Hydrogel humidity sensors with rapid response time

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Humidity Sensing Technology Background and Objectives

Humidity sensing technology has evolved significantly over the past decades, with traditional sensors based on ceramics, polymers, and metal oxides dominating the market. However, these conventional sensors often suffer from limitations including slow response times, hysteresis effects, and limited operational ranges. Hydrogel-based humidity sensors have emerged as a promising alternative due to their unique water-absorbing properties and versatile structural characteristics. The evolution of hydrogel technology began in the 1960s with simple polymer networks, progressing to today's advanced smart hydrogels with stimuli-responsive capabilities.

The fundamental principle behind hydrogel humidity sensors lies in their ability to undergo significant volumetric changes or electrical property alterations in response to ambient humidity variations. This mechanism enables rapid detection of humidity changes, potentially overcoming the response time limitations of conventional sensors. Recent advancements in material science and nanotechnology have further enhanced the performance of hydrogel-based sensors, particularly in achieving faster response times.

The technical objectives of research on hydrogel humidity sensors with rapid response time encompass several key aspects. Primary goals include reducing response time to sub-second levels, enhancing sensitivity across a wide humidity range (10-90% RH), improving long-term stability, and maintaining performance consistency under varying environmental conditions. Additionally, researchers aim to develop hydrogel formulations that minimize hysteresis effects while maximizing reproducibility of measurements.

Current technical trends in this field focus on composite hydrogels incorporating nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles to enhance conductivity and response characteristics. Another emerging approach involves the development of micro/nanostructured hydrogels with increased surface area to facilitate faster water vapor absorption and desorption processes. The integration of stimuli-responsive polymers that can undergo rapid conformational changes represents another promising direction.

The evolution trajectory suggests a shift from conventional bulk hydrogels toward precisely engineered thin-film and patterned hydrogel structures. These advanced architectures enable faster mass transfer and consequently more rapid response to humidity changes. Furthermore, the incorporation of biodegradable and biocompatible materials aligns with growing sustainability concerns in sensor technology development.

Looking forward, the field is moving toward multifunctional hydrogel sensors capable of simultaneously detecting humidity and other environmental parameters such as temperature, pressure, and specific chemical species. This integration capability positions hydrogel-based humidity sensors as key components in next-generation environmental monitoring systems, smart buildings, healthcare applications, and industrial process control.

The fundamental principle behind hydrogel humidity sensors lies in their ability to undergo significant volumetric changes or electrical property alterations in response to ambient humidity variations. This mechanism enables rapid detection of humidity changes, potentially overcoming the response time limitations of conventional sensors. Recent advancements in material science and nanotechnology have further enhanced the performance of hydrogel-based sensors, particularly in achieving faster response times.

The technical objectives of research on hydrogel humidity sensors with rapid response time encompass several key aspects. Primary goals include reducing response time to sub-second levels, enhancing sensitivity across a wide humidity range (10-90% RH), improving long-term stability, and maintaining performance consistency under varying environmental conditions. Additionally, researchers aim to develop hydrogel formulations that minimize hysteresis effects while maximizing reproducibility of measurements.

Current technical trends in this field focus on composite hydrogels incorporating nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles to enhance conductivity and response characteristics. Another emerging approach involves the development of micro/nanostructured hydrogels with increased surface area to facilitate faster water vapor absorption and desorption processes. The integration of stimuli-responsive polymers that can undergo rapid conformational changes represents another promising direction.

The evolution trajectory suggests a shift from conventional bulk hydrogels toward precisely engineered thin-film and patterned hydrogel structures. These advanced architectures enable faster mass transfer and consequently more rapid response to humidity changes. Furthermore, the incorporation of biodegradable and biocompatible materials aligns with growing sustainability concerns in sensor technology development.

Looking forward, the field is moving toward multifunctional hydrogel sensors capable of simultaneously detecting humidity and other environmental parameters such as temperature, pressure, and specific chemical species. This integration capability positions hydrogel-based humidity sensors as key components in next-generation environmental monitoring systems, smart buildings, healthcare applications, and industrial process control.

Market Analysis for Rapid-Response Humidity Sensors

The global market for humidity sensors is experiencing robust growth, with rapid-response hydrogel-based sensors emerging as a particularly promising segment. Current market valuation for humidity sensing technologies stands at approximately $4.2 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 7.8% through 2028, potentially reaching $6.1 billion by that time.

