Enhancements in AMOLED for extreme low-temperature operations.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Low-Temp Tech Evolution

The evolution of AMOLED technology for extreme low-temperature operations has been driven by the increasing demand for displays that can function reliably in harsh environments. This technological progression can be traced through several key stages, each marked by significant advancements and innovative solutions.

In the early 2000s, AMOLED displays were primarily designed for operation in standard temperature ranges, typically between 0°C and 40°C. The focus was on improving color reproduction, contrast ratios, and power efficiency. However, as applications in automotive, aerospace, and outdoor digital signage expanded, the need for displays capable of withstanding extreme temperatures became apparent.

The first major breakthrough came in the mid-2000s with the development of temperature-compensated driving schemes. These schemes adjusted the voltage and current supplied to the OLED pixels based on ambient temperature, helping to maintain consistent brightness and color accuracy in colder environments. This approach, while effective, was limited in its ability to address the fundamental challenges posed by extremely low temperatures.

By the early 2010s, researchers began focusing on the molecular structure of OLED materials. The goal was to develop organic compounds that could maintain their electroluminescent properties at sub-zero temperatures. This led to the introduction of new host materials and dopants specifically engineered for low-temperature stability, significantly improving display performance in cold conditions.

Concurrently, advancements in thin-film encapsulation techniques played a crucial role in enhancing the durability of AMOLED displays. Improved barrier layers were developed to protect the sensitive organic materials from moisture and oxygen ingress, which become more problematic at low temperatures due to increased condensation risks.

The mid-2010s saw a shift towards addressing the mechanical challenges associated with extreme cold. Innovations in flexible substrate materials and bonding techniques allowed for displays that could withstand thermal expansion and contraction without compromising pixel integrity or causing delamination.

More recently, the integration of advanced temperature sensing and management systems has further enhanced the low-temperature capabilities of AMOLED displays. These systems allow for real-time adjustments to display parameters, ensuring optimal performance across a wide temperature range.

Looking forward, the evolution of AMOLED technology for extreme low-temperature operations is likely to continue along several paths. These include the development of novel organic materials with intrinsic low-temperature stability, advanced thermal management solutions integrated directly into display panels, and the exploration of hybrid organic-inorganic systems that combine the benefits of OLED technology with the robustness of inorganic materials.

In the early 2000s, AMOLED displays were primarily designed for operation in standard temperature ranges, typically between 0°C and 40°C. The focus was on improving color reproduction, contrast ratios, and power efficiency. However, as applications in automotive, aerospace, and outdoor digital signage expanded, the need for displays capable of withstanding extreme temperatures became apparent.

The first major breakthrough came in the mid-2000s with the development of temperature-compensated driving schemes. These schemes adjusted the voltage and current supplied to the OLED pixels based on ambient temperature, helping to maintain consistent brightness and color accuracy in colder environments. This approach, while effective, was limited in its ability to address the fundamental challenges posed by extremely low temperatures.

By the early 2010s, researchers began focusing on the molecular structure of OLED materials. The goal was to develop organic compounds that could maintain their electroluminescent properties at sub-zero temperatures. This led to the introduction of new host materials and dopants specifically engineered for low-temperature stability, significantly improving display performance in cold conditions.

Concurrently, advancements in thin-film encapsulation techniques played a crucial role in enhancing the durability of AMOLED displays. Improved barrier layers were developed to protect the sensitive organic materials from moisture and oxygen ingress, which become more problematic at low temperatures due to increased condensation risks.

The mid-2010s saw a shift towards addressing the mechanical challenges associated with extreme cold. Innovations in flexible substrate materials and bonding techniques allowed for displays that could withstand thermal expansion and contraction without compromising pixel integrity or causing delamination.

More recently, the integration of advanced temperature sensing and management systems has further enhanced the low-temperature capabilities of AMOLED displays. These systems allow for real-time adjustments to display parameters, ensuring optimal performance across a wide temperature range.

