Hydrogel encapsulation for long-term sensor stability

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Encapsulation Background and Objectives

Hydrogel encapsulation technology has emerged as a promising solution for enhancing the longevity and reliability of biosensors and implantable medical devices. The development of this technology can be traced back to the early 1990s when researchers began exploring biocompatible materials for medical applications. Over the past three decades, hydrogels have evolved from simple polymeric networks to sophisticated smart materials capable of responding to various environmental stimuli while providing protective functions.

The evolution of hydrogel encapsulation technology has been driven by the increasing demand for long-term implantable sensors in continuous health monitoring and personalized medicine. Traditional sensor protection methods often fail to address the harsh biological environment, leading to sensor drift, biofouling, and eventual failure. Hydrogels, with their unique water-retention properties and tunable mechanical characteristics, present an ideal platform for sensor encapsulation.

Current technological trends in hydrogel encapsulation focus on developing materials with enhanced permeability for target analytes while maintaining impermeability to interfering substances. Advanced composite hydrogels incorporating nanomaterials, antimicrobial agents, and anti-fouling components represent the cutting edge of this field. The integration of stimuli-responsive elements that can modulate gel properties in response to specific triggers is another significant trend.

The primary objective of hydrogel encapsulation research is to extend sensor functional lifetime from weeks to years without compromising measurement accuracy or response time. This involves addressing several key challenges: maintaining consistent diffusion rates of target analytes, preventing protein adsorption and cellular adhesion, ensuring mechanical stability under physiological conditions, and preserving sensor functionality during long-term implantation.

Secondary objectives include developing hydrogel formulations that can be easily processed using scalable manufacturing techniques, ensuring biocompatibility for long-term implantation, and creating systems capable of self-healing or regeneration when damaged. The ultimate goal is to create "set-and-forget" sensor systems that can operate reliably in vivo without requiring frequent replacement or recalibration.

From a technological perspective, achieving these objectives requires interdisciplinary approaches combining polymer chemistry, materials science, bioengineering, and sensor technology. The field is moving toward precision-engineered hydrogel systems with spatially controlled properties and multi-functional capabilities that can simultaneously address multiple failure modes of implanted sensors.

The evolution of hydrogel encapsulation technology has been driven by the increasing demand for long-term implantable sensors in continuous health monitoring and personalized medicine. Traditional sensor protection methods often fail to address the harsh biological environment, leading to sensor drift, biofouling, and eventual failure. Hydrogels, with their unique water-retention properties and tunable mechanical characteristics, present an ideal platform for sensor encapsulation.

Current technological trends in hydrogel encapsulation focus on developing materials with enhanced permeability for target analytes while maintaining impermeability to interfering substances. Advanced composite hydrogels incorporating nanomaterials, antimicrobial agents, and anti-fouling components represent the cutting edge of this field. The integration of stimuli-responsive elements that can modulate gel properties in response to specific triggers is another significant trend.

The primary objective of hydrogel encapsulation research is to extend sensor functional lifetime from weeks to years without compromising measurement accuracy or response time. This involves addressing several key challenges: maintaining consistent diffusion rates of target analytes, preventing protein adsorption and cellular adhesion, ensuring mechanical stability under physiological conditions, and preserving sensor functionality during long-term implantation.

Secondary objectives include developing hydrogel formulations that can be easily processed using scalable manufacturing techniques, ensuring biocompatibility for long-term implantation, and creating systems capable of self-healing or regeneration when damaged. The ultimate goal is to create "set-and-forget" sensor systems that can operate reliably in vivo without requiring frequent replacement or recalibration.

From a technological perspective, achieving these objectives requires interdisciplinary approaches combining polymer chemistry, materials science, bioengineering, and sensor technology. The field is moving toward precision-engineered hydrogel systems with spatially controlled properties and multi-functional capabilities that can simultaneously address multiple failure modes of implanted sensors.

