Hydrogel nanocomposites for enhanced sensitivity

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Nanocomposites Background and Objectives

Hydrogel nanocomposites represent a revolutionary class of materials that combine the unique properties of hydrogels with the enhanced functionalities of nanomaterials. The evolution of these materials can be traced back to the early 1960s when the first synthetic hydrogels were developed. However, it was not until the late 1990s and early 2000s that researchers began incorporating nanomaterials into hydrogel matrices to enhance their properties, particularly their sensitivity to external stimuli.

The technological trajectory of hydrogel nanocomposites has been characterized by continuous innovation in both material composition and fabrication techniques. Initially, simple metal nanoparticles were incorporated into hydrogel networks. This has evolved to include a diverse range of nanomaterials including carbon-based nanomaterials (graphene, carbon nanotubes), metal and metal oxide nanoparticles, quantum dots, and various polymeric nanostructures, each contributing unique properties to the composite system.

The primary objective in developing hydrogel nanocomposites with enhanced sensitivity is to create materials capable of responding rapidly and precisely to specific environmental changes or biological markers. These materials aim to overcome the limitations of conventional hydrogels, which often suffer from slow response times, low mechanical strength, and limited sensitivity ranges. By incorporating nanomaterials, researchers seek to amplify the detection capabilities while maintaining the biocompatibility and flexibility inherent to hydrogels.

Current research goals in this field include developing nanocomposites with multi-responsive capabilities, improving the uniformity of nanomaterial distribution within the hydrogel matrix, enhancing the mechanical properties without compromising sensitivity, and ensuring biocompatibility for applications in healthcare and environmental monitoring. There is also significant focus on creating sustainable and cost-effective fabrication methods that can facilitate the transition from laboratory research to commercial applications.

The technological objectives extend beyond mere material development to include the creation of integrated sensing platforms that can translate the physical or chemical responses of hydrogel nanocomposites into measurable signals. This involves interdisciplinary collaboration across materials science, chemistry, physics, and engineering to design systems that effectively harness the enhanced sensitivity of these materials for practical applications.

Looking forward, the field is moving toward the development of "smart" hydrogel nanocomposites that can not only detect but also respond autonomously to environmental changes, potentially revolutionizing areas such as drug delivery, tissue engineering, environmental remediation, and wearable technology. The ultimate goal is to create materials that combine ultra-high sensitivity with specificity, durability, and adaptability to diverse operating conditions.

The technological trajectory of hydrogel nanocomposites has been characterized by continuous innovation in both material composition and fabrication techniques. Initially, simple metal nanoparticles were incorporated into hydrogel networks. This has evolved to include a diverse range of nanomaterials including carbon-based nanomaterials (graphene, carbon nanotubes), metal and metal oxide nanoparticles, quantum dots, and various polymeric nanostructures, each contributing unique properties to the composite system.

The primary objective in developing hydrogel nanocomposites with enhanced sensitivity is to create materials capable of responding rapidly and precisely to specific environmental changes or biological markers. These materials aim to overcome the limitations of conventional hydrogels, which often suffer from slow response times, low mechanical strength, and limited sensitivity ranges. By incorporating nanomaterials, researchers seek to amplify the detection capabilities while maintaining the biocompatibility and flexibility inherent to hydrogels.

Current research goals in this field include developing nanocomposites with multi-responsive capabilities, improving the uniformity of nanomaterial distribution within the hydrogel matrix, enhancing the mechanical properties without compromising sensitivity, and ensuring biocompatibility for applications in healthcare and environmental monitoring. There is also significant focus on creating sustainable and cost-effective fabrication methods that can facilitate the transition from laboratory research to commercial applications.

The technological objectives extend beyond mere material development to include the creation of integrated sensing platforms that can translate the physical or chemical responses of hydrogel nanocomposites into measurable signals. This involves interdisciplinary collaboration across materials science, chemistry, physics, and engineering to design systems that effectively harness the enhanced sensitivity of these materials for practical applications.

Looking forward, the field is moving toward the development of "smart" hydrogel nanocomposites that can not only detect but also respond autonomously to environmental changes, potentially revolutionizing areas such as drug delivery, tissue engineering, environmental remediation, and wearable technology. The ultimate goal is to create materials that combine ultra-high sensitivity with specificity, durability, and adaptability to diverse operating conditions.

