Hydrogel-based wearable patches for physiological monitoring

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Wearable Patch Technology Background and Objectives

Hydrogel-based wearable patches represent a revolutionary advancement in the field of non-invasive physiological monitoring technologies. The evolution of these materials began in the late 1960s with the development of the first synthetic hydrogels, but their application in wearable health monitoring has gained significant momentum only in the past decade. This acceleration has been driven by the convergence of materials science, flexible electronics, and the growing demand for continuous health monitoring solutions.

The technological trajectory of hydrogel patches has been characterized by progressive improvements in biocompatibility, adhesion properties, and electrical conductivity. Early iterations faced challenges related to skin irritation, limited durability, and poor signal quality. However, recent developments have yielded hydrogels with enhanced mechanical properties, improved water retention capabilities, and superior ion conductivity—critical factors for accurate physiological signal detection.

Current research focuses on developing multi-functional hydrogel platforms capable of simultaneously monitoring various physiological parameters including heart rate, skin temperature, sweat composition, and muscle activity. These advanced materials are designed to maintain stable interfaces with human skin while providing reliable data transmission under diverse environmental conditions and physical activities.

The integration of nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles into hydrogel matrices has significantly enhanced their electrical properties and sensing capabilities. This integration represents a key technological milestone, enabling the development of highly sensitive and responsive monitoring systems that can detect subtle physiological changes with unprecedented accuracy.

The primary technical objectives in this field include developing hydrogel formulations with extended wear time (7+ days), minimal signal drift, and self-healing properties to enhance durability. Additionally, researchers aim to create patches with integrated wireless communication capabilities and low-power requirements to enable practical, long-term deployment for continuous health monitoring.

Another critical goal is the development of manufacturing processes that allow for cost-effective mass production while maintaining precise control over material properties and performance characteristics. This includes exploring novel crosslinking methods, innovative molding techniques, and scalable fabrication approaches compatible with existing manufacturing infrastructure.

The ultimate technical vision encompasses creating fully integrated, biocompatible hydrogel systems that seamlessly interface with the human body while providing comprehensive physiological data with clinical-grade accuracy. These systems would ideally be capable of not only monitoring health parameters but also delivering therapeutic agents in response to detected physiological changes, representing a paradigm shift in personalized healthcare delivery and preventive medicine.

The technological trajectory of hydrogel patches has been characterized by progressive improvements in biocompatibility, adhesion properties, and electrical conductivity. Early iterations faced challenges related to skin irritation, limited durability, and poor signal quality. However, recent developments have yielded hydrogels with enhanced mechanical properties, improved water retention capabilities, and superior ion conductivity—critical factors for accurate physiological signal detection.

Current research focuses on developing multi-functional hydrogel platforms capable of simultaneously monitoring various physiological parameters including heart rate, skin temperature, sweat composition, and muscle activity. These advanced materials are designed to maintain stable interfaces with human skin while providing reliable data transmission under diverse environmental conditions and physical activities.

The integration of nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles into hydrogel matrices has significantly enhanced their electrical properties and sensing capabilities. This integration represents a key technological milestone, enabling the development of highly sensitive and responsive monitoring systems that can detect subtle physiological changes with unprecedented accuracy.

The primary technical objectives in this field include developing hydrogel formulations with extended wear time (7+ days), minimal signal drift, and self-healing properties to enhance durability. Additionally, researchers aim to create patches with integrated wireless communication capabilities and low-power requirements to enable practical, long-term deployment for continuous health monitoring.

Another critical goal is the development of manufacturing processes that allow for cost-effective mass production while maintaining precise control over material properties and performance characteristics. This includes exploring novel crosslinking methods, innovative molding techniques, and scalable fabrication approaches compatible with existing manufacturing infrastructure.

The ultimate technical vision encompasses creating fully integrated, biocompatible hydrogel systems that seamlessly interface with the human body while providing comprehensive physiological data with clinical-grade accuracy. These systems would ideally be capable of not only monitoring health parameters but also delivering therapeutic agents in response to detected physiological changes, representing a paradigm shift in personalized healthcare delivery and preventive medicine.

Market Analysis for Physiological Monitoring Wearables

The global market for physiological monitoring wearables has experienced remarkable growth, with the hydrogel-based wearable patches segment emerging as a particularly promising area. Current market valuations place the overall wearable health monitoring market at approximately 13.8 billion USD in 2022, with projections indicating growth to reach 37.4 billion USD by 2028, representing a compound annual growth rate (CAGR) of 18.3%.

