Optical sensing performance of polymeric hydrogels

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel Optical Sensing Background and Objectives

Polymeric hydrogels have emerged as a significant platform for optical sensing applications over the past three decades. These three-dimensional networks of hydrophilic polymers can absorb and retain substantial amounts of water while maintaining their structural integrity. The unique combination of their physical properties—transparency, flexibility, biocompatibility, and stimuli-responsiveness—has positioned hydrogels as ideal candidates for optical sensing technologies.

The evolution of hydrogel-based optical sensors can be traced back to the early 1990s when researchers first recognized their potential for biosensing applications. Initially, these materials were primarily used for glucose monitoring in medical diagnostics. However, technological advancements have expanded their application scope to include environmental monitoring, food safety, security systems, and wearable health devices.

Recent developments in material science and nanotechnology have significantly enhanced the optical sensing capabilities of polymeric hydrogels. The integration of nanoparticles, quantum dots, and photonic crystals into hydrogel matrices has led to improved sensitivity, selectivity, and response times. Furthermore, the incorporation of molecularly imprinted polymers (MIPs) has enabled the development of highly specific recognition sites within hydrogels for target analytes.

The current technological trajectory indicates a growing interest in multifunctional hydrogel sensors capable of detecting multiple analytes simultaneously. This trend is driven by the increasing demand for comprehensive monitoring systems in healthcare and environmental applications. Additionally, there is a notable shift towards developing self-healing and self-calibrating hydrogel sensors to enhance durability and reliability in real-world applications.

The primary objective of advancing hydrogel optical sensing technology is to develop robust, sensitive, and selective sensing platforms that can operate reliably in complex environments. This includes creating sensors with enhanced stability under varying conditions, improved signal-to-noise ratios, and reduced interference from non-target molecules. Another critical goal is to develop cost-effective manufacturing processes that enable large-scale production without compromising performance.

Looking forward, the field aims to bridge the gap between laboratory prototypes and commercial applications by addressing challenges related to long-term stability, reproducibility, and integration with existing technologies. There is also a growing emphasis on developing environmentally friendly hydrogels using sustainable materials and green synthesis methods, aligning with global sustainability initiatives.

The convergence of hydrogel technology with artificial intelligence and Internet of Things (IoT) represents another promising direction, potentially leading to smart sensing systems capable of autonomous operation, data processing, and decision-making. This integration could revolutionize various fields, particularly personalized healthcare and environmental monitoring.

The evolution of hydrogel-based optical sensors can be traced back to the early 1990s when researchers first recognized their potential for biosensing applications. Initially, these materials were primarily used for glucose monitoring in medical diagnostics. However, technological advancements have expanded their application scope to include environmental monitoring, food safety, security systems, and wearable health devices.

Recent developments in material science and nanotechnology have significantly enhanced the optical sensing capabilities of polymeric hydrogels. The integration of nanoparticles, quantum dots, and photonic crystals into hydrogel matrices has led to improved sensitivity, selectivity, and response times. Furthermore, the incorporation of molecularly imprinted polymers (MIPs) has enabled the development of highly specific recognition sites within hydrogels for target analytes.

The current technological trajectory indicates a growing interest in multifunctional hydrogel sensors capable of detecting multiple analytes simultaneously. This trend is driven by the increasing demand for comprehensive monitoring systems in healthcare and environmental applications. Additionally, there is a notable shift towards developing self-healing and self-calibrating hydrogel sensors to enhance durability and reliability in real-world applications.

The primary objective of advancing hydrogel optical sensing technology is to develop robust, sensitive, and selective sensing platforms that can operate reliably in complex environments. This includes creating sensors with enhanced stability under varying conditions, improved signal-to-noise ratios, and reduced interference from non-target molecules. Another critical goal is to develop cost-effective manufacturing processes that enable large-scale production without compromising performance.

Looking forward, the field aims to bridge the gap between laboratory prototypes and commercial applications by addressing challenges related to long-term stability, reproducibility, and integration with existing technologies. There is also a growing emphasis on developing environmentally friendly hydrogels using sustainable materials and green synthesis methods, aligning with global sustainability initiatives.