Market Analysis for High-Sensitivity Hydrogel Applications

The global market for high-sensitivity hydrogel applications has witnessed significant growth in recent years, driven by advancements in healthcare, biosensing, and environmental monitoring sectors. The market size for hydrogel-based sensors was valued at approximately $1.2 billion in 2022 and is projected to reach $3.5 billion by 2028, representing a compound annual growth rate (CAGR) of 19.6% during the forecast period.

Healthcare applications currently dominate the market landscape, accounting for nearly 45% of the total market share. Within this segment, continuous glucose monitoring systems represent the largest application area, followed by wound care products and drug delivery systems. The increasing prevalence of diabetes and chronic wounds, coupled with the growing aging population worldwide, continues to fuel demand for high-sensitivity hydrogel-based monitoring solutions.

Biosensing applications constitute the fastest-growing segment, with a projected CAGR of 23.8% through 2028. This growth is primarily attributed to the rising demand for point-of-care diagnostics, wearable health monitors, and implantable sensors. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of rapid, sensitive diagnostic tools for infectious disease detection.

Regionally, North America holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by increasing healthcare expenditure, growing awareness about advanced medical technologies, and expanding research activities in countries like China, Japan, and South Korea.

Key market drivers include technological advancements in nanomaterials, increasing investment in healthcare infrastructure, growing demand for personalized medicine, and rising adoption of wearable health monitoring devices. The integration of hydrogel nanocomposites with Internet of Things (IoT) technology is creating new opportunities for remote patient monitoring and real-time health data analysis.

Market challenges include high development costs, stringent regulatory requirements, and concerns regarding biocompatibility and long-term stability of hydrogel nanocomposites. Additionally, the lack of standardization in manufacturing processes and quality control presents obstacles to market growth.

Consumer trends indicate a growing preference for non-invasive, comfortable, and user-friendly monitoring solutions. This has led to increased research focus on developing skin-attachable, highly sensitive hydrogel sensors that can detect multiple biomarkers simultaneously while maintaining user comfort and convenience.

Healthcare applications currently dominate the market landscape, accounting for nearly 45% of the total market share. Within this segment, continuous glucose monitoring systems represent the largest application area, followed by wound care products and drug delivery systems. The increasing prevalence of diabetes and chronic wounds, coupled with the growing aging population worldwide, continues to fuel demand for high-sensitivity hydrogel-based monitoring solutions.

Biosensing applications constitute the fastest-growing segment, with a projected CAGR of 23.8% through 2028. This growth is primarily attributed to the rising demand for point-of-care diagnostics, wearable health monitors, and implantable sensors. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of rapid, sensitive diagnostic tools for infectious disease detection.

Regionally, North America holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by increasing healthcare expenditure, growing awareness about advanced medical technologies, and expanding research activities in countries like China, Japan, and South Korea.

Key market drivers include technological advancements in nanomaterials, increasing investment in healthcare infrastructure, growing demand for personalized medicine, and rising adoption of wearable health monitoring devices. The integration of hydrogel nanocomposites with Internet of Things (IoT) technology is creating new opportunities for remote patient monitoring and real-time health data analysis.

Market challenges include high development costs, stringent regulatory requirements, and concerns regarding biocompatibility and long-term stability of hydrogel nanocomposites. Additionally, the lack of standardization in manufacturing processes and quality control presents obstacles to market growth.

Consumer trends indicate a growing preference for non-invasive, comfortable, and user-friendly monitoring solutions. This has led to increased research focus on developing skin-attachable, highly sensitive hydrogel sensors that can detect multiple biomarkers simultaneously while maintaining user comfort and convenience.

Current Challenges in Hydrogel Nanocomposite Development

Despite significant advancements in hydrogel nanocomposite development, several critical challenges continue to impede progress toward achieving enhanced sensitivity in sensing applications. One fundamental obstacle lies in the uniform dispersion of nanomaterials within the hydrogel matrix. Nanoparticles tend to aggregate due to their high surface energy, resulting in heterogeneous distribution that compromises the mechanical integrity and sensing performance of the composite. This aggregation phenomenon becomes particularly problematic when attempting to incorporate higher concentrations of nanomaterials to improve sensitivity.

