Energy Density Optimization in Battery Using Conformal Coating

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Coating Technology Background and Objectives

Battery coating technology has evolved significantly over the past decades, transitioning from basic protective layers to sophisticated engineered interfaces that actively contribute to battery performance. The journey began in the 1990s with rudimentary polymer coatings primarily designed to prevent moisture ingress and mechanical damage. By the early 2000s, researchers recognized that surface modifications could address fundamental electrochemical challenges in battery systems, leading to the development of more functional coating approaches.

The conformal coating technology represents a pivotal advancement in this evolution, offering uniform, pinhole-free coverage that conforms precisely to electrode geometries at the microscale. This approach emerged from semiconductor manufacturing techniques and has been progressively adapted for energy storage applications over the past decade, with significant acceleration in research output since 2015.

Current technological objectives for conformal battery coatings center on three primary goals: enhancing energy density through more efficient material utilization, improving cycle life by mitigating degradation mechanisms, and addressing safety concerns by suppressing unwanted side reactions. The energy density optimization specifically targets the reduction of inactive material volume while maintaining or enhancing protective functions.

Market pressures from electric vehicles, portable electronics, and grid storage applications have intensified the need for higher energy density solutions, creating a technology pull that has attracted substantial research investment. Regulatory frameworks around battery safety and environmental impact have further shaped development priorities, particularly regarding coating materials selection and processing methods.

The technical landscape shows a convergence of approaches from materials science, electrochemistry, and advanced manufacturing. Atomic layer deposition (ALD), molecular layer deposition (MLD), and solution-based techniques represent the primary methodologies, each offering distinct advantages in terms of scalability, precision, and cost-effectiveness.

Looking forward, the field aims to achieve coating technologies that can enable silicon and lithium metal anodes, high-nickel cathodes, and solid-state electrolyte interfaces—all critical components for next-generation batteries with energy densities exceeding 400 Wh/kg. This represents approximately double the current commercial standards, potentially revolutionizing applications from transportation to consumer electronics.

The interdisciplinary nature of this technology necessitates collaboration across traditional boundaries, with innovations increasingly emerging from the intersection of battery chemistry, surface science, and advanced manufacturing techniques.

The conformal coating technology represents a pivotal advancement in this evolution, offering uniform, pinhole-free coverage that conforms precisely to electrode geometries at the microscale. This approach emerged from semiconductor manufacturing techniques and has been progressively adapted for energy storage applications over the past decade, with significant acceleration in research output since 2015.

Current technological objectives for conformal battery coatings center on three primary goals: enhancing energy density through more efficient material utilization, improving cycle life by mitigating degradation mechanisms, and addressing safety concerns by suppressing unwanted side reactions. The energy density optimization specifically targets the reduction of inactive material volume while maintaining or enhancing protective functions.

Market pressures from electric vehicles, portable electronics, and grid storage applications have intensified the need for higher energy density solutions, creating a technology pull that has attracted substantial research investment. Regulatory frameworks around battery safety and environmental impact have further shaped development priorities, particularly regarding coating materials selection and processing methods.

The technical landscape shows a convergence of approaches from materials science, electrochemistry, and advanced manufacturing. Atomic layer deposition (ALD), molecular layer deposition (MLD), and solution-based techniques represent the primary methodologies, each offering distinct advantages in terms of scalability, precision, and cost-effectiveness.

Looking forward, the field aims to achieve coating technologies that can enable silicon and lithium metal anodes, high-nickel cathodes, and solid-state electrolyte interfaces—all critical components for next-generation batteries with energy densities exceeding 400 Wh/kg. This represents approximately double the current commercial standards, potentially revolutionizing applications from transportation to consumer electronics.

The interdisciplinary nature of this technology necessitates collaboration across traditional boundaries, with innovations increasingly emerging from the intersection of battery chemistry, surface science, and advanced manufacturing techniques.

Market Analysis for High Energy Density Batteries

The high energy density battery market is experiencing unprecedented growth, driven by the expanding electric vehicle (EV) sector, portable electronics, and renewable energy storage systems. Current market valuations indicate the global high energy density battery market reached approximately 45 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 18-20% through 2030, potentially reaching 190 billion USD by the end of the decade.

