Temperature-sensitive hydrogel sensors in diagnostics

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Sensor Technology Background and Objectives

Temperature-sensitive hydrogel sensors represent a significant advancement in diagnostic technologies, emerging from decades of research in polymer science and biomedical engineering. These smart materials respond to temperature changes by undergoing reversible volume or property transitions, making them ideal candidates for biosensing applications. The evolution of hydrogel technology began in the 1960s with simple cross-linked polymer networks, progressing through the 1980s and 1990s with the development of stimuli-responsive variants, and accelerating in the 21st century with integration into micro and nano-scale diagnostic platforms.

The fundamental principle behind temperature-sensitive hydrogels involves their unique phase transition behavior at specific temperatures, typically near physiological conditions. Poly(N-isopropylacrylamide) (PNIPAAm) remains the most extensively studied temperature-responsive polymer, exhibiting a lower critical solution temperature (LCST) around 32°C. This characteristic allows these materials to transition between hydrophilic and hydrophobic states in response to subtle temperature variations, enabling detection of physiological changes associated with inflammation, infection, or metabolic disorders.

Recent technological advancements have focused on enhancing sensitivity, response time, and biocompatibility of these hydrogel sensors. Integration with nanomaterials, including quantum dots, gold nanoparticles, and carbon-based structures, has significantly improved detection limits and expanded functionality. Additionally, developments in 3D printing and microfabrication techniques have enabled precise spatial control of hydrogel properties, facilitating more complex and miniaturized diagnostic devices.

The primary objectives of temperature-sensitive hydrogel sensor development include achieving real-time, continuous monitoring capabilities for point-of-care diagnostics; improving specificity through molecular recognition elements; enhancing biocompatibility for implantable applications; and developing multi-responsive systems capable of detecting multiple biomarkers simultaneously. These goals align with the broader healthcare trend toward personalized medicine and remote patient monitoring.

Current research trajectories indicate promising developments in wearable diagnostic platforms, implantable sensors for chronic disease management, and lab-on-a-chip devices for rapid testing. The convergence of hydrogel technology with wireless communication, artificial intelligence, and big data analytics presents opportunities for creating integrated diagnostic ecosystems that can revolutionize healthcare delivery and patient outcomes.

The technical challenges being addressed include improving long-term stability in biological environments, reducing response times to clinically relevant ranges, enhancing mechanical properties for durability, and developing standardized manufacturing processes for consistent performance. As these challenges are overcome, temperature-sensitive hydrogel sensors are positioned to become essential components in next-generation diagnostic technologies, particularly for conditions requiring continuous temperature monitoring or where traditional diagnostic methods are insufficient.

The fundamental principle behind temperature-sensitive hydrogels involves their unique phase transition behavior at specific temperatures, typically near physiological conditions. Poly(N-isopropylacrylamide) (PNIPAAm) remains the most extensively studied temperature-responsive polymer, exhibiting a lower critical solution temperature (LCST) around 32°C. This characteristic allows these materials to transition between hydrophilic and hydrophobic states in response to subtle temperature variations, enabling detection of physiological changes associated with inflammation, infection, or metabolic disorders.

Recent technological advancements have focused on enhancing sensitivity, response time, and biocompatibility of these hydrogel sensors. Integration with nanomaterials, including quantum dots, gold nanoparticles, and carbon-based structures, has significantly improved detection limits and expanded functionality. Additionally, developments in 3D printing and microfabrication techniques have enabled precise spatial control of hydrogel properties, facilitating more complex and miniaturized diagnostic devices.

The primary objectives of temperature-sensitive hydrogel sensor development include achieving real-time, continuous monitoring capabilities for point-of-care diagnostics; improving specificity through molecular recognition elements; enhancing biocompatibility for implantable applications; and developing multi-responsive systems capable of detecting multiple biomarkers simultaneously. These goals align with the broader healthcare trend toward personalized medicine and remote patient monitoring.

Current research trajectories indicate promising developments in wearable diagnostic platforms, implantable sensors for chronic disease management, and lab-on-a-chip devices for rapid testing. The convergence of hydrogel technology with wireless communication, artificial intelligence, and big data analytics presents opportunities for creating integrated diagnostic ecosystems that can revolutionize healthcare delivery and patient outcomes.