The demand for hydrogel-based wearable patches is primarily driven by several key factors. The aging global population has created an increased need for continuous health monitoring solutions that can detect early warning signs of deteriorating health conditions. Additionally, the rising prevalence of chronic diseases such as diabetes, cardiovascular disorders, and respiratory conditions has accelerated the adoption of wearable monitoring technologies that offer non-invasive, continuous data collection capabilities.

Consumer behavior trends indicate a significant shift toward preventive healthcare approaches, with individuals becoming more proactive about monitoring their physiological parameters. This behavioral change has expanded the target market beyond traditional medical applications into consumer wellness segments, including fitness enthusiasts, professional athletes, and health-conscious individuals.

Regional market analysis reveals that North America currently dominates the physiological monitoring wearables market, accounting for approximately 42% of global market share. This dominance is attributed to advanced healthcare infrastructure, higher healthcare spending, and greater technology adoption rates. However, the Asia-Pacific region is expected to witness the fastest growth rate of 22.7% during the forecast period, driven by improving healthcare access, rising disposable incomes, and increasing awareness about preventive healthcare.

The hydrogel-based wearable patches segment specifically is projected to grow at a CAGR of 24.1% through 2028, outpacing other wearable form factors. This accelerated growth is attributed to the unique advantages of hydrogel technology, including superior skin compatibility, enhanced signal quality, and the ability to integrate multiple sensing modalities within a single patch.

Market segmentation analysis indicates diverse application areas, with cardiac monitoring representing the largest segment at 31% market share, followed by glucose monitoring (24%), respiratory monitoring (18%), and other physiological parameters (27%). The consumer segment is growing faster than the medical segment, suggesting expanding opportunities beyond traditional healthcare settings.

Key market challenges include concerns regarding data privacy and security, regulatory hurdles for medical-grade devices, and the need for improved battery life and power management solutions. Despite these challenges, the overall market outlook remains highly positive, with technological advancements in materials science and sensor miniaturization expected to further accelerate market growth.

The demand for hydrogel-based wearable patches is primarily driven by several key factors. The aging global population has created an increased need for continuous health monitoring solutions that can detect early warning signs of deteriorating health conditions. Additionally, the rising prevalence of chronic diseases such as diabetes, cardiovascular disorders, and respiratory conditions has accelerated the adoption of wearable monitoring technologies that offer non-invasive, continuous data collection capabilities.

Consumer behavior trends indicate a significant shift toward preventive healthcare approaches, with individuals becoming more proactive about monitoring their physiological parameters. This behavioral change has expanded the target market beyond traditional medical applications into consumer wellness segments, including fitness enthusiasts, professional athletes, and health-conscious individuals.

Regional market analysis reveals that North America currently dominates the physiological monitoring wearables market, accounting for approximately 42% of global market share. This dominance is attributed to advanced healthcare infrastructure, higher healthcare spending, and greater technology adoption rates. However, the Asia-Pacific region is expected to witness the fastest growth rate of 22.7% during the forecast period, driven by improving healthcare access, rising disposable incomes, and increasing awareness about preventive healthcare.

The hydrogel-based wearable patches segment specifically is projected to grow at a CAGR of 24.1% through 2028, outpacing other wearable form factors. This accelerated growth is attributed to the unique advantages of hydrogel technology, including superior skin compatibility, enhanced signal quality, and the ability to integrate multiple sensing modalities within a single patch.

Market segmentation analysis indicates diverse application areas, with cardiac monitoring representing the largest segment at 31% market share, followed by glucose monitoring (24%), respiratory monitoring (18%), and other physiological parameters (27%). The consumer segment is growing faster than the medical segment, suggesting expanding opportunities beyond traditional healthcare settings.

Key market challenges include concerns regarding data privacy and security, regulatory hurdles for medical-grade devices, and the need for improved battery life and power management solutions. Despite these challenges, the overall market outlook remains highly positive, with technological advancements in materials science and sensor miniaturization expected to further accelerate market growth.