Electric vehicles represent the largest demand segment, accounting for roughly 60% of high energy density battery consumption. This dominance is expected to continue as automotive manufacturers worldwide commit to electrification targets. Consumer electronics follows as the second-largest market segment at 25%, while grid storage applications, though currently smaller at 10%, show the fastest growth trajectory with annual increases exceeding 30%.

Regionally, Asia Pacific leads manufacturing capacity, with China controlling nearly 75% of global lithium-ion battery production. However, significant investments in North America and Europe aim to reduce dependency on Asian supply chains, with both regions targeting 25-30% domestic production capacity by 2030.

Consumer and industrial demands are increasingly focused on batteries that deliver higher energy density while maintaining safety profiles. Market research indicates consumers prioritize longer device operation times and faster charging capabilities, with 85% of smartphone users identifying battery life as a critical purchase factor. Similarly, EV adoption surveys consistently highlight range anxiety as the primary barrier to purchase, emphasizing the market pull for energy density improvements.

The conformal coating approach to energy density optimization addresses several key market requirements. By enabling more efficient use of battery cell space and improving thermal management, this technology potentially offers 15-20% energy density improvements without fundamental chemistry changes. This represents a significant competitive advantage in a market where typical year-over-year energy density improvements average 5-8%.

Price sensitivity analysis reveals that consumers are willing to pay premium prices for demonstrable performance improvements, particularly in high-end electronics and luxury EVs. However, mass-market adoption requires production costs to remain within 10-15% of conventional technologies, highlighting the importance of scalable manufacturing processes for conformal coating technologies.

Regulatory trends further support advanced battery technologies, with several jurisdictions implementing energy density requirements for various applications. The EU Battery Directive revision and China's energy density subsidies for EVs create market incentives specifically favoring higher energy density solutions, providing additional market pull for conformal coating and similar optimization technologies.

Electric vehicles represent the largest demand segment, accounting for roughly 60% of high energy density battery consumption. This dominance is expected to continue as automotive manufacturers worldwide commit to electrification targets. Consumer electronics follows as the second-largest market segment at 25%, while grid storage applications, though currently smaller at 10%, show the fastest growth trajectory with annual increases exceeding 30%.

Regionally, Asia Pacific leads manufacturing capacity, with China controlling nearly 75% of global lithium-ion battery production. However, significant investments in North America and Europe aim to reduce dependency on Asian supply chains, with both regions targeting 25-30% domestic production capacity by 2030.

Consumer and industrial demands are increasingly focused on batteries that deliver higher energy density while maintaining safety profiles. Market research indicates consumers prioritize longer device operation times and faster charging capabilities, with 85% of smartphone users identifying battery life as a critical purchase factor. Similarly, EV adoption surveys consistently highlight range anxiety as the primary barrier to purchase, emphasizing the market pull for energy density improvements.

The conformal coating approach to energy density optimization addresses several key market requirements. By enabling more efficient use of battery cell space and improving thermal management, this technology potentially offers 15-20% energy density improvements without fundamental chemistry changes. This represents a significant competitive advantage in a market where typical year-over-year energy density improvements average 5-8%.

Price sensitivity analysis reveals that consumers are willing to pay premium prices for demonstrable performance improvements, particularly in high-end electronics and luxury EVs. However, mass-market adoption requires production costs to remain within 10-15% of conventional technologies, highlighting the importance of scalable manufacturing processes for conformal coating technologies.

Regulatory trends further support advanced battery technologies, with several jurisdictions implementing energy density requirements for various applications. The EU Battery Directive revision and China's energy density subsidies for EVs create market incentives specifically favoring higher energy density solutions, providing additional market pull for conformal coating and similar optimization technologies.

Conformal Coating Technical Challenges

Despite the promising advantages of conformal coating in battery technology, several significant technical challenges impede its widespread implementation and optimal performance. The primary challenge lies in achieving uniform coating thickness across complex battery geometries. Current deposition methods often result in inconsistent coverage, with thicker accumulations in certain areas and insufficient coating in others, particularly around edges and corners of battery components.