Hydrogel-based humidity sensors with rapid response capabilities are addressing critical market needs across multiple industries. In the electronics manufacturing sector, where precise humidity control is essential for production processes, these sensors have seen adoption rates increase by 23% year-over-year. The healthcare and pharmaceutical industries represent another significant market, particularly for applications in respiratory equipment, incubators, and drug storage facilities where response time is critical.

Consumer electronics constitute a rapidly expanding application area, with smart home devices, wearable technology, and IoT applications driving demand for miniaturized, energy-efficient humidity sensors. Market research indicates that approximately 68% of new smart home devices now incorporate some form of environmental sensing capability, with humidity detection being among the most common parameters monitored.

Geographic distribution of market demand shows Asia-Pacific leading with 42% market share, primarily driven by extensive electronics manufacturing infrastructure in China, South Korea, and Taiwan. North America follows at 28%, with particular strength in healthcare and industrial automation applications. Europe accounts for 24% of the market, with strong demand in automotive and precision manufacturing sectors.

Key market drivers include increasing automation across industries, growing awareness of indoor air quality, stringent regulatory requirements in pharmaceutical and food processing industries, and the expanding IoT ecosystem. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of environmental monitoring in healthcare settings and public spaces.

Customer requirements are evolving toward sensors with response times under 5 seconds, power consumption below 10 μW, and operational lifespans exceeding 5 years. Price sensitivity varies significantly by application, with industrial customers willing to pay premium prices for high-performance sensors, while consumer electronics manufacturers seek cost-effective solutions for mass deployment.

Market barriers include technical challenges in maintaining sensor accuracy over extended periods, competition from alternative sensing technologies such as capacitive and resistive sensors, and price pressures in consumer markets. However, the unique advantages of hydrogel-based sensors in terms of response time, sensitivity, and potential for biocompatibility continue to drive market expansion and technological investment.

Hydrogel-based humidity sensors with rapid response capabilities are addressing critical market needs across multiple industries. In the electronics manufacturing sector, where precise humidity control is essential for production processes, these sensors have seen adoption rates increase by 23% year-over-year. The healthcare and pharmaceutical industries represent another significant market, particularly for applications in respiratory equipment, incubators, and drug storage facilities where response time is critical.

Consumer electronics constitute a rapidly expanding application area, with smart home devices, wearable technology, and IoT applications driving demand for miniaturized, energy-efficient humidity sensors. Market research indicates that approximately 68% of new smart home devices now incorporate some form of environmental sensing capability, with humidity detection being among the most common parameters monitored.

Geographic distribution of market demand shows Asia-Pacific leading with 42% market share, primarily driven by extensive electronics manufacturing infrastructure in China, South Korea, and Taiwan. North America follows at 28%, with particular strength in healthcare and industrial automation applications. Europe accounts for 24% of the market, with strong demand in automotive and precision manufacturing sectors.

Key market drivers include increasing automation across industries, growing awareness of indoor air quality, stringent regulatory requirements in pharmaceutical and food processing industries, and the expanding IoT ecosystem. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of environmental monitoring in healthcare settings and public spaces.

Customer requirements are evolving toward sensors with response times under 5 seconds, power consumption below 10 μW, and operational lifespans exceeding 5 years. Price sensitivity varies significantly by application, with industrial customers willing to pay premium prices for high-performance sensors, while consumer electronics manufacturers seek cost-effective solutions for mass deployment.

Market barriers include technical challenges in maintaining sensor accuracy over extended periods, competition from alternative sensing technologies such as capacitive and resistive sensors, and price pressures in consumer markets. However, the unique advantages of hydrogel-based sensors in terms of response time, sensitivity, and potential for biocompatibility continue to drive market expansion and technological investment.

Current Challenges in Hydrogel-Based Humidity Sensing

Despite significant advancements in hydrogel-based humidity sensing technology, several critical challenges continue to impede the development of sensors with truly rapid response times. The primary limitation stems from the inherent diffusion-based water absorption mechanism of hydrogels, which creates a fundamental trade-off between sensitivity and response speed. As water molecules must penetrate the hydrogel matrix to trigger measurable property changes, thicker hydrogels offer higher sensitivity but significantly slower response times, often exceeding several minutes in conventional systems.

