Enhancing Ferrofluid Stability for Long-Term Industrial Use

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Stability Challenges and Objectives

Ferrofluids, colloidal suspensions of magnetic nanoparticles in a carrier fluid, have garnered significant attention in various industrial applications due to their unique magnetic properties. However, the long-term stability of ferrofluids remains a critical challenge, hindering their widespread adoption in industrial settings. This technical report aims to explore the current state of ferrofluid stability and outline the objectives for enhancing their long-term performance.

The development of ferrofluids dates back to the 1960s, with initial applications primarily in aerospace and mechanical engineering. Over the years, the technology has evolved, finding its way into diverse fields such as biomedicine, energy harvesting, and electronics cooling. Despite these advancements, the stability of ferrofluids over extended periods remains a persistent issue, limiting their potential in industrial applications that require prolonged operational lifetimes.

The primary stability challenges faced by ferrofluids include particle agglomeration, sedimentation, and oxidation of magnetic nanoparticles. These phenomena can lead to a gradual degradation of the ferrofluid's magnetic properties and overall performance. Particle agglomeration occurs when magnetic nanoparticles cluster together, forming larger aggregates that compromise the fluid's homogeneity. Sedimentation, on the other hand, results in the settling of particles due to gravitational forces, causing a non-uniform distribution of magnetic material within the fluid.

Oxidation of magnetic nanoparticles, particularly in the case of iron-based ferrofluids, can lead to a reduction in magnetic susceptibility and altered rheological properties. This oxidation process is often accelerated by exposure to air and elevated temperatures, further complicating the stability issue in industrial environments.

The objectives for enhancing ferrofluid stability for long-term industrial use are multifaceted. Firstly, there is a need to develop more effective surfactant coatings for magnetic nanoparticles that can prevent agglomeration and provide better dispersion stability. This involves exploring novel surfactant chemistries and optimizing coating techniques to ensure long-lasting particle isolation.

Secondly, research efforts should focus on improving the carrier fluid properties to minimize sedimentation effects. This may include the development of carrier fluids with tailored viscosities and densities that can better suspend magnetic nanoparticles over extended periods.

Thirdly, addressing the oxidation challenge requires innovative approaches to nanoparticle synthesis and protection. This could involve the development of core-shell structures or the use of more stable magnetic materials that are less susceptible to oxidation.

Lastly, there is a need to establish standardized testing protocols and performance metrics for evaluating ferrofluid stability under various industrial conditions. This will enable more accurate comparisons between different ferrofluid formulations and guide future development efforts.

The development of ferrofluids dates back to the 1960s, with initial applications primarily in aerospace and mechanical engineering. Over the years, the technology has evolved, finding its way into diverse fields such as biomedicine, energy harvesting, and electronics cooling. Despite these advancements, the stability of ferrofluids over extended periods remains a persistent issue, limiting their potential in industrial applications that require prolonged operational lifetimes.

The primary stability challenges faced by ferrofluids include particle agglomeration, sedimentation, and oxidation of magnetic nanoparticles. These phenomena can lead to a gradual degradation of the ferrofluid's magnetic properties and overall performance. Particle agglomeration occurs when magnetic nanoparticles cluster together, forming larger aggregates that compromise the fluid's homogeneity. Sedimentation, on the other hand, results in the settling of particles due to gravitational forces, causing a non-uniform distribution of magnetic material within the fluid.

Oxidation of magnetic nanoparticles, particularly in the case of iron-based ferrofluids, can lead to a reduction in magnetic susceptibility and altered rheological properties. This oxidation process is often accelerated by exposure to air and elevated temperatures, further complicating the stability issue in industrial environments.

The objectives for enhancing ferrofluid stability for long-term industrial use are multifaceted. Firstly, there is a need to develop more effective surfactant coatings for magnetic nanoparticles that can prevent agglomeration and provide better dispersion stability. This involves exploring novel surfactant chemistries and optimizing coating techniques to ensure long-lasting particle isolation.

Secondly, research efforts should focus on improving the carrier fluid properties to minimize sedimentation effects. This may include the development of carrier fluids with tailored viscosities and densities that can better suspend magnetic nanoparticles over extended periods.

