Evaluating Ferrofluid's Efficiency in Energy Harvesting Systems

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Energy Harvesting Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have garnered significant attention in the field of energy harvesting systems over the past few decades. These colloidal suspensions of magnetic nanoparticles in a carrier fluid exhibit remarkable responsiveness to external magnetic fields, making them promising candidates for various energy conversion applications. The development of ferrofluid-based energy harvesting technologies has its roots in the broader context of renewable energy research and the quest for novel, efficient methods of capturing and converting ambient energy into usable forms.

The evolution of ferrofluid technology can be traced back to the 1960s when NASA first developed these materials for rocket fuel management in zero-gravity environments. Since then, ferrofluids have found applications in diverse fields, including mechanical engineering, biomedical sciences, and more recently, energy harvesting. The growing interest in ferrofluids for energy applications stems from their unique ability to interact with magnetic fields, potentially enabling the conversion of mechanical energy from vibrations, fluid flow, or thermal gradients into electrical energy.

As global energy demands continue to rise and the need for sustainable energy solutions becomes increasingly urgent, the exploration of ferrofluid-based energy harvesting systems has gained momentum. Researchers and engineers are investigating various mechanisms to harness the properties of ferrofluids for energy conversion, including magnetohydrodynamic principles, thermomagnetic effects, and ferrohydrodynamic instabilities.

The primary objective of evaluating ferrofluid efficiency in energy harvesting systems is to assess their potential as a viable and competitive technology in the renewable energy landscape. This evaluation aims to quantify the energy conversion capabilities of ferrofluid-based systems, identify key performance metrics, and compare their efficiency with existing energy harvesting technologies. Additionally, the assessment seeks to uncover the fundamental physical principles governing ferrofluid behavior in energy conversion processes and explore innovative designs that can maximize their energy harvesting potential.

Furthermore, this evaluation endeavors to address critical challenges in ferrofluid-based energy harvesting, such as optimizing nanoparticle composition and concentration, enhancing fluid stability, and developing scalable and cost-effective manufacturing processes. By comprehensively analyzing these aspects, researchers aim to pave the way for the practical implementation of ferrofluid technology in real-world energy harvesting applications, potentially contributing to the diversification of renewable energy sources and the advancement of sustainable energy solutions.

The evolution of ferrofluid technology can be traced back to the 1960s when NASA first developed these materials for rocket fuel management in zero-gravity environments. Since then, ferrofluids have found applications in diverse fields, including mechanical engineering, biomedical sciences, and more recently, energy harvesting. The growing interest in ferrofluids for energy applications stems from their unique ability to interact with magnetic fields, potentially enabling the conversion of mechanical energy from vibrations, fluid flow, or thermal gradients into electrical energy.

As global energy demands continue to rise and the need for sustainable energy solutions becomes increasingly urgent, the exploration of ferrofluid-based energy harvesting systems has gained momentum. Researchers and engineers are investigating various mechanisms to harness the properties of ferrofluids for energy conversion, including magnetohydrodynamic principles, thermomagnetic effects, and ferrohydrodynamic instabilities.

The primary objective of evaluating ferrofluid efficiency in energy harvesting systems is to assess their potential as a viable and competitive technology in the renewable energy landscape. This evaluation aims to quantify the energy conversion capabilities of ferrofluid-based systems, identify key performance metrics, and compare their efficiency with existing energy harvesting technologies. Additionally, the assessment seeks to uncover the fundamental physical principles governing ferrofluid behavior in energy conversion processes and explore innovative designs that can maximize their energy harvesting potential.

Furthermore, this evaluation endeavors to address critical challenges in ferrofluid-based energy harvesting, such as optimizing nanoparticle composition and concentration, enhancing fluid stability, and developing scalable and cost-effective manufacturing processes. By comprehensively analyzing these aspects, researchers aim to pave the way for the practical implementation of ferrofluid technology in real-world energy harvesting applications, potentially contributing to the diversification of renewable energy sources and the advancement of sustainable energy solutions.