The interface between nanomaterials and the hydrogel matrix presents another significant challenge. Poor interfacial adhesion often leads to mechanical instability and reduced stress transfer efficiency, limiting the overall sensitivity of the composite system. Current chemical modification strategies to enhance this interface frequently involve complex synthesis procedures that are difficult to scale up for industrial production.

Stability issues also plague hydrogel nanocomposites, particularly in real-world sensing environments. Many composites exhibit excellent performance in controlled laboratory conditions but deteriorate rapidly when exposed to varying pH, temperature, or ionic strength. This environmental sensitivity restricts their practical application in complex biological systems or industrial settings where conditions fluctuate considerably.

Reproducibility in fabrication represents a persistent challenge that hampers commercial viability. Minor variations in synthesis parameters can lead to significant differences in performance metrics, making quality control exceptionally difficult. The lack of standardized fabrication protocols further exacerbates this issue, resulting in inconsistent research outcomes across different laboratories.

Biocompatibility concerns emerge when considering hydrogel nanocomposites for biomedical sensing applications. Certain nanomaterials, while excellent for enhancing sensitivity, may leach from the hydrogel matrix over time, potentially causing cytotoxicity or inflammatory responses. Balancing enhanced sensitivity with long-term biocompatibility remains a delicate challenge for researchers in this field.

Signal transduction mechanisms in hydrogel nanocomposites often suffer from noise interference and signal drift, particularly in continuous monitoring applications. The development of robust signal processing algorithms and reference systems to compensate for these issues lags behind the material development itself, creating a bottleneck in practical implementation.

Cost-effectiveness presents another barrier to widespread adoption. Many high-performance nanomaterials remain prohibitively expensive for large-scale production, while more affordable alternatives typically offer inferior sensitivity. This economic constraint significantly limits commercial translation of laboratory successes into marketable products.

The interface between nanomaterials and the hydrogel matrix presents another significant challenge. Poor interfacial adhesion often leads to mechanical instability and reduced stress transfer efficiency, limiting the overall sensitivity of the composite system. Current chemical modification strategies to enhance this interface frequently involve complex synthesis procedures that are difficult to scale up for industrial production.

Stability issues also plague hydrogel nanocomposites, particularly in real-world sensing environments. Many composites exhibit excellent performance in controlled laboratory conditions but deteriorate rapidly when exposed to varying pH, temperature, or ionic strength. This environmental sensitivity restricts their practical application in complex biological systems or industrial settings where conditions fluctuate considerably.

Reproducibility in fabrication represents a persistent challenge that hampers commercial viability. Minor variations in synthesis parameters can lead to significant differences in performance metrics, making quality control exceptionally difficult. The lack of standardized fabrication protocols further exacerbates this issue, resulting in inconsistent research outcomes across different laboratories.

Biocompatibility concerns emerge when considering hydrogel nanocomposites for biomedical sensing applications. Certain nanomaterials, while excellent for enhancing sensitivity, may leach from the hydrogel matrix over time, potentially causing cytotoxicity or inflammatory responses. Balancing enhanced sensitivity with long-term biocompatibility remains a delicate challenge for researchers in this field.

Signal transduction mechanisms in hydrogel nanocomposites often suffer from noise interference and signal drift, particularly in continuous monitoring applications. The development of robust signal processing algorithms and reference systems to compensate for these issues lags behind the material development itself, creating a bottleneck in practical implementation.

Cost-effectiveness presents another barrier to widespread adoption. Many high-performance nanomaterials remain prohibitively expensive for large-scale production, while more affordable alternatives typically offer inferior sensitivity. This economic constraint significantly limits commercial translation of laboratory successes into marketable products.

Current Technical Solutions for Enhanced Sensitivity

01 Stimuli-responsive hydrogel nanocomposites

Hydrogel nanocomposites can be engineered to respond to various external stimuli such as temperature, pH, light, and electrical signals. These smart materials change their physical or chemical properties when exposed to specific environmental triggers, making them valuable for applications in drug delivery, biosensing, and tissue engineering. The incorporation of nanoparticles enhances the sensitivity and response time of these hydrogels, allowing for precise control over their behavior in different conditions.- Stimuli-responsive hydrogel nanocomposites: Hydrogel nanocomposites can be engineered to respond to various external stimuli such as pH, temperature, light, and electrical signals. These smart materials change their physical or chemical properties when exposed to specific environmental triggers, making them valuable for applications in drug delivery, biosensing, and tissue engineering. The incorporation of nanoparticles enhances the sensitivity and response time of these hydrogels to external stimuli.