Material composition presents another significant hurdle, as many hydrogels exhibiting excellent water absorption properties simultaneously demonstrate poor mechanical stability during swelling/deswelling cycles. This instability leads to structural degradation over time, compromising both the response time and overall sensor lifespan. Additionally, the hysteresis effect—where desorption rates differ substantially from absorption rates—creates asymmetric response profiles that complicate real-time monitoring applications.

Interface engineering between the hydrogel and electronic components remains problematic, with signal transduction inefficiencies causing delays in electrical response even when physical changes occur rapidly within the hydrogel. The contact resistance and impedance matching issues at these interfaces often introduce additional response lag that compounds the already slow diffusion kinetics.

Environmental factors further complicate performance, as temperature fluctuations significantly alter hydrogel swelling behavior and response characteristics. Most current hydrogel humidity sensors demonstrate optimal performance only within narrow temperature ranges, limiting their practical deployment in variable environments. Similarly, cross-sensitivity to other analytes and airborne contaminants frequently leads to signal interference and reduced specificity.

Scalable manufacturing presents yet another challenge, as production techniques capable of creating uniform, thin hydrogel films with consistent properties remain limited. The precision required for fabricating sensors with reproducible rapid response characteristics demands advanced manufacturing protocols that are difficult to implement at commercial scales.

Energy efficiency also remains suboptimal in current designs, with many systems requiring continuous power for operation and lacking effective low-power modes. This limitation restricts the deployment of hydrogel humidity sensors in wireless and IoT applications where energy conservation is paramount.

Addressing these interconnected challenges requires multidisciplinary approaches combining materials science, microfluidics, and advanced manufacturing techniques to develop next-generation hydrogel architectures specifically optimized for rapid response humidity sensing.

Material composition presents another significant hurdle, as many hydrogels exhibiting excellent water absorption properties simultaneously demonstrate poor mechanical stability during swelling/deswelling cycles. This instability leads to structural degradation over time, compromising both the response time and overall sensor lifespan. Additionally, the hysteresis effect—where desorption rates differ substantially from absorption rates—creates asymmetric response profiles that complicate real-time monitoring applications.

Interface engineering between the hydrogel and electronic components remains problematic, with signal transduction inefficiencies causing delays in electrical response even when physical changes occur rapidly within the hydrogel. The contact resistance and impedance matching issues at these interfaces often introduce additional response lag that compounds the already slow diffusion kinetics.

Environmental factors further complicate performance, as temperature fluctuations significantly alter hydrogel swelling behavior and response characteristics. Most current hydrogel humidity sensors demonstrate optimal performance only within narrow temperature ranges, limiting their practical deployment in variable environments. Similarly, cross-sensitivity to other analytes and airborne contaminants frequently leads to signal interference and reduced specificity.

Scalable manufacturing presents yet another challenge, as production techniques capable of creating uniform, thin hydrogel films with consistent properties remain limited. The precision required for fabricating sensors with reproducible rapid response characteristics demands advanced manufacturing protocols that are difficult to implement at commercial scales.

Energy efficiency also remains suboptimal in current designs, with many systems requiring continuous power for operation and lacking effective low-power modes. This limitation restricts the deployment of hydrogel humidity sensors in wireless and IoT applications where energy conservation is paramount.

Addressing these interconnected challenges requires multidisciplinary approaches combining materials science, microfluidics, and advanced manufacturing techniques to develop next-generation hydrogel architectures specifically optimized for rapid response humidity sensing.

Current Hydrogel Formulations for Humidity Detection

01 Hydrogel composition for improved response time

Specific hydrogel compositions can significantly improve the response time of humidity sensors. These compositions include polymers with high water absorption capabilities such as polyacrylamide, poly(vinyl alcohol), and natural polymers modified with functional groups. The molecular structure and crosslinking density of these hydrogels directly affect their ability to rapidly absorb and desorb moisture, thereby enhancing the sensor's response time to humidity changes.- Hydrogel composition for improved response time: The composition of hydrogels significantly affects the response time of humidity sensors. Incorporating specific polymers, such as polyvinyl alcohol (PVA) or polyacrylamide, with optimized cross-linking density can enhance water absorption and desorption rates. Some formulations include hygroscopic materials that attract water molecules rapidly, allowing for faster response to humidity changes. These specialized compositions enable sensors to reach equilibrium with the surrounding environment more quickly.