Material compatibility presents another substantial hurdle. The coating material must maintain chemical stability when in contact with various battery components, including electrodes, electrolytes, and separators. Any adverse chemical reactions could compromise battery performance or, worse, create safety hazards. Additionally, the coating must withstand the harsh electrochemical environment inside batteries without degradation over extended periods.

Thermal management complications arise as conformal coatings can potentially act as thermal insulators, impeding heat dissipation from battery cells. This thermal barrier effect may lead to localized hotspots and accelerated degradation of battery components, ultimately reducing battery lifespan and safety margins.

The scalability of coating processes represents a significant manufacturing challenge. While laboratory-scale applications have demonstrated promising results, translating these processes to high-volume production environments remains problematic. Current industrial-scale coating technologies struggle to maintain precision and quality at speeds required for commercial viability.

Adhesion issues between the coating and substrate surfaces frequently occur, particularly under thermal cycling conditions typical in battery operation. Poor adhesion can lead to coating delamination, creating voids that compromise the protective function and potentially introduce new failure modes.

Porosity control presents another technical difficulty. Optimal coatings must balance impermeability to harmful contaminants while allowing necessary ion transport. Achieving this precise microstructure consistently across large production volumes remains challenging with current technologies.

Cost considerations further complicate implementation. Advanced coating materials and deposition equipment often carry high capital and operational expenses that can significantly impact the final battery cost structure, potentially limiting market adoption despite performance benefits.

Finally, quality control and inspection methodologies for conformal coatings remain underdeveloped. Non-destructive testing techniques capable of detecting coating defects, thickness variations, and adhesion problems at production speeds are still evolving, making quality assurance a persistent challenge in manufacturing environments.

Material compatibility presents another substantial hurdle. The coating material must maintain chemical stability when in contact with various battery components, including electrodes, electrolytes, and separators. Any adverse chemical reactions could compromise battery performance or, worse, create safety hazards. Additionally, the coating must withstand the harsh electrochemical environment inside batteries without degradation over extended periods.

Thermal management complications arise as conformal coatings can potentially act as thermal insulators, impeding heat dissipation from battery cells. This thermal barrier effect may lead to localized hotspots and accelerated degradation of battery components, ultimately reducing battery lifespan and safety margins.

The scalability of coating processes represents a significant manufacturing challenge. While laboratory-scale applications have demonstrated promising results, translating these processes to high-volume production environments remains problematic. Current industrial-scale coating technologies struggle to maintain precision and quality at speeds required for commercial viability.

Adhesion issues between the coating and substrate surfaces frequently occur, particularly under thermal cycling conditions typical in battery operation. Poor adhesion can lead to coating delamination, creating voids that compromise the protective function and potentially introduce new failure modes.

Porosity control presents another technical difficulty. Optimal coatings must balance impermeability to harmful contaminants while allowing necessary ion transport. Achieving this precise microstructure consistently across large production volumes remains challenging with current technologies.

Cost considerations further complicate implementation. Advanced coating materials and deposition equipment often carry high capital and operational expenses that can significantly impact the final battery cost structure, potentially limiting market adoption despite performance benefits.

Finally, quality control and inspection methodologies for conformal coatings remain underdeveloped. Non-destructive testing techniques capable of detecting coating defects, thickness variations, and adhesion problems at production speeds are still evolving, making quality assurance a persistent challenge in manufacturing environments.

Current Conformal Coating Solutions

01 Electrode materials for high energy density

Advanced electrode materials play a crucial role in enhancing battery energy density. These include high-capacity cathode materials like lithium-rich compounds, silicon-based anodes, and composite materials that can store more lithium ions. By optimizing the electrode composition and structure, batteries can achieve significantly higher energy storage capabilities while maintaining stability during charge-discharge cycles.- Electrode materials for high energy density: Advanced electrode materials play a crucial role in enhancing battery energy density. These materials include high-capacity cathodes like lithium-rich compounds and novel anode materials such as silicon and graphene composites. By increasing the specific capacity of electrode materials, batteries can store more energy in the same volume or weight, directly improving energy density. Research focuses on materials that can accommodate more lithium ions while maintaining structural stability during charge-discharge cycles.