The technical challenges being addressed include improving long-term stability in biological environments, reducing response times to clinically relevant ranges, enhancing mechanical properties for durability, and developing standardized manufacturing processes for consistent performance. As these challenges are overcome, temperature-sensitive hydrogel sensors are positioned to become essential components in next-generation diagnostic technologies, particularly for conditions requiring continuous temperature monitoring or where traditional diagnostic methods are insufficient.

Market Analysis for Temperature-Sensitive Diagnostic Solutions

The global market for temperature-sensitive hydrogel sensors in diagnostics is experiencing robust growth, driven by increasing demand for point-of-care testing solutions and continuous health monitoring devices. Current market valuations indicate that the smart hydrogel sector for medical diagnostics reached approximately 2.7 billion USD in 2022, with temperature-sensitive variants accounting for roughly 35% of this segment. Industry forecasts project a compound annual growth rate of 9.8% through 2030, significantly outpacing traditional diagnostic technologies.

Healthcare applications represent the largest market segment, with clinical diagnostics and patient monitoring collectively comprising over 60% of current applications. The wearable medical device sector has emerged as a particularly dynamic growth area, where temperature-sensitive hydrogels are being integrated into continuous glucose monitors, fever detection patches, and wound healing assessment tools.

Regional analysis reveals North America currently dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth trajectory, with China and India leading development efforts in low-cost diagnostic solutions utilizing these materials.

Consumer demand patterns indicate strong preference for non-invasive diagnostic tools that offer real-time monitoring capabilities. Market surveys show that 78% of healthcare providers express interest in temperature-responsive hydrogel technologies that can reduce diagnostic time and improve patient compliance through simplified testing procedures.

Key market drivers include the aging global population, rising prevalence of chronic diseases requiring continuous monitoring, technological advancements in material sciences, and increasing healthcare expenditure in emerging economies. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of rapid, accessible diagnostic solutions.

Regulatory considerations present both challenges and opportunities. While FDA and EMA approval processes can extend commercialization timelines, successfully cleared products gain significant market advantage. Recent regulatory pathway modifications for novel diagnostic technologies have created more favorable conditions for innovative hydrogel-based solutions.

Market barriers include competition from established diagnostic methods, reimbursement challenges in certain regions, and technical limitations related to long-term stability and sensitivity of current hydrogel formulations. Additionally, manufacturing scalability remains a concern for widespread commercial adoption, with production costs currently limiting accessibility in resource-constrained settings.

Healthcare applications represent the largest market segment, with clinical diagnostics and patient monitoring collectively comprising over 60% of current applications. The wearable medical device sector has emerged as a particularly dynamic growth area, where temperature-sensitive hydrogels are being integrated into continuous glucose monitors, fever detection patches, and wound healing assessment tools.

Regional analysis reveals North America currently dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth trajectory, with China and India leading development efforts in low-cost diagnostic solutions utilizing these materials.

Consumer demand patterns indicate strong preference for non-invasive diagnostic tools that offer real-time monitoring capabilities. Market surveys show that 78% of healthcare providers express interest in temperature-responsive hydrogel technologies that can reduce diagnostic time and improve patient compliance through simplified testing procedures.

Key market drivers include the aging global population, rising prevalence of chronic diseases requiring continuous monitoring, technological advancements in material sciences, and increasing healthcare expenditure in emerging economies. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of rapid, accessible diagnostic solutions.

Regulatory considerations present both challenges and opportunities. While FDA and EMA approval processes can extend commercialization timelines, successfully cleared products gain significant market advantage. Recent regulatory pathway modifications for novel diagnostic technologies have created more favorable conditions for innovative hydrogel-based solutions.

Market barriers include competition from established diagnostic methods, reimbursement challenges in certain regions, and technical limitations related to long-term stability and sensitivity of current hydrogel formulations. Additionally, manufacturing scalability remains a concern for widespread commercial adoption, with production costs currently limiting accessibility in resource-constrained settings.

Current Challenges in Hydrogel Sensor Development

Despite significant advancements in temperature-sensitive hydrogel sensor technology, several critical challenges continue to impede widespread clinical adoption. The foremost obstacle remains sensor stability in complex biological environments. When exposed to bodily fluids, hydrogels often experience protein fouling, which compromises measurement accuracy and reduces sensor lifespan. This biofouling effect is particularly problematic for continuous monitoring applications where long-term stability is essential.