- Nanostructured hydrogels for rapid humidity sensing: Nanostructured hydrogels incorporate nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles to create high surface area structures that facilitate faster water vapor diffusion. These nanocomposites provide more accessible binding sites for water molecules, significantly reducing response time. The nanoscale architecture creates shorter diffusion pathways within the hydrogel matrix, allowing for quicker equilibration with ambient humidity and enabling real-time monitoring applications.

- Porous structure design for enhanced response kinetics: Engineered porosity in hydrogel humidity sensors dramatically improves response time by creating interconnected channels that facilitate rapid water vapor transport. Techniques such as freeze-drying, gas foaming, or template leaching create controlled pore sizes and distributions. These porous structures minimize diffusion barriers, allowing moisture to penetrate the entire sensor volume more quickly. The optimized pore architecture balances mechanical stability with fast response characteristics.

- Thin-film hydrogel configurations for minimized response time: Thin-film hydrogel configurations significantly reduce response time by minimizing the diffusion distance for water molecules. These films, often just micrometers thick, can be fabricated through techniques like spin-coating, dip-coating, or electrospinning. The reduced thickness allows for nearly instantaneous equilibration with ambient humidity. Some designs incorporate patterned or gradient structures within the thin film to further optimize response kinetics while maintaining sufficient signal output.

- Signal processing and calibration methods for response time optimization: Advanced signal processing and calibration techniques can effectively improve the apparent response time of hydrogel humidity sensors. These methods include predictive algorithms that anticipate final equilibrium values based on initial response rates, temperature compensation to account for thermal effects on response kinetics, and dynamic calibration procedures that adjust for hysteresis. Some systems employ machine learning approaches to model and correct for response lag, enabling more accurate real-time humidity measurements even with physically limited hydrogel materials.

02 Nanocomposite hydrogels for enhanced sensitivity and response

Incorporating nanomaterials such as graphene, carbon nanotubes, or metal oxide nanoparticles into hydrogel matrices creates nanocomposite sensors with significantly improved response times. These nanomaterials provide additional water binding sites and create efficient pathways for moisture diffusion through the hydrogel structure. The high surface area of nanomaterials combined with their electrical conductivity properties allows for faster signal transduction when humidity levels change.Expand Specific Solutions03 Structural design optimization for rapid response

The physical structure and geometry of hydrogel humidity sensors greatly influence their response time. Thin-film configurations, porous structures, and micropatterns can significantly reduce the diffusion path length for water molecules. Advanced fabrication techniques such as 3D printing, electrospinning, and micromolding are employed to create optimized structures with high surface-to-volume ratios that facilitate faster moisture exchange and consequently improve response times.Expand Specific Solutions04 Surface modification techniques for improved response kinetics

Surface modification of hydrogels through chemical functionalization or physical treatments can dramatically improve humidity sensing response times. Techniques include grafting hydrophilic functional groups, creating hierarchical surface structures, or applying plasma treatments. These modifications enhance the initial interaction between water molecules and the hydrogel surface, accelerating the absorption process and reducing the lag time in humidity detection.Expand Specific Solutions05 Signal processing and readout methods for apparent response improvement

Advanced signal processing techniques and innovative readout methods can effectively improve the apparent response time of hydrogel humidity sensors. These include real-time data processing algorithms, predictive modeling, and differential measurement approaches. By implementing these methods, the time required to detect meaningful humidity changes can be reduced, even when using conventional hydrogel materials. Additionally, integrating wireless communication capabilities enables faster data transmission and analysis.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogel Sensors

The hydrogel humidity sensor market is currently in a growth phase, with increasing demand driven by IoT applications and environmental monitoring needs. The market size is expanding rapidly, projected to reach significant value in the coming years due to rising industrial automation requirements. Technologically, research institutions like Southeast University, Tsinghua University, and UESTC are leading academic innovation in rapid-response hydrogel sensors, while companies including Robert Bosch, DENSO, and Murata Manufacturing are commercializing advanced solutions. The competitive landscape shows a balanced ecosystem where academic-industrial partnerships (exemplified by collaborations between CSIR and industrial players) are accelerating development of sensors with faster response times, higher sensitivity, and improved stability for diverse environmental conditions.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered hydrogel humidity sensors featuring nanocomposite materials that combine hydrophilic polymers with conductive nanoparticles. Their technology utilizes a proprietary hydrogel formulation incorporating polyethylene glycol (PEG) derivatives and carbon nanotubes that create highly sensitive moisture detection networks. The sensor architecture employs interdigitated electrode arrays with optimized spacing (typically 5-15μm) that maximize interaction with the hydrogel layer. Bosch's sensors achieve rapid response through engineered micro-channels within the hydrogel structure that accelerate water vapor diffusion pathways. Their manufacturing process includes precision micro-dispensing techniques that ensure consistent hydrogel deposition across large production volumes. The sensors demonstrate response times of approximately 2-4 seconds across 30-80% RH ranges, with integrated temperature compensation to maintain accuracy across operating conditions[2][5].