Looking forward, the evolution of AMOLED technology for extreme low-temperature operations is likely to continue along several paths. These include the development of novel organic materials with intrinsic low-temperature stability, advanced thermal management solutions integrated directly into display panels, and the exploration of hybrid organic-inorganic systems that combine the benefits of OLED technology with the robustness of inorganic materials.

Market Demand Analysis

The market demand for AMOLED displays capable of operating in extreme low-temperature environments has been steadily increasing, driven by the growing need for reliable display technologies in harsh conditions. Industries such as aerospace, automotive, and outdoor equipment manufacturing are particularly interested in these advancements, as they require displays that can maintain performance in sub-zero temperatures.

In the aerospace sector, there is a significant demand for AMOLED displays that can function effectively in the extreme cold of high altitudes and space environments. Cockpit displays, satellite communication systems, and space exploration equipment all require displays that can withstand temperatures well below freezing without compromising visibility or responsiveness.

The automotive industry is another key driver of market demand for low-temperature AMOLED technology. As electric vehicles become more prevalent, there is an increasing need for displays that can perform reliably in cold climates. Dashboard displays, infotainment systems, and advanced driver assistance systems (ADAS) all require consistent performance across a wide range of temperatures, including extreme cold.

Outdoor equipment manufacturers, particularly those producing devices for use in polar regions or high-altitude environments, are also contributing to the growing demand. This includes manufacturers of scientific instruments, weather monitoring equipment, and outdoor recreational devices that need to function in sub-zero temperatures.

The market for low-temperature AMOLED displays is expected to expand as more industries recognize the benefits of this technology. Military applications, for instance, are likely to drive further demand as armed forces seek display solutions that can operate in extreme environments without failure.

Consumer electronics manufacturers are also showing interest in low-temperature AMOLED technology, albeit to a lesser extent. While most consumer devices are not typically used in extreme cold, there is a niche market for rugged smartphones and tablets designed for outdoor enthusiasts and professionals working in cold climates.

As climate change leads to more extreme weather conditions, the need for displays that can withstand a wider range of temperatures is likely to increase across various sectors. This trend is expected to further boost the market demand for AMOLED displays with enhanced low-temperature capabilities.

The potential market size for low-temperature AMOLED technology is substantial, considering the combined needs of multiple industries. While precise market valuations are challenging to determine due to the emerging nature of this specific application, industry analysts predict significant growth in this segment over the next decade.

In the aerospace sector, there is a significant demand for AMOLED displays that can function effectively in the extreme cold of high altitudes and space environments. Cockpit displays, satellite communication systems, and space exploration equipment all require displays that can withstand temperatures well below freezing without compromising visibility or responsiveness.

The automotive industry is another key driver of market demand for low-temperature AMOLED technology. As electric vehicles become more prevalent, there is an increasing need for displays that can perform reliably in cold climates. Dashboard displays, infotainment systems, and advanced driver assistance systems (ADAS) all require consistent performance across a wide range of temperatures, including extreme cold.

Outdoor equipment manufacturers, particularly those producing devices for use in polar regions or high-altitude environments, are also contributing to the growing demand. This includes manufacturers of scientific instruments, weather monitoring equipment, and outdoor recreational devices that need to function in sub-zero temperatures.

The market for low-temperature AMOLED displays is expected to expand as more industries recognize the benefits of this technology. Military applications, for instance, are likely to drive further demand as armed forces seek display solutions that can operate in extreme environments without failure.

Consumer electronics manufacturers are also showing interest in low-temperature AMOLED technology, albeit to a lesser extent. While most consumer devices are not typically used in extreme cold, there is a niche market for rugged smartphones and tablets designed for outdoor enthusiasts and professionals working in cold climates.

As climate change leads to more extreme weather conditions, the need for displays that can withstand a wider range of temperatures is likely to increase across various sectors. This trend is expected to further boost the market demand for AMOLED displays with enhanced low-temperature capabilities.