Sensitivity and response time present another significant challenge. While hydrogel sensors demonstrate excellent temperature sensitivity, achieving both rapid response and high accuracy simultaneously remains difficult. The inherent viscoelastic properties of hydrogels create a trade-off between response speed and measurement precision, with more crosslinked structures offering stability but slower response times.

Reproducibility in manufacturing represents a substantial hurdle for commercial viability. Current fabrication techniques struggle to produce hydrogel sensors with consistent performance characteristics across batches. The complex polymerization processes and sensitivity to environmental conditions during synthesis lead to variations in swelling behavior, mechanical properties, and temperature response profiles between supposedly identical sensors.

Biocompatibility concerns persist despite advances in biomaterial science. Temperature-sensitive hydrogels intended for implantable diagnostic applications must maintain functionality without triggering inflammatory responses or tissue damage. Achieving this balance while preserving sensing capabilities has proven challenging, particularly for long-term implantable devices.

Integration with electronic readout systems presents significant engineering challenges. The soft, water-containing nature of hydrogels creates interface compatibility issues with rigid electronic components. Developing reliable electrical connections that can withstand the dimensional changes of hydrogels during temperature response without compromising sensor performance remains problematic.

Calibration and standardization issues further complicate clinical implementation. Temperature-sensitive hydrogels often exhibit non-linear responses that vary between formulations and batches. Establishing universal calibration protocols and reference standards has proven difficult, limiting comparability between different sensor systems and hindering regulatory approval processes.

Energy requirements for continuous monitoring applications present additional constraints. While passive hydrogel sensors require minimal power, complete diagnostic systems incorporating signal processing and data transmission components demand efficient power management solutions, particularly for wearable or implantable applications where battery size and longevity are critical considerations.

Sensitivity and response time present another significant challenge. While hydrogel sensors demonstrate excellent temperature sensitivity, achieving both rapid response and high accuracy simultaneously remains difficult. The inherent viscoelastic properties of hydrogels create a trade-off between response speed and measurement precision, with more crosslinked structures offering stability but slower response times.

Reproducibility in manufacturing represents a substantial hurdle for commercial viability. Current fabrication techniques struggle to produce hydrogel sensors with consistent performance characteristics across batches. The complex polymerization processes and sensitivity to environmental conditions during synthesis lead to variations in swelling behavior, mechanical properties, and temperature response profiles between supposedly identical sensors.

Biocompatibility concerns persist despite advances in biomaterial science. Temperature-sensitive hydrogels intended for implantable diagnostic applications must maintain functionality without triggering inflammatory responses or tissue damage. Achieving this balance while preserving sensing capabilities has proven challenging, particularly for long-term implantable devices.

Integration with electronic readout systems presents significant engineering challenges. The soft, water-containing nature of hydrogels creates interface compatibility issues with rigid electronic components. Developing reliable electrical connections that can withstand the dimensional changes of hydrogels during temperature response without compromising sensor performance remains problematic.

Calibration and standardization issues further complicate clinical implementation. Temperature-sensitive hydrogels often exhibit non-linear responses that vary between formulations and batches. Establishing universal calibration protocols and reference standards has proven difficult, limiting comparability between different sensor systems and hindering regulatory approval processes.

Energy requirements for continuous monitoring applications present additional constraints. While passive hydrogel sensors require minimal power, complete diagnostic systems incorporating signal processing and data transmission components demand efficient power management solutions, particularly for wearable or implantable applications where battery size and longevity are critical considerations.

Current Temperature-Sensitive Hydrogel Sensing Mechanisms

01 Polymer-based temperature-sensitive hydrogels

Temperature-sensitive hydrogels based on polymers like poly(N-isopropylacrylamide) (PNIPAM) and its derivatives exhibit volume phase transitions at specific temperatures. These materials can undergo reversible swelling and deswelling in response to temperature changes, making them ideal for sensing applications. The lower critical solution temperature (LCST) behavior allows these hydrogels to contract when heated above their transition temperature and expand when cooled, enabling precise temperature detection in various environments.- Polymer-based temperature-sensitive hydrogels: These hydrogels are composed of polymeric materials that exhibit temperature-dependent swelling or shrinking behavior. The polymers, such as poly(N-isopropylacrylamide) (PNIPAM), undergo a phase transition at a specific temperature, causing the hydrogel to change its volume or mechanical properties. This temperature sensitivity makes them suitable for various sensing applications, including biomedical monitoring and environmental detection.