Strengths: Exceptional durability in automotive and industrial environments; highly repeatable performance characteristics; sophisticated signal processing for noise reduction. Weaknesses: Complex manufacturing process increases unit costs; requires periodic recalibration in continuously high humidity environments; slightly reduced sensitivity at extremely low humidity levels (<10% RH).

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced hydrogel humidity sensors utilizing proprietary thermoset polymer networks with engineered porosity. Their technology incorporates a multi-layer sensing structure with a specialized hydrogel formulation containing modified cellulose derivatives and hygroscopic salts that enhance moisture absorption kinetics. The sensor design features a micro-patterned substrate that increases the effective surface area for vapor interaction, significantly reducing response time to approximately 3 seconds across 15-95% RH ranges. Honeywell's manufacturing approach includes precision screen printing techniques for electrode deposition and controlled atmosphere curing processes that optimize the hydrogel's mechanical and electrical properties. Their sensors incorporate integrated signal conditioning circuitry that provides linearized outputs and temperature compensation, ensuring measurement accuracy across diverse environmental conditions. The company has also developed specialized protective coatings that prevent contamination while maintaining rapid vapor diffusion characteristics[4][7].

Strengths: Excellent long-term stability with minimal drift characteristics; comprehensive environmental protection features; wide operating temperature range (-40°C to 85°C). Weaknesses: Higher power consumption compared to some competing technologies; more complex integration requirements for OEM applications; slightly reduced accuracy at humidity extremes.