Market Analysis for Long-term Stable Sensors

The global market for long-term stable sensors is experiencing robust growth, driven by increasing demand across multiple industries including healthcare, environmental monitoring, industrial automation, and consumer electronics. The market value for advanced sensing technologies reached approximately $180 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2030, with hydrogel-encapsulated sensors representing an emerging segment with significant potential.

Healthcare applications currently dominate the market for long-term stable sensors, accounting for nearly 35% of total market share. The continuous glucose monitoring segment alone is valued at $5.1 billion, with hydrogel-based solutions gaining traction due to their biocompatibility and potential for extended wear time. Patient comfort and reduced replacement frequency represent key value propositions driving adoption.

Industrial applications represent the second-largest market segment, particularly in harsh environment monitoring where sensor longevity directly impacts maintenance costs and system reliability. The industrial IoT sensor market, valued at $9.2 billion in 2022, increasingly demands solutions that can withstand challenging conditions while maintaining calibration stability.

Environmental monitoring applications are experiencing the fastest growth rate at 9.3% annually, driven by climate change concerns and stricter regulatory requirements. Water quality monitoring, soil analysis, and atmospheric sensing all benefit from extended sensor lifespans, reducing deployment costs in remote locations.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate through 2030, driven by rapid industrialization and healthcare infrastructure development in China and India.

Key market drivers include the aging global population increasing demand for continuous health monitoring, industrial automation trends requiring more reliable sensing technologies, and environmental regulations mandating more comprehensive monitoring programs. The push toward preventive maintenance in manufacturing has created particular demand for sensors that can operate reliably for years without replacement.

Market challenges include price sensitivity in emerging economies, technical limitations in achieving multi-year stability across diverse operating conditions, and regulatory hurdles for implantable or long-term wearable sensors. Competition from alternative technologies such as optical sensing and MEMS-based solutions also presents market pressure.

Customer requirements analysis indicates that extended calibration intervals, reduced maintenance costs, and improved accuracy over the sensor lifetime represent the most valued attributes across all market segments. The potential for hydrogel encapsulation to address these needs positions this technology favorably for market expansion.

Healthcare applications currently dominate the market for long-term stable sensors, accounting for nearly 35% of total market share. The continuous glucose monitoring segment alone is valued at $5.1 billion, with hydrogel-based solutions gaining traction due to their biocompatibility and potential for extended wear time. Patient comfort and reduced replacement frequency represent key value propositions driving adoption.

Industrial applications represent the second-largest market segment, particularly in harsh environment monitoring where sensor longevity directly impacts maintenance costs and system reliability. The industrial IoT sensor market, valued at $9.2 billion in 2022, increasingly demands solutions that can withstand challenging conditions while maintaining calibration stability.

Environmental monitoring applications are experiencing the fastest growth rate at 9.3% annually, driven by climate change concerns and stricter regulatory requirements. Water quality monitoring, soil analysis, and atmospheric sensing all benefit from extended sensor lifespans, reducing deployment costs in remote locations.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate through 2030, driven by rapid industrialization and healthcare infrastructure development in China and India.

Key market drivers include the aging global population increasing demand for continuous health monitoring, industrial automation trends requiring more reliable sensing technologies, and environmental regulations mandating more comprehensive monitoring programs. The push toward preventive maintenance in manufacturing has created particular demand for sensors that can operate reliably for years without replacement.

Market challenges include price sensitivity in emerging economies, technical limitations in achieving multi-year stability across diverse operating conditions, and regulatory hurdles for implantable or long-term wearable sensors. Competition from alternative technologies such as optical sensing and MEMS-based solutions also presents market pressure.

Customer requirements analysis indicates that extended calibration intervals, reduced maintenance costs, and improved accuracy over the sensor lifetime represent the most valued attributes across all market segments. The potential for hydrogel encapsulation to address these needs positions this technology favorably for market expansion.