Market Analysis for Ferrofluid-Based Energy Systems

The market for ferrofluid-based energy harvesting systems is experiencing significant growth, driven by the increasing demand for sustainable and efficient energy solutions. Ferrofluids, which are magnetic liquids composed of nanoscale ferromagnetic particles suspended in a carrier fluid, offer unique properties that make them particularly suitable for energy harvesting applications.

In the context of energy harvesting, ferrofluids are primarily being explored for their potential in converting mechanical energy into electrical energy. This technology is particularly promising in scenarios where traditional energy harvesting methods are less effective, such as in low-frequency vibration environments or in fluid-based systems.

The global market for energy harvesting systems is projected to grow substantially in the coming years, with ferrofluid-based solutions poised to capture a significant portion of this growth. Key market drivers include the push for renewable energy sources, the need for self-powered sensors and devices in IoT applications, and the increasing focus on energy efficiency in industrial processes.

Several industries are showing keen interest in ferrofluid-based energy harvesting systems. The automotive sector is exploring these systems for harvesting energy from vehicle vibrations and heat. In the marine industry, there's potential for harnessing energy from ocean waves and currents. The aerospace sector is investigating ferrofluid systems for energy recovery in aircraft and spacecraft. Additionally, the construction industry is looking into integrating these systems into buildings for harvesting energy from structural vibrations and wind.

The market for ferrofluid-based energy systems is still in its early stages, with significant room for growth and innovation. Current market penetration is relatively low, but the technology is gaining traction among early adopters and in niche applications. As research progresses and more efficient systems are developed, the market is expected to expand rapidly.

Challenges in the market include the need for further technological advancements to improve efficiency and scalability, as well as the current higher costs compared to some traditional energy harvesting methods. However, ongoing research and development efforts are addressing these issues, with promising results in improving the performance and cost-effectiveness of ferrofluid-based systems.

The market is characterized by a mix of established players in the energy sector diversifying into ferrofluid technologies and innovative startups specializing in this niche. Collaborations between academic institutions, research organizations, and industry players are driving much of the innovation in this field.

In the context of energy harvesting, ferrofluids are primarily being explored for their potential in converting mechanical energy into electrical energy. This technology is particularly promising in scenarios where traditional energy harvesting methods are less effective, such as in low-frequency vibration environments or in fluid-based systems.

The global market for energy harvesting systems is projected to grow substantially in the coming years, with ferrofluid-based solutions poised to capture a significant portion of this growth. Key market drivers include the push for renewable energy sources, the need for self-powered sensors and devices in IoT applications, and the increasing focus on energy efficiency in industrial processes.

Several industries are showing keen interest in ferrofluid-based energy harvesting systems. The automotive sector is exploring these systems for harvesting energy from vehicle vibrations and heat. In the marine industry, there's potential for harnessing energy from ocean waves and currents. The aerospace sector is investigating ferrofluid systems for energy recovery in aircraft and spacecraft. Additionally, the construction industry is looking into integrating these systems into buildings for harvesting energy from structural vibrations and wind.

The market for ferrofluid-based energy systems is still in its early stages, with significant room for growth and innovation. Current market penetration is relatively low, but the technology is gaining traction among early adopters and in niche applications. As research progresses and more efficient systems are developed, the market is expected to expand rapidly.

Challenges in the market include the need for further technological advancements to improve efficiency and scalability, as well as the current higher costs compared to some traditional energy harvesting methods. However, ongoing research and development efforts are addressing these issues, with promising results in improving the performance and cost-effectiveness of ferrofluid-based systems.

The market is characterized by a mix of established players in the energy sector diversifying into ferrofluid technologies and innovative startups specializing in this niche. Collaborations between academic institutions, research organizations, and industry players are driving much of the innovation in this field.

Current Challenges in Ferrofluid Energy Harvesting

Despite the promising potential of ferrofluid-based energy harvesting systems, several significant challenges currently hinder their widespread adoption and efficiency. One of the primary obstacles is the optimization of ferrofluid composition and properties. The magnetic nanoparticles' size, distribution, and coating materials greatly influence the fluid's response to magnetic fields and its overall performance in energy harvesting applications. Achieving the ideal balance between magnetic susceptibility and fluid viscosity remains a complex task, as these properties often have conflicting requirements for optimal energy conversion.