Thirdly, addressing the oxidation challenge requires innovative approaches to nanoparticle synthesis and protection. This could involve the development of core-shell structures or the use of more stable magnetic materials that are less susceptible to oxidation.

Lastly, there is a need to establish standardized testing protocols and performance metrics for evaluating ferrofluid stability under various industrial conditions. This will enable more accurate comparisons between different ferrofluid formulations and guide future development efforts.

Industrial Demand for Stable Ferrofluids

The industrial demand for stable ferrofluids has been steadily increasing across various sectors due to their unique properties and versatile applications. Ferrofluids, which are colloidal suspensions of magnetic nanoparticles in a carrier fluid, offer a combination of magnetic responsiveness and liquid-like behavior that makes them invaluable in numerous industrial processes.

In the manufacturing sector, stable ferrofluids are crucial for precision engineering and advanced machining processes. They are used in magnetic seals for rotating shafts, providing an effective barrier against contaminants while minimizing friction. This application is particularly important in industries requiring high-purity environments, such as semiconductor manufacturing and pharmaceutical production.

The energy sector has also shown a growing interest in stable ferrofluids. In oil and gas exploration, ferrofluids are utilized for enhanced oil recovery techniques, where they can be used to improve the efficiency of extraction processes. Additionally, the renewable energy industry is exploring the use of ferrofluids in solar thermal collectors and wind turbine generators to enhance heat transfer and power generation capabilities.

In the automotive industry, stable ferrofluids are finding applications in adaptive suspension systems and shock absorbers. These smart fluids can rapidly change their viscosity in response to magnetic fields, allowing for real-time adjustments in vehicle handling and ride comfort. As the automotive sector moves towards more advanced and autonomous vehicles, the demand for such responsive materials is expected to grow significantly.

The medical and biotech industries are also driving the demand for stable ferrofluids. In medical imaging, ferrofluids are used as contrast agents for magnetic resonance imaging (MRI), enabling more precise diagnostics. Furthermore, researchers are exploring the potential of ferrofluids in targeted drug delivery systems and hyperthermia treatments for cancer therapy.

In the electronics sector, stable ferrofluids are being investigated for their potential in cooling systems for high-performance computing and data centers. Their ability to be precisely controlled by magnetic fields makes them promising candidates for next-generation liquid cooling solutions that can efficiently manage heat in compact electronic devices.

The aerospace industry is another sector showing increased interest in stable ferrofluids. Applications range from advanced damping systems in aircraft to potential use in spacecraft propulsion systems. The ability of ferrofluids to operate in zero-gravity environments makes them particularly attractive for space applications.

As industries continue to push the boundaries of technology and seek more efficient and innovative solutions, the demand for stable ferrofluids is expected to grow. However, this growth is contingent upon overcoming the challenges related to long-term stability, which is crucial for ensuring reliable performance in industrial applications. Addressing these stability issues is therefore a key focus area for researchers and manufacturers in the field of ferrofluid technology.

In the manufacturing sector, stable ferrofluids are crucial for precision engineering and advanced machining processes. They are used in magnetic seals for rotating shafts, providing an effective barrier against contaminants while minimizing friction. This application is particularly important in industries requiring high-purity environments, such as semiconductor manufacturing and pharmaceutical production.

The energy sector has also shown a growing interest in stable ferrofluids. In oil and gas exploration, ferrofluids are utilized for enhanced oil recovery techniques, where they can be used to improve the efficiency of extraction processes. Additionally, the renewable energy industry is exploring the use of ferrofluids in solar thermal collectors and wind turbine generators to enhance heat transfer and power generation capabilities.

In the automotive industry, stable ferrofluids are finding applications in adaptive suspension systems and shock absorbers. These smart fluids can rapidly change their viscosity in response to magnetic fields, allowing for real-time adjustments in vehicle handling and ride comfort. As the automotive sector moves towards more advanced and autonomous vehicles, the demand for such responsive materials is expected to grow significantly.

The medical and biotech industries are also driving the demand for stable ferrofluids. In medical imaging, ferrofluids are used as contrast agents for magnetic resonance imaging (MRI), enabling more precise diagnostics. Furthermore, researchers are exploring the potential of ferrofluids in targeted drug delivery systems and hyperthermia treatments for cancer therapy.

