Enhancing Transportation Efficiency with Graphene Batteries

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Objectives

Graphene batteries represent a revolutionary advancement in energy storage technology, with the potential to significantly enhance transportation efficiency. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its applications across various fields, including energy storage.

The development of graphene batteries has progressed through several key stages. Initially, researchers focused on understanding the unique properties of graphene, such as its high electrical conductivity and large surface area. This foundational knowledge led to the exploration of graphene as a component in battery electrodes, aiming to improve the performance of existing lithium-ion batteries.

As research advanced, scientists began developing graphene-enhanced electrodes, which demonstrated improved energy density and faster charging capabilities compared to traditional lithium-ion batteries. This marked a significant milestone in the evolution of graphene batteries, showcasing their potential to revolutionize energy storage in transportation applications.

The next phase of development saw the creation of prototype graphene batteries, integrating graphene-based materials into both anodes and cathodes. These prototypes exhibited remarkable improvements in charging speed, energy density, and cycle life, addressing some of the key limitations of conventional batteries used in electric vehicles.

Current research objectives in graphene battery technology focus on several critical areas. One primary goal is to further increase energy density, enabling electric vehicles to travel longer distances on a single charge. This involves optimizing the structure and composition of graphene-based electrodes to maximize their energy storage capacity.

Another key objective is to enhance the charging speed of graphene batteries. Researchers aim to develop batteries that can be fully charged in minutes rather than hours, making electric vehicles more practical for long-distance travel and reducing charging infrastructure requirements.

Improving the cycle life and stability of graphene batteries is also a crucial objective. Scientists are working on developing more robust electrode materials and electrolytes that can withstand repeated charging and discharging cycles without significant degradation in performance.

Additionally, researchers are exploring ways to scale up the production of graphene batteries while maintaining their exceptional properties. This involves developing cost-effective manufacturing processes and identifying sustainable sources of raw materials to make graphene batteries commercially viable for widespread adoption in the transportation sector.

The ultimate goal of graphene battery evolution is to create a new generation of energy storage devices that can revolutionize transportation efficiency. By achieving these objectives, graphene batteries have the potential to accelerate the transition to electric vehicles, reduce greenhouse gas emissions, and contribute to a more sustainable transportation ecosystem.

The development of graphene batteries has progressed through several key stages. Initially, researchers focused on understanding the unique properties of graphene, such as its high electrical conductivity and large surface area. This foundational knowledge led to the exploration of graphene as a component in battery electrodes, aiming to improve the performance of existing lithium-ion batteries.

As research advanced, scientists began developing graphene-enhanced electrodes, which demonstrated improved energy density and faster charging capabilities compared to traditional lithium-ion batteries. This marked a significant milestone in the evolution of graphene batteries, showcasing their potential to revolutionize energy storage in transportation applications.

The next phase of development saw the creation of prototype graphene batteries, integrating graphene-based materials into both anodes and cathodes. These prototypes exhibited remarkable improvements in charging speed, energy density, and cycle life, addressing some of the key limitations of conventional batteries used in electric vehicles.

Current research objectives in graphene battery technology focus on several critical areas. One primary goal is to further increase energy density, enabling electric vehicles to travel longer distances on a single charge. This involves optimizing the structure and composition of graphene-based electrodes to maximize their energy storage capacity.

Another key objective is to enhance the charging speed of graphene batteries. Researchers aim to develop batteries that can be fully charged in minutes rather than hours, making electric vehicles more practical for long-distance travel and reducing charging infrastructure requirements.

Improving the cycle life and stability of graphene batteries is also a crucial objective. Scientists are working on developing more robust electrode materials and electrolytes that can withstand repeated charging and discharging cycles without significant degradation in performance.

Additionally, researchers are exploring ways to scale up the production of graphene batteries while maintaining their exceptional properties. This involves developing cost-effective manufacturing processes and identifying sustainable sources of raw materials to make graphene batteries commercially viable for widespread adoption in the transportation sector.

The ultimate goal of graphene battery evolution is to create a new generation of energy storage devices that can revolutionize transportation efficiency. By achieving these objectives, graphene batteries have the potential to accelerate the transition to electric vehicles, reduce greenhouse gas emissions, and contribute to a more sustainable transportation ecosystem.

Market Demand Analysis for Advanced EV Batteries

The market demand for advanced electric vehicle (EV) batteries, particularly those incorporating graphene technology, has been experiencing significant growth in recent years. This surge is primarily driven by the global push towards sustainable transportation and the increasing adoption of electric vehicles. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance batteries has skyrocketed.