- Electrolyte formulations for improved performance: Specialized electrolyte formulations can significantly impact battery energy density by enabling wider operating voltage windows and improving ion transport. Advanced electrolytes, including solid-state, polymer, and ionic liquid electrolytes, allow batteries to operate at higher voltages without decomposition, directly increasing energy density. These formulations also enhance ionic conductivity, reduce internal resistance, and improve the stability of electrode-electrolyte interfaces, all contributing to higher energy storage capabilities.

- Battery cell design and architecture: Innovative cell designs and architectures can maximize energy density by optimizing space utilization and reducing non-active components. Approaches include stacked and folded electrode configurations, bipolar designs, and three-dimensional structures that increase the active material loading per unit volume. By minimizing the proportion of inactive components such as separators, current collectors, and packaging materials, these designs increase the energy density of the overall battery system.

- Nanomaterials and composite structures: Nanomaterials and composite structures offer unique advantages for high energy density batteries. These include nanostructured electrodes, carbon-based composites, and core-shell particles that provide larger surface areas for reactions, shorter ion diffusion paths, and better electrical conductivity. By engineering materials at the nanoscale, batteries can achieve higher capacity utilization, faster charge-discharge rates, and improved cycle life while maintaining high energy density.

- Thermal management and safety systems: Effective thermal management and safety systems are essential for high energy density batteries. These include advanced cooling systems, phase change materials, and intelligent battery management systems that monitor and control temperature distribution. By preventing thermal runaway and maintaining optimal operating temperatures, these systems allow batteries to operate safely at higher energy densities without compromising performance or safety, extending battery life and enabling more energy-dense chemistries to be used practically.

02 Electrolyte innovations for energy density improvement

Novel electrolyte formulations contribute to increased battery energy density by enabling wider operating voltage windows and improving ion transport. These include solid-state electrolytes, ionic liquids, and electrolyte additives that enhance interfacial stability. Advanced electrolytes also help prevent dendrite formation and reduce internal resistance, allowing batteries to operate more efficiently at higher energy densities.Expand Specific Solutions03 Battery cell design and architecture

Innovative cell designs and architectures significantly impact energy density. This includes stacked and folded electrode configurations, bipolar designs, and optimized packaging that reduces inactive components. By maximizing the active material content while minimizing the volume and weight of non-energy-contributing components, these designs achieve higher volumetric and gravimetric energy densities.Expand Specific Solutions04 Nanomaterials and nanostructured components

Nanomaterials and nanostructured components enhance battery energy density by providing larger surface areas for electrochemical reactions and shorter diffusion paths for ions. These include nanoparticles, nanotubes, nanowires, and hierarchical porous structures that improve charge storage capacity and rate capability. Nanoengineering approaches also help mitigate volume expansion issues in high-capacity electrode materials.Expand Specific Solutions05 Thermal management and safety systems

Advanced thermal management and safety systems enable batteries to operate safely at higher energy densities. These include phase change materials, heat dissipation structures, and intelligent battery management systems that monitor and control temperature distribution. By preventing thermal runaway and maintaining optimal operating temperatures, these systems allow for more energy-dense battery designs without compromising safety.Expand Specific Solutions