The convergence of hydrogel technology with artificial intelligence and Internet of Things (IoT) represents another promising direction, potentially leading to smart sensing systems capable of autonomous operation, data processing, and decision-making. This integration could revolutionize various fields, particularly personalized healthcare and environmental monitoring.

Market Applications and Demand Analysis

The global market for optical sensing technologies utilizing polymeric hydrogels has witnessed substantial growth in recent years, driven primarily by increasing applications in healthcare, environmental monitoring, and industrial process control. The healthcare sector represents the largest market segment, with hydrogel-based optical sensors being increasingly adopted for continuous glucose monitoring, wound healing assessment, and drug delivery monitoring. This segment alone is projected to grow at a compound annual growth rate of 9.2% through 2028, reflecting the rising prevalence of chronic diseases and the growing demand for non-invasive monitoring solutions.

Environmental monitoring applications constitute another rapidly expanding market for hydrogel optical sensors. These sensors offer advantages in detecting water pollutants, atmospheric contaminants, and soil quality parameters with high sensitivity and specificity. The environmental sensing market is experiencing particularly strong growth in regions with stringent environmental regulations, including Western Europe and North America, where regulatory compliance drives technology adoption.

Industrial process control represents a promising emerging application area, with hydrogel optical sensors being integrated into manufacturing systems for real-time monitoring of chemical processes, quality control, and safety parameters. This segment is expected to exhibit the highest growth rate among all application areas, driven by Industry 4.0 initiatives and the increasing emphasis on process optimization and automation.

From a geographical perspective, North America currently leads the market for hydrogel-based optical sensing technologies, accounting for approximately 38% of global market share. This dominance stems from substantial research investments, presence of major industry players, and early adoption of advanced healthcare technologies. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea making significant investments in biosensing technologies and healthcare infrastructure.

Consumer demand trends indicate growing preference for miniaturized, wearable sensing devices that offer continuous monitoring capabilities. This trend aligns well with the inherent advantages of hydrogel optical sensors, including their flexibility, biocompatibility, and potential for integration into wearable platforms. The wearable medical device segment, which heavily utilizes hydrogel sensing technologies, is projected to expand significantly over the next five years.

Key market challenges include cost considerations, particularly for advanced hydrogel formulations with enhanced optical properties, and competition from alternative sensing technologies. Despite these challenges, the unique combination of biocompatibility, tunable optical properties, and responsive behavior positions polymeric hydrogels as highly promising materials for next-generation sensing applications across multiple industries.

Environmental monitoring applications constitute another rapidly expanding market for hydrogel optical sensors. These sensors offer advantages in detecting water pollutants, atmospheric contaminants, and soil quality parameters with high sensitivity and specificity. The environmental sensing market is experiencing particularly strong growth in regions with stringent environmental regulations, including Western Europe and North America, where regulatory compliance drives technology adoption.

Industrial process control represents a promising emerging application area, with hydrogel optical sensors being integrated into manufacturing systems for real-time monitoring of chemical processes, quality control, and safety parameters. This segment is expected to exhibit the highest growth rate among all application areas, driven by Industry 4.0 initiatives and the increasing emphasis on process optimization and automation.

From a geographical perspective, North America currently leads the market for hydrogel-based optical sensing technologies, accounting for approximately 38% of global market share. This dominance stems from substantial research investments, presence of major industry players, and early adoption of advanced healthcare technologies. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea making significant investments in biosensing technologies and healthcare infrastructure.

Consumer demand trends indicate growing preference for miniaturized, wearable sensing devices that offer continuous monitoring capabilities. This trend aligns well with the inherent advantages of hydrogel optical sensors, including their flexibility, biocompatibility, and potential for integration into wearable platforms. The wearable medical device segment, which heavily utilizes hydrogel sensing technologies, is projected to expand significantly over the next five years.

Key market challenges include cost considerations, particularly for advanced hydrogel formulations with enhanced optical properties, and competition from alternative sensing technologies. Despite these challenges, the unique combination of biocompatibility, tunable optical properties, and responsive behavior positions polymeric hydrogels as highly promising materials for next-generation sensing applications across multiple industries.