Graphene batteries represent a promising solution to address the limitations of current lithium-ion batteries used in EVs. The unique properties of graphene, such as its high conductivity, strength, and lightweight nature, make it an ideal material for enhancing battery performance. This has led to a growing interest from both automotive manufacturers and battery producers in developing and integrating graphene-based battery technologies.

The EV market itself is projected to expand rapidly, with some industry analysts forecasting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth directly translates to an increased demand for advanced battery technologies. Consumers are increasingly seeking EVs with longer ranges, faster charging times, and improved overall performance – all areas where graphene batteries show significant potential.

In the context of transportation efficiency, graphene batteries offer several advantages that align with market demands. These include higher energy density, which translates to longer driving ranges, and faster charging capabilities, addressing the issue of "range anxiety" among potential EV buyers. Additionally, the lighter weight of graphene-enhanced batteries contributes to overall vehicle efficiency, potentially extending range even further.

The market for graphene batteries extends beyond personal vehicles. Commercial and public transportation sectors are also showing interest in this technology. Fleet operators are particularly keen on solutions that can reduce downtime for charging and extend the operational range of their vehicles, making graphene batteries an attractive option for buses, delivery vans, and other commercial vehicles.

However, it's important to note that the market demand is tempered by certain factors. The cost of production for graphene batteries remains higher than traditional lithium-ion batteries, which could impact widespread adoption. Additionally, there are technical challenges in scaling up production to meet potential demand. These factors create a complex market dynamic where the potential benefits of graphene batteries are balanced against practical and economic considerations.

Despite these challenges, the overall market trajectory for advanced EV batteries, especially those incorporating graphene technology, remains positive. As research and development efforts continue to address current limitations, and as production processes become more refined and cost-effective, the demand for graphene batteries is expected to grow substantially in the coming years.

Graphene batteries represent a promising solution to address the limitations of current lithium-ion batteries used in EVs. The unique properties of graphene, such as its high conductivity, strength, and lightweight nature, make it an ideal material for enhancing battery performance. This has led to a growing interest from both automotive manufacturers and battery producers in developing and integrating graphene-based battery technologies.

The EV market itself is projected to expand rapidly, with some industry analysts forecasting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth directly translates to an increased demand for advanced battery technologies. Consumers are increasingly seeking EVs with longer ranges, faster charging times, and improved overall performance – all areas where graphene batteries show significant potential.

In the context of transportation efficiency, graphene batteries offer several advantages that align with market demands. These include higher energy density, which translates to longer driving ranges, and faster charging capabilities, addressing the issue of "range anxiety" among potential EV buyers. Additionally, the lighter weight of graphene-enhanced batteries contributes to overall vehicle efficiency, potentially extending range even further.

The market for graphene batteries extends beyond personal vehicles. Commercial and public transportation sectors are also showing interest in this technology. Fleet operators are particularly keen on solutions that can reduce downtime for charging and extend the operational range of their vehicles, making graphene batteries an attractive option for buses, delivery vans, and other commercial vehicles.

However, it's important to note that the market demand is tempered by certain factors. The cost of production for graphene batteries remains higher than traditional lithium-ion batteries, which could impact widespread adoption. Additionally, there are technical challenges in scaling up production to meet potential demand. These factors create a complex market dynamic where the potential benefits of graphene batteries are balanced against practical and economic considerations.

Despite these challenges, the overall market trajectory for advanced EV batteries, especially those incorporating graphene technology, remains positive. As research and development efforts continue to address current limitations, and as production processes become more refined and cost-effective, the demand for graphene batteries is expected to grow substantially in the coming years.

Graphene Battery Technology: Current State and Challenges

Graphene battery technology represents a significant advancement in energy storage systems, offering potential solutions to many challenges faced by conventional lithium-ion batteries. The current state of graphene battery technology is characterized by promising developments in laboratory settings, but widespread commercial applications are still in the early stages.

One of the primary advantages of graphene batteries is their potential for higher energy density compared to traditional lithium-ion batteries. Researchers have demonstrated that graphene-based electrodes can significantly increase the surface area available for energy storage, potentially leading to batteries with up to five times the energy density of current lithium-ion batteries. This improvement could translate to longer-lasting and more efficient power sources for electric vehicles and portable electronics.