The potential market size for low-temperature AMOLED technology is substantial, considering the combined needs of multiple industries. While precise market valuations are challenging to determine due to the emerging nature of this specific application, industry analysts predict significant growth in this segment over the next decade.

Current Challenges

AMOLED displays face significant challenges when operating in extreme low-temperature environments. The primary issue stems from the organic materials used in these displays, which exhibit reduced performance and reliability at temperatures below -20°C. The mobility of charge carriers within the organic semiconductors decreases dramatically, leading to slower response times and reduced efficiency.

One of the most pressing challenges is the increased power consumption at low temperatures. As the organic materials become less conductive, higher voltages are required to maintain the same brightness levels, resulting in increased energy demand. This not only affects battery life in portable devices but also raises concerns about the long-term durability of the display components under such stress.

Another critical issue is the color shift and reduced color accuracy at extreme low temperatures. The emission spectra of organic materials can change significantly, leading to inconsistent and unreliable color reproduction. This is particularly problematic in applications that require precise color rendering, such as in automotive displays or outdoor digital signage in cold climates.

The mechanical properties of AMOLED displays also pose challenges in low-temperature operations. The organic layers and substrate materials can become brittle and prone to cracking when exposed to extreme cold. This vulnerability to physical damage limits the use of AMOLED technology in rugged environments or outdoor applications in cold regions.

Pixel degradation and non-uniform aging of organic materials accelerate at low temperatures, leading to issues such as image retention and burn-in. The uneven degradation of pixels can result in visible artifacts and reduced display quality over time, shortening the overall lifespan of the display.

The encapsulation of AMOLED displays, crucial for protecting the organic materials from moisture and oxygen, becomes less effective at extreme low temperatures. The thermal contraction of materials can create micro-cracks or gaps in the encapsulation layer, potentially exposing the sensitive organic components to environmental factors and accelerating degradation.

Current manufacturing processes for AMOLED displays are not optimized for extreme low-temperature performance. The development of new materials and production techniques that can withstand and perform well in cold environments presents a significant engineering challenge. This includes the need for innovative approaches to thermal management and material science to overcome the inherent limitations of organic semiconductors at low temperatures.

Addressing these challenges requires a multidisciplinary approach, combining advances in material science, electrical engineering, and manufacturing processes. The development of new organic materials with improved low-temperature characteristics, enhanced encapsulation technologies, and novel pixel architectures are all areas of active research in the pursuit of AMOLED displays capable of reliable operation in extreme cold conditions.

One of the most pressing challenges is the increased power consumption at low temperatures. As the organic materials become less conductive, higher voltages are required to maintain the same brightness levels, resulting in increased energy demand. This not only affects battery life in portable devices but also raises concerns about the long-term durability of the display components under such stress.

Another critical issue is the color shift and reduced color accuracy at extreme low temperatures. The emission spectra of organic materials can change significantly, leading to inconsistent and unreliable color reproduction. This is particularly problematic in applications that require precise color rendering, such as in automotive displays or outdoor digital signage in cold climates.

The mechanical properties of AMOLED displays also pose challenges in low-temperature operations. The organic layers and substrate materials can become brittle and prone to cracking when exposed to extreme cold. This vulnerability to physical damage limits the use of AMOLED technology in rugged environments or outdoor applications in cold regions.

Pixel degradation and non-uniform aging of organic materials accelerate at low temperatures, leading to issues such as image retention and burn-in. The uneven degradation of pixels can result in visible artifacts and reduced display quality over time, shortening the overall lifespan of the display.

The encapsulation of AMOLED displays, crucial for protecting the organic materials from moisture and oxygen, becomes less effective at extreme low temperatures. The thermal contraction of materials can create micro-cracks or gaps in the encapsulation layer, potentially exposing the sensitive organic components to environmental factors and accelerating degradation.

Current manufacturing processes for AMOLED displays are not optimized for extreme low-temperature performance. The development of new materials and production techniques that can withstand and perform well in cold environments presents a significant engineering challenge. This includes the need for innovative approaches to thermal management and material science to overcome the inherent limitations of organic semiconductors at low temperatures.