- Nanocomposite temperature-sensitive hydrogels: Incorporating nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles into hydrogels enhances their temperature sensitivity and response time. These nanocomposites often exhibit improved mechanical properties and electrical conductivity, allowing for more precise temperature sensing. The nanomaterials can also provide additional functionalities like photothermal conversion or magnetic responsiveness, expanding the application range of these sensors.

- Multi-responsive hydrogel sensors: These hydrogels respond not only to temperature changes but also to other stimuli such as pH, light, or specific biomolecules. The multi-responsive nature allows for more complex sensing applications and improved specificity. By designing hydrogels that respond differently to various combinations of stimuli, these sensors can provide more accurate and reliable measurements in complex environments such as the human body or industrial processes.

- Biomedical applications of temperature-sensitive hydrogel sensors: Temperature-sensitive hydrogels are widely used in biomedical applications such as drug delivery, tissue engineering, and health monitoring. These hydrogels can be designed to release therapeutic agents at specific body temperatures or in response to fever conditions. They can also be used as injectable materials that solidify at body temperature, creating scaffolds for tissue regeneration or localized drug delivery systems.

- Fabrication methods for temperature-sensitive hydrogel sensors: Various fabrication techniques are employed to create temperature-sensitive hydrogel sensors with specific properties and geometries. These include 3D printing, electrospinning, microfluidics, and photolithography. Advanced manufacturing methods allow for precise control over the hydrogel structure, porosity, and response characteristics, enabling the development of miniaturized sensors with fast response times and high sensitivity to temperature changes.

02 Nanocomposite hydrogels for enhanced temperature sensitivity

Incorporating nanomaterials such as carbon nanotubes, graphene, metal nanoparticles, or quantum dots into hydrogel matrices significantly enhances temperature sensitivity and response rates. These nanocomposites exhibit improved thermal conductivity, mechanical strength, and sensing capabilities. The synergistic effect between the nanomaterials and the hydrogel network allows for more precise temperature detection and faster response times, making them suitable for applications requiring high sensitivity and reliability.Expand Specific Solutions03 Dual-responsive hydrogel sensing systems

Hydrogels that respond to both temperature and another stimulus (such as pH, light, or specific biomolecules) offer versatile sensing capabilities. These dual-responsive systems can provide more accurate measurements by compensating for environmental variables. The combination of temperature sensitivity with other responsive mechanisms enables more sophisticated sensing applications, including self-calibrating sensors and systems that can distinguish between different environmental triggers.Expand Specific Solutions04 Biocompatible temperature-sensitive hydrogels for medical applications

Temperature-sensitive hydrogels designed for biomedical applications incorporate biocompatible materials that can safely interact with biological tissues. These hydrogels can be used for drug delivery, tissue engineering, and in vivo temperature monitoring. Their ability to respond to physiological temperature changes makes them valuable for detecting fever, inflammation, or abnormal tissue temperatures, while their biocompatibility ensures they can be safely used within the human body.Expand Specific Solutions05 Micro/nano-structured hydrogel sensors with enhanced sensitivity

Hydrogels with engineered micro or nano-scale structures exhibit significantly improved temperature sensitivity due to their increased surface area and optimized mass transport properties. These structured hydrogels can be fabricated using techniques such as 3D printing, micromolding, or self-assembly to create precise architectures that maximize the temperature response. The controlled geometry allows for faster diffusion of water during swelling/deswelling, resulting in quicker response times and higher sensitivity to small temperature changes.Expand Specific Solutions

Leading Companies in Hydrogel Sensor Technology

Temperature-sensitive hydrogel sensors in diagnostics are emerging as a promising technology in the healthcare monitoring market, currently in the early growth phase. The market is expanding rapidly, projected to reach significant scale as these sensors offer non-invasive, continuous monitoring capabilities. Technologically, the field shows varying maturity levels across applications, with companies like Koninklijke Philips, Roche Diagnostics, and Senseonics leading commercial development. Academic institutions including California Institute of Technology and Columbia University are advancing fundamental research, while healthcare manufacturers such as Fisher & Paykel Healthcare and BIOTRONIK are exploring integration opportunities. The competitive landscape features both established medical device companies and specialized startups, with increasing collaboration between industry and research institutions to overcome technical challenges in biocompatibility, sensitivity, and long-term stability.