Another notable feature of graphene batteries is their rapid charging capability. Some prototypes have shown the ability to charge up to 70% capacity in just two minutes, a substantial improvement over conventional batteries. This fast-charging characteristic could revolutionize the electric vehicle industry by reducing charging times and alleviating range anxiety.

Despite these promising advancements, several challenges remain in the development and commercialization of graphene batteries. One significant hurdle is the high production cost of high-quality graphene. Current manufacturing processes are expensive and not easily scalable, making mass production of graphene batteries economically unfeasible for many applications.

Additionally, there are technical challenges related to the integration of graphene into existing battery architectures. While graphene shows excellent conductivity and strength properties, incorporating it into battery electrodes while maintaining structural stability and long-term performance remains a complex task. Researchers are working on developing new manufacturing techniques and composite materials to address these issues.

Safety concerns also present a challenge in graphene battery development. While graphene itself is not inherently dangerous, the high energy density and rapid charging capabilities of these batteries require careful management to prevent overheating and potential safety hazards. Developing robust battery management systems and safety protocols is crucial for the widespread adoption of this technology.

Lastly, the environmental impact and recyclability of graphene batteries are areas that require further investigation. While graphene is a carbon-based material and potentially more environmentally friendly than some current battery components, the long-term ecological effects of large-scale graphene production and disposal need to be thoroughly assessed.

One of the primary advantages of graphene batteries is their potential for higher energy density compared to traditional lithium-ion batteries. Researchers have demonstrated that graphene-based electrodes can significantly increase the surface area available for energy storage, potentially leading to batteries with up to five times the energy density of current lithium-ion batteries. This improvement could translate to longer-lasting and more efficient power sources for electric vehicles and portable electronics.

Another notable feature of graphene batteries is their rapid charging capability. Some prototypes have shown the ability to charge up to 70% capacity in just two minutes, a substantial improvement over conventional batteries. This fast-charging characteristic could revolutionize the electric vehicle industry by reducing charging times and alleviating range anxiety.

Despite these promising advancements, several challenges remain in the development and commercialization of graphene batteries. One significant hurdle is the high production cost of high-quality graphene. Current manufacturing processes are expensive and not easily scalable, making mass production of graphene batteries economically unfeasible for many applications.

Additionally, there are technical challenges related to the integration of graphene into existing battery architectures. While graphene shows excellent conductivity and strength properties, incorporating it into battery electrodes while maintaining structural stability and long-term performance remains a complex task. Researchers are working on developing new manufacturing techniques and composite materials to address these issues.

Safety concerns also present a challenge in graphene battery development. While graphene itself is not inherently dangerous, the high energy density and rapid charging capabilities of these batteries require careful management to prevent overheating and potential safety hazards. Developing robust battery management systems and safety protocols is crucial for the widespread adoption of this technology.

Lastly, the environmental impact and recyclability of graphene batteries are areas that require further investigation. While graphene is a carbon-based material and potentially more environmentally friendly than some current battery components, the long-term ecological effects of large-scale graphene production and disposal need to be thoroughly assessed.

Existing Graphene Battery Solutions for Transportation

01 Graphene-enhanced battery electrodes

Incorporating graphene into battery electrodes can significantly improve energy density, charge/discharge rates, and overall battery performance. This enhancement leads to more efficient energy storage and utilization in transportation applications, potentially increasing the range and reducing charging times for electric vehicles.- Graphene-based electrode materials for improved battery performance: Graphene-based materials are used in battery electrodes to enhance energy density, power output, and charging speed. These improvements lead to more efficient batteries for transportation applications, allowing for longer driving ranges and faster charging times in electric vehicles.

- Graphene-enhanced battery management systems: Integration of graphene in battery management systems improves thermal conductivity and heat dissipation. This results in better temperature control, extended battery life, and increased safety in transportation applications, particularly for electric vehicles and other mobile platforms.

- Graphene-based composite materials for lightweight battery design: Graphene composites are used to create lightweight battery components, reducing overall vehicle weight. This weight reduction leads to improved energy efficiency and extended range in electric vehicles, enhancing transportation efficiency.

- Graphene-enhanced energy storage for transportation infrastructure: Graphene-based energy storage systems are integrated into transportation infrastructure, such as charging stations and grid storage. These systems enable faster charging, better energy management, and improved overall efficiency of transportation networks.