Addressing these challenges requires a multidisciplinary approach, combining advances in material science, electrical engineering, and manufacturing processes. The development of new organic materials with improved low-temperature characteristics, enhanced encapsulation technologies, and novel pixel architectures are all areas of active research in the pursuit of AMOLED displays capable of reliable operation in extreme cold conditions.

Existing Solutions

01 Temperature compensation techniques

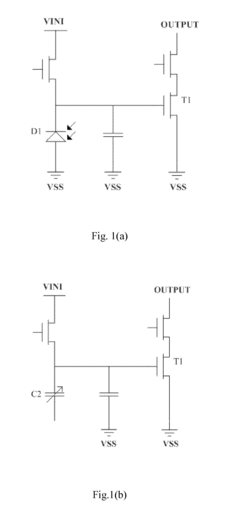

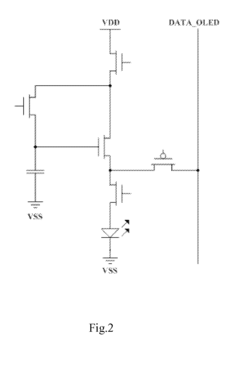

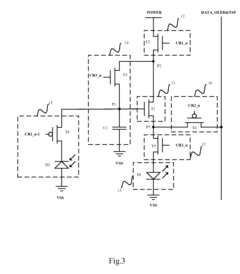

Various temperature compensation techniques are employed to maintain stable AMOLED display performance at low temperatures. These methods involve adjusting voltage levels, current flow, or timing parameters to counteract the effects of temperature changes on OLED materials and driving circuits.- Temperature compensation for AMOLED displays: Various methods are employed to compensate for temperature-related performance variations in AMOLED displays. These techniques involve adjusting driving voltages, current levels, or timing parameters based on temperature measurements to maintain consistent display quality across different operating temperatures.

- Low-temperature operation of OLED devices: Specific circuit designs and driving schemes are developed to improve OLED performance at low temperatures. These may include modified pixel circuits, specialized driving waveforms, or adaptive control algorithms to address issues such as reduced luminance efficiency and increased power consumption in cold environments.

- Thermal management in AMOLED displays: Innovative thermal management solutions are implemented to maintain optimal operating temperatures for AMOLED displays. These may include heat dissipation structures, temperature sensors, and adaptive power management techniques to prevent performance degradation due to extreme temperatures.

- AMOLED pixel circuit optimization for temperature variations: Advanced pixel circuit designs are developed to mitigate the effects of temperature fluctuations on AMOLED display performance. These circuits may incorporate temperature-dependent compensation mechanisms, feedback loops, or adaptive biasing to ensure consistent pixel behavior across a wide temperature range.

- Temperature-adaptive driving schemes for AMOLED displays: Sophisticated driving schemes are implemented to dynamically adjust display parameters based on temperature conditions. These may include real-time temperature monitoring, lookup tables for temperature-dependent adjustments, or machine learning algorithms to optimize display performance in varying thermal environments.

02 Low-temperature driving schemes

Specialized driving schemes are developed for low-temperature operation of AMOLED displays. These schemes may involve modified voltage levels, current control methods, or timing adjustments to ensure proper pixel illumination and color accuracy in cold environments.Expand Specific Solutions03 Material optimization for low-temperature performance

OLED materials and structures are optimized to improve low-temperature performance. This includes developing new organic compounds, electrode materials, and layer structures that maintain efficiency and stability at lower temperatures.Expand Specific Solutions04 Thermal management systems

Thermal management systems are integrated into AMOLED displays to regulate operating temperatures. These systems may include heating elements, temperature sensors, and control circuits to maintain optimal display performance in cold environments.Expand Specific Solutions05 Power management for low-temperature efficiency