Current Challenges in Hydrogel-based Sensing Technologies

Despite significant advancements in hydrogel-based wearable patches for physiological monitoring, several critical challenges continue to impede their widespread adoption and clinical application. The foremost challenge lies in achieving long-term stability of hydrogels when exposed to various environmental conditions. Hydrogels tend to dehydrate over time, leading to altered mechanical properties and diminished sensing capabilities. This dehydration issue becomes particularly problematic in continuous monitoring scenarios where patches must maintain functionality for extended periods.

Biocompatibility and skin irritation remain persistent concerns, especially for long-term wear applications. While hydrogels are generally considered biocompatible, prolonged contact with skin can lead to adverse reactions in some users, including redness, itching, or allergic responses. The adhesion-irritation paradox presents a significant design challenge: stronger adhesion often correlates with increased skin irritation, while more skin-friendly formulations may not adhere adequately during physical activity or sweating.

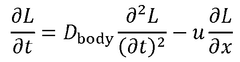

Signal fidelity and noise reduction represent another major technical hurdle. Hydrogel-based sensors are susceptible to motion artifacts, particularly during user movement, which can significantly compromise data quality. The interface between the hydrogel and electronic components often introduces noise that requires sophisticated signal processing algorithms to filter effectively. Additionally, maintaining consistent electrical conductivity across the hydrogel-skin interface remains difficult due to variations in skin moisture and natural oils.

Scalable manufacturing processes for hydrogel-based wearable patches present considerable challenges. Current production methods often involve complex, multi-step processes that are difficult to scale while maintaining quality control. The integration of sensing elements within hydrogel matrices without compromising their functionality requires precise manufacturing techniques that are not yet fully optimized for mass production.

Power management constitutes another significant limitation. Most advanced sensing capabilities require continuous power supply, yet incorporating batteries increases device bulk and reduces wearability. While energy harvesting technologies show promise, their current efficiency levels are insufficient for powering comprehensive physiological monitoring systems continuously.

Data security and privacy concerns have emerged as increasingly important challenges as these devices collect sensitive health information. The wireless transmission of physiological data introduces vulnerabilities that must be addressed through robust encryption and security protocols, adding another layer of complexity to system design.

Regulatory approval pathways remain unclear for many hydrogel-based monitoring technologies, particularly those that straddle the boundary between consumer wellness products and medical devices. This regulatory uncertainty has slowed commercialization efforts and limited investment in some promising technologies.

Biocompatibility and skin irritation remain persistent concerns, especially for long-term wear applications. While hydrogels are generally considered biocompatible, prolonged contact with skin can lead to adverse reactions in some users, including redness, itching, or allergic responses. The adhesion-irritation paradox presents a significant design challenge: stronger adhesion often correlates with increased skin irritation, while more skin-friendly formulations may not adhere adequately during physical activity or sweating.

Signal fidelity and noise reduction represent another major technical hurdle. Hydrogel-based sensors are susceptible to motion artifacts, particularly during user movement, which can significantly compromise data quality. The interface between the hydrogel and electronic components often introduces noise that requires sophisticated signal processing algorithms to filter effectively. Additionally, maintaining consistent electrical conductivity across the hydrogel-skin interface remains difficult due to variations in skin moisture and natural oils.

Scalable manufacturing processes for hydrogel-based wearable patches present considerable challenges. Current production methods often involve complex, multi-step processes that are difficult to scale while maintaining quality control. The integration of sensing elements within hydrogel matrices without compromising their functionality requires precise manufacturing techniques that are not yet fully optimized for mass production.

Power management constitutes another significant limitation. Most advanced sensing capabilities require continuous power supply, yet incorporating batteries increases device bulk and reduces wearability. While energy harvesting technologies show promise, their current efficiency levels are insufficient for powering comprehensive physiological monitoring systems continuously.

Data security and privacy concerns have emerged as increasingly important challenges as these devices collect sensitive health information. The wireless transmission of physiological data introduces vulnerabilities that must be addressed through robust encryption and security protocols, adding another layer of complexity to system design.

Regulatory approval pathways remain unclear for many hydrogel-based monitoring technologies, particularly those that straddle the boundary between consumer wellness products and medical devices. This regulatory uncertainty has slowed commercialization efforts and limited investment in some promising technologies.

