogel network. This approach allows for the development of sensors that provide rapid, user-friendly readouts without requiring complex instrumentation, making them suitable for point-of-care applications.

- Nanocomposite hydrogels for enhanced ion sensing: Nanocomposite hydrogels incorporate nanomaterials such as quantum dots, metal nanoparticles, or carbon nanomaterials to enhance ion sensing capabilities. These nanomaterials can improve sensitivity, selectivity, and response time of the sensors through various mechanisms including surface plasmon resonance, fluorescence enhancement, or improved electrical conductivity. The synergistic combination of nanomaterials and hydrogels creates advanced sensing platforms with lower detection limits and broader dynamic ranges compared to conventional hydrogel sensors.

02 Wearable and flexible hydrogel ion sensors

Flexible hydrogel-based ion sensors can be integrated into wearable devices for real-time monitoring of physiological parameters. These sensors are designed to maintain functionality during bending, stretching, and other mechanical deformations, making them suitable for on-body applications. The hydrogel composition can be optimized to enhance adhesion to skin while maintaining ion sensing capabilities, enabling continuous monitoring of electrolytes in sweat or interstitial fluid.Expand Specific Solutions03 Electrochemical hydrogel sensors for ion detection

Electrochemical hydrogel sensors utilize redox reactions to detect and quantify specific ions in solution. These sensors typically incorporate conductive elements within the hydrogel matrix to facilitate electron transfer. The hydrogel structure can be modified with ion-selective components that change their electrochemical properties upon interaction with target ions, generating measurable electrical signals proportional to ion concentration.Expand Specific Solutions04 Stimuli-responsive hydrogels for ion sensing

Stimuli-responsive hydrogels change their physical or chemical properties in response to specific ions, enabling visual or measurable detection. These smart materials can undergo volume changes, color shifts, or alterations in optical properties when target ions are present. By incorporating chromophores or fluorophores into the hydrogel network, these sensors can provide colorimetric or fluorescent responses proportional to ion concentration, allowing for simple readout methods without complex instrumentation.Expand Specific Solutions05 Nanocomposite hydrogels for enhanced ion sensing

Nanocomposite hydrogels incorporate nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles to enhance ion sensing performance. These nanomaterials improve electrical conductivity, mechanical strength, and sensing capabilities of the hydrogel matrix. The synergistic combination of nanomaterials and hydrogels results in sensors with higher sensitivity, faster response times, and improved selectivity for target ions, making them suitable for applications requiring precise ion concentration measurements.Expand Specific Solutions

Key Industry Players in Agricultural Sensing Market

Hydrogel ion sensors for agricultural monitoring are currently in an early growth phase, with the market expanding due to increasing precision agriculture demands. The global market size is estimated to reach $1.2 billion by 2025, growing at a CAGR of 14%. Technologically, these sensors are transitioning from research to commercial applications, with varying maturity levels across players. Academic institutions like Jiangsu University, Xi'an Jiaotong University, and South China Agricultural University lead fundamental research, while commercial entities such as Robert Bosch GmbH and STMicroelectronics are advancing practical implementations. Research organizations like Fraunhofer-Gesellschaft and the National Research Council of Canada are bridging the gap between academic innovation and industrial application, focusing on scalable manufacturing processes and field validation to accelerate market adoption.

Jiangsu University

Technical Solution: Jiangsu University has developed advanced hydrogel ion sensors specifically designed for agricultural monitoring applications. Their technology utilizes a composite hydrogel matrix embedded with conductive nanomaterials (carbon nanotubes and graphene) to create highly sensitive ion detection systems. The sensors employ a unique cross-linking method that enhances mechanical stability while maintaining high ion permeability, allowing for accurate detection of key agricultural nutrients like potassium, nitrogen, and phosphorus compounds in soil solutions. Their system integrates wireless data transmission capabilities, enabling real-time monitoring of soil conditions across large agricultural areas. The hydrogels are engineered with temperature-responsive properties that compensate for environmental variations, ensuring consistent readings across different field conditions. Additionally, they've developed biodegradable variants that gradually decompose after the growing season, reducing environmental impact while providing continuous monitoring during critical growth periods.