In the electronics sector, stable ferrofluids are being investigated for their potential in cooling systems for high-performance computing and data centers. Their ability to be precisely controlled by magnetic fields makes them promising candidates for next-generation liquid cooling solutions that can efficiently manage heat in compact electronic devices.

The aerospace industry is another sector showing increased interest in stable ferrofluids. Applications range from advanced damping systems in aircraft to potential use in spacecraft propulsion systems. The ability of ferrofluids to operate in zero-gravity environments makes them particularly attractive for space applications.

As industries continue to push the boundaries of technology and seek more efficient and innovative solutions, the demand for stable ferrofluids is expected to grow. However, this growth is contingent upon overcoming the challenges related to long-term stability, which is crucial for ensuring reliable performance in industrial applications. Addressing these stability issues is therefore a key focus area for researchers and manufacturers in the field of ferrofluid technology.

Current Limitations in Ferrofluid Longevity

Ferrofluids, despite their remarkable properties and potential applications, face significant challenges in maintaining long-term stability for industrial use. One of the primary limitations is the tendency of magnetic nanoparticles to agglomerate over time, leading to a loss of fluid homogeneity and magnetic responsiveness. This agglomeration is driven by strong magnetic dipole-dipole interactions between particles, which can overcome the stabilizing effects of surfactants or other dispersing agents.

Another critical issue is the oxidation of magnetic nanoparticles, particularly those composed of iron or iron oxides. Exposure to oxygen, even in small amounts, can lead to gradual degradation of the particles' magnetic properties, reducing the overall performance of the ferrofluid. This oxidation process is often accelerated in industrial environments where the fluid may be subjected to elevated temperatures or harsh chemical conditions.

The stability of the surfactant layer surrounding the magnetic nanoparticles is also a concern for long-term use. Over time, surfactants can degrade or become detached from the particle surface, compromising the colloidal stability of the ferrofluid. This can result in phase separation, sedimentation, or the formation of larger aggregates, all of which negatively impact the fluid's performance and reliability in industrial applications.

Temperature fluctuations pose another challenge to ferrofluid longevity. Extreme temperatures, both high and low, can affect the viscosity of the carrier fluid, alter the surfactant behavior, and potentially cause irreversible changes to the magnetic nanoparticles. This sensitivity to temperature limits the range of environments in which ferrofluids can be effectively deployed for extended periods.

The carrier fluid itself can also contribute to stability issues. Evaporation of volatile carrier fluids can lead to changes in concentration and viscosity, affecting the overall behavior of the ferrofluid. Additionally, some carrier fluids may degrade over time, especially when exposed to UV light or certain chemical environments, further compromising the ferrofluid's long-term stability.

Mechanical stress is another factor that can limit ferrofluid longevity. In applications involving continuous or high-frequency movement, such as in seals or bearings, the constant shear forces can lead to the breakdown of the surfactant layer or cause physical damage to the magnetic nanoparticles. This mechanical wear can significantly reduce the lifespan of the ferrofluid in industrial settings.

Lastly, the presence of contaminants in industrial environments can adversely affect ferrofluid stability. Dust, debris, or other particulate matter can interfere with the magnetic properties of the fluid or disrupt the delicate balance of forces maintaining the colloidal suspension. These contaminants may also catalyze chemical reactions that degrade the ferrofluid components over time.

Another critical issue is the oxidation of magnetic nanoparticles, particularly those composed of iron or iron oxides. Exposure to oxygen, even in small amounts, can lead to gradual degradation of the particles' magnetic properties, reducing the overall performance of the ferrofluid. This oxidation process is often accelerated in industrial environments where the fluid may be subjected to elevated temperatures or harsh chemical conditions.

The stability of the surfactant layer surrounding the magnetic nanoparticles is also a concern for long-term use. Over time, surfactants can degrade or become detached from the particle surface, compromising the colloidal stability of the ferrofluid. This can result in phase separation, sedimentation, or the formation of larger aggregates, all of which negatively impact the fluid's performance and reliability in industrial applications.