Current Hydrogel Patch Design and Sensing Mechanisms

01 Hydrogel compositions for wearable physiological sensors

Specialized hydrogel compositions are formulated for use in wearable physiological monitoring patches. These hydrogels typically contain biocompatible polymers, conductive elements, and adhesive components that enable stable skin contact while maintaining flexibility and breathability. The compositions are designed to enhance signal quality for accurate monitoring of vital signs while minimizing skin irritation during prolonged wear.- Hydrogel composition for wearable physiological sensors: Specialized hydrogel compositions are developed for wearable physiological monitoring patches. These hydrogels typically contain biocompatible polymers, conductive elements, and adhesive components that enable stable skin contact while maintaining flexibility and breathability. The formulations are designed to optimize signal transduction for accurate physiological measurements while minimizing skin irritation during prolonged wear. These advanced materials allow for continuous monitoring of vital signs while maintaining user comfort.

- Multi-parameter monitoring systems in hydrogel patches: Hydrogel-based wearable patches are designed to simultaneously monitor multiple physiological parameters. These integrated systems can track combinations of vital signs such as heart rate, body temperature, blood oxygen levels, glucose concentration, and sweat composition. The multi-parameter approach provides comprehensive health data through a single wearable device, enabling more holistic health assessment and correlation between different physiological indicators for improved diagnostic capabilities.

- Data processing and wireless communication features: Advanced hydrogel patches incorporate data processing capabilities and wireless communication technologies. These features enable real-time analysis of physiological data, transmission to smartphones or cloud platforms, and integration with healthcare systems. The patches contain miniaturized circuits embedded within or attached to the hydrogel layer that process signals from sensors before transmission. This connectivity allows for continuous remote monitoring, automated alerts for abnormal readings, and integration with telehealth services.

- Specialized applications for specific health conditions: Hydrogel patches are developed for monitoring specific health conditions or patient populations. These specialized applications include patches designed for diabetes management, cardiovascular monitoring, neonatal care, athletic performance tracking, and sleep disorder assessment. The hydrogel formulations and sensor configurations are tailored to the specific physiological parameters most relevant to each condition, optimizing sensitivity and accuracy for the target application while addressing the unique requirements of different user groups.

- Manufacturing and structural design innovations: Innovations in manufacturing processes and structural designs enhance the performance and usability of hydrogel-based monitoring patches. These include layered architectures that separate sensing elements from adhesive components, microneedle integration for improved signal acquisition, stretchable electronics that maintain functionality during movement, and environmentally responsive elements that adapt to changing conditions. Advanced fabrication techniques such as 3D printing and microfluidic integration enable more complex and functional patch designs while improving production efficiency and reducing costs.

02 Multi-parameter monitoring systems in hydrogel patches

Advanced hydrogel-based wearable patches incorporate multiple sensing elements to simultaneously monitor various physiological parameters. These integrated systems can track combinations of vital signs such as heart rate, respiration, temperature, blood oxygen levels, and perspiration biomarkers. The multi-parameter approach provides comprehensive health data through a single wearable device, enabling more complete physiological assessment for medical and fitness applications.Expand Specific Solutions03 Data processing and wireless communication features

Hydrogel-based monitoring patches incorporate advanced data processing capabilities and wireless communication modules. These features enable real-time signal processing, data analysis, and transmission to smartphones or healthcare systems. The integration of low-power microprocessors and wireless technologies (Bluetooth, NFC, or cellular) allows for continuous remote monitoring while maintaining user mobility and extending battery life of the wearable device.Expand Specific Solutions04 Structural design innovations for comfort and durability

Innovative structural designs enhance the comfort and durability of hydrogel-based monitoring patches. These designs include layered architectures that separate sensing elements from adhesive components, stretchable substrates that accommodate body movement, and breathable structures that prevent moisture accumulation. Advanced manufacturing techniques create ultra-thin, conformable patches that maintain functionality during physical activity while providing extended wear time.Expand Specific Solutions05 Specialized applications for specific physiological monitoring

Hydrogel patches are designed for specialized physiological monitoring applications, including continuous glucose monitoring, cardiac activity assessment, neurological signal detection, and sweat analysis. These application-specific designs incorporate targeted sensing elements and algorithms optimized for particular biomarkers or signals. The specialized patches address specific medical conditions or health monitoring needs with enhanced accuracy and reliability for their intended purpose.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogel Wearables

The hydrogel-based wearable patch market for physiological monitoring is in a growth phase, characterized by increasing adoption across healthcare applications and expanding market size projected to reach billions by 2030. The technology maturity varies across applications, with companies at different development stages. Industry leaders like Abbott Diabetes Care and Koninklijke Philips have established commercial products, while innovative startups such as LifeSignals, Bardy Diagnostics, and PRAMAND are advancing specialized applications. Academic institutions including Zhejiang University, Shanghai Jiao Tong University, and UC Regents are driving fundamental research, while companies like Eli Lilly are exploring pharmaceutical integration. The competitive landscape shows a mix of established medical device manufacturers, specialized startups, and research institutions collaborating to overcome technical challenges in biocompatibility, sensor integration, and long-term stability.