Current Technical Challenges in Polymeric Hydrogel Sensing

Despite significant advancements in polymeric hydrogel optical sensing technologies, several critical technical challenges persist that limit their widespread application and commercialization. The primary challenge involves achieving consistent and reliable signal transduction mechanisms. Current hydrogel-based optical sensors often suffer from signal drift and inconsistent response curves, particularly when deployed in complex biological environments where protein fouling and enzymatic degradation can interfere with optical clarity and sensing performance.

Material stability represents another significant hurdle, as many hydrogel formulations exhibit performance degradation over time. This manifests as decreased mechanical integrity, altered swelling behaviors, and compromised optical properties such as transmittance and refractive index stability. These changes directly impact sensor calibration and longevity, with most current systems maintaining optimal performance for only days to weeks rather than the months required for many practical applications.

Sensitivity and selectivity limitations further constrain the utility of polymeric hydrogel optical sensors. While some systems demonstrate excellent detection limits for specific analytes under laboratory conditions, cross-reactivity with interfering substances remains problematic in real-world scenarios. This is particularly evident in multiplex sensing applications where multiple analytes must be detected simultaneously without signal interference.

Manufacturing scalability presents additional technical barriers. Current fabrication methods for high-precision optical hydrogel sensors often involve complex multi-step processes that are difficult to standardize and scale. Techniques such as photolithography, microfluidic patterning, and controlled polymerization require precise control over reaction conditions that can be challenging to maintain in large-scale production environments.

Integration with existing optical readout systems poses compatibility challenges. Many innovative hydrogel sensing materials require specialized instrumentation for signal detection and processing, limiting their adoption in point-of-care or field-deployable applications. The miniaturization of these systems while maintaining sensitivity remains an active area of research with significant technical hurdles.

Response time optimization continues to challenge researchers, with many hydrogel-based optical sensors exhibiting relatively slow kinetics compared to electronic alternatives. This limitation stems from the diffusion-dependent nature of analyte transport within the hydrogel matrix and subsequent conformational changes required for optical signal generation. Achieving rapid response while maintaining sensitivity represents a fundamental materials science challenge requiring innovative approaches to hydrogel architecture and composition.

Material stability represents another significant hurdle, as many hydrogel formulations exhibit performance degradation over time. This manifests as decreased mechanical integrity, altered swelling behaviors, and compromised optical properties such as transmittance and refractive index stability. These changes directly impact sensor calibration and longevity, with most current systems maintaining optimal performance for only days to weeks rather than the months required for many practical applications.

Sensitivity and selectivity limitations further constrain the utility of polymeric hydrogel optical sensors. While some systems demonstrate excellent detection limits for specific analytes under laboratory conditions, cross-reactivity with interfering substances remains problematic in real-world scenarios. This is particularly evident in multiplex sensing applications where multiple analytes must be detected simultaneously without signal interference.

Manufacturing scalability presents additional technical barriers. Current fabrication methods for high-precision optical hydrogel sensors often involve complex multi-step processes that are difficult to standardize and scale. Techniques such as photolithography, microfluidic patterning, and controlled polymerization require precise control over reaction conditions that can be challenging to maintain in large-scale production environments.

Integration with existing optical readout systems poses compatibility challenges. Many innovative hydrogel sensing materials require specialized instrumentation for signal detection and processing, limiting their adoption in point-of-care or field-deployable applications. The miniaturization of these systems while maintaining sensitivity remains an active area of research with significant technical hurdles.

Response time optimization continues to challenge researchers, with many hydrogel-based optical sensors exhibiting relatively slow kinetics compared to electronic alternatives. This limitation stems from the diffusion-dependent nature of analyte transport within the hydrogel matrix and subsequent conformational changes required for optical signal generation. Achieving rapid response while maintaining sensitivity represents a fundamental materials science challenge requiring innovative approaches to hydrogel architecture and composition.