Key Industry Players in Conformal Coating

The energy density optimization in battery using conformal coating technology is currently in a growth phase, with the market expected to expand significantly due to increasing demand for high-performance batteries in electric vehicles and energy storage systems. Key players like Contemporary Amperex Technology (CATL), LG Energy Solution, Panasonic, Samsung SDI, and BYD are leading innovation in this space, with emerging competition from specialized companies such as EVE Energy and Zhuhai CosMX. The technology is approaching maturity in consumer electronics applications but remains in development for automotive-grade implementations. Research partnerships between companies like Toyota and academic institutions such as Rice University are accelerating technological advancement, focusing on nanoscale coating techniques to enhance battery safety, longevity, and energy density.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an advanced conformal coating technology called Cell-to-Pack (CTP) that optimizes energy density by applying protective nano-coatings directly to battery electrodes. Their third-generation CTP technology achieves energy densities exceeding 255 Wh/kg at the pack level, representing a 13% improvement over traditional battery designs. The conformal coating process utilizes atomic layer deposition (ALD) to create uniform, ultra-thin protective layers (typically 5-20nm thick) on electrode surfaces, which effectively prevents electrolyte decomposition at the electrode-electrolyte interface while maintaining excellent ionic conductivity. This approach has enabled CATL to reduce inactive materials in battery packs by approximately 40%, significantly increasing volumetric energy density. Additionally, their coatings incorporate flame-retardant compounds that enhance thermal stability and safety performance during extreme conditions.

Strengths: Industry-leading energy density achievements; scalable manufacturing process already implemented in mass production; comprehensive protection against multiple degradation mechanisms. Weaknesses: Higher initial production costs compared to conventional batteries; requires specialized equipment for precise nanoscale deposition; some coating materials may have limited availability in large-scale production.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has pioneered a silicon-graphite composite anode technology with specialized conformal coating that addresses the volume expansion issues inherent in silicon-based anodes. Their proprietary coating consists of a flexible polymer-ceramic hybrid material applied via chemical vapor deposition (CVD) at precisely controlled temperatures (150-200°C). This coating creates a 50-100nm elastic buffer layer that accommodates the 300%+ volume changes of silicon during charge/discharge cycles while maintaining electrical connectivity. The coating also incorporates lithium-ion conductive additives that enhance rate capability by 30% compared to uncoated materials. Panasonic's approach enables silicon content of up to 15% in commercial cells, achieving energy densities of approximately 800 Wh/L at the cell level. Their manufacturing process integrates seamlessly with existing production lines, requiring minimal additional capital investment while delivering substantial performance improvements.

Strengths: Effectively addresses silicon expansion issues; compatible with existing manufacturing infrastructure; significantly improves cycle life of high-capacity materials. Weaknesses: Coating process adds production time; performance benefits diminish at extremely high charge/discharge rates; coating thickness must be precisely controlled to avoid capacity losses.

Core Patents in Battery Coating Technology

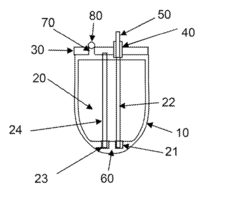

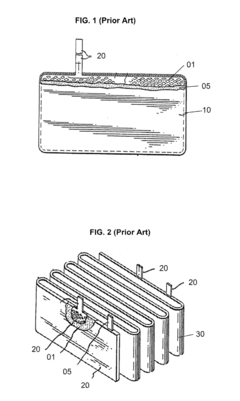

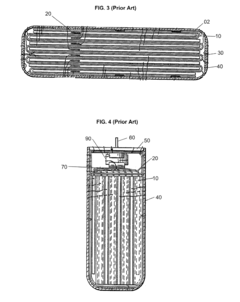

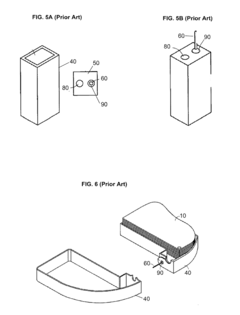

High energy density battery for use in implantable medical devices and methods of manufacture

PatentInactiveUS20110151310A1

Innovation

- A high energy density battery design with optimized placement of current carrying leads within the battery enclosure, allowing for a greater volume of active material and reduced size, featuring a case with a header assembly and electrode stacks connected via current collecting leads, and an electrolyte solution for efficient energy storage.

Safety Standards for Coated Battery Systems

The implementation of conformal coating technology in battery systems necessitates adherence to rigorous safety standards to ensure operational reliability and user protection. Currently, several international organizations have established comprehensive frameworks governing coated battery systems, including IEC 62133 for secondary cells and batteries, UL 1642 for lithium batteries, and UN 38.3 for transportation safety requirements. These standards specifically address the unique characteristics of conformal coatings, requiring manufacturers to demonstrate that such coatings maintain integrity under thermal stress, mechanical impact, and electrical abuse conditions.