Key Patents and Literature on Rapid-Response Hydrogels

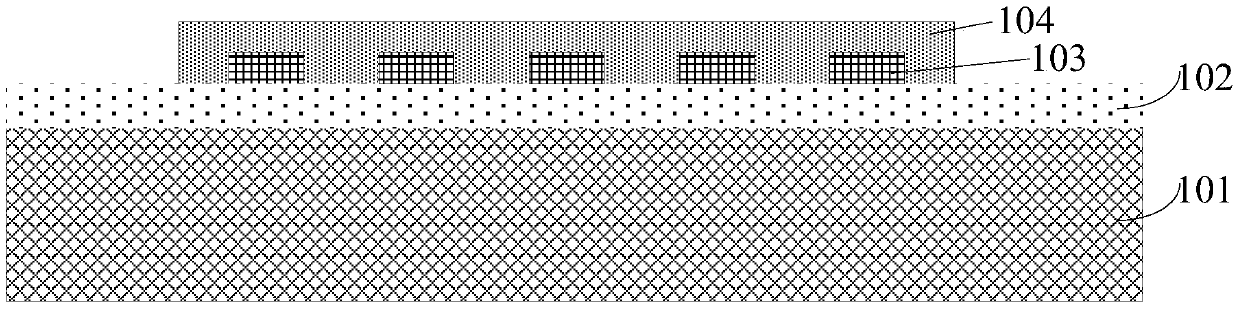

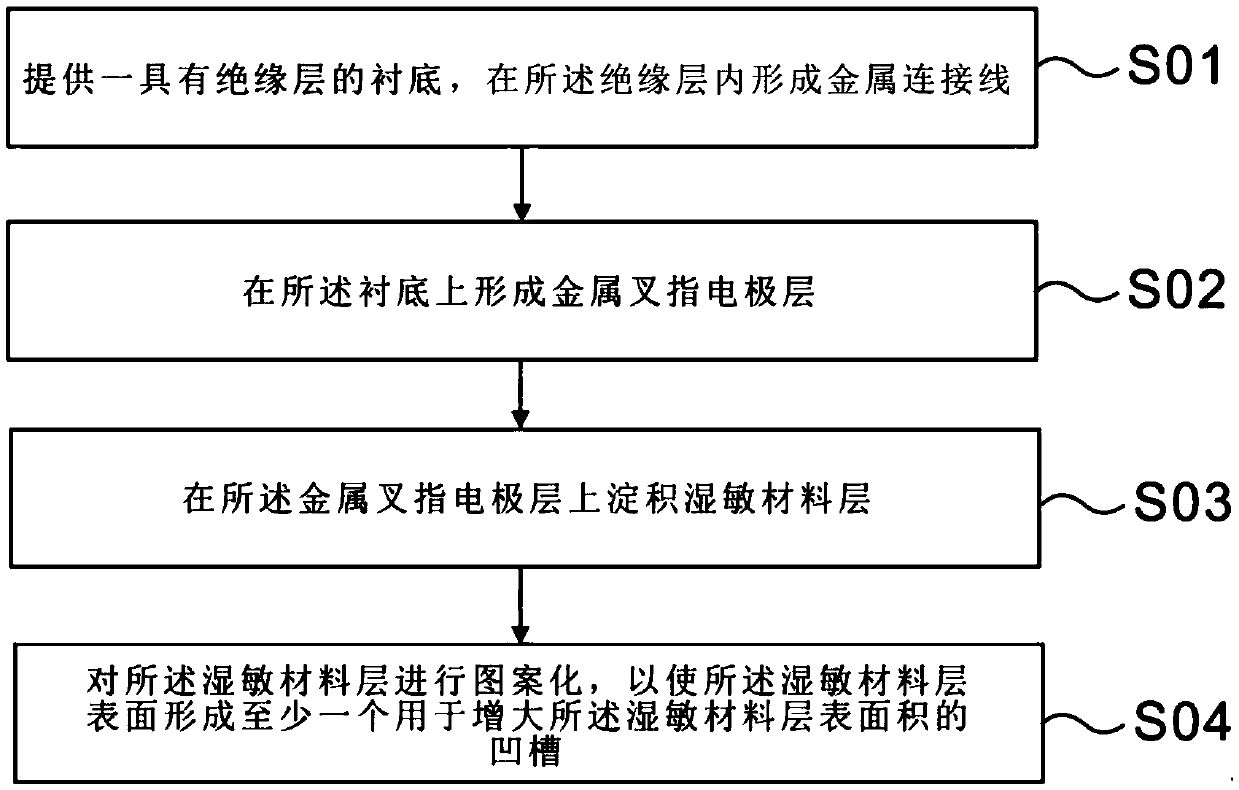

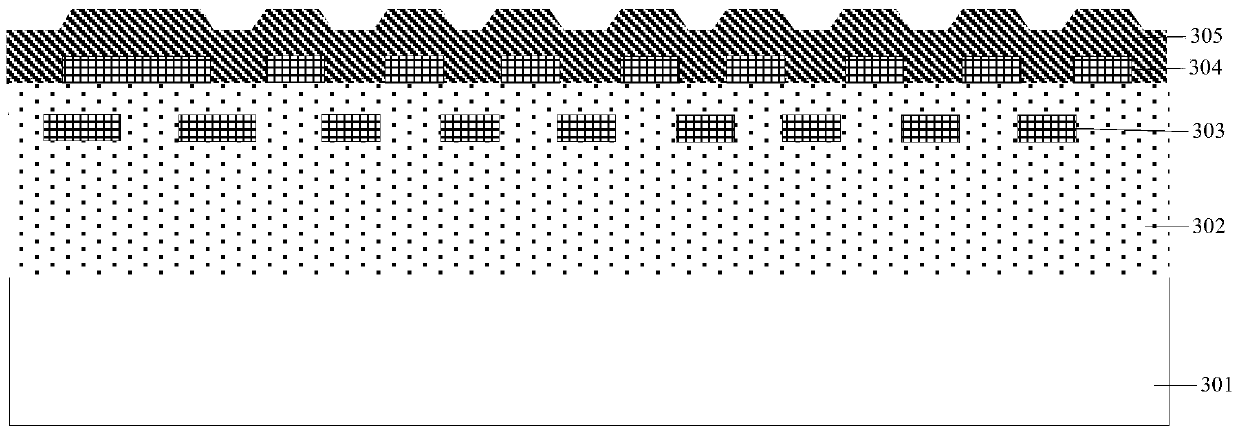

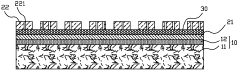

Rapidly-responsive humidity sensor and manufacturing method thereof

PatentActiveCN105510404A

Innovation

- Single or multiple grooves are formed in the moisture-sensitive material layer to increase the surface area of the moisture-sensitive material and shorten the movement path of water molecules, thereby improving the response speed of the humidity sensor.