Current Challenges in Sensor Stability Technologies

Despite significant advancements in sensor technologies, maintaining long-term stability remains a critical challenge across various applications. Current sensor systems face multiple stability issues that compromise their reliability and performance over extended periods. Biofouling represents one of the most significant obstacles, particularly for implantable and environmental sensors, where protein adsorption and cellular adhesion gradually form a biofilm that interferes with sensing mechanisms and reduces sensitivity.

Material degradation constitutes another major challenge, with sensor components experiencing chemical breakdown, mechanical fatigue, and structural changes when exposed to harsh environments. This degradation is especially problematic in industrial settings with extreme temperatures, corrosive chemicals, or high-pressure conditions, leading to drift in sensor readings and eventual failure.

Signal drift presents a persistent technical hurdle, manifesting as gradual, unpredictable changes in sensor output despite constant analyte concentrations. This phenomenon necessitates frequent recalibration, which is impractical for many applications, particularly implantable medical devices or remote environmental monitoring systems.

Encapsulation technologies currently employed face limitations in providing comprehensive protection while maintaining sensor functionality. Traditional rigid encapsulants offer excellent barrier properties but often impede diffusion-dependent sensing mechanisms. Conversely, permeable materials allow necessary diffusion but provide insufficient protection against environmental factors.

Hydrogel-based encapsulation has emerged as a promising approach but faces its own set of challenges. Current hydrogel formulations struggle with mechanical stability, experiencing significant swelling/deswelling cycles that affect sensor performance. Many hydrogels also demonstrate inadequate adhesion to sensor surfaces, creating potential failure points where environmental factors can penetrate.

The biocompatibility of encapsulation materials remains problematic, particularly for medical applications where foreign body responses can trigger inflammation, fibrosis, and sensor isolation. Additionally, achieving consistent mass transport properties through hydrogel matrices presents significant engineering challenges, as variations in diffusion rates directly impact sensor response times and accuracy.

Power management for encapsulated sensors represents another critical challenge, as encapsulation materials can impede wireless power transfer and increase energy requirements. This is particularly problematic for implantable sensors where battery replacement is invasive and costly.

Manufacturing scalability also limits widespread adoption, with current hydrogel encapsulation techniques often requiring complex, multi-step processes that are difficult to standardize and scale for commercial production. The integration of hydrogels with existing sensor fabrication processes presents compatibility issues that have yet to be fully resolved.

Material degradation constitutes another major challenge, with sensor components experiencing chemical breakdown, mechanical fatigue, and structural changes when exposed to harsh environments. This degradation is especially problematic in industrial settings with extreme temperatures, corrosive chemicals, or high-pressure conditions, leading to drift in sensor readings and eventual failure.

Signal drift presents a persistent technical hurdle, manifesting as gradual, unpredictable changes in sensor output despite constant analyte concentrations. This phenomenon necessitates frequent recalibration, which is impractical for many applications, particularly implantable medical devices or remote environmental monitoring systems.

Encapsulation technologies currently employed face limitations in providing comprehensive protection while maintaining sensor functionality. Traditional rigid encapsulants offer excellent barrier properties but often impede diffusion-dependent sensing mechanisms. Conversely, permeable materials allow necessary diffusion but provide insufficient protection against environmental factors.

Hydrogel-based encapsulation has emerged as a promising approach but faces its own set of challenges. Current hydrogel formulations struggle with mechanical stability, experiencing significant swelling/deswelling cycles that affect sensor performance. Many hydrogels also demonstrate inadequate adhesion to sensor surfaces, creating potential failure points where environmental factors can penetrate.

The biocompatibility of encapsulation materials remains problematic, particularly for medical applications where foreign body responses can trigger inflammation, fibrosis, and sensor isolation. Additionally, achieving consistent mass transport properties through hydrogel matrices presents significant engineering challenges, as variations in diffusion rates directly impact sensor response times and accuracy.