Temperature fluctuations pose another challenge to ferrofluid longevity. Extreme temperatures, both high and low, can affect the viscosity of the carrier fluid, alter the surfactant behavior, and potentially cause irreversible changes to the magnetic nanoparticles. This sensitivity to temperature limits the range of environments in which ferrofluids can be effectively deployed for extended periods.

The carrier fluid itself can also contribute to stability issues. Evaporation of volatile carrier fluids can lead to changes in concentration and viscosity, affecting the overall behavior of the ferrofluid. Additionally, some carrier fluids may degrade over time, especially when exposed to UV light or certain chemical environments, further compromising the ferrofluid's long-term stability.

Mechanical stress is another factor that can limit ferrofluid longevity. In applications involving continuous or high-frequency movement, such as in seals or bearings, the constant shear forces can lead to the breakdown of the surfactant layer or cause physical damage to the magnetic nanoparticles. This mechanical wear can significantly reduce the lifespan of the ferrofluid in industrial settings.

Lastly, the presence of contaminants in industrial environments can adversely affect ferrofluid stability. Dust, debris, or other particulate matter can interfere with the magnetic properties of the fluid or disrupt the delicate balance of forces maintaining the colloidal suspension. These contaminants may also catalyze chemical reactions that degrade the ferrofluid components over time.

Existing Ferrofluid Stabilization Techniques

01 Surfactant and carrier fluid selection

The stability of ferrofluids can be improved by carefully selecting surfactants and carrier fluids. Appropriate surfactants help prevent particle agglomeration, while suitable carrier fluids maintain the dispersion of magnetic particles. This combination enhances the overall stability and performance of the ferrofluid.- Surfactant-based stabilization: Ferrofluids can be stabilized using surfactants, which coat the magnetic particles and prevent agglomeration. This method enhances the colloidal stability of the ferrofluid by creating a repulsive force between particles, allowing for long-term stability and preventing sedimentation.

- Temperature control for stability: Maintaining optimal temperature conditions is crucial for ferrofluid stability. Temperature control systems can be implemented to prevent thermal degradation and maintain the fluid's magnetic properties. This approach helps in preserving the stability of ferrofluids in various applications, including seals and bearings.

- Magnetic field-induced stabilization: Applying controlled magnetic fields can enhance ferrofluid stability by aligning the magnetic particles and preventing sedimentation. This technique is particularly useful in applications such as seals, dampers, and bearings, where maintaining the fluid's position and properties is critical.

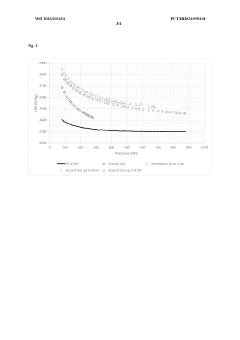

- Nanoparticle size and composition optimization: Optimizing the size and composition of magnetic nanoparticles in ferrofluids can significantly improve their stability. Smaller particle sizes and careful selection of magnetic materials can enhance colloidal stability and prevent agglomeration, leading to more stable ferrofluid formulations.

- Carrier fluid selection and modification: The choice of carrier fluid and its modification play a crucial role in ferrofluid stability. Selecting appropriate carrier fluids with suitable viscosity and chemical properties, or modifying them with additives, can improve the overall stability of the ferrofluid system and enhance its performance in various applications.

02 Magnetic particle size and distribution control

Controlling the size and distribution of magnetic particles in ferrofluids is crucial for stability. Optimizing particle size and ensuring a narrow size distribution can prevent sedimentation and maintain the fluid's magnetic properties over time. This approach contributes to the long-term stability of ferrofluids.Expand Specific Solutions03 Temperature and environmental stability

Enhancing the temperature and environmental stability of ferrofluids is essential for their practical applications. This can be achieved by developing formulations that maintain their properties across a wide range of temperatures and environmental conditions, ensuring consistent performance in various applications.Expand Specific Solutions04 Additives for improved stability

Incorporating specific additives into ferrofluid formulations can significantly enhance their stability. These additives may include anti-oxidants, anti-settling agents, or other stabilizing compounds that prevent degradation, maintain particle suspension, and extend the shelf life of the ferrofluid.Expand Specific Solutions05 Encapsulation and coating techniques