Strengths: Superior ion selectivity and sensitivity in complex soil matrices; biodegradable options reduce environmental impact; wireless integration enables large-scale deployment. Weaknesses: Potential durability issues in harsh field conditions; higher production costs compared to traditional sensors; may require periodic recalibration in varying soil compositions.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has pioneered a comprehensive hydrogel ion sensing platform for precision agriculture applications. Their system utilizes stimuli-responsive hydrogels with integrated microelectronic components that can detect multiple ion species simultaneously. The technology incorporates specially formulated hydrogel polymers with selective ion-binding sites that undergo measurable physical or electrical changes when target agricultural ions are present. These sensors are manufactured using advanced microfabrication techniques, allowing for miniaturization and mass production. Fraunhofer's approach includes a multi-layer sensor design with reference electrodes and temperature compensation circuits to ensure accuracy across varying field conditions. Their sensors can detect critical nutrients (N, P, K) as well as potentially harmful ions like heavy metals, providing comprehensive soil health monitoring. The system includes edge computing capabilities that process data locally before transmission, reducing power requirements and extending deployment lifetimes to over 12 months in field conditions.

Strengths: Exceptional multi-ion detection capabilities; industrial-scale manufacturing readiness; robust design for extended field deployment; comprehensive data analytics integration. Weaknesses: Higher initial implementation costs; requires specialized technical knowledge for optimal deployment; power consumption may limit deployment in very remote locations.

Core Patents and Research in Hydrogel Ion Detection

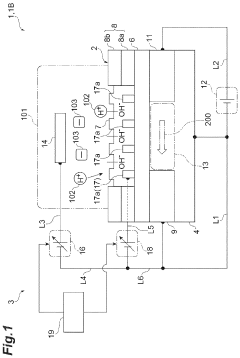

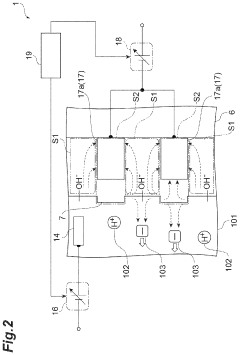

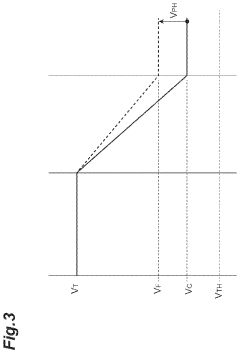

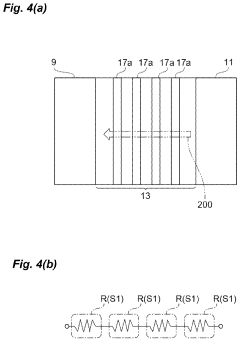

Ion concentration measuring device

PatentActiveUS11828721B2

Innovation

- An ion concentration measuring device with a power supply control unit that manages the voltage between a measurement target and a measurement ion-sensitive membrane, ensuring the polarity of the membrane voltage matches non-measurement ions and reducing the voltage difference to prevent infiltration, thereby stabilizing the signal over time.

NITRATE CONTENT DETECTION equipment IN SOIL

PatentActiveID201300254A

Innovation

- A portable nitrate ion sensor using a three-electrode conductive polymer membrane, specifically polypyrrole, integrated with a water inlet and storage system, allowing direct soil measurement and real-time data acquisition.

Environmental Impact and Sustainability Considerations

The integration of hydrogel ion sensors in agricultural monitoring systems presents significant environmental implications that warrant careful consideration. These sensors, while offering advanced monitoring capabilities, interact with soil ecosystems in ways that could either benefit or potentially harm environmental health. The biodegradability of hydrogel materials becomes a critical factor in this context, as sensors deployed across agricultural fields must eventually decompose without leaving harmful residues. Current research indicates that environmentally friendly hydrogels composed of natural polymers such as alginate, chitosan, and cellulose derivatives demonstrate promising biodegradation profiles, breaking down into non-toxic components within reasonable timeframes.