Power management for encapsulated sensors represents another critical challenge, as encapsulation materials can impede wireless power transfer and increase energy requirements. This is particularly problematic for implantable sensors where battery replacement is invasive and costly.

Manufacturing scalability also limits widespread adoption, with current hydrogel encapsulation techniques often requiring complex, multi-step processes that are difficult to standardize and scale for commercial production. The integration of hydrogels with existing sensor fabrication processes presents compatibility issues that have yet to be fully resolved.

Existing Hydrogel Encapsulation Solutions

01 Hydrogel composition for enhanced stability

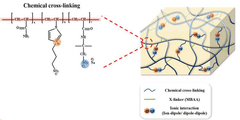

Specific hydrogel compositions can be formulated to enhance the stability of encapsulated materials. These compositions may include crosslinking agents, stabilizers, and specific polymer combinations that create a robust matrix structure. The selection of appropriate hydrogel materials and their ratios significantly impacts the long-term stability of the encapsulated compounds, particularly under varying environmental conditions.- Crosslinking methods for hydrogel stability: Various crosslinking methods can be employed to enhance the stability of hydrogel encapsulation systems. Chemical crosslinking using agents such as glutaraldehyde or physical crosslinking through ionic interactions can create more robust hydrogel networks. These methods strengthen the structural integrity of the hydrogel matrix, preventing premature degradation and maintaining the encapsulated materials in a stable environment for extended periods. The crosslinking density can be optimized to balance stability with other desired properties such as controlled release characteristics.

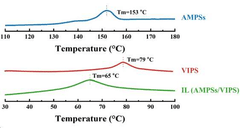

- Temperature-responsive hydrogel formulations: Temperature-responsive hydrogels offer enhanced stability for encapsulation applications through their unique phase transition properties. These smart materials can transition between sol and gel states in response to temperature changes, allowing for easy incorporation of active ingredients at lower temperatures and forming stable gels at physiological temperatures. This property is particularly valuable for maintaining the stability of temperature-sensitive compounds and controlling their release profiles. The thermosensitive nature of these hydrogels also contributes to their mechanical stability under various environmental conditions.

- Polymer composition optimization for stability: The stability of hydrogel encapsulation systems can be significantly improved through optimization of polymer compositions. Blending natural polymers like alginate or chitosan with synthetic polymers such as polyethylene glycol (PEG) or polyvinyl alcohol (PVA) creates hybrid hydrogels with enhanced mechanical properties and degradation resistance. The molecular weight, concentration, and ratio of these polymers can be tailored to achieve desired stability profiles. Additionally, incorporating specific functional groups into the polymer backbone can provide resistance to enzymatic degradation and pH variations, further enhancing the overall stability of the encapsulation system.

- Stabilizing additives for hydrogel encapsulation: Various additives can be incorporated into hydrogel formulations to enhance their stability for encapsulation applications. Antioxidants prevent oxidative degradation of both the hydrogel matrix and encapsulated compounds. Osmotic agents help maintain water balance within the hydrogel structure. pH buffers ensure stability across varying environmental conditions by maintaining optimal pH levels. Additionally, specific ions or molecules can be added to strengthen the hydrogel network through secondary interactions. These stabilizing additives work synergistically to extend shelf life, prevent premature degradation, and maintain the functional integrity of the encapsulation system.

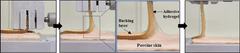

- Surface modification techniques for hydrogel stability: Surface modification of hydrogels can significantly enhance their stability for encapsulation applications. Techniques such as layer-by-layer coating, plasma treatment, or chemical grafting can create protective barriers that prevent water loss, reduce enzymatic degradation, and improve mechanical strength. These modifications can also alter the surface charge or hydrophilicity/hydrophobicity balance, affecting interactions with surrounding environments. Additionally, surface functionalization with specific ligands or biomolecules can provide targeted protection against particular degradation mechanisms, resulting in more stable hydrogel encapsulation systems with improved performance in various applications.