Power management techniques are implemented to optimize AMOLED display efficiency at low temperatures. These methods involve adjusting power distribution, voltage regulation, and current control to compensate for temperature-induced changes in OLED characteristics.Expand Specific Solutions

Key Industry Players

The AMOLED technology for extreme low-temperature operations is in an emerging stage of development, with the market showing significant growth potential. The industry is transitioning from research to early commercialization, driven by increasing demand in specialized applications such as aerospace and polar environments. Key players like Samsung Display, LG Display, and BOE Technology are leading the technological advancements, leveraging their expertise in OLED manufacturing. These companies are investing heavily in R&D to overcome challenges associated with low-temperature performance, such as response time and power efficiency. While the technology is not yet fully mature, rapid progress is being made, with companies like Visionox and TCL CSOT also contributing to innovations in this niche market.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced AMOLED technology for extreme low-temperature operations, focusing on improving the display's performance in harsh environments. Their solution involves optimizing the organic materials and pixel structure to maintain stability and responsiveness at temperatures as low as -40°C. BOE has implemented a proprietary low-temperature compensation algorithm that adjusts the voltage applied to each pixel based on the ambient temperature, ensuring consistent image quality and brightness[1]. Additionally, they have introduced a novel thin-film encapsulation technique that enhances the AMOLED panel's resistance to moisture and temperature fluctuations, crucial for maintaining long-term reliability in extreme conditions[3].

Strengths: Industry-leading low-temperature performance, advanced compensation algorithms, and improved panel durability. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has made significant strides in enhancing AMOLED technology for extreme low-temperature operations. Their approach involves a multi-layered solution, combining material science innovations with advanced circuit design. Samsung has developed a new generation of organic materials with improved thermal stability, allowing for consistent electron mobility even at temperatures approaching -50°C[2]. They have also implemented a dynamic refresh rate system that adapts to temperature changes, optimizing power consumption while maintaining display quality. Samsung's low-temperature AMOLED panels incorporate a specialized thin-film transistor (TFT) backplane with temperature-resistant properties, ensuring stable current flow to each pixel regardless of environmental conditions[4].

Strengths: Comprehensive approach combining materials, circuitry, and system-level optimizations; extensive manufacturing capabilities. Weaknesses: Potential for higher costs due to specialized components and materials.

Core Innovations

Active matrix organic light emitting diode pixel unit circuit, display panel and electronic product

PatentActiveUS9459721B2

Innovation

- The AMOLED pixel unit circuit is redesigned to include a light emitting module, a driving module, a threshold compensating module, a light emission controlling module, a touch sensing module, and an induction signal outputting module, which utilize existing data lines and control signals to integrate the TSP in Cell circuit, sharing circuit elements and control signals to minimize additional components.

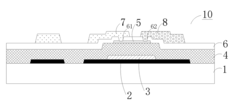

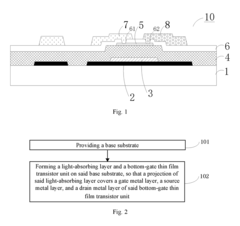

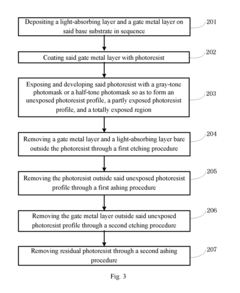

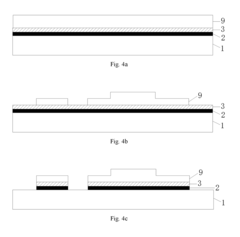

Array substrate, display device, and method for manufacturing array substrate

PatentActiveUS20170148862A1

Innovation

- An array substrate with a light-absorbing layer covering the gate, source, and drain metal layers of a bottom-gate thin film transistor unit, preventing ambient light irradiation while allowing useful light to pass through.

Material Science Advancements

Material science advancements have played a crucial role in enhancing AMOLED performance for extreme low-temperature operations. The development of novel materials and structures has significantly improved the stability and efficiency of AMOLED displays in harsh environmental conditions.