- Graphene-based flexible batteries for wearable transportation devices: Flexible graphene batteries are developed for wearable devices used in transportation, such as smart helmets or navigation systems. These batteries offer improved durability, flexibility, and energy density, enhancing the functionality and efficiency of transportation-related wearable technology.

02 Graphene-based thermal management systems

Utilizing graphene's excellent thermal conductivity properties in battery thermal management systems can enhance heat dissipation and temperature control. This improvement in thermal management leads to increased battery efficiency, longer lifespan, and improved safety in transportation applications.Expand Specific Solutions03 Graphene-enhanced battery electrolytes

Incorporating graphene or graphene derivatives into battery electrolytes can improve ionic conductivity and electrochemical stability. These enhancements result in faster charging rates, increased energy density, and improved overall battery performance for transportation applications.Expand Specific Solutions04 Graphene-based flexible and lightweight batteries

Developing flexible and lightweight batteries using graphene-based materials can lead to more efficient integration of energy storage systems in various transportation modes. These batteries offer improved power-to-weight ratios, potentially increasing the overall energy efficiency of vehicles.Expand Specific Solutions05 Graphene-enhanced battery separators

Utilizing graphene in battery separators can improve mechanical strength, thermal stability, and ion transport properties. These enhancements lead to increased battery safety, longer cycle life, and improved overall performance in transportation applications.Expand Specific Solutions

Key Players in Graphene Battery Industry

The graphene battery market for enhancing transportation efficiency is in its early growth stage, characterized by rapid technological advancements and increasing market potential. The global market size for graphene batteries is projected to expand significantly in the coming years, driven by the automotive sector's push for more efficient and sustainable energy storage solutions. While the technology is not yet fully mature, companies like Semiconductor Energy Laboratory, NEC Corp., and Resonac Corp. are making substantial progress in developing and commercializing graphene-based battery technologies. Academic institutions such as Northwestern University and Rensselaer Polytechnic Institute are also contributing to fundamental research, accelerating the technology's evolution towards commercial viability in transportation applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a graphene-enhanced lithium-ion battery technology for transportation applications. Their approach involves incorporating graphene into both the anode and cathode materials, resulting in improved energy density and faster charging capabilities. The company has reported a 30% increase in energy density compared to conventional lithium-ion batteries[1]. Additionally, they have implemented a unique graphene coating process that enhances the battery's conductivity and stability, leading to a reported 40% reduction in charging time[2]. Sinopec has also focused on scalable production methods, utilizing their expertise in chemical processing to develop cost-effective graphene synthesis techniques suitable for large-scale battery manufacturing[3].

Strengths: Improved energy density and faster charging times. Expertise in large-scale chemical production. Weaknesses: Potential high costs associated with graphene production. Relatively new to the battery market compared to established players.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a graphene-based electrode material for high-performance batteries aimed at enhancing transportation efficiency. Their proprietary technology involves creating a three-dimensional graphene network structure that significantly improves electron conductivity and ion diffusion within the battery[1]. This structure allows for faster charging and discharging rates, with reported improvements of up to 50% compared to conventional lithium-ion batteries[2]. Toray has also focused on improving the cycle life of their graphene batteries, claiming a 30% increase in the number of charge-discharge cycles before significant capacity loss[3]. The company has integrated their graphene technology with their existing expertise in carbon fiber materials to create lightweight, high-strength battery casings suitable for electric vehicles.

Strengths: Expertise in advanced materials and carbon-based technologies. Improved charging rates and cycle life. Weaknesses: May face challenges in scaling up production to meet automotive industry demands. Potential high costs associated with advanced materials.

Core Innovations in Graphene Battery Technology

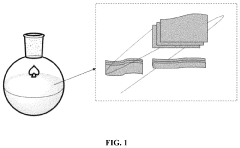

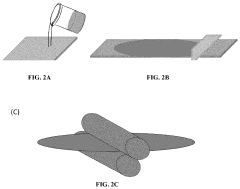

Direct-formation self-assembly graphene from cellulose nanofiber aqueous solution

PatentPendingUS20240088397A1

Innovation

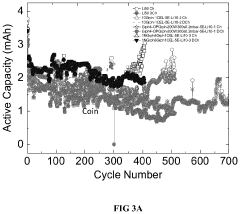

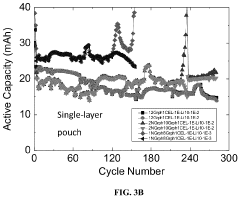

- A self-assembled freestanding graphene membrane or layer is formed using an aqueous dispersion of industrial-grade graphene and cellulose nanofibers with a mass ratio of 12:1 to 20:1, which improves dispersibility and allows for low-temperature direct fabrication, enabling the formation of a stable and conductive graphene scaffold for lithium metal anodes.