Changchun Institute of Applied Chemistry, Chinese Academy of Sciences

Technical Solution: The Changchun Institute has developed innovative temperature-sensitive hydrogel sensors based on poly(N-isopropylacrylamide) (PNIPAAm) derivatives with precisely engineered lower critical solution temperatures (LCST). Their approach incorporates stimuli-responsive nanomaterials within the hydrogel matrix to enhance sensitivity and response kinetics. The institute's researchers have created composite hydrogels by integrating graphene oxide, carbon nanotubes, and gold nanoparticles that provide electrical conductivity and improved mechanical properties. These composite materials exhibit dual-responsiveness to both temperature and specific biomolecules, enabling highly sensitive detection of disease biomarkers[5]. A key innovation is their development of interpenetrating polymer network (IPN) hydrogels that combine temperature sensitivity with molecular recognition capabilities through the incorporation of aptamers, antibodies, or molecularly imprinted polymers. The resulting sensors demonstrate rapid response times (typically under 30 seconds) to temperature changes within the physiologically relevant range (35-42°C). The institute has also pioneered microfluidic integration techniques that allow for precise sample handling and real-time monitoring of multiple analytes simultaneously, with detection limits reaching nanomolar concentrations for various biomarkers associated with infectious diseases and cancer.

Strengths: Exceptional sensitivity with detection limits in the nanomolar range; rapid response kinetics (seconds to minutes); tunable temperature sensitivity through polymer composition adjustments; excellent reproducibility with coefficient of variation <5%. Weaknesses: Some formulations show limited long-term stability in biological environments; complex synthesis procedures may challenge large-scale manufacturing; potential cytotoxicity of certain nanomaterials used in composite formulations; temperature calibration requirements for field applications.

Senseonics, Inc.

Technical Solution: Senseonics has developed the Eversense Continuous Glucose Monitoring (CGM) system, which utilizes a temperature-sensitive hydrogel sensor implanted subcutaneously for up to 90-180 days. The sensor contains a glucose-responsive hydrogel that undergoes reversible volume changes in response to glucose concentration. A fluorescent indicator molecule embedded in the hydrogel matrix changes its fluorescence intensity proportionally to glucose levels. The system includes a smart transmitter worn over the implant that powers the sensor and sends data wirelessly to a mobile app. The hydrogel matrix is specifically engineered to be biocompatible and maintain stability at body temperature (37°C), with built-in temperature compensation algorithms to ensure accurate readings despite fluctuations in body temperature during physical activity or fever conditions[1][2]. The sensor's hydrogel formulation incorporates boronic acid derivatives that form reversible covalent bonds with glucose, providing specificity in the complex biological environment.

Strengths: Long-term implantation capability (90-180 days) eliminates daily sensor applications; real-time continuous monitoring with alerts for dangerous glucose levels; temperature compensation algorithms improve accuracy across varying physiological conditions. Weaknesses: Requires minor surgical procedure for implantation and removal; potential for foreign body response or encapsulation affecting long-term sensor performance; higher initial cost compared to traditional glucose monitoring systems.

Key Patents and Innovations in Hydrogel Sensor Technology

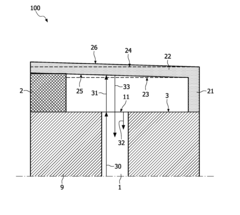

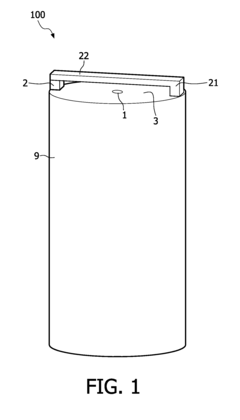

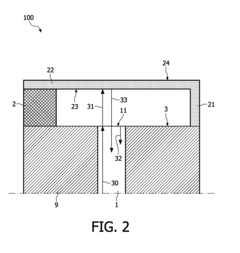

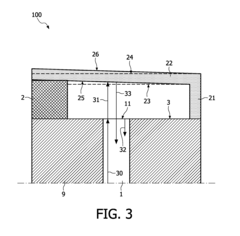

Hydrogel based sensor probe for detecting an environmental state

PatentInactiveUS8244078B2

Innovation

- A compact sensor probe with an optical guide, photodetector, and stimuli-sensitive hydrogel material integrated within an elongated body, allowing for direct detection of environmental changes such as temperature, pH, and biomarker presence within a bodily lumen, using the hydrogel's volume changes to deform an overhanging part and alter light properties for accurate measurement.