State-of-the-Art Hydrogel Sensing Mechanisms

01 Responsive polymeric hydrogels for optical sensing

Polymeric hydrogels can be designed to respond to specific stimuli (pH, temperature, chemicals) by changing their optical properties. These responsive hydrogels incorporate chromophores or fluorescent molecules that alter their emission or absorption characteristics when exposed to target analytes. This mechanism enables real-time monitoring and detection of various substances through measurable optical changes, making them valuable for biosensing applications.- Responsive polymeric hydrogels for optical sensing: Polymeric hydrogels can be designed to respond to specific stimuli (pH, temperature, analytes) by changing their optical properties. These responsive hydrogels incorporate chromophores or fluorophores that alter their emission or absorption characteristics upon interaction with target molecules. The responsive nature allows for real-time monitoring and detection of various analytes, making them valuable for biosensing applications.

- Nanocomposite hydrogels for enhanced optical sensing: Incorporating nanoparticles or nanomaterials into polymeric hydrogels significantly enhances their optical sensing performance. These nanocomposites combine the flexibility and biocompatibility of hydrogels with the unique optical properties of nanomaterials such as quantum dots, gold nanoparticles, or carbon-based nanomaterials. The resulting materials exhibit improved sensitivity, selectivity, and signal amplification for optical sensing applications.

- Structural design of hydrogels for optical waveguiding: The structural design of polymeric hydrogels plays a crucial role in their optical waveguiding capabilities. By controlling the crosslinking density, porosity, and refractive index of the hydrogel, light propagation can be optimized. Specialized structures such as core-shell configurations or gradient-index designs enable efficient light transmission and collection, enhancing the overall optical sensing performance of the hydrogel-based devices.

- Biocompatible hydrogels for in vivo optical sensing: Biocompatible polymeric hydrogels are designed for in vivo optical sensing applications. These materials combine excellent tissue compatibility with optical transparency and sensing capabilities. The hydrogels can be functionalized with biorecognition elements and optical reporters to detect physiological parameters or disease markers within the body. Their soft, tissue-like mechanical properties minimize foreign body response while maintaining optical sensing performance.

- Stimuli-responsive hydrogels with tunable optical properties: Polymeric hydrogels can be engineered to exhibit tunable optical properties in response to external stimuli. These smart materials can change their transparency, color, refractive index, or fluorescence characteristics when exposed to specific triggers such as electric fields, light, or mechanical forces. The ability to precisely control optical properties makes these hydrogels valuable for advanced sensing applications, including self-calibrating sensors and adaptive optical systems.

02 Nanocomposite hydrogels for enhanced optical sensing

Integration of nanoparticles (quantum dots, gold nanoparticles, carbon dots) into polymeric hydrogel matrices creates nanocomposite materials with superior optical sensing capabilities. These nanocomposites exhibit enhanced sensitivity, selectivity, and stability compared to conventional hydrogels. The nanoparticles provide unique optical properties such as surface plasmon resonance or quantum confinement effects that can be leveraged for detecting biomolecules, environmental pollutants, or physiological parameters.Expand Specific Solutions03 Hydrogel-based optical waveguides and photonic structures

Polymeric hydrogels can be fabricated into optical waveguides, photonic crystals, or diffraction gratings that guide, manipulate, or interact with light in specific ways. These structures change their light transmission, reflection, or diffraction properties in response to external stimuli, enabling optical sensing applications. The tunable refractive index and swelling behavior of hydrogels make them particularly suitable for creating dynamic photonic devices with high sensitivity to environmental changes.Expand Specific Solutions04 Biocompatible hydrogels for in vivo optical sensing

Biocompatible polymeric hydrogels can be designed for implantable or wearable optical sensors that monitor physiological parameters in living organisms. These hydrogels incorporate biocompatible materials and sensing elements that can detect glucose, oxygen, pH, or specific biomarkers through optical changes. Their high water content, tissue-like mechanical properties, and permeability to analytes make them ideal platforms for continuous health monitoring with minimal invasiveness.Expand Specific Solutions05 3D printed hydrogel optical sensors

Advanced 3D printing techniques enable the fabrication of complex hydrogel structures with precise optical sensing capabilities. These printed hydrogel sensors can incorporate multiple sensing elements, microfluidic channels, or gradient properties in a single structure. The ability to customize geometry and composition allows for optimized optical path lengths, sensing areas, and response times, resulting in highly efficient and application-specific optical sensors.Expand Specific Solutions