Utilizing encapsulation and coating techniques can improve the stability of ferrofluids. By encapsulating magnetic particles or applying protective coatings, the particles' susceptibility to environmental factors and agglomeration can be reduced, leading to enhanced overall stability of the ferrofluid system.Expand Specific Solutions

Key Players in Ferrofluid Industry

The ferrofluid stability enhancement market is in a growth phase, driven by increasing industrial applications and demand for long-term stability. The market size is expanding, with projections indicating significant growth potential in various sectors. Technologically, ferrofluid stability is advancing, with companies like Ferrotec, LORD Corp., and TDK Corp. leading innovation. These firms are developing improved formulations and manufacturing processes to enhance long-term stability. Research institutions such as Fraunhofer-Gesellschaft and universities like Delft University of Technology are contributing to fundamental advancements in ferrofluid science. The competitive landscape is diverse, with both established players and emerging companies vying for market share through technological differentiation and application-specific solutions.

Teledyne Scientific & Imaging LLC

Technical Solution: Teledyne Scientific & Imaging LLC has focused on enhancing ferrofluid stability through advanced particle engineering and surface modification techniques. Their approach involves the synthesis of core-shell nanoparticles with a magnetic core and a chemically inert shell, providing improved stability against oxidation and agglomeration[2]. The company has also developed a proprietary surface functionalization process that allows for tailored interactions between particles and carrier fluids, enhancing long-term colloidal stability[4]. Additionally, Teledyne has implemented a novel microfluidic-based production method that ensures consistent particle size distribution and uniform surface coating, contributing to improved overall ferrofluid stability[6].

Strengths: Advanced particle engineering, surface modification techniques, and microfluidic production methods. Weaknesses: Potentially complex manufacturing processes and higher production costs.

Clariant International AG

Technical Solution: Clariant International AG has developed a comprehensive approach to enhancing ferrofluid stability for long-term industrial use. Their strategy involves the use of specially designed polymeric dispersants that create a steric barrier around magnetic nanoparticles, preventing agglomeration and sedimentation[1]. The company has also introduced a novel carrier fluid formulation that combines high-stability synthetic base oils with nano-engineered additives, resulting in improved thermal and oxidative stability of the ferrofluid system[3]. Additionally, Clariant has implemented an advanced particle surface treatment process that enhances the compatibility between magnetic nanoparticles and the carrier fluid, further improving long-term colloidal stability[5].

Strengths: Expertise in polymeric dispersants, advanced carrier fluid formulations, and particle surface treatments. Weaknesses: Potential scalability issues for large-scale production and higher costs associated with specialized additives.

Core Innovations in Ferrofluid Stability

Ferrofluid having improved oxidation resistance, and manufacturing method thereof

PatentInactiveJP2008306198A

Innovation

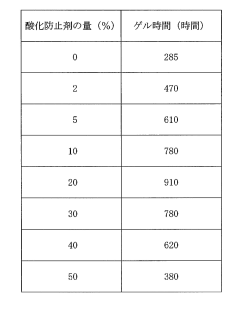

- A ferrofluid composition with improved oxidation resistance is achieved by incorporating 5-50% by weight of an antioxidant, such as alkylarylamines, into the carrier liquid to stabilize the colloidal suspension and extend the gelation time.

A device for stabilizing nanofluids based on exerting controlled pressure

PatentWO2023031654A1

Innovation

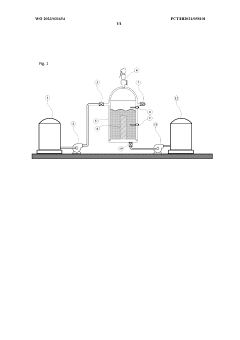

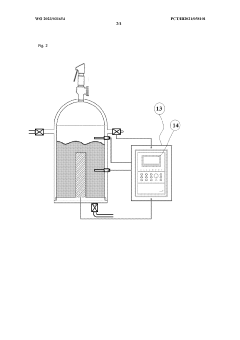

- A device that uses controlled pressurization to increase the stability and enthalpy of nanofluids by forming new hydrogen bonds and fixing them, preventing agglomeration and sedimentation, with a stainless steel pressure vessel and control system capable of pressurizing up to 8 bar.