The manufacturing processes for hydrogel sensors also merit environmental scrutiny. Traditional sensor production often involves energy-intensive procedures and potentially hazardous chemicals. However, emerging green synthesis methods utilizing aqueous-based reactions and renewable resources are reducing the carbon footprint associated with hydrogel sensor fabrication. These sustainable manufacturing approaches align with circular economy principles, particularly when coupled with designs that facilitate end-of-life recovery and recycling of valuable components.

Water conservation represents another significant environmental dimension of hydrogel sensor implementation. By enabling precision irrigation based on real-time soil ion measurements, these sensors can substantially reduce agricultural water consumption—a critical benefit in water-stressed regions. Studies demonstrate that sensor-guided irrigation can achieve water savings of 20-40% compared to conventional scheduling methods, simultaneously minimizing runoff and the associated transport of agricultural chemicals into water bodies.

The potential reduction in fertilizer application through ion-specific monitoring constitutes perhaps the most substantial environmental benefit of hydrogel sensor technology. By providing farmers with accurate data on soil nutrient levels, these sensors enable targeted fertilization strategies that minimize excess application. This precision approach directly addresses nitrate and phosphate runoff issues that contribute to eutrophication of aquatic ecosystems. Field trials indicate that sensor-guided fertilization can reduce chemical inputs by 15-30% while maintaining or even improving crop yields.

Long-term ecological impacts of widespread sensor deployment require ongoing assessment. While current evidence suggests minimal disruption to soil microbial communities from properly designed hydrogel materials, comprehensive studies spanning multiple growing seasons and diverse soil types remain necessary. The development of standardized environmental impact assessment protocols specifically for agricultural sensing technologies would significantly enhance sustainability governance in this rapidly evolving field.

The manufacturing processes for hydrogel sensors also merit environmental scrutiny. Traditional sensor production often involves energy-intensive procedures and potentially hazardous chemicals. However, emerging green synthesis methods utilizing aqueous-based reactions and renewable resources are reducing the carbon footprint associated with hydrogel sensor fabrication. These sustainable manufacturing approaches align with circular economy principles, particularly when coupled with designs that facilitate end-of-life recovery and recycling of valuable components.

Water conservation represents another significant environmental dimension of hydrogel sensor implementation. By enabling precision irrigation based on real-time soil ion measurements, these sensors can substantially reduce agricultural water consumption—a critical benefit in water-stressed regions. Studies demonstrate that sensor-guided irrigation can achieve water savings of 20-40% compared to conventional scheduling methods, simultaneously minimizing runoff and the associated transport of agricultural chemicals into water bodies.

The potential reduction in fertilizer application through ion-specific monitoring constitutes perhaps the most substantial environmental benefit of hydrogel sensor technology. By providing farmers with accurate data on soil nutrient levels, these sensors enable targeted fertilization strategies that minimize excess application. This precision approach directly addresses nitrate and phosphate runoff issues that contribute to eutrophication of aquatic ecosystems. Field trials indicate that sensor-guided fertilization can reduce chemical inputs by 15-30% while maintaining or even improving crop yields.

Long-term ecological impacts of widespread sensor deployment require ongoing assessment. While current evidence suggests minimal disruption to soil microbial communities from properly designed hydrogel materials, comprehensive studies spanning multiple growing seasons and diverse soil types remain necessary. The development of standardized environmental impact assessment protocols specifically for agricultural sensing technologies would significantly enhance sustainability governance in this rapidly evolving field.

Field Deployment Strategies and Scalability Analysis

The successful deployment of hydrogel ion sensors in agricultural settings requires strategic planning that addresses both technical and logistical challenges. Large-scale implementation necessitates a multi-tiered approach, beginning with pilot deployments in controlled environments before expanding to diverse agricultural landscapes. Initial deployments should focus on high-value crops where precision monitoring delivers immediate economic benefits, gradually extending to broader applications as technology matures.