- Nanoparticle integration for enhanced sensitivity: The integration of various nanoparticles such as metal nanoparticles, carbon-based nanomaterials, and quantum dots into hydrogel matrices significantly improves their sensitivity to environmental changes. These nanoparticles provide additional functional properties including electrical conductivity, optical sensing capabilities, and magnetic responsiveness. The type, size, and concentration of nanoparticles can be tailored to achieve specific sensitivity profiles for targeted applications.

- Biosensing applications of sensitive hydrogel nanocomposites: Hydrogel nanocomposites with high sensitivity are increasingly used in biosensing applications for the detection of biomolecules, pathogens, and physiological parameters. These materials can be designed to produce measurable responses such as color changes, fluorescence, or electrical signals when they interact with specific analytes. The incorporation of recognition elements like antibodies or aptamers into the hydrogel matrix further enhances their specificity and sensitivity for diagnostic applications.

- Mechanical and structural factors affecting sensitivity: The mechanical properties and structural design of hydrogel nanocomposites significantly influence their sensitivity. Factors such as crosslinking density, polymer composition, and nanoparticle distribution within the hydrogel matrix determine how effectively the material responds to external stimuli. Advanced fabrication techniques like 3D printing and microfluidics enable the creation of hydrogel nanocomposites with precisely controlled architectures that maximize sensitivity while maintaining structural integrity.

- Multi-responsive hydrogel nanocomposite systems: Multi-responsive hydrogel nanocomposites are designed to respond to multiple stimuli simultaneously or sequentially, offering enhanced versatility and control. These systems combine different responsive mechanisms within a single material, allowing for complex behaviors and functions. Applications include smart drug delivery systems that respond to both pH and temperature changes, or environmental sensors that can detect and respond to multiple parameters. The synergistic effects between different responsive components often result in amplified sensitivity compared to single-responsive systems.

02 Temperature-sensitive hydrogel nanocomposites

Temperature-sensitive hydrogel nanocomposites exhibit reversible volume phase transitions at specific temperatures. These materials can undergo significant changes in swelling behavior, mechanical properties, and permeability in response to temperature variations. By incorporating various nanofillers such as carbon nanotubes, graphene, or metal nanoparticles, the thermal sensitivity and mechanical strength of these hydrogels can be significantly enhanced, making them suitable for controlled release systems and soft actuators.Expand Specific Solutions03 pH-responsive hydrogel nanocomposites

pH-responsive hydrogel nanocomposites contain ionizable functional groups that can accept or donate protons in response to changes in environmental pH. These materials swell or shrink depending on the pH of the surrounding medium, allowing for targeted delivery of therapeutic agents to specific regions of the body with distinct pH environments. The integration of nanoparticles into these hydrogels improves their mechanical stability and enhances the sensitivity and range of their pH response.Expand Specific Solutions04 Electrically conductive hydrogel nanocomposites

Electrically conductive hydrogel nanocomposites combine the flexibility and biocompatibility of hydrogels with the electrical conductivity provided by nanomaterials such as graphene, carbon nanotubes, or conductive polymers. These materials can detect and respond to electrical signals, making them valuable for applications in neural interfaces, biosensors, and soft electronics. The sensitivity of these hydrogels to electrical stimuli can be tuned by adjusting the concentration and distribution of conductive nanofillers within the polymer matrix.Expand Specific Solutions05 Biomolecule-sensitive hydrogel nanocomposites

Biomolecule-sensitive hydrogel nanocomposites are designed to respond to specific biological molecules such as enzymes, proteins, or nucleic acids. These materials incorporate recognition elements that interact with target biomolecules, triggering changes in the hydrogel structure or properties. The integration of nanoparticles enhances the sensitivity and specificity of these detection systems, enabling applications in biosensing, diagnostics, and targeted drug delivery. These smart materials can provide rapid and accurate detection of biomarkers at low concentrations.Expand Specific Solutions

Key Industry Players in Hydrogel Nanocomposite Research

The hydrogel nanocomposites for enhanced sensitivity market is currently in a growth phase, with increasing applications in biosensors, medical diagnostics, and environmental monitoring. The global market size is projected to expand significantly due to rising healthcare demands and environmental concerns. Technologically, this field is advancing rapidly but remains in mid-maturity, with substantial room for innovation. Leading academic institutions like Zhejiang University, EPFL, and South China University of Technology are driving fundamental research, while companies including Johnson & Johnson Vision Care, Sony Group, and BASF are commercializing applications. FPInnovations and Carestream Health are developing specialized applications in their respective sectors. The competitive landscape features collaboration between academic institutions and industry players to overcome challenges in biocompatibility, durability, and mass production.