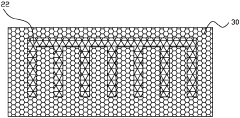

Humidity sensor, humidity sensitive material and manufacturing method

PatentPendingCN109557145A

Innovation

- Using moisture-sensitive materials with an airgel structure, a multi-branched nanoporous three-dimensional network structure with high porosity and high specific surface area is formed through cross-linking reaction and supercritical drying treatment to enhance the adsorption capacity and penetration speed of the moisture-sensitive materials. The design is Refers to the electrode and layered electrode structure to improve the sensitivity of the humidity sensor.

Material Sustainability and Environmental Impact

The sustainability of hydrogel materials used in humidity sensors represents a critical consideration in their development and deployment. Traditional humidity sensing technologies often rely on materials with significant environmental footprints, including non-biodegradable polymers and rare earth elements. In contrast, many hydrogel formulations offer improved environmental credentials through the use of naturally derived polymers such as cellulose, alginate, and chitosan, which are renewable and biodegradable.

The manufacturing processes for hydrogel humidity sensors generally require less energy compared to conventional semiconductor-based sensors, resulting in reduced carbon emissions. Additionally, the water-based synthesis methods commonly employed for hydrogels typically generate fewer toxic byproducts than solvent-based alternatives used in traditional sensor fabrication. This advantage is particularly notable in rapid-response hydrogels, which often utilize simpler network structures that can be produced with more environmentally friendly crosslinking methods.

End-of-life considerations for hydrogel humidity sensors present both challenges and opportunities. Biodegradable hydrogels can significantly reduce electronic waste accumulation, addressing a growing environmental concern in sensor technologies. However, the integration of these materials with electronic components may complicate disposal and recycling processes. Research into modular designs that facilitate the separation of biodegradable hydrogel elements from electronic components shows promise for improving overall lifecycle sustainability.

Water consumption during hydrogel production remains a concern, particularly for rapid-response sensors that may require specific processing conditions. Innovations in water recycling systems within manufacturing facilities and the development of less water-intensive synthesis methods are emerging as potential solutions to this challenge. Some research groups have demonstrated closed-loop production systems that recover and reuse up to 80% of process water.

The durability and lifespan of hydrogel humidity sensors directly impact their sustainability profile. Rapid-response hydrogels must maintain their performance characteristics over extended periods to minimize replacement frequency. Recent advances in self-healing hydrogels and protective encapsulation techniques have shown promising results in extending sensor lifespans under various environmental conditions, thereby reducing material consumption and waste generation over time.

Regulatory frameworks increasingly emphasize environmental considerations in electronic components, including sensors. The development of hydrogel humidity sensors with rapid response times must therefore balance performance requirements with emerging sustainability standards, such as the European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide.

The manufacturing processes for hydrogel humidity sensors generally require less energy compared to conventional semiconductor-based sensors, resulting in reduced carbon emissions. Additionally, the water-based synthesis methods commonly employed for hydrogels typically generate fewer toxic byproducts than solvent-based alternatives used in traditional sensor fabrication. This advantage is particularly notable in rapid-response hydrogels, which often utilize simpler network structures that can be produced with more environmentally friendly crosslinking methods.

End-of-life considerations for hydrogel humidity sensors present both challenges and opportunities. Biodegradable hydrogels can significantly reduce electronic waste accumulation, addressing a growing environmental concern in sensor technologies. However, the integration of these materials with electronic components may complicate disposal and recycling processes. Research into modular designs that facilitate the separation of biodegradable hydrogel elements from electronic components shows promise for improving overall lifecycle sustainability.

Water consumption during hydrogel production remains a concern, particularly for rapid-response sensors that may require specific processing conditions. Innovations in water recycling systems within manufacturing facilities and the development of less water-intensive synthesis methods are emerging as potential solutions to this challenge. Some research groups have demonstrated closed-loop production systems that recover and reuse up to 80% of process water.