02 Temperature-responsive hydrogel encapsulation systems

Temperature-responsive hydrogels provide controlled release and improved stability of encapsulated compounds. These systems undergo reversible phase transitions in response to temperature changes, allowing for targeted delivery and protection of active ingredients. The temperature sensitivity can be tuned by modifying the polymer composition, enabling customized stability profiles for various applications and environmental conditions.Expand Specific Solutions03 Cross-linking methods for stability enhancement

Various cross-linking methods can be employed to enhance the stability of hydrogel encapsulation systems. Chemical cross-linking using agents like glutaraldehyde or physical cross-linking through ionic interactions can significantly improve the mechanical strength and durability of hydrogels. These techniques create more robust networks that resist degradation and maintain structural integrity over extended periods, thereby improving the protection of encapsulated materials.Expand Specific Solutions04 pH-responsive hydrogel systems for stability control

pH-responsive hydrogels offer controlled stability profiles based on environmental pH changes. These systems can protect encapsulated materials in one pH environment while releasing them in another, providing targeted delivery and enhanced stability. The incorporation of pH-sensitive functional groups allows for customized response profiles, making these systems particularly valuable for applications requiring stability in varying pH conditions.Expand Specific Solutions05 Novel additives for hydrogel encapsulation stability

Incorporating specific additives into hydrogel formulations can significantly enhance encapsulation stability. These additives include antioxidants, preservatives, and specific ions that interact with the hydrogel matrix to improve its structural integrity. Natural compounds such as polyphenols and certain proteins have also shown promise in enhancing the stability of hydrogel encapsulation systems by providing additional protective mechanisms against degradation factors.Expand Specific Solutions

Leading Companies in Hydrogel Sensor Technology

The hydrogel encapsulation for long-term sensor stability market is currently in a growth phase, with increasing adoption across biomedical and industrial applications. The global market size is estimated to reach $3.5-4 billion by 2027, driven by rising demand for continuous monitoring systems in healthcare. Leading companies like Robert Bosch GmbH, Siemens AG, and BASF Corp. are advancing the technology's maturity through significant R&D investments, while specialized firms such as Biolinq, EyeSense AG, and Glucovation are developing innovative applications specifically for biosensors. Academic institutions including MIT and CUHK are contributing fundamental research, creating a competitive landscape where industrial-academic partnerships are accelerating commercialization of more durable and biocompatible hydrogel encapsulation solutions.

BASF Corp.

Technical Solution: BASF has developed an advanced hydrogel encapsulation platform for industrial and environmental sensors based on their expertise in polymer chemistry. Their approach utilizes a proprietary blend of polyurethane-based hydrogels with tailored hydrophilic/hydrophobic balance to optimize both mechanical durability and selective permeability. The hydrogel system incorporates a gradient structure with varying crosslinking densities from core to surface, providing robust mechanical protection while maintaining rapid analyte diffusion. BASF's technology includes chemically bound UV stabilizers and antioxidants distributed throughout the hydrogel matrix to prevent degradation under harsh environmental conditions. For sensors exposed to extreme pH environments, their hydrogels contain buffering agents that maintain a stable microenvironment around the sensing elements. The company has demonstrated sensor stability for over 3 years in industrial process monitoring applications, with minimal drift even in the presence of organic solvents and high salt concentrations. Their manufacturing process allows for precise control of hydrogel thickness and properties, enabling customization for specific sensing applications ranging from water quality monitoring to chemical process control.