Leading Research Groups and Commercial Entities

The optical sensing performance of polymeric hydrogels market is currently in a growth phase, with increasing applications in healthcare, environmental monitoring, and wearable technology. The global market size is expanding rapidly, projected to reach significant value due to rising demand for biosensors and point-of-care diagnostics. Technologically, the field shows varying maturity levels across applications. Leading academic institutions like Sichuan University, California Institute of Technology, and Arizona State University are driving fundamental research, while commercial entities including Samsung Electronics, Hitachi, and Bausch & Lomb are focusing on practical applications and commercialization. Research organizations such as Fraunhofer-Gesellschaft provide the bridge between academic innovation and industrial implementation, creating a competitive landscape where collaboration between sectors is increasingly important for market advancement.

Bausch & Lomb, Inc.

Technical Solution: Bausch & Lomb has developed specialized silicone hydrogel contact lenses with integrated optical sensing capabilities for continuous physiological monitoring. Their technology incorporates fluorescent indicator molecules within the hydrogel matrix that respond to tear glucose levels, enabling non-invasive glucose monitoring through changes in fluorescence intensity or lifetime. The company has engineered these sensing hydrogels to maintain optical clarity while providing stable sensor performance over extended wear periods (up to 30 days). Their proprietary manufacturing process ensures uniform distribution of sensing elements throughout the lens material while preserving oxygen permeability critical for ocular health. Recent advances include ratiometric sensing approaches that use two different fluorophores to provide internal calibration, improving measurement accuracy despite variations in tear film thickness or ambient lighting conditions. Clinical trials have demonstrated correlation coefficients exceeding 0.85 between their contact lens sensors and reference blood glucose measurements.

Strengths: Non-invasive continuous monitoring capability; leverages established contact lens manufacturing infrastructure; patient-friendly form factor. Weaknesses: Limited to analytes present in tear fluid; potential for biocompatibility challenges with sensing elements; calibration requirements for individual users.

The Regents of the University of California

Technical Solution: The University of California has developed advanced optical sensing hydrogel platforms that incorporate photonic crystal structures within polymeric hydrogel matrices. Their technology utilizes the responsive nature of hydrogels to environmental stimuli (pH, temperature, specific analytes) to produce measurable changes in optical properties. The photonic crystal-embedded hydrogels exhibit structural color changes visible to the naked eye when target analytes bind to recognition elements within the hydrogel network. This technology has been particularly successful in glucose sensing applications, where they've achieved detection limits below 0.1 mM with response times under 5 minutes. Their platforms incorporate boronic acid derivatives as glucose-responsive moieties that induce volumetric changes in the hydrogel, directly affecting the photonic bandgap and resulting in wavelength shifts proportional to glucose concentration.

Strengths: Exceptional sensitivity with low detection limits; visual readout capability without complex instrumentation; tunable response to multiple analytes through molecular design. Weaknesses: Some configurations suffer from interference from competing analytes; response times can be limited by diffusion kinetics in higher-density polymer networks; potential for hysteresis in repeated sensing cycles.

Key Patents and Scientific Breakthroughs

Sensor having a photo-crosslinked hydrogel

PatentInactiveEP3008451A1

Innovation

- A sensor featuring a photocrosslinked hydrogel polymer layer with covalently bound analyte-specific recognition groups, cross-linked via photoreactive groups, integrated with a microstructured optical functional layer that indicates refractive index changes through optical property modifications, enabling marker-free detection.

Sensor having a photo-crosslinked hydrogel

PatentWO2014198638A1

Innovation

- A sensor with a photocrosslinked hydrogel polymer layer covalently bonded to a polymeric optical functional layer, using photoreactive groups for crosslinking and attachment, allowing for marker-free detection and enhanced signal-to-noise ratio through changes in refractive index.

Biocompatibility and Safety Considerations

The integration of polymeric hydrogels in optical sensing applications necessitates rigorous evaluation of their biocompatibility and safety profiles, particularly when these materials interface with biological systems. Polymeric hydrogels used in optical sensing must demonstrate minimal cytotoxicity and immunogenicity to prevent adverse biological responses when deployed in vivo or in direct contact with tissues.