The durability and lifespan of hydrogel humidity sensors directly impact their sustainability profile. Rapid-response hydrogels must maintain their performance characteristics over extended periods to minimize replacement frequency. Recent advances in self-healing hydrogels and protective encapsulation techniques have shown promising results in extending sensor lifespans under various environmental conditions, thereby reducing material consumption and waste generation over time.

Regulatory frameworks increasingly emphasize environmental considerations in electronic components, including sensors. The development of hydrogel humidity sensors with rapid response times must therefore balance performance requirements with emerging sustainability standards, such as the European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide.

Commercialization Pathways and Industry Applications

The commercialization of hydrogel humidity sensors with rapid response time presents significant market opportunities across multiple industries. These sensors can be integrated into various product lines through strategic partnerships with established manufacturers in electronics, healthcare, and environmental monitoring sectors. The path to market typically involves prototype refinement, pilot production, and scaled manufacturing, with potential licensing agreements or direct production depending on the innovating entity's resources.

Smart home applications represent one of the most promising commercial avenues, where rapid-response humidity sensors can enhance HVAC systems, smart thermostats, and indoor air quality monitors. The consumer electronics market values the miniaturization capabilities of hydrogel sensors, allowing for integration into wearable devices and smartphones for personalized environmental monitoring.

In the healthcare sector, these sensors offer critical applications in respiratory equipment, incubators, and wound care products where precise humidity control directly impacts patient outcomes. Medical device manufacturers are particularly interested in sensors that combine rapid response with biocompatibility and sterilization resistance, creating premium pricing opportunities for specialized formulations.

Agricultural technology presents another substantial market, with hydrogel sensors enabling precision irrigation systems and greenhouse environmental controls. The ability to detect subtle humidity changes quickly allows for water conservation and optimal growing conditions, directly impacting crop yields and resource efficiency.

Industrial applications span from manufacturing process controls to data center environmental monitoring, where preventing condensation and maintaining optimal humidity levels protects valuable equipment. The automotive industry has also shown interest in these sensors for cabin climate control and anti-fogging systems, particularly as vehicle electronics become more sophisticated.

The commercialization timeline typically ranges from 18-36 months from laboratory prototype to market-ready product, with regulatory considerations varying significantly by application field. Medical applications face the most stringent approval processes, while consumer electronics can achieve faster market entry through established certification pathways.

Cost considerations remain critical to widespread adoption, with current manufacturing techniques requiring optimization to achieve price points competitive with traditional capacitive sensors. However, the performance advantages of rapid response time and potential for flexible form factors justify premium positioning in specialized applications where traditional sensors underperform.

Smart home applications represent one of the most promising commercial avenues, where rapid-response humidity sensors can enhance HVAC systems, smart thermostats, and indoor air quality monitors. The consumer electronics market values the miniaturization capabilities of hydrogel sensors, allowing for integration into wearable devices and smartphones for personalized environmental monitoring.

In the healthcare sector, these sensors offer critical applications in respiratory equipment, incubators, and wound care products where precise humidity control directly impacts patient outcomes. Medical device manufacturers are particularly interested in sensors that combine rapid response with biocompatibility and sterilization resistance, creating premium pricing opportunities for specialized formulations.

Agricultural technology presents another substantial market, with hydrogel sensors enabling precision irrigation systems and greenhouse environmental controls. The ability to detect subtle humidity changes quickly allows for water conservation and optimal growing conditions, directly impacting crop yields and resource efficiency.

Industrial applications span from manufacturing process controls to data center environmental monitoring, where preventing condensation and maintaining optimal humidity levels protects valuable equipment. The automotive industry has also shown interest in these sensors for cabin climate control and anti-fogging systems, particularly as vehicle electronics become more sophisticated.

The commercialization timeline typically ranges from 18-36 months from laboratory prototype to market-ready product, with regulatory considerations varying significantly by application field. Medical applications face the most stringent approval processes, while consumer electronics can achieve faster market entry through established certification pathways.

Cost considerations remain critical to widespread adoption, with current manufacturing techniques requiring optimization to achieve price points competitive with traditional capacitive sensors. However, the performance advantages of rapid response time and potential for flexible form factors justify premium positioning in specialized applications where traditional sensors underperform.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!