Abbott Diabetes Care, Inc.

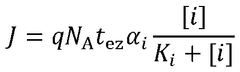

Technical Solution: Abbott has developed advanced hydrogel-based wearable patches for continuous glucose monitoring (CGM), particularly with their FreeStyle Libre system. Their technology utilizes specialized hydrogel matrices that maintain sensor stability while allowing glucose diffusion to the sensing element. The hydrogel composition is designed to be biocompatible and reduce foreign body responses, extending wear time up to 14 days. Abbott's patches incorporate enzyme-based electrochemical sensors embedded within the hydrogel layer that generates electrical signals proportional to glucose concentration. The hydrogel serves as both an adhesive and a biointerface that maintains proper hydration of the sensor-tissue interface, crucial for accurate glucose readings. Their latest iterations feature improved hydrogel formulations that reduce skin irritation while maintaining strong adhesion during physical activity.

Strengths: Long wear duration (up to 14 days), minimal calibration requirements, and established manufacturing infrastructure. Their hydrogel formulation balances adhesion, comfort, and biocompatibility effectively. Weaknesses: Limited to glucose monitoring specifically, and the hydrogel platform hasn't been widely adapted for other analytes or physiological parameters beyond glucose.

The Regents of the University of California

Technical Solution: The University of California has pioneered several breakthrough technologies in hydrogel-based wearable patches through their research teams. Their most notable contribution is the development of stretchable, self-healing hydrogels with integrated electronics for comprehensive physiological monitoring. UC researchers have created "smart bandages" using alginate-polyacrylamide hybrid hydrogels that can stretch up to 20 times their original length while maintaining electrical conductivity. These patches incorporate microfluidic channels within the hydrogel matrix to sample and analyze sweat biomarkers including glucose, lactate, pH, and electrolytes simultaneously. Their technology utilizes screen-printed electrodes embedded within the hydrogel structure, allowing for real-time, wireless transmission of multiple physiological parameters. UC researchers have also developed photopatternable hydrogels that enable precise spatial control of sensor elements, creating multi-analyte detection capabilities within a single patch platform.

Strengths: Cutting-edge research in stretchable electronics integration with hydrogels, superior mechanical properties (self-healing, high elasticity), and multi-analyte detection capabilities. Weaknesses: Many technologies remain in research phase with limited commercialization pathways, and manufacturing scalability challenges exist for complex hydrogel-electronic hybrid systems.

Key Patents and Scientific Breakthroughs in Hydrogel Sensors

Wearable sensor patch

PatentWO2025117631A1

Innovation

- A wearable sensor patch incorporating hydrogel microneedles and a flexible sensor element with elastomeric electrodes, allowing for minimally invasive ISF collection and simultaneous biomarker measurement in-situ. The patch is designed to accommodate hydrogel swelling and skin deformation, ensuring consistent signal stability.

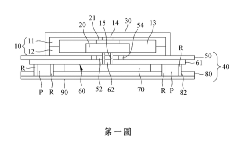

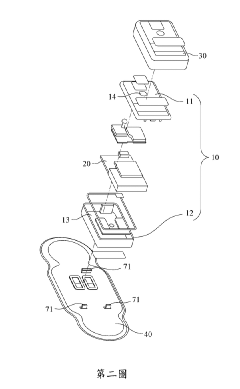

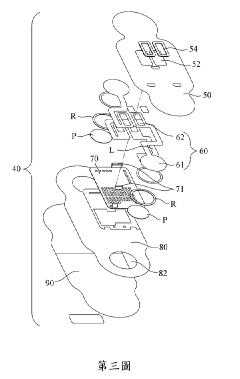

Physiological monitoring device

PatentActiveTW202126257A

Innovation

- A physiological monitor design featuring an upper and lower moisture-permeable layer made of non-waterproof materials with high air and moisture permeability, combined with a closed casing and adhesive attachment, allowing for continuous signal sensing and recording without discomfort.