Strengths: Exceptional chemical resistance suitable for harsh industrial environments; highly customizable formulations for specific applications; proven long-term stability in field deployments. Weaknesses: Higher cost compared to simpler encapsulation methods; potentially less suitable for biomedical applications due to focus on industrial durability; may have slower response times for certain analytes due to robust barrier properties.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced hydrogel encapsulation systems for biosensors that combine polyethylene glycol (PEG) with alginate networks to create a dual-protection mechanism. Their approach involves creating a semi-interpenetrating polymer network that maintains sensor functionality while providing a robust barrier against biofouling and environmental degradation. The hydrogel matrix is engineered with controlled porosity to allow analyte diffusion while blocking larger proteins and cells. MIT researchers have demonstrated long-term stability of glucose sensors encapsulated in these hydrogels for over 6 months in vivo, maintaining over 90% of initial sensitivity. Their technology incorporates anti-inflammatory agents directly into the hydrogel structure to mitigate foreign body responses, and utilizes photocrosslinking techniques that enable precise control over mechanical properties and degradation rates. The hydrogels are also designed with self-healing capabilities to extend sensor lifetime under mechanical stress conditions.

Strengths: Superior biocompatibility with minimal foreign body response; precise control over mechanical properties through photocrosslinking; demonstrated long-term stability in vivo. Weaknesses: Complex fabrication process requiring specialized equipment; potential challenges in scaling manufacturing; higher cost compared to simpler encapsulation methods.

Key Patents in Hydrogel Sensor Protection

Hydrogel implant for sensing metabolites in body tissue

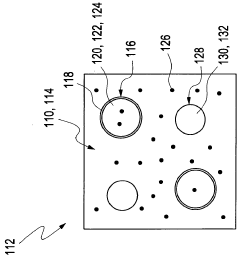

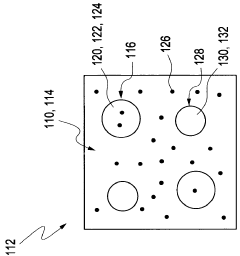

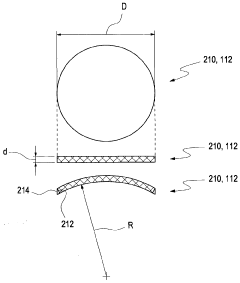

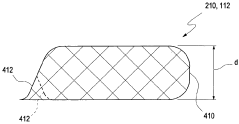

PatentWO2008142158A2

Innovation

- The development of a hydrogel implant with sensor components encapsulated in microparticles or nanoparticles dispersed within a hydrogel matrix, allowing for optimal mechanical strength and sensor activity, where sensor particles are designed to be permeable to analytes and react specifically, and reference components are used to maintain stability and accuracy.

Hydrogel for wearable sensor with strong skin adhesive, conductivity and long-term stability, and method of preparing same

PatentActiveKR1020240073628A

Innovation

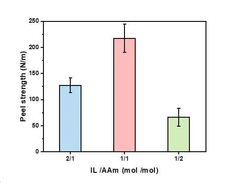

- A hydrogel composition incorporating sulfonic acid groups, imidazole-based compounds, and acrylamide-based compounds, forming a stable network structure through ionic interactions and secondary cross-links, enhancing skin adhesion and conductivity.

Biocompatibility and Safety Considerations

Biocompatibility is a critical consideration for hydrogel encapsulation systems used in long-term implantable sensors. The interface between the hydrogel material and biological tissues must be carefully engineered to minimize foreign body responses that could compromise sensor functionality. Current research indicates that hydrogels composed of natural polymers such as alginate, collagen, and hyaluronic acid demonstrate superior biocompatibility profiles compared to synthetic alternatives. These materials closely mimic the extracellular matrix, reducing immune system recognition and subsequent inflammatory responses.

The inflammatory cascade triggered by implanted sensors represents a significant challenge to long-term stability. When foreign materials contact biological tissues, protein adsorption occurs within minutes, followed by leukocyte recruitment and potential fibrous encapsulation. Hydrogel encapsulation strategies that incorporate anti-inflammatory agents or surface modifications have shown promising results in mitigating these responses. For instance, hydrogels functionalized with anti-inflammatory peptides or loaded with controlled-release anti-inflammatory drugs can significantly extend sensor lifetime in vivo.