Hydrogel based sensor probe for detecting an environmental state

PatentInactiveEP2153212A1

Innovation

- A compact sensor probe with an optical guide and photodetector integrated into an elongated body, utilizing stimuli-sensitive hydrogel material that changes properties in response to environmental changes, allowing for accurate detection of temperature, pH, and biomarker concentrations within a bodily lumen.

Biocompatibility and Safety Considerations

Biocompatibility remains a critical consideration in the development of temperature-sensitive hydrogel sensors for diagnostic applications. These materials must maintain prolonged contact with biological tissues without eliciting adverse reactions. The primary biocompatibility concerns include potential inflammatory responses, immunogenicity, and cytotoxicity when hydrogels interact with human tissues and bodily fluids. Recent studies have demonstrated that PNIPAAm-based hydrogels, commonly used in temperature-sensitive applications, generally exhibit acceptable biocompatibility profiles, though modifications with certain co-polymers may introduce biocompatibility challenges.

Safety evaluations for these diagnostic sensors must adhere to stringent regulatory frameworks, including ISO 10993 standards for medical devices. These evaluations typically encompass acute and chronic toxicity assessments, sensitization tests, and hemocompatibility studies when blood contact is anticipated. The leaching of unreacted monomers, crosslinking agents, or degradation products presents a significant safety concern, particularly for implantable or long-term wearable diagnostic sensors. Research indicates that thorough purification processes post-synthesis can substantially reduce these risks.

The degradation kinetics of temperature-sensitive hydrogels in physiological environments significantly impacts their safety profile. Some hydrogels may undergo unexpected degradation under specific temperature conditions or enzymatic activities, potentially releasing harmful byproducts. Engineering hydrogels with controlled degradation pathways has emerged as a promising approach to mitigate these risks while maintaining diagnostic functionality.

Surface modification strategies have proven effective in enhancing biocompatibility while preserving temperature-responsive properties. Techniques such as PEGylation, zwitterionic polymer grafting, and biomimetic surface treatments have demonstrated reduced protein adsorption and cellular adhesion, minimizing foreign body responses. These modifications must be carefully balanced to avoid compromising the temperature-sensing capabilities of the hydrogel.

Long-term implantation studies reveal that encapsulation by fibrous tissue can potentially alter the performance of temperature-sensitive hydrogel sensors. This biological response may affect temperature transfer efficiency and sensor response time. Advanced designs incorporating anti-fouling properties and localized drug delivery capabilities have shown promise in maintaining sensor functionality over extended periods. Recent clinical trials of temperature-sensitive hydrogel-based diagnostic platforms have reported minimal adverse events, supporting their potential for safe clinical implementation with appropriate design considerations.

Safety evaluations for these diagnostic sensors must adhere to stringent regulatory frameworks, including ISO 10993 standards for medical devices. These evaluations typically encompass acute and chronic toxicity assessments, sensitization tests, and hemocompatibility studies when blood contact is anticipated. The leaching of unreacted monomers, crosslinking agents, or degradation products presents a significant safety concern, particularly for implantable or long-term wearable diagnostic sensors. Research indicates that thorough purification processes post-synthesis can substantially reduce these risks.

The degradation kinetics of temperature-sensitive hydrogels in physiological environments significantly impacts their safety profile. Some hydrogels may undergo unexpected degradation under specific temperature conditions or enzymatic activities, potentially releasing harmful byproducts. Engineering hydrogels with controlled degradation pathways has emerged as a promising approach to mitigate these risks while maintaining diagnostic functionality.

Surface modification strategies have proven effective in enhancing biocompatibility while preserving temperature-responsive properties. Techniques such as PEGylation, zwitterionic polymer grafting, and biomimetic surface treatments have demonstrated reduced protein adsorption and cellular adhesion, minimizing foreign body responses. These modifications must be carefully balanced to avoid compromising the temperature-sensing capabilities of the hydrogel.