Biocompatibility and Safety Considerations

Biocompatibility remains a critical consideration for hydrogel-based wearable patches used in physiological monitoring. These devices maintain prolonged contact with skin, necessitating materials that do not trigger adverse immune responses or inflammation. Current research focuses on developing hydrogels with enhanced biocompatibility through incorporation of natural polymers such as alginate, hyaluronic acid, and chitosan, which demonstrate superior tissue compatibility compared to synthetic alternatives.

Safety evaluations for these wearable patches must address multiple dimensions, including cytotoxicity, sensitization potential, and irritation risks. ISO 10993 standards provide the regulatory framework for biological evaluation of medical devices, with specific protocols for skin-contact applications. Recent studies indicate that hydrogels containing silver nanoparticles or certain crosslinking agents may present cytotoxicity concerns, prompting researchers to explore alternative antimicrobial strategies.

Skin sensitization represents another significant challenge, particularly for patients with pre-existing dermatological conditions. Clinical trials have demonstrated that approximately 8-12% of users experience mild skin irritation with prolonged wear of hydrogel patches, necessitating careful material selection and patch design optimization. Water content regulation within hydrogels proves essential for maintaining skin barrier function while preventing maceration from excessive moisture.

The degradation profiles of hydrogel materials warrant careful consideration, as breakdown products must not induce toxicity. Biodegradable hydrogels based on poly(vinyl alcohol) and gelatin derivatives have shown promising safety profiles in recent investigations, with controlled degradation rates that minimize accumulation of potentially harmful byproducts.

Sterilization processes significantly impact both biocompatibility and functional performance of hydrogel patches. While gamma irradiation remains the industry standard, it can alter mechanical properties and water retention capabilities of certain hydrogel formulations. Alternative methods such as ethylene oxide treatment and supercritical CO2 sterilization are emerging as viable options that preserve material integrity.

Long-term safety monitoring protocols are increasingly emphasized in regulatory frameworks, with post-market surveillance data indicating that material fatigue and adhesive degradation represent the most common safety concerns in extended-wear scenarios. Manufacturers have responded by implementing accelerated aging tests and improved packaging technologies to extend shelf life while maintaining safety profiles.

Recent innovations include "smart" biocompatibility features, where hydrogels respond to inflammatory markers by releasing anti-inflammatory agents or changing properties to minimize tissue reaction. These adaptive materials represent the next frontier in biocompatible wearable technology, potentially enabling truly personalized physiological monitoring solutions with enhanced safety profiles.

Safety evaluations for these wearable patches must address multiple dimensions, including cytotoxicity, sensitization potential, and irritation risks. ISO 10993 standards provide the regulatory framework for biological evaluation of medical devices, with specific protocols for skin-contact applications. Recent studies indicate that hydrogels containing silver nanoparticles or certain crosslinking agents may present cytotoxicity concerns, prompting researchers to explore alternative antimicrobial strategies.

Skin sensitization represents another significant challenge, particularly for patients with pre-existing dermatological conditions. Clinical trials have demonstrated that approximately 8-12% of users experience mild skin irritation with prolonged wear of hydrogel patches, necessitating careful material selection and patch design optimization. Water content regulation within hydrogels proves essential for maintaining skin barrier function while preventing maceration from excessive moisture.

The degradation profiles of hydrogel materials warrant careful consideration, as breakdown products must not induce toxicity. Biodegradable hydrogels based on poly(vinyl alcohol) and gelatin derivatives have shown promising safety profiles in recent investigations, with controlled degradation rates that minimize accumulation of potentially harmful byproducts.

Sterilization processes significantly impact both biocompatibility and functional performance of hydrogel patches. While gamma irradiation remains the industry standard, it can alter mechanical properties and water retention capabilities of certain hydrogel formulations. Alternative methods such as ethylene oxide treatment and supercritical CO2 sterilization are emerging as viable options that preserve material integrity.

Long-term safety monitoring protocols are increasingly emphasized in regulatory frameworks, with post-market surveillance data indicating that material fatigue and adhesive degradation represent the most common safety concerns in extended-wear scenarios. Manufacturers have responded by implementing accelerated aging tests and improved packaging technologies to extend shelf life while maintaining safety profiles.