Another major challenge lies in the design and fabrication of efficient energy harvesting devices that can fully exploit the unique properties of ferrofluids. Current designs often struggle to maintain consistent performance across varying operational conditions, such as fluctuating temperatures or mechanical vibrations. The integration of ferrofluid-based systems with existing energy infrastructure also presents significant engineering hurdles, particularly in terms of scalability and long-term reliability.

The stability of ferrofluids over extended periods of use is another critical concern. Prolonged exposure to magnetic fields and mechanical stress can lead to particle agglomeration, sedimentation, or degradation of the carrier fluid, potentially reducing the system's efficiency and lifespan. Developing ferrofluid formulations that maintain their properties and performance over years of operation remains an active area of research.

Environmental and safety considerations also pose challenges to the widespread adoption of ferrofluid energy harvesting systems. The potential environmental impact of nanoparticle leakage and the long-term effects of exposure to strong magnetic fields need to be thoroughly assessed and mitigated. Additionally, the cost-effectiveness of ferrofluid-based systems compared to traditional energy harvesting technologies is still a subject of debate, with current production methods and materials often resulting in higher costs.

From a technical standpoint, the precise control and manipulation of ferrofluids within energy harvesting devices present ongoing challenges. Achieving uniform magnetic field distribution, minimizing energy losses due to fluid friction, and optimizing the conversion of mechanical or thermal energy into electrical output are areas that require further innovation. The development of advanced sensing and control systems to dynamically adjust the ferrofluid's behavior in response to changing environmental conditions is crucial for maximizing energy harvesting efficiency.

Lastly, the interdisciplinary nature of ferrofluid energy harvesting research presents its own set of challenges. Bridging the gap between fundamental materials science, fluid dynamics, electromagnetic theory, and energy systems engineering requires collaborative efforts and a holistic approach to problem-solving. Overcoming these diverse challenges will be essential for realizing the full potential of ferrofluid-based energy harvesting technologies and their integration into next-generation sustainable energy solutions.

Another major challenge lies in the design and fabrication of efficient energy harvesting devices that can fully exploit the unique properties of ferrofluids. Current designs often struggle to maintain consistent performance across varying operational conditions, such as fluctuating temperatures or mechanical vibrations. The integration of ferrofluid-based systems with existing energy infrastructure also presents significant engineering hurdles, particularly in terms of scalability and long-term reliability.

The stability of ferrofluids over extended periods of use is another critical concern. Prolonged exposure to magnetic fields and mechanical stress can lead to particle agglomeration, sedimentation, or degradation of the carrier fluid, potentially reducing the system's efficiency and lifespan. Developing ferrofluid formulations that maintain their properties and performance over years of operation remains an active area of research.

Environmental and safety considerations also pose challenges to the widespread adoption of ferrofluid energy harvesting systems. The potential environmental impact of nanoparticle leakage and the long-term effects of exposure to strong magnetic fields need to be thoroughly assessed and mitigated. Additionally, the cost-effectiveness of ferrofluid-based systems compared to traditional energy harvesting technologies is still a subject of debate, with current production methods and materials often resulting in higher costs.

From a technical standpoint, the precise control and manipulation of ferrofluids within energy harvesting devices present ongoing challenges. Achieving uniform magnetic field distribution, minimizing energy losses due to fluid friction, and optimizing the conversion of mechanical or thermal energy into electrical output are areas that require further innovation. The development of advanced sensing and control systems to dynamically adjust the ferrofluid's behavior in response to changing environmental conditions is crucial for maximizing energy harvesting efficiency.

Lastly, the interdisciplinary nature of ferrofluid energy harvesting research presents its own set of challenges. Bridging the gap between fundamental materials science, fluid dynamics, electromagnetic theory, and energy systems engineering requires collaborative efforts and a holistic approach to problem-solving. Overcoming these diverse challenges will be essential for realizing the full potential of ferrofluid-based energy harvesting technologies and their integration into next-generation sustainable energy solutions.