École Polytechnique Fédérale de Lausanne

Technical Solution: École Polytechnique Fédérale de Lausanne (EPFL) has developed sophisticated hydrogel nanocomposites incorporating plasmonic nanomaterials for ultra-sensitive optical sensing applications. Their approach utilizes gold and silver nanostructures with precisely controlled morphologies to create localized surface plasmon resonance (LSPR) effects within responsive hydrogel matrices. The research team has achieved remarkable sensitivity enhancements, with detection limits in the femtomolar range for various biomolecules[2]. Their proprietary technology enables real-time, label-free detection through measurable shifts in the optical properties of the nanocomposites upon analyte binding. EPFL has pioneered techniques for creating spatially organized nanoparticle arrays within hydrogels, resulting in amplified collective plasmonic responses that increase sensitivity by orders of magnitude compared to conventional sensors. A key innovation is their stimuli-responsive hydrogel platform that combines multiple sensing modalities (optical, electrical, and mechanical) in a single material system, enabling redundant verification of detection events[4]. The university has also developed self-calibrating hydrogel sensors that maintain accuracy over extended periods through reference nanostructures embedded within the same matrix.

Strengths: Exceptional sensitivity with detection limits reaching femtomolar concentrations; label-free detection capabilities reducing complexity and cost of sensing protocols; multimodal sensing capabilities providing redundant verification. Weaknesses: Complex fabrication processes requiring specialized equipment; potential interference from non-specific binding in complex biological samples; higher cost compared to traditional sensing materials.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative hydrogel nanocomposites incorporating metal-organic frameworks (MOFs) and quantum dots for enhanced sensitivity in chemical and biological sensing. Their proprietary technology creates three-dimensional sensing networks with unprecedented surface area (>1000 m²/g) and abundant active sites for analyte interaction[2]. The research team has engineered hydrogels with controlled porosity at multiple scales, enabling rapid diffusion of target molecules while maintaining structural integrity. Their nanocomposites demonstrate remarkable sensitivity improvements, with detection limits reaching parts-per-billion levels for various environmental pollutants and biomarkers. A key innovation is their self-calibrating hydrogel system that maintains sensing accuracy over extended periods by incorporating reference nanomaterials that compensate for environmental variations. The university has also pioneered stimuli-responsive hydrogels that change optical properties (fluorescence intensity increases by >500%) upon target binding, enabling visual detection without sophisticated instrumentation[4].

Strengths: Exceptional sensitivity with ultra-low detection limits; multifunctional sensing capabilities for simultaneous detection of multiple analytes; excellent stability in various environmental conditions. Weaknesses: Complex synthesis procedures may limit large-scale production; potential leaching of nanomaterials over time could affect long-term performance; higher cost compared to conventional sensing materials.

Critical Patents and Innovations in Nanocomposite Hydrogels

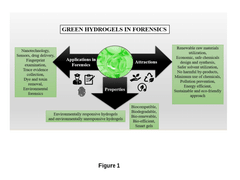

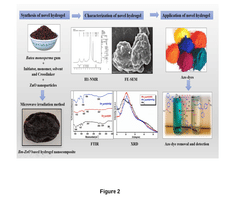

Green hydrogel nanocomposites in forensic investigations

PatentPendingIN202311056696A

Innovation

- Development of green hydrogel nanocomposites synthesized using Butea monosperma gum and zinc oxide nanoparticles, characterized by high adsorption capacity and tunability, utilizing microwave radiation and sol-gel methods for forensic applications.