Recent innovations include "smart" biocompatibility features, where hydrogels respond to inflammatory markers by releasing anti-inflammatory agents or changing properties to minimize tissue reaction. These adaptive materials represent the next frontier in biocompatible wearable technology, potentially enabling truly personalized physiological monitoring solutions with enhanced safety profiles.

Manufacturing Scalability and Cost Analysis

The scalability of hydrogel-based wearable patch manufacturing represents a critical factor in their commercial viability and widespread adoption. Current manufacturing processes predominantly rely on laboratory-scale production methods, including casting, molding, and 3D printing, which present significant challenges when transitioning to mass production. These challenges include maintaining consistent material properties, ensuring uniform thickness, and preserving the functional integrity of embedded sensors and electronics.

Cost analysis reveals that material expenses constitute approximately 30-40% of total production costs, with high-quality biocompatible hydrogels commanding premium prices ranging from $50-200 per kilogram depending on composition and functionality. Specialized conductive hydrogels incorporating nanomaterials such as silver nanowires or graphene can increase material costs by 200-300%. Additionally, the integration of electronic components and sensors adds $5-15 per unit, while packaging and sterilization processes contribute another $3-7 per device.

Economies of scale present promising opportunities for cost reduction, with projections indicating potential manufacturing cost decreases of 40-60% when production volumes exceed 100,000 units annually. However, achieving these economies requires substantial initial capital investment in specialized equipment and facilities, estimated at $2-5 million for a medium-scale production line. Return on investment calculations suggest a 3-5 year payback period depending on market penetration rates and pricing strategies.

Several technological innovations are emerging to address manufacturing challenges. Roll-to-roll processing techniques show particular promise for continuous production of hydrogel sheets with embedded electronics, potentially reducing unit costs by 30-50% compared to batch processing methods. Automated dispensing systems for precise hydrogel deposition and laser-cutting technologies for accurate dimensioning are further enhancing production efficiency and reducing material waste.

Regulatory compliance adds another layer of complexity to manufacturing scalability, with medical-grade production facilities requiring ISO 13485 certification and adherence to Good Manufacturing Practices (GMP). These regulatory requirements add approximately 15-25% to overall production costs but are essential for market access in healthcare applications. Companies pursuing consumer-grade applications face fewer regulatory hurdles but must still address quality control and safety standards.

Strategic partnerships between material scientists, electronics manufacturers, and medical device companies are emerging as a viable approach to distribute development costs and leverage existing manufacturing infrastructure. This collaborative model has demonstrated success in recent commercial ventures, reducing time-to-market by 30-40% compared to vertically integrated approaches.

Cost analysis reveals that material expenses constitute approximately 30-40% of total production costs, with high-quality biocompatible hydrogels commanding premium prices ranging from $50-200 per kilogram depending on composition and functionality. Specialized conductive hydrogels incorporating nanomaterials such as silver nanowires or graphene can increase material costs by 200-300%. Additionally, the integration of electronic components and sensors adds $5-15 per unit, while packaging and sterilization processes contribute another $3-7 per device.

Economies of scale present promising opportunities for cost reduction, with projections indicating potential manufacturing cost decreases of 40-60% when production volumes exceed 100,000 units annually. However, achieving these economies requires substantial initial capital investment in specialized equipment and facilities, estimated at $2-5 million for a medium-scale production line. Return on investment calculations suggest a 3-5 year payback period depending on market penetration rates and pricing strategies.

Several technological innovations are emerging to address manufacturing challenges. Roll-to-roll processing techniques show particular promise for continuous production of hydrogel sheets with embedded electronics, potentially reducing unit costs by 30-50% compared to batch processing methods. Automated dispensing systems for precise hydrogel deposition and laser-cutting technologies for accurate dimensioning are further enhancing production efficiency and reducing material waste.

Regulatory compliance adds another layer of complexity to manufacturing scalability, with medical-grade production facilities requiring ISO 13485 certification and adherence to Good Manufacturing Practices (GMP). These regulatory requirements add approximately 15-25% to overall production costs but are essential for market access in healthcare applications. Companies pursuing consumer-grade applications face fewer regulatory hurdles but must still address quality control and safety standards.

Strategic partnerships between material scientists, electronics manufacturers, and medical device companies are emerging as a viable approach to distribute development costs and leverage existing manufacturing infrastructure. This collaborative model has demonstrated success in recent commercial ventures, reducing time-to-market by 30-40% compared to vertically integrated approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!