One of the key advancements in material science for low-temperature AMOLED operation is the development of thermally stable organic semiconductors. These materials maintain their electronic properties and structural integrity even at extremely low temperatures, ensuring consistent display performance. Researchers have focused on designing molecules with strong intermolecular interactions and rigid backbones, which resist thermal contraction and maintain charge transport efficiency in cold environments.

Another important area of progress is the development of flexible and durable encapsulation materials. These materials protect the sensitive organic layers from moisture and oxygen ingress, which can be particularly problematic at low temperatures due to increased condensation and material stress. Advanced multi-layer barrier films incorporating inorganic and organic layers have been engineered to provide superior protection while maintaining flexibility.

Advancements in electrode materials have also contributed to improved low-temperature performance. Transparent conductive oxides (TCOs) with enhanced conductivity and stability at low temperatures have been developed, ensuring efficient charge injection and extraction. Additionally, novel metal alloys and nanostructured electrodes have been explored to minimize resistance changes and maintain uniform current distribution across the display at low temperatures.

The development of low-temperature-resistant charge transport layers (CTLs) has been another focus area. These layers facilitate the movement of electrons and holes between the electrodes and the emissive layer. Materials with high glass transition temperatures and low activation energies for charge transport have been synthesized, maintaining efficient charge injection and transport even in extreme cold conditions.

Emissive layer materials have also seen significant improvements. Phosphorescent and thermally activated delayed fluorescence (TADF) emitters with enhanced quantum efficiency at low temperatures have been developed. These materials maintain their emission properties and color purity across a wide temperature range, ensuring consistent display quality in varying environmental conditions.

Furthermore, advancements in substrate materials have contributed to the overall robustness of AMOLED displays in extreme temperatures. Flexible substrates with low coefficients of thermal expansion and high dimensional stability have been engineered to minimize stress on the device layers during temperature fluctuations.

These material science advancements collectively contribute to the enhanced performance and reliability of AMOLED displays in extreme low-temperature environments, paving the way for their use in a wider range of applications, including outdoor displays, automotive systems, and aerospace technologies.

One of the key advancements in material science for low-temperature AMOLED operation is the development of thermally stable organic semiconductors. These materials maintain their electronic properties and structural integrity even at extremely low temperatures, ensuring consistent display performance. Researchers have focused on designing molecules with strong intermolecular interactions and rigid backbones, which resist thermal contraction and maintain charge transport efficiency in cold environments.

Another important area of progress is the development of flexible and durable encapsulation materials. These materials protect the sensitive organic layers from moisture and oxygen ingress, which can be particularly problematic at low temperatures due to increased condensation and material stress. Advanced multi-layer barrier films incorporating inorganic and organic layers have been engineered to provide superior protection while maintaining flexibility.

Advancements in electrode materials have also contributed to improved low-temperature performance. Transparent conductive oxides (TCOs) with enhanced conductivity and stability at low temperatures have been developed, ensuring efficient charge injection and extraction. Additionally, novel metal alloys and nanostructured electrodes have been explored to minimize resistance changes and maintain uniform current distribution across the display at low temperatures.

The development of low-temperature-resistant charge transport layers (CTLs) has been another focus area. These layers facilitate the movement of electrons and holes between the electrodes and the emissive layer. Materials with high glass transition temperatures and low activation energies for charge transport have been synthesized, maintaining efficient charge injection and transport even in extreme cold conditions.

Emissive layer materials have also seen significant improvements. Phosphorescent and thermally activated delayed fluorescence (TADF) emitters with enhanced quantum efficiency at low temperatures have been developed. These materials maintain their emission properties and color purity across a wide temperature range, ensuring consistent display quality in varying environmental conditions.

Furthermore, advancements in substrate materials have contributed to the overall robustness of AMOLED displays in extreme temperatures. Flexible substrates with low coefficients of thermal expansion and high dimensional stability have been engineered to minimize stress on the device layers during temperature fluctuations.