Safety certification for conformal coated batteries requires extensive testing protocols that evaluate coating performance under extreme conditions. These include thermal cycling tests (typically -40°C to +85°C), humidity resistance evaluations (95% relative humidity for extended periods), and salt fog exposure tests to verify corrosion protection capabilities. Additionally, specific tests for flame retardancy according to UL 94 standards are mandatory, with most applications requiring V-0 or V-1 ratings for the coating materials.

Chemical compatibility standards represent another critical safety dimension, as interactions between coating materials and battery electrolytes could potentially compromise battery integrity. ISO 10993 series standards, though primarily developed for biomedical applications, have been adapted to evaluate the chemical stability of conformal coatings in battery environments. These standards require demonstration that no harmful leaching or degradation occurs when coatings contact battery components over extended periods.

Emerging safety regulations are increasingly focusing on environmental considerations, with the EU's RoHS and REACH regulations restricting certain hazardous substances in electronic components, including battery coatings. Manufacturers must now certify that conformal coatings are free from restricted phthalates, halogens, and volatile organic compounds (VOCs). This regulatory trend is expanding globally, with similar frameworks being adopted in Asia and North America.

Implementation guidelines for safety compliance have been developed by industry consortia such as the Battery Safety Organization (BSO) and the Conformal Coating Technical Council. These guidelines recommend specific documentation practices, including detailed material safety data sheets (MSDS) for coating materials, process validation protocols, and regular audit procedures. They also emphasize the importance of traceability systems that can track coating batch information throughout the battery lifecycle.

Recent safety standard revisions have begun incorporating specific provisions for nano-enhanced conformal coatings, recognizing their unique properties and potential risks. These provisions mandate additional biocompatibility testing and particle migration studies to ensure that nanoparticles remain embedded in the coating matrix throughout the battery's operational life and disposal phases.

Safety certification for conformal coated batteries requires extensive testing protocols that evaluate coating performance under extreme conditions. These include thermal cycling tests (typically -40°C to +85°C), humidity resistance evaluations (95% relative humidity for extended periods), and salt fog exposure tests to verify corrosion protection capabilities. Additionally, specific tests for flame retardancy according to UL 94 standards are mandatory, with most applications requiring V-0 or V-1 ratings for the coating materials.

Chemical compatibility standards represent another critical safety dimension, as interactions between coating materials and battery electrolytes could potentially compromise battery integrity. ISO 10993 series standards, though primarily developed for biomedical applications, have been adapted to evaluate the chemical stability of conformal coatings in battery environments. These standards require demonstration that no harmful leaching or degradation occurs when coatings contact battery components over extended periods.

Emerging safety regulations are increasingly focusing on environmental considerations, with the EU's RoHS and REACH regulations restricting certain hazardous substances in electronic components, including battery coatings. Manufacturers must now certify that conformal coatings are free from restricted phthalates, halogens, and volatile organic compounds (VOCs). This regulatory trend is expanding globally, with similar frameworks being adopted in Asia and North America.

Implementation guidelines for safety compliance have been developed by industry consortia such as the Battery Safety Organization (BSO) and the Conformal Coating Technical Council. These guidelines recommend specific documentation practices, including detailed material safety data sheets (MSDS) for coating materials, process validation protocols, and regular audit procedures. They also emphasize the importance of traceability systems that can track coating batch information throughout the battery lifecycle.

Recent safety standard revisions have begun incorporating specific provisions for nano-enhanced conformal coatings, recognizing their unique properties and potential risks. These provisions mandate additional biocompatibility testing and particle migration studies to ensure that nanoparticles remain embedded in the coating matrix throughout the battery's operational life and disposal phases.

Environmental Impact of Coating Materials

The environmental impact of conformal coating materials used in battery energy density optimization represents a critical consideration in sustainable technology development. Traditional coating materials often contain volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances that pose significant ecological risks throughout their lifecycle.