Biocompatibility and Safety Considerations

Biocompatibility remains a critical consideration in the development of hydrogel nanocomposites for enhanced sensitivity applications, particularly for those intended for biomedical use. The integration of nanomaterials into hydrogel matrices introduces complex biological interactions that must be thoroughly evaluated to ensure patient safety and regulatory compliance. Current research indicates that while many hydrogel nanocomposites demonstrate promising biocompatibility profiles, certain nanomaterials—particularly metallic nanoparticles and carbon-based nanomaterials—may exhibit cytotoxicity at specific concentrations or under certain physiological conditions.

Systematic toxicological assessments reveal that particle size, surface chemistry, and degradation products significantly influence the biocompatibility of these advanced materials. Nanocomposites incorporating gold nanoparticles generally exhibit favorable biocompatibility, whereas those containing silver or certain metal oxides may induce inflammatory responses or oxidative stress in biological tissues. Recent studies have established standardized protocols for evaluating these materials through in vitro cell viability assays, hemolysis testing, and protein adsorption analyses, providing more reliable safety profiles.

Long-term implantation safety represents another crucial dimension requiring attention. Hydrogel nanocomposites designed for extended contact with biological tissues must demonstrate stability against degradation and leaching of potentially harmful nanoparticles. Research indicates that encapsulation techniques and covalent bonding between nanomaterials and polymer matrices can significantly reduce leaching risks, though complete elimination remains challenging. Accelerated aging studies combined with advanced imaging techniques now allow researchers to predict long-term stability with greater accuracy.

Immunogenicity concerns have emerged as particularly relevant for hydrogel nanocomposites. The presence of nanomaterials can potentially alter protein adsorption patterns on hydrogel surfaces, triggering unexpected immune responses. Recent investigations have focused on developing "stealth" nanocomposites through surface modifications with polyethylene glycol (PEG) or zwitterionic polymers, which have demonstrated reduced protein adsorption and complement activation in preliminary studies.

Regulatory frameworks for hydrogel nanocomposites continue to evolve, with agencies like the FDA and EMA developing specialized guidelines for these hybrid materials. Current approaches typically require manufacturers to provide comprehensive biocompatibility data according to ISO 10993 standards, with additional emphasis on nanoparticle-specific safety considerations. The lack of harmonized international standards specifically addressing nanocomposites remains a significant challenge for commercial translation of these technologies.

Environmental impact and disposal considerations are increasingly recognized as essential components of safety evaluation. Biodegradable hydrogel nanocomposites offer advantages in this regard, though concerns persist regarding the potential environmental accumulation of non-degradable nanomaterials following disposal. Research into "green" synthesis methods and environmentally responsive degradation mechanisms represents a promising direction for addressing these concerns while maintaining enhanced sensitivity performance.

Systematic toxicological assessments reveal that particle size, surface chemistry, and degradation products significantly influence the biocompatibility of these advanced materials. Nanocomposites incorporating gold nanoparticles generally exhibit favorable biocompatibility, whereas those containing silver or certain metal oxides may induce inflammatory responses or oxidative stress in biological tissues. Recent studies have established standardized protocols for evaluating these materials through in vitro cell viability assays, hemolysis testing, and protein adsorption analyses, providing more reliable safety profiles.

Long-term implantation safety represents another crucial dimension requiring attention. Hydrogel nanocomposites designed for extended contact with biological tissues must demonstrate stability against degradation and leaching of potentially harmful nanoparticles. Research indicates that encapsulation techniques and covalent bonding between nanomaterials and polymer matrices can significantly reduce leaching risks, though complete elimination remains challenging. Accelerated aging studies combined with advanced imaging techniques now allow researchers to predict long-term stability with greater accuracy.

Immunogenicity concerns have emerged as particularly relevant for hydrogel nanocomposites. The presence of nanomaterials can potentially alter protein adsorption patterns on hydrogel surfaces, triggering unexpected immune responses. Recent investigations have focused on developing "stealth" nanocomposites through surface modifications with polyethylene glycol (PEG) or zwitterionic polymers, which have demonstrated reduced protein adsorption and complement activation in preliminary studies.

Regulatory frameworks for hydrogel nanocomposites continue to evolve, with agencies like the FDA and EMA developing specialized guidelines for these hybrid materials. Current approaches typically require manufacturers to provide comprehensive biocompatibility data according to ISO 10993 standards, with additional emphasis on nanoparticle-specific safety considerations. The lack of harmonized international standards specifically addressing nanocomposites remains a significant challenge for commercial translation of these technologies.