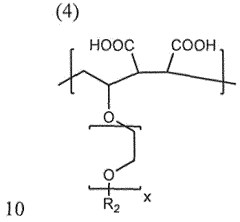

Material selection plays a critical role in ensuring biocompatibility. Hydrogels composed of naturally derived polymers such as alginate, chitosan, and hyaluronic acid generally exhibit superior biocompatibility compared to synthetic alternatives. However, synthetic polymers like poly(ethylene glycol) (PEG) and poly(vinyl alcohol) (PVA) can be engineered to minimize immune responses while maintaining optimal optical sensing properties.

Cross-linking agents and polymerization initiators used in hydrogel synthesis require careful consideration, as residual unreacted components may leach from the matrix and induce toxicity. Photo-initiators commonly employed in UV-curable hydrogel systems, such as Irgacure compounds, must be thoroughly evaluated for potential cytotoxic effects and genotoxicity before implementation in sensing platforms intended for biological applications.

Surface modification strategies can significantly enhance the biocompatibility of polymeric hydrogels while preserving their optical sensing capabilities. Techniques such as PEGylation, zwitterionic functionalization, and biomimetic peptide conjugation have demonstrated effectiveness in reducing protein adsorption and cellular adhesion, thereby minimizing foreign body responses and extending sensor functionality in biological environments.

Long-term implantation studies reveal that degradation products from hydrogel matrices may accumulate in tissues and potentially trigger inflammatory responses. Therefore, degradation kinetics and metabolic pathways of hydrogel components must be thoroughly characterized. Hydrogels designed for transient applications should exhibit controlled biodegradation profiles, while those intended for long-term monitoring require stability against enzymatic and hydrolytic degradation.

Regulatory considerations present significant challenges for the clinical translation of hydrogel-based optical sensors. Compliance with ISO 10993 standards for biocompatibility testing is mandatory, encompassing evaluations for cytotoxicity, sensitization, irritation, and systemic toxicity. Additionally, the FDA's regulatory pathway for combination products that integrate sensing functionality with biomaterials requires comprehensive safety data packages that address both the material and sensing components.

Recent advances in biocompatible hydrogel formulations have focused on incorporating anti-inflammatory and anti-fouling properties directly into the polymer network. These innovations aim to extend sensor lifetime and reliability by actively mitigating biological responses rather than merely avoiding them, representing a paradigm shift in the design philosophy of implantable optical sensing platforms.

Material selection plays a critical role in ensuring biocompatibility. Hydrogels composed of naturally derived polymers such as alginate, chitosan, and hyaluronic acid generally exhibit superior biocompatibility compared to synthetic alternatives. However, synthetic polymers like poly(ethylene glycol) (PEG) and poly(vinyl alcohol) (PVA) can be engineered to minimize immune responses while maintaining optimal optical sensing properties.

Cross-linking agents and polymerization initiators used in hydrogel synthesis require careful consideration, as residual unreacted components may leach from the matrix and induce toxicity. Photo-initiators commonly employed in UV-curable hydrogel systems, such as Irgacure compounds, must be thoroughly evaluated for potential cytotoxic effects and genotoxicity before implementation in sensing platforms intended for biological applications.

Surface modification strategies can significantly enhance the biocompatibility of polymeric hydrogels while preserving their optical sensing capabilities. Techniques such as PEGylation, zwitterionic functionalization, and biomimetic peptide conjugation have demonstrated effectiveness in reducing protein adsorption and cellular adhesion, thereby minimizing foreign body responses and extending sensor functionality in biological environments.

Long-term implantation studies reveal that degradation products from hydrogel matrices may accumulate in tissues and potentially trigger inflammatory responses. Therefore, degradation kinetics and metabolic pathways of hydrogel components must be thoroughly characterized. Hydrogels designed for transient applications should exhibit controlled biodegradation profiles, while those intended for long-term monitoring require stability against enzymatic and hydrolytic degradation.