Fluoropolymer-based coatings, commonly used for their excellent chemical resistance and thermal stability, present particular environmental challenges. These materials contain perfluorinated compounds that are extremely persistent in the environment, with degradation timeframes measured in centuries. Their bioaccumulative properties and potential toxicity have raised concerns among environmental regulatory bodies worldwide.

Silicone-based conformal coatings offer a relatively lower environmental impact compared to fluoropolymers, with reduced persistence and toxicity profiles. However, their production still involves energy-intensive processes and precursor chemicals that may contribute to environmental pollution if not properly managed. The siloxane compounds in these coatings can potentially contribute to atmospheric particulate formation when released.

Acrylic and polyurethane coatings present intermediate environmental concerns, with their impact largely dependent on the specific formulation and solvent systems employed. Water-based versions have emerged as environmentally preferable alternatives, though they may not always deliver the same performance characteristics as solvent-based systems in battery applications.

Recent innovations in bio-based and biodegradable coating materials show promising environmental profiles. These include coatings derived from plant oils, cellulose derivatives, and other renewable resources that can significantly reduce carbon footprint while maintaining necessary protective properties for battery components.

End-of-life considerations reveal additional environmental dimensions of coating materials. The presence of certain coating compounds can complicate battery recycling processes, potentially reducing recovery rates of valuable materials or requiring additional energy-intensive separation steps. Coatings that can be easily removed or that do not interfere with established recycling protocols offer significant advantages from a circular economy perspective.

Lifecycle assessment studies indicate that the environmental benefits of optimized energy density through conformal coatings generally outweigh the environmental costs of the coating materials themselves. Higher energy density batteries require fewer raw materials per unit of energy storage and can extend device lifespans, creating net positive environmental outcomes despite the additional materials introduced through coating processes.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating materials, with restrictions on certain compounds driving innovation toward greener alternatives. This regulatory landscape continues to evolve, with particular focus on persistent organic pollutants and compounds with bioaccumulative potential.

Fluoropolymer-based coatings, commonly used for their excellent chemical resistance and thermal stability, present particular environmental challenges. These materials contain perfluorinated compounds that are extremely persistent in the environment, with degradation timeframes measured in centuries. Their bioaccumulative properties and potential toxicity have raised concerns among environmental regulatory bodies worldwide.

Silicone-based conformal coatings offer a relatively lower environmental impact compared to fluoropolymers, with reduced persistence and toxicity profiles. However, their production still involves energy-intensive processes and precursor chemicals that may contribute to environmental pollution if not properly managed. The siloxane compounds in these coatings can potentially contribute to atmospheric particulate formation when released.

Acrylic and polyurethane coatings present intermediate environmental concerns, with their impact largely dependent on the specific formulation and solvent systems employed. Water-based versions have emerged as environmentally preferable alternatives, though they may not always deliver the same performance characteristics as solvent-based systems in battery applications.

Recent innovations in bio-based and biodegradable coating materials show promising environmental profiles. These include coatings derived from plant oils, cellulose derivatives, and other renewable resources that can significantly reduce carbon footprint while maintaining necessary protective properties for battery components.

End-of-life considerations reveal additional environmental dimensions of coating materials. The presence of certain coating compounds can complicate battery recycling processes, potentially reducing recovery rates of valuable materials or requiring additional energy-intensive separation steps. Coatings that can be easily removed or that do not interfere with established recycling protocols offer significant advantages from a circular economy perspective.

Lifecycle assessment studies indicate that the environmental benefits of optimized energy density through conformal coatings generally outweigh the environmental costs of the coating materials themselves. Higher energy density batteries require fewer raw materials per unit of energy storage and can extend device lifespans, creating net positive environmental outcomes despite the additional materials introduced through coating processes.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating materials, with restrictions on certain compounds driving innovation toward greener alternatives. This regulatory landscape continues to evolve, with particular focus on persistent organic pollutants and compounds with bioaccumulative potential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!