Cytotoxicity assessment of hydrogel materials reveals varying degrees of cellular compatibility depending on composition and crosslinking mechanisms. Physical crosslinking methods generally produce more biocompatible hydrogels compared to chemical crosslinking approaches that may leave residual toxic agents. Recent advances in photoinitiated crosslinking systems have improved safety profiles while maintaining mechanical integrity necessary for sensor protection.

Degradation byproducts present another safety consideration for long-term implanted hydrogel-encapsulated sensors. Ideal hydrogel systems should either remain stable throughout the sensor lifetime or degrade into non-toxic metabolites that can be safely eliminated through natural physiological processes. Synthetic hydrogels based on poly(ethylene glycol) derivatives offer tunable degradation profiles, while natural polymer-based hydrogels may exhibit less predictable breakdown patterns influenced by host enzymatic activity.

Regulatory considerations for hydrogel-encapsulated sensors have become increasingly stringent, requiring comprehensive biocompatibility testing according to ISO 10993 standards. This includes evaluation of genotoxicity, carcinogenicity, and systemic toxicity beyond basic cytotoxicity assessments. The FDA has recently emphasized the need for long-term biocompatibility data for implantable sensors, particularly those intended to function for periods exceeding 30 days.

Sterilization compatibility represents another critical safety consideration, as hydrogels must maintain their structural and functional properties following sterilization processes. Gamma irradiation, ethylene oxide treatment, and autoclave sterilization can significantly alter hydrogel properties, potentially compromising both biocompatibility and sensor performance. Recent innovations in supercritical CO2 sterilization offer promising alternatives that preserve hydrogel integrity while ensuring sterility.

The inflammatory cascade triggered by implanted sensors represents a significant challenge to long-term stability. When foreign materials contact biological tissues, protein adsorption occurs within minutes, followed by leukocyte recruitment and potential fibrous encapsulation. Hydrogel encapsulation strategies that incorporate anti-inflammatory agents or surface modifications have shown promising results in mitigating these responses. For instance, hydrogels functionalized with anti-inflammatory peptides or loaded with controlled-release anti-inflammatory drugs can significantly extend sensor lifetime in vivo.

Cytotoxicity assessment of hydrogel materials reveals varying degrees of cellular compatibility depending on composition and crosslinking mechanisms. Physical crosslinking methods generally produce more biocompatible hydrogels compared to chemical crosslinking approaches that may leave residual toxic agents. Recent advances in photoinitiated crosslinking systems have improved safety profiles while maintaining mechanical integrity necessary for sensor protection.

Degradation byproducts present another safety consideration for long-term implanted hydrogel-encapsulated sensors. Ideal hydrogel systems should either remain stable throughout the sensor lifetime or degrade into non-toxic metabolites that can be safely eliminated through natural physiological processes. Synthetic hydrogels based on poly(ethylene glycol) derivatives offer tunable degradation profiles, while natural polymer-based hydrogels may exhibit less predictable breakdown patterns influenced by host enzymatic activity.

Regulatory considerations for hydrogel-encapsulated sensors have become increasingly stringent, requiring comprehensive biocompatibility testing according to ISO 10993 standards. This includes evaluation of genotoxicity, carcinogenicity, and systemic toxicity beyond basic cytotoxicity assessments. The FDA has recently emphasized the need for long-term biocompatibility data for implantable sensors, particularly those intended to function for periods exceeding 30 days.

Sterilization compatibility represents another critical safety consideration, as hydrogels must maintain their structural and functional properties following sterilization processes. Gamma irradiation, ethylene oxide treatment, and autoclave sterilization can significantly alter hydrogel properties, potentially compromising both biocompatibility and sensor performance. Recent innovations in supercritical CO2 sterilization offer promising alternatives that preserve hydrogel integrity while ensuring sterility.