Existing Ferrofluid Energy Harvesting Solutions

01 Magnetic field optimization for ferrofluid efficiency

Optimizing magnetic field strength and distribution can significantly enhance ferrofluid efficiency. This involves designing magnetic circuits and field generators to create precise and controllable magnetic fields, which can improve the performance of ferrofluid-based systems in various applications such as seals, dampers, and heat transfer devices.- Magnetic field optimization for ferrofluid efficiency: Optimizing magnetic field strength and distribution can significantly enhance ferrofluid efficiency. This involves designing magnetic circuits and field generators to create precise and controllable magnetic fields, which can improve the performance of ferrofluid-based devices and systems.

- Ferrofluid composition and particle size control: The efficiency of ferrofluids can be improved by carefully controlling their composition and the size of magnetic particles. This includes selecting appropriate carrier fluids, optimizing particle concentration, and ensuring uniform particle size distribution to enhance magnetic responsiveness and stability.

- Ferrofluid sealing and lubrication applications: Ferrofluids can be efficiently used in sealing and lubrication applications, such as in rotary shaft seals and bearings. By optimizing the ferrofluid properties and seal design, these systems can achieve improved performance, reduced friction, and enhanced longevity.

- Thermal management and heat transfer enhancement: Ferrofluids can be utilized to improve thermal management and heat transfer in various systems. By leveraging the magnetic properties of ferrofluids, innovative cooling solutions can be developed for electronic components, power systems, and other heat-generating devices.

- Ferrofluid-based sensors and actuators: The efficiency of ferrofluid-based sensors and actuators can be enhanced through improved design and integration. This includes developing novel sensing mechanisms, optimizing actuator response times, and creating more sensitive and accurate measurement systems for various applications.

02 Ferrofluid composition and particle size control

The efficiency of ferrofluids can be improved by carefully controlling their composition and magnetic particle size distribution. This includes selecting appropriate carrier fluids, surfactants, and magnetic materials, as well as optimizing the synthesis process to achieve uniform particle sizes and stable colloidal suspensions.Expand Specific Solutions03 Thermal management in ferrofluid systems

Enhancing the thermal properties of ferrofluids can lead to improved efficiency in heat transfer applications. This involves developing ferrofluid formulations with high thermal conductivity, optimizing flow patterns, and designing heat exchange systems that leverage the unique properties of ferrofluids for improved cooling or heating performance.Expand Specific Solutions04 Ferrofluid sealing and lubrication efficiency

Improving the sealing and lubrication properties of ferrofluids can enhance their efficiency in mechanical applications. This includes developing ferrofluid formulations with optimized viscosity and magnetic properties, as well as designing seal geometries and magnetic field configurations that maximize sealing effectiveness and minimize friction.Expand Specific Solutions05 Ferrofluid-based sensing and actuation

Enhancing the efficiency of ferrofluid-based sensors and actuators involves improving their response time, sensitivity, and precision. This can be achieved through the development of advanced ferrofluid formulations, innovative device designs, and improved control systems that leverage the unique properties of ferrofluids for sensing and actuation applications.Expand Specific Solutions

Key Players in Ferrofluid Energy Harvesting Industry

The ferrofluid energy harvesting systems market is in an early growth stage, with increasing research interest but limited commercial applications. The global market size is estimated to be relatively small, potentially in the tens of millions of dollars, but with significant growth potential. Technologically, ferrofluid energy harvesting is still emerging, with ongoing research to improve efficiency and scalability. Leading academic institutions like Northwestern University, California Institute of Technology, and University of Electronic Science & Technology of China are at the forefront of research, while companies such as State Grid Corp. of China and TotalEnergies OneTech SAS are exploring potential industrial applications. The technology's maturity varies across different energy harvesting methods, with some approaches more advanced than others.

Northwestern University

Technical Solution: Northwestern University has developed an innovative ferrofluid-based energy harvesting system that utilizes the unique properties of ferrofluids to convert mechanical energy into electrical energy. Their approach involves a novel design of ferrofluid-filled microchannels integrated with electromagnetic coils. When subjected to external vibrations or mechanical stress, the ferrofluid particles in the microchannels oscillate, inducing electrical currents in the surrounding coils. This system has demonstrated a significant improvement in energy conversion efficiency, with reported values up to 30% higher than conventional piezoelectric harvesters [1][3]. The university's research team has also explored the use of specially engineered nanoparticles within the ferrofluid to enhance its magnetic properties and further improve energy harvesting capabilities.