Environmental Impact of Ferrofluids

The environmental impact of ferrofluids is a critical consideration in their long-term industrial use. These magnetic nanofluids, while offering unique properties and applications, also pose potential risks to ecosystems and human health. The production and disposal of ferrofluids can lead to the release of nanoparticles into the environment, raising concerns about their fate and effects on various organisms.

In aquatic environments, ferrofluid nanoparticles may accumulate in sediments or be ingested by marine life, potentially disrupting food chains and ecosystems. The magnetic properties of these particles could interfere with the navigation systems of certain species, particularly those that rely on Earth's magnetic field for orientation. Furthermore, the small size of nanoparticles allows them to penetrate cell membranes, potentially causing oxidative stress and cellular damage in exposed organisms.

Terrestrial ecosystems are also at risk from ferrofluid contamination. Soil microorganisms, which play crucial roles in nutrient cycling and soil health, may be adversely affected by the presence of ferrofluid nanoparticles. Changes in soil microbial communities could have far-reaching consequences for plant growth and overall ecosystem functioning. Additionally, there are concerns about the potential for these nanoparticles to enter the food chain through uptake by plants, leading to bioaccumulation in higher trophic levels.

The atmospheric dispersion of ferrofluid nanoparticles, while less studied, is another potential environmental concern. Aerosolized particles could contribute to air pollution and may have implications for respiratory health in both humans and animals. The long-range transport of these particles through air currents could extend their environmental impact far beyond the point of release.

To mitigate these environmental risks, research is ongoing to develop more environmentally friendly ferrofluids and improve containment strategies. Biodegradable carrier fluids and non-toxic magnetic nanoparticles are being explored as alternatives to traditional ferrofluid compositions. Additionally, advanced filtration and treatment technologies are being developed to prevent the release of nanoparticles during industrial processes and waste disposal.

Regulatory frameworks are also evolving to address the unique challenges posed by nanomaterials like ferrofluids. Environmental impact assessments and life cycle analyses are becoming increasingly important in the development and deployment of ferrofluid technologies. These measures aim to ensure that the benefits of ferrofluids can be realized while minimizing their potential negative impacts on the environment.

In aquatic environments, ferrofluid nanoparticles may accumulate in sediments or be ingested by marine life, potentially disrupting food chains and ecosystems. The magnetic properties of these particles could interfere with the navigation systems of certain species, particularly those that rely on Earth's magnetic field for orientation. Furthermore, the small size of nanoparticles allows them to penetrate cell membranes, potentially causing oxidative stress and cellular damage in exposed organisms.

Terrestrial ecosystems are also at risk from ferrofluid contamination. Soil microorganisms, which play crucial roles in nutrient cycling and soil health, may be adversely affected by the presence of ferrofluid nanoparticles. Changes in soil microbial communities could have far-reaching consequences for plant growth and overall ecosystem functioning. Additionally, there are concerns about the potential for these nanoparticles to enter the food chain through uptake by plants, leading to bioaccumulation in higher trophic levels.

The atmospheric dispersion of ferrofluid nanoparticles, while less studied, is another potential environmental concern. Aerosolized particles could contribute to air pollution and may have implications for respiratory health in both humans and animals. The long-range transport of these particles through air currents could extend their environmental impact far beyond the point of release.

To mitigate these environmental risks, research is ongoing to develop more environmentally friendly ferrofluids and improve containment strategies. Biodegradable carrier fluids and non-toxic magnetic nanoparticles are being explored as alternatives to traditional ferrofluid compositions. Additionally, advanced filtration and treatment technologies are being developed to prevent the release of nanoparticles during industrial processes and waste disposal.

Regulatory frameworks are also evolving to address the unique challenges posed by nanomaterials like ferrofluids. Environmental impact assessments and life cycle analyses are becoming increasingly important in the development and deployment of ferrofluid technologies. These measures aim to ensure that the benefits of ferrofluids can be realized while minimizing their potential negative impacts on the environment.