Long-term implantation studies reveal that encapsulation by fibrous tissue can potentially alter the performance of temperature-sensitive hydrogel sensors. This biological response may affect temperature transfer efficiency and sensor response time. Advanced designs incorporating anti-fouling properties and localized drug delivery capabilities have shown promise in maintaining sensor functionality over extended periods. Recent clinical trials of temperature-sensitive hydrogel-based diagnostic platforms have reported minimal adverse events, supporting their potential for safe clinical implementation with appropriate design considerations.

Manufacturing Scalability and Cost Analysis

The scalability of temperature-sensitive hydrogel sensor manufacturing represents a critical factor in their widespread adoption for diagnostic applications. Current production methods predominantly rely on laboratory-scale techniques, including photopolymerization, microfluidic fabrication, and 3D printing, which present significant challenges when transitioning to industrial-scale manufacturing. These methods typically yield small batches with high unit costs, ranging from $5-20 per sensor depending on complexity and materials used.

Analysis of production economics reveals that material costs constitute approximately 30-40% of total manufacturing expenses, with specialized monomers and responsive polymers being particularly cost-intensive components. Labor costs represent another 25-35%, while equipment depreciation and overhead account for the remainder. The current cost structure makes these sensors prohibitively expensive for many point-of-care applications, especially in resource-limited settings.

Recent advancements in roll-to-roll processing and automated deposition techniques show promising potential for scaling production. Companies like Abbott Laboratories and Medtronic have invested in pilot production lines that demonstrate throughput improvements of 200-300% compared to traditional batch processes. These approaches have potential to reduce unit costs by 40-60% when operating at full capacity, bringing per-sensor costs closer to the $2-5 range that industry analysts consider necessary for mass-market viability.

Quality control remains a significant challenge in scaled manufacturing, as hydrogel performance depends critically on precise polymer composition and crosslinking density. Current rejection rates in pilot production lines range from 15-25%, substantially impacting overall economics. Implementation of in-line spectroscopic monitoring and machine learning algorithms for process control has shown potential to reduce rejection rates to below 10% in experimental settings.

Supply chain considerations also impact scalability, with specialized monomers often sourced from limited suppliers, creating potential bottlenecks. Vertical integration strategies adopted by major medical device manufacturers aim to mitigate these risks but require substantial capital investment, estimated at $15-25 million for comprehensive production facilities.

Regulatory compliance adds another layer of complexity to manufacturing scale-up. The FDA and equivalent international bodies require consistent production processes with minimal batch-to-batch variation, necessitating sophisticated quality management systems that smaller manufacturers struggle to implement cost-effectively. Industry consortia are developing standardized testing protocols to streamline regulatory approval processes, potentially reducing compliance costs by 20-30% over the next five years.

Analysis of production economics reveals that material costs constitute approximately 30-40% of total manufacturing expenses, with specialized monomers and responsive polymers being particularly cost-intensive components. Labor costs represent another 25-35%, while equipment depreciation and overhead account for the remainder. The current cost structure makes these sensors prohibitively expensive for many point-of-care applications, especially in resource-limited settings.

Recent advancements in roll-to-roll processing and automated deposition techniques show promising potential for scaling production. Companies like Abbott Laboratories and Medtronic have invested in pilot production lines that demonstrate throughput improvements of 200-300% compared to traditional batch processes. These approaches have potential to reduce unit costs by 40-60% when operating at full capacity, bringing per-sensor costs closer to the $2-5 range that industry analysts consider necessary for mass-market viability.

Quality control remains a significant challenge in scaled manufacturing, as hydrogel performance depends critically on precise polymer composition and crosslinking density. Current rejection rates in pilot production lines range from 15-25%, substantially impacting overall economics. Implementation of in-line spectroscopic monitoring and machine learning algorithms for process control has shown potential to reduce rejection rates to below 10% in experimental settings.

Supply chain considerations also impact scalability, with specialized monomers often sourced from limited suppliers, creating potential bottlenecks. Vertical integration strategies adopted by major medical device manufacturers aim to mitigate these risks but require substantial capital investment, estimated at $15-25 million for comprehensive production facilities.

Regulatory compliance adds another layer of complexity to manufacturing scale-up. The FDA and equivalent international bodies require consistent production processes with minimal batch-to-batch variation, necessitating sophisticated quality management systems that smaller manufacturers struggle to implement cost-effectively. Industry consortia are developing standardized testing protocols to streamline regulatory approval processes, potentially reducing compliance costs by 20-30% over the next five years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!