These material science advancements collectively contribute to the enhanced performance and reliability of AMOLED displays in extreme low-temperature environments, paving the way for their use in a wider range of applications, including outdoor displays, automotive systems, and aerospace technologies.

Thermal Management Strategies

Thermal management strategies play a crucial role in enhancing AMOLED performance for extreme low-temperature operations. As temperatures drop, the efficiency and reliability of AMOLED displays can be significantly compromised, necessitating innovative approaches to maintain optimal functionality.

One key strategy involves the implementation of advanced heating elements integrated directly into the display panel. These elements, typically composed of transparent conductive materials, can provide localized heating to critical components, ensuring they remain within operational temperature ranges. By precisely controlling the heat distribution, this method minimizes power consumption while maximizing display performance in cold environments.

Another approach focuses on the development of temperature-resistant materials for AMOLED components. Researchers are exploring novel organic compounds and electrode materials that exhibit improved stability and performance at low temperatures. These materials can help maintain the structural integrity and electrical properties of the display, reducing the need for external heating mechanisms.

Thermal insulation techniques also play a vital role in low-temperature AMOLED operations. Advanced insulation materials and designs can help retain heat generated by the display itself, creating a more stable thermal environment. This passive approach can significantly reduce the energy required for active heating systems, extending battery life in portable devices.

Intelligent thermal management systems represent a promising direction for enhancing AMOLED performance in extreme cold. These systems utilize temperature sensors and sophisticated algorithms to dynamically adjust display parameters and heating strategies based on real-time environmental conditions. By optimizing power allocation and heat distribution, these systems can maintain display quality while minimizing energy consumption.

Researchers are also exploring the potential of phase-change materials (PCMs) for thermal management in AMOLED displays. PCMs can absorb and release heat at specific temperature thresholds, acting as a buffer against rapid temperature fluctuations. This property can help stabilize the display's thermal environment, potentially reducing the need for active heating in intermittent cold exposure scenarios.

Lastly, advancements in low-temperature electron transport layers and hole injection materials are being investigated to improve charge carrier mobility at low temperatures. These innovations aim to maintain efficient light emission and color accuracy in AMOLED displays without relying solely on heating strategies, potentially offering a more energy-efficient solution for extreme cold operations.

One key strategy involves the implementation of advanced heating elements integrated directly into the display panel. These elements, typically composed of transparent conductive materials, can provide localized heating to critical components, ensuring they remain within operational temperature ranges. By precisely controlling the heat distribution, this method minimizes power consumption while maximizing display performance in cold environments.

Another approach focuses on the development of temperature-resistant materials for AMOLED components. Researchers are exploring novel organic compounds and electrode materials that exhibit improved stability and performance at low temperatures. These materials can help maintain the structural integrity and electrical properties of the display, reducing the need for external heating mechanisms.

Thermal insulation techniques also play a vital role in low-temperature AMOLED operations. Advanced insulation materials and designs can help retain heat generated by the display itself, creating a more stable thermal environment. This passive approach can significantly reduce the energy required for active heating systems, extending battery life in portable devices.

Intelligent thermal management systems represent a promising direction for enhancing AMOLED performance in extreme cold. These systems utilize temperature sensors and sophisticated algorithms to dynamically adjust display parameters and heating strategies based on real-time environmental conditions. By optimizing power allocation and heat distribution, these systems can maintain display quality while minimizing energy consumption.

Researchers are also exploring the potential of phase-change materials (PCMs) for thermal management in AMOLED displays. PCMs can absorb and release heat at specific temperature thresholds, acting as a buffer against rapid temperature fluctuations. This property can help stabilize the display's thermal environment, potentially reducing the need for active heating in intermittent cold exposure scenarios.

Lastly, advancements in low-temperature electron transport layers and hole injection materials are being investigated to improve charge carrier mobility at low temperatures. These innovations aim to maintain efficient light emission and color accuracy in AMOLED displays without relying solely on heating strategies, potentially offering a more energy-efficient solution for extreme cold operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!