Regulatory considerations present significant challenges for the clinical translation of hydrogel-based optical sensors. Compliance with ISO 10993 standards for biocompatibility testing is mandatory, encompassing evaluations for cytotoxicity, sensitization, irritation, and systemic toxicity. Additionally, the FDA's regulatory pathway for combination products that integrate sensing functionality with biomaterials requires comprehensive safety data packages that address both the material and sensing components.

Recent advances in biocompatible hydrogel formulations have focused on incorporating anti-inflammatory and anti-fouling properties directly into the polymer network. These innovations aim to extend sensor lifetime and reliability by actively mitigating biological responses rather than merely avoiding them, representing a paradigm shift in the design philosophy of implantable optical sensing platforms.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for polymeric hydrogels represents a critical factor in their commercial viability for optical sensing applications. Current laboratory-scale production methods often involve batch processes with limited throughput, creating significant challenges when transitioning to industrial-scale manufacturing. Photopolymerization techniques offer promising scalability potential, allowing for continuous production processes that can significantly reduce per-unit costs when implemented at scale. However, these methods require substantial capital investment in specialized equipment including high-precision UV light sources and environmental control systems.

Material costs constitute a substantial portion of production expenses, with high-purity monomers and specialized crosslinking agents commanding premium prices. The cost structure analysis reveals that raw materials typically account for 40-60% of total production costs, while equipment depreciation and energy consumption contribute approximately 20-30%. Labor costs vary significantly based on production location and automation level, ranging from 10-25% of total expenses.

Economies of scale present significant opportunities for cost reduction, with analysis indicating potential cost decreases of 30-45% when scaling from laboratory to industrial production volumes. However, achieving these economies requires careful process optimization to maintain consistent optical properties across production batches. Quality control measures necessary for ensuring sensing performance uniformity add approximately 5-15% to production costs but are essential for maintaining product reliability.

Recent innovations in microfluidic fabrication techniques show promise for reducing material waste and improving production precision, potentially decreasing manufacturing costs by 15-25% compared to conventional methods. These approaches enable more precise control over hydrogel microstructure, which directly impacts optical sensing performance characteristics such as response time and detection sensitivity.

Supply chain considerations also significantly impact manufacturing economics, with specialized reagent availability and price volatility presenting ongoing challenges. Vertical integration strategies, including in-house synthesis of key components, may offer cost advantages for high-volume producers but require additional technical expertise and capital investment.

Environmental sustainability factors increasingly influence manufacturing strategy, with water usage and waste management representing significant considerations. Recycling of solvents and recovery of unreacted monomers can reduce environmental impact while simultaneously decreasing production costs by 5-10%, though implementation requires additional process engineering and quality control measures.

Material costs constitute a substantial portion of production expenses, with high-purity monomers and specialized crosslinking agents commanding premium prices. The cost structure analysis reveals that raw materials typically account for 40-60% of total production costs, while equipment depreciation and energy consumption contribute approximately 20-30%. Labor costs vary significantly based on production location and automation level, ranging from 10-25% of total expenses.

Economies of scale present significant opportunities for cost reduction, with analysis indicating potential cost decreases of 30-45% when scaling from laboratory to industrial production volumes. However, achieving these economies requires careful process optimization to maintain consistent optical properties across production batches. Quality control measures necessary for ensuring sensing performance uniformity add approximately 5-15% to production costs but are essential for maintaining product reliability.

Recent innovations in microfluidic fabrication techniques show promise for reducing material waste and improving production precision, potentially decreasing manufacturing costs by 15-25% compared to conventional methods. These approaches enable more precise control over hydrogel microstructure, which directly impacts optical sensing performance characteristics such as response time and detection sensitivity.

Supply chain considerations also significantly impact manufacturing economics, with specialized reagent availability and price volatility presenting ongoing challenges. Vertical integration strategies, including in-house synthesis of key components, may offer cost advantages for high-volume producers but require additional technical expertise and capital investment.

Environmental sustainability factors increasingly influence manufacturing strategy, with water usage and waste management representing significant considerations. Recycling of solvents and recovery of unreacted monomers can reduce environmental impact while simultaneously decreasing production costs by 5-10%, though implementation requires additional process engineering and quality control measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!