Ferrofluid Safety and Handling Protocols

Ferrofluid safety and handling protocols are critical for ensuring the long-term stability and safe use of these magnetic nanofluids in industrial applications. Proper handling procedures begin with personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and lab coats. When working with ferrofluids, it is essential to avoid skin contact and inhalation of vapors or mists.

Storage of ferrofluids requires careful consideration. They should be kept in tightly sealed containers made of non-reactive materials such as glass or certain plastics. The storage area should be cool, dry, and away from direct sunlight or strong magnetic fields. Temperature control is crucial, as extreme temperatures can affect the stability of the colloidal suspension.

Spill management is an important aspect of ferrofluid handling. In case of a spill, the area should be immediately cordoned off to prevent spreading. Absorbent materials specifically designed for oil-based liquids should be used for cleanup. It is important to note that conventional water-based cleaning methods may not be effective and could potentially worsen the situation.

Disposal of ferrofluids must comply with local and national regulations for hazardous waste. They should never be poured down drains or released into the environment. Instead, they should be collected in designated containers and disposed of through authorized waste management facilities.

When transferring ferrofluids between containers, care must be taken to minimize splashing and aerosolization. The use of pumps or pouring aids designed for viscous liquids can help reduce the risk of spills and exposure. Additionally, all equipment used with ferrofluids should be thoroughly cleaned after use to prevent cross-contamination and ensure accurate results in subsequent applications.

Regular training and education of personnel working with ferrofluids are essential. This should cover not only the handling procedures but also the potential hazards associated with these materials, including their magnetic properties and the nano-scale particles they contain. Emergency response protocols should be established and regularly reviewed to ensure preparedness in case of accidents or unexpected reactions.

Monitoring the condition of ferrofluids over time is crucial for maintaining their stability and effectiveness. This includes regular checks for signs of separation, agglomeration, or changes in viscosity. Implementing a quality control program with scheduled testing can help identify any degradation early, allowing for timely intervention to maintain the fluid's properties.

By adhering to these comprehensive safety and handling protocols, industries can maximize the benefits of ferrofluids while minimizing risks to personnel and equipment. These practices not only ensure the longevity and stability of the ferrofluids but also contribute to the overall safety and efficiency of industrial processes utilizing these innovative materials.

Storage of ferrofluids requires careful consideration. They should be kept in tightly sealed containers made of non-reactive materials such as glass or certain plastics. The storage area should be cool, dry, and away from direct sunlight or strong magnetic fields. Temperature control is crucial, as extreme temperatures can affect the stability of the colloidal suspension.

Spill management is an important aspect of ferrofluid handling. In case of a spill, the area should be immediately cordoned off to prevent spreading. Absorbent materials specifically designed for oil-based liquids should be used for cleanup. It is important to note that conventional water-based cleaning methods may not be effective and could potentially worsen the situation.

Disposal of ferrofluids must comply with local and national regulations for hazardous waste. They should never be poured down drains or released into the environment. Instead, they should be collected in designated containers and disposed of through authorized waste management facilities.

When transferring ferrofluids between containers, care must be taken to minimize splashing and aerosolization. The use of pumps or pouring aids designed for viscous liquids can help reduce the risk of spills and exposure. Additionally, all equipment used with ferrofluids should be thoroughly cleaned after use to prevent cross-contamination and ensure accurate results in subsequent applications.

Regular training and education of personnel working with ferrofluids are essential. This should cover not only the handling procedures but also the potential hazards associated with these materials, including their magnetic properties and the nano-scale particles they contain. Emergency response protocols should be established and regularly reviewed to ensure preparedness in case of accidents or unexpected reactions.

Monitoring the condition of ferrofluids over time is crucial for maintaining their stability and effectiveness. This includes regular checks for signs of separation, agglomeration, or changes in viscosity. Implementing a quality control program with scheduled testing can help identify any degradation early, allowing for timely intervention to maintain the fluid's properties.

By adhering to these comprehensive safety and handling protocols, industries can maximize the benefits of ferrofluids while minimizing risks to personnel and equipment. These practices not only ensure the longevity and stability of the ferrofluids but also contribute to the overall safety and efficiency of industrial processes utilizing these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!