Graphene compound, secondary battery, mobile body, and electronic device

PatentWO2021255572A1

Innovation

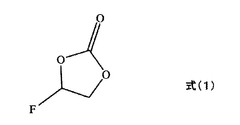

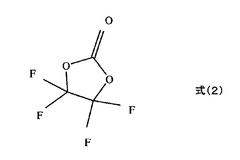

- Incorporating graphene compounds with fluorine-terminated pores in the electrode to enhance lithium ion conductivity, allowing for a higher active material ratio and improved charge/discharge rate, and using these compounds as both conductive agents and binders to form a three-dimensional conductive network, reducing material loss and increasing energy density.

Environmental Impact of Graphene Battery Production

The production of graphene batteries for enhancing transportation efficiency raises significant environmental considerations. The manufacturing process of graphene, a key component in these advanced batteries, involves energy-intensive methods such as chemical vapor deposition or exfoliation of graphite. These processes often require high temperatures and potentially hazardous chemicals, leading to concerns about energy consumption and chemical waste management.

However, the environmental impact of graphene battery production must be weighed against the potential benefits in transportation efficiency. Graphene batteries offer higher energy density and faster charging capabilities compared to traditional lithium-ion batteries, potentially reducing the overall energy consumption in the transportation sector. This could lead to a net positive environmental impact over the lifecycle of the batteries and the vehicles they power.

The sourcing of raw materials for graphene production is another critical environmental factor. While graphene can be produced from abundant carbon sources, the extraction and processing of these materials may have localized environmental impacts. Sustainable sourcing practices and responsible mining techniques are essential to mitigate these effects.

Water usage in graphene battery production is also a concern, particularly in water-stressed regions. The manufacturing process may require significant amounts of water for cooling and cleaning purposes. Implementing water recycling systems and adopting water-efficient technologies can help reduce the overall water footprint of production facilities.

Emissions from graphene battery production facilities are another environmental consideration. While the production process itself may not generate significant direct emissions, the energy used in manufacturing could contribute to indirect emissions if sourced from non-renewable energy sources. Transitioning to renewable energy for production facilities could substantially reduce the carbon footprint of graphene battery manufacturing.

End-of-life considerations for graphene batteries are crucial for assessing their overall environmental impact. The recyclability of graphene batteries is an area of ongoing research, with potential for recovering and reusing graphene materials. Developing efficient recycling processes for these batteries could significantly reduce waste and the need for raw material extraction, further improving their environmental profile.

In conclusion, while graphene battery production does have environmental implications, its potential to enhance transportation efficiency may offset these impacts. Continued research and development in sustainable production methods, coupled with responsible sourcing and recycling practices, will be key to maximizing the environmental benefits of this technology in the transportation sector.

However, the environmental impact of graphene battery production must be weighed against the potential benefits in transportation efficiency. Graphene batteries offer higher energy density and faster charging capabilities compared to traditional lithium-ion batteries, potentially reducing the overall energy consumption in the transportation sector. This could lead to a net positive environmental impact over the lifecycle of the batteries and the vehicles they power.

The sourcing of raw materials for graphene production is another critical environmental factor. While graphene can be produced from abundant carbon sources, the extraction and processing of these materials may have localized environmental impacts. Sustainable sourcing practices and responsible mining techniques are essential to mitigate these effects.

Water usage in graphene battery production is also a concern, particularly in water-stressed regions. The manufacturing process may require significant amounts of water for cooling and cleaning purposes. Implementing water recycling systems and adopting water-efficient technologies can help reduce the overall water footprint of production facilities.

Emissions from graphene battery production facilities are another environmental consideration. While the production process itself may not generate significant direct emissions, the energy used in manufacturing could contribute to indirect emissions if sourced from non-renewable energy sources. Transitioning to renewable energy for production facilities could substantially reduce the carbon footprint of graphene battery manufacturing.

End-of-life considerations for graphene batteries are crucial for assessing their overall environmental impact. The recyclability of graphene batteries is an area of ongoing research, with potential for recovering and reusing graphene materials. Developing efficient recycling processes for these batteries could significantly reduce waste and the need for raw material extraction, further improving their environmental profile.