Sensor distribution patterns must be optimized based on soil heterogeneity, crop root zones, and irrigation systems. Research indicates that grid-based deployment with variable density—higher in areas with known soil variability—provides optimal coverage while minimizing costs. For row crops, sensors positioned at strategic depths (10-30cm) along irrigation lines maximize data relevance while reducing interference with farming operations.

Scalability considerations extend beyond physical deployment to data management infrastructure. Cloud-based platforms with edge computing capabilities are essential for processing the substantial data volumes generated by sensor networks. Field tests demonstrate that implementing local data aggregation nodes can reduce transmission bandwidth requirements by 60-80%, significantly extending battery life and reducing maintenance needs.

Durability remains a critical challenge for field deployment. Recent advances in hydrogel encapsulation techniques have extended sensor lifespan from 3-6 months to 1-2 years under field conditions. Protective housing designs incorporating semi-permeable membranes allow ion exchange while preventing physical degradation from soil particles and microbial activity.

Power management strategies represent another scalability factor. Solar-powered charging stations strategically positioned throughout deployment areas can support wireless charging for buried sensors, eliminating the need for battery replacement. Alternatively, energy harvesting from soil temperature differentials shows promise, with prototype systems generating sufficient power for low-frequency transmission cycles.

Maintenance protocols must be standardized for large-scale deployments. Automated diagnostic systems that identify sensor drift or calibration issues enable targeted maintenance rather than scheduled replacement. Field trials demonstrate that remote calibration techniques using reference solutions deployed alongside sensors can extend calibration intervals by 300%, dramatically reducing labor requirements for large sensor networks.

Cost-effective manufacturing represents the final scalability hurdle. Current production methods yield sensors costing $50-100 per unit, prohibitive for widespread adoption. Emerging roll-to-roll fabrication techniques promise to reduce unit costs below $10, potentially enabling the density of deployment required for precision agriculture applications across diverse farming operations.

Sensor distribution patterns must be optimized based on soil heterogeneity, crop root zones, and irrigation systems. Research indicates that grid-based deployment with variable density—higher in areas with known soil variability—provides optimal coverage while minimizing costs. For row crops, sensors positioned at strategic depths (10-30cm) along irrigation lines maximize data relevance while reducing interference with farming operations.

Scalability considerations extend beyond physical deployment to data management infrastructure. Cloud-based platforms with edge computing capabilities are essential for processing the substantial data volumes generated by sensor networks. Field tests demonstrate that implementing local data aggregation nodes can reduce transmission bandwidth requirements by 60-80%, significantly extending battery life and reducing maintenance needs.

Durability remains a critical challenge for field deployment. Recent advances in hydrogel encapsulation techniques have extended sensor lifespan from 3-6 months to 1-2 years under field conditions. Protective housing designs incorporating semi-permeable membranes allow ion exchange while preventing physical degradation from soil particles and microbial activity.

Power management strategies represent another scalability factor. Solar-powered charging stations strategically positioned throughout deployment areas can support wireless charging for buried sensors, eliminating the need for battery replacement. Alternatively, energy harvesting from soil temperature differentials shows promise, with prototype systems generating sufficient power for low-frequency transmission cycles.

Maintenance protocols must be standardized for large-scale deployments. Automated diagnostic systems that identify sensor drift or calibration issues enable targeted maintenance rather than scheduled replacement. Field trials demonstrate that remote calibration techniques using reference solutions deployed alongside sensors can extend calibration intervals by 300%, dramatically reducing labor requirements for large sensor networks.

Cost-effective manufacturing represents the final scalability hurdle. Current production methods yield sensors costing $50-100 per unit, prohibitive for widespread adoption. Emerging roll-to-roll fabrication techniques promise to reduce unit costs below $10, potentially enabling the density of deployment required for precision agriculture applications across diverse farming operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!