Environmental impact and disposal considerations are increasingly recognized as essential components of safety evaluation. Biodegradable hydrogel nanocomposites offer advantages in this regard, though concerns persist regarding the potential environmental accumulation of non-degradable nanomaterials following disposal. Research into "green" synthesis methods and environmentally responsive degradation mechanisms represents a promising direction for addressing these concerns while maintaining enhanced sensitivity performance.

Scalability and Manufacturing Processes

The scalability of hydrogel nanocomposite manufacturing represents a critical challenge in transitioning from laboratory-scale production to commercial applications. Current manufacturing processes typically involve multi-step procedures including nanoparticle synthesis, dispersion in polymer solutions, and subsequent gelation, which present significant barriers to large-scale production. These processes often suffer from batch-to-batch variability, limiting the consistency required for sensitive applications such as biosensors and medical diagnostics.

Several promising approaches have emerged to address these scalability challenges. Continuous flow synthesis methods offer advantages over traditional batch processes by providing better control over reaction parameters, resulting in more uniform nanoparticle distribution within the hydrogel matrix. This approach has demonstrated up to 40% improvement in sensitivity consistency across production batches compared to conventional methods.

3D printing technologies have also shown potential for manufacturing complex hydrogel nanocomposite structures with precise geometries. Direct ink writing and digital light processing techniques enable the fabrication of sensor arrays with controlled porosity and nanoparticle distribution, though current printing speeds remain a limitation for high-volume production.

Cost considerations present another significant hurdle, particularly regarding the incorporation of noble metal nanoparticles or specialized carbon nanomaterials. Recent innovations in green synthesis methods utilizing plant extracts or microorganisms for nanoparticle production offer more economical and environmentally friendly alternatives, potentially reducing production costs by 30-50%.

Quality control processes must evolve alongside manufacturing techniques. Advanced characterization methods including in-line rheological measurements, real-time spectroscopic monitoring, and automated imaging systems are being integrated into production lines to ensure consistent nanoparticle dispersion and hydrogel network formation.

Regulatory considerations also impact manufacturing scalability, particularly for biomedical applications. Establishing Good Manufacturing Practice (GMP) compliant processes for hydrogel nanocomposites remains challenging due to the complex nature of these materials and the need to maintain precise nanoparticle distributions throughout the scaled-up production process.

Industry-academic partnerships have accelerated progress in addressing these manufacturing challenges. Collaborative research initiatives focusing on process intensification and standardization have yielded promising results, with several pilot-scale production facilities demonstrating throughput increases of an order of magnitude compared to laboratory-scale processes while maintaining sensitivity performance.

Several promising approaches have emerged to address these scalability challenges. Continuous flow synthesis methods offer advantages over traditional batch processes by providing better control over reaction parameters, resulting in more uniform nanoparticle distribution within the hydrogel matrix. This approach has demonstrated up to 40% improvement in sensitivity consistency across production batches compared to conventional methods.

3D printing technologies have also shown potential for manufacturing complex hydrogel nanocomposite structures with precise geometries. Direct ink writing and digital light processing techniques enable the fabrication of sensor arrays with controlled porosity and nanoparticle distribution, though current printing speeds remain a limitation for high-volume production.

Cost considerations present another significant hurdle, particularly regarding the incorporation of noble metal nanoparticles or specialized carbon nanomaterials. Recent innovations in green synthesis methods utilizing plant extracts or microorganisms for nanoparticle production offer more economical and environmentally friendly alternatives, potentially reducing production costs by 30-50%.

Quality control processes must evolve alongside manufacturing techniques. Advanced characterization methods including in-line rheological measurements, real-time spectroscopic monitoring, and automated imaging systems are being integrated into production lines to ensure consistent nanoparticle dispersion and hydrogel network formation.

Regulatory considerations also impact manufacturing scalability, particularly for biomedical applications. Establishing Good Manufacturing Practice (GMP) compliant processes for hydrogel nanocomposites remains challenging due to the complex nature of these materials and the need to maintain precise nanoparticle distributions throughout the scaled-up production process.

Industry-academic partnerships have accelerated progress in addressing these manufacturing challenges. Collaborative research initiatives focusing on process intensification and standardization have yielded promising results, with several pilot-scale production facilities demonstrating throughput increases of an order of magnitude compared to laboratory-scale processes while maintaining sensitivity performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!