In conclusion, while graphene battery production does have environmental implications, its potential to enhance transportation efficiency may offset these impacts. Continued research and development in sustainable production methods, coupled with responsible sourcing and recycling practices, will be key to maximizing the environmental benefits of this technology in the transportation sector.

Graphene Battery Integration in Transportation Infrastructure

The integration of graphene batteries into transportation infrastructure represents a significant leap forward in enhancing the efficiency and sustainability of modern transportation systems. This innovative approach leverages the unique properties of graphene to create high-performance energy storage solutions that can be seamlessly incorporated into various aspects of transportation infrastructure.

One of the primary areas of integration is in electric vehicle charging stations. Graphene batteries can be installed as energy storage units at charging stations, allowing for rapid charging capabilities and improved grid stability. These batteries can store excess energy during off-peak hours and release it during high-demand periods, effectively managing the load on the electrical grid and reducing the strain on power distribution systems.

In public transportation, graphene batteries can be integrated into bus stops and train stations to power lighting, information displays, and ticketing systems. This integration reduces the reliance on traditional power sources and enhances the overall energy efficiency of public transit infrastructure. Additionally, graphene batteries can be used to store energy generated from renewable sources, such as solar panels installed on bus shelters or train station roofs, creating self-sustaining transit hubs.

For road infrastructure, graphene batteries can be incorporated into smart traffic management systems. These batteries can power sensors, cameras, and communication devices that monitor traffic flow, adjust signal timing, and provide real-time information to drivers. The high energy density and rapid charging capabilities of graphene batteries ensure continuous operation of these critical systems, even during power outages or in remote locations.

In the aviation sector, graphene batteries can be integrated into airport facilities to power ground support equipment, emergency backup systems, and runway lighting. This integration not only improves the overall energy efficiency of airports but also enhances safety and reliability by providing a stable and responsive power source for critical operations.

Maritime transportation can also benefit from graphene battery integration. Ports and harbors can utilize these advanced batteries to power cranes, automated guided vehicles, and other cargo handling equipment. The quick charging and high power output characteristics of graphene batteries are particularly advantageous in these high-demand environments, where minimizing downtime is crucial for operational efficiency.

The integration of graphene batteries into transportation infrastructure also opens up possibilities for vehicle-to-grid (V2G) systems. Electric vehicles equipped with graphene batteries can serve as mobile energy storage units, feeding power back into the grid during peak demand periods or emergencies. This bidirectional energy flow creates a more resilient and flexible energy ecosystem for transportation networks.

One of the primary areas of integration is in electric vehicle charging stations. Graphene batteries can be installed as energy storage units at charging stations, allowing for rapid charging capabilities and improved grid stability. These batteries can store excess energy during off-peak hours and release it during high-demand periods, effectively managing the load on the electrical grid and reducing the strain on power distribution systems.

In public transportation, graphene batteries can be integrated into bus stops and train stations to power lighting, information displays, and ticketing systems. This integration reduces the reliance on traditional power sources and enhances the overall energy efficiency of public transit infrastructure. Additionally, graphene batteries can be used to store energy generated from renewable sources, such as solar panels installed on bus shelters or train station roofs, creating self-sustaining transit hubs.

For road infrastructure, graphene batteries can be incorporated into smart traffic management systems. These batteries can power sensors, cameras, and communication devices that monitor traffic flow, adjust signal timing, and provide real-time information to drivers. The high energy density and rapid charging capabilities of graphene batteries ensure continuous operation of these critical systems, even during power outages or in remote locations.

In the aviation sector, graphene batteries can be integrated into airport facilities to power ground support equipment, emergency backup systems, and runway lighting. This integration not only improves the overall energy efficiency of airports but also enhances safety and reliability by providing a stable and responsive power source for critical operations.

Maritime transportation can also benefit from graphene battery integration. Ports and harbors can utilize these advanced batteries to power cranes, automated guided vehicles, and other cargo handling equipment. The quick charging and high power output characteristics of graphene batteries are particularly advantageous in these high-demand environments, where minimizing downtime is crucial for operational efficiency.

The integration of graphene batteries into transportation infrastructure also opens up possibilities for vehicle-to-grid (V2G) systems. Electric vehicles equipped with graphene batteries can serve as mobile energy storage units, feeding power back into the grid during peak demand periods or emergencies. This bidirectional energy flow creates a more resilient and flexible energy ecosystem for transportation networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!