Environmental Impact of Hydrogel Materials

The environmental impact of hydrogel materials used in sensor encapsulation represents a critical consideration in the sustainable development of long-term sensing technologies. Hydrogels, while offering exceptional properties for sensor protection, introduce various environmental concerns throughout their lifecycle. The biodegradability of hydrogels varies significantly depending on their composition, with naturally derived hydrogels such as alginate and chitosan demonstrating superior environmental profiles compared to synthetic alternatives like polyacrylamide or polyvinyl alcohol.

Manufacturing processes for hydrogels often involve chemical crosslinking agents and solvents that may pose environmental hazards if improperly managed. The energy consumption during production, particularly for synthetic hydrogels requiring complex polymerization reactions, contributes to their overall carbon footprint. However, recent advancements in green chemistry approaches have yielded more environmentally friendly synthesis methods, including enzyme-mediated crosslinking and aqueous-based processing techniques.

Disposal considerations for hydrogel-encapsulated sensors present significant challenges. Non-biodegradable hydrogels may persist in the environment for extended periods, potentially contributing to microplastic pollution when degraded. The composite nature of encapsulated sensors complicates recycling efforts, as separation of the hydrogel component from electronic elements often proves technically difficult and economically unfeasible.

Water consumption represents another environmental concern, as hydrogels inherently require substantial water resources during manufacturing. This aspect becomes particularly relevant in water-stressed regions where sensor deployment may be critical for environmental monitoring applications. Additionally, the leaching potential of unreacted monomers, crosslinking agents, or degradation products from certain hydrogels raises concerns about water and soil contamination.

Recent research has focused on developing eco-friendly alternatives, including fully biodegradable hydrogels derived from agricultural waste products. These materials offer promising pathways toward reducing environmental impact while maintaining the protective properties required for sensor stability. Innovations in this space include cellulose-based hydrogels and those derived from food industry byproducts, which demonstrate reduced environmental footprints while offering comparable performance characteristics.

Life cycle assessment (LCA) studies comparing different hydrogel formulations have revealed that material selection significantly influences overall environmental impact. These assessments consider factors including raw material sourcing, manufacturing energy requirements, transportation, use-phase durability, and end-of-life scenarios. Such comprehensive evaluations provide valuable guidance for researchers and manufacturers seeking to optimize both sensor performance and environmental sustainability.

Manufacturing processes for hydrogels often involve chemical crosslinking agents and solvents that may pose environmental hazards if improperly managed. The energy consumption during production, particularly for synthetic hydrogels requiring complex polymerization reactions, contributes to their overall carbon footprint. However, recent advancements in green chemistry approaches have yielded more environmentally friendly synthesis methods, including enzyme-mediated crosslinking and aqueous-based processing techniques.

Disposal considerations for hydrogel-encapsulated sensors present significant challenges. Non-biodegradable hydrogels may persist in the environment for extended periods, potentially contributing to microplastic pollution when degraded. The composite nature of encapsulated sensors complicates recycling efforts, as separation of the hydrogel component from electronic elements often proves technically difficult and economically unfeasible.

Water consumption represents another environmental concern, as hydrogels inherently require substantial water resources during manufacturing. This aspect becomes particularly relevant in water-stressed regions where sensor deployment may be critical for environmental monitoring applications. Additionally, the leaching potential of unreacted monomers, crosslinking agents, or degradation products from certain hydrogels raises concerns about water and soil contamination.

Recent research has focused on developing eco-friendly alternatives, including fully biodegradable hydrogels derived from agricultural waste products. These materials offer promising pathways toward reducing environmental impact while maintaining the protective properties required for sensor stability. Innovations in this space include cellulose-based hydrogels and those derived from food industry byproducts, which demonstrate reduced environmental footprints while offering comparable performance characteristics.

Life cycle assessment (LCA) studies comparing different hydrogel formulations have revealed that material selection significantly influences overall environmental impact. These assessments consider factors including raw material sourcing, manufacturing energy requirements, transportation, use-phase durability, and end-of-life scenarios. Such comprehensive evaluations provide valuable guidance for researchers and manufacturers seeking to optimize both sensor performance and environmental sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!