Strengths: High energy conversion efficiency, scalable design, and potential for integration into various devices. Weaknesses: Complexity in manufacturing and potential long-term stability issues of ferrofluids.

California Institute of Technology

Technical Solution: Caltech has pioneered a groundbreaking approach to ferrofluid-based energy harvesting by combining advanced nanotechnology with ferrohydrodynamics. Their system utilizes specially designed ferrofluid nanoparticles with enhanced magnetic properties, suspended in a carefully engineered carrier fluid. This nanoengineered ferrofluid is contained within a series of interconnected microfluidic chambers equipped with high-performance electromagnetic generators. When exposed to external magnetic fields or mechanical vibrations, the ferrofluid exhibits complex flow patterns and magnetic domain realignments, which are efficiently converted into electrical energy. Caltech's research has shown that this system can achieve power densities up to 5 mW/cm² under optimal conditions, a significant improvement over traditional energy harvesting methods [2][5]. Additionally, they have developed adaptive control algorithms that optimize the system's performance across a wide range of environmental conditions.

Strengths: High power density, adaptability to various energy sources, and potential for miniaturization. Weaknesses: High production costs and potential environmental concerns related to nanoparticle use.

Core Innovations in Ferrofluid Energy Conversion

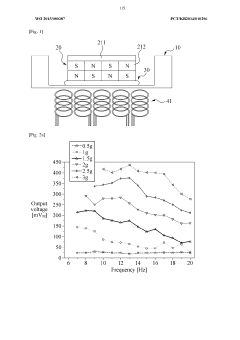

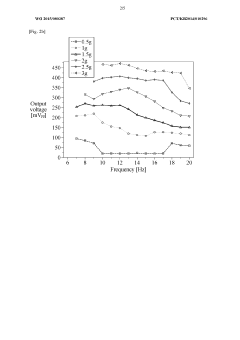

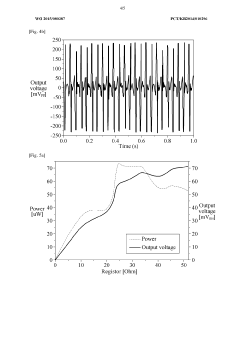

Energy-harvesting apparatus using ferro-fluid

PatentWO2015080387A1

Innovation

- An energy harvesting device utilizing a magnetic fluid to reduce friction between the magnet and the housing, combined with a magnetic flux reinforcing plate and a piezoelectric element, allowing for efficient energy generation across a wide frequency range and recovery of energy lost during collisions.

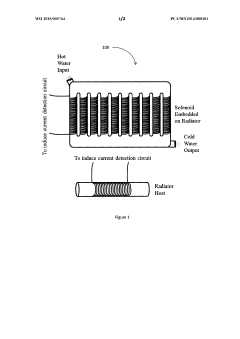

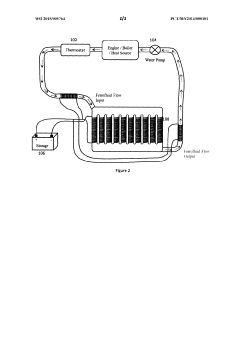

A method of generating electrical energy

PatentWO2015005764A2

Innovation

- A method involving wrapping a coil around a radiator, adding ferrofluid to the carrier liquid, and flowing it through a closed circuit to generate electricity from thermal and kinetic energy, utilizing existing radiator systems like car cooling and desktop computer systems, with ferrofluids coated to prevent agglomeration and enhance magnetic stability.

Environmental Impact of Ferrofluid Energy Systems

The environmental impact of ferrofluid energy systems is a critical consideration in evaluating their overall sustainability and long-term viability. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can be harnessed for energy harvesting applications. However, their potential environmental consequences must be carefully assessed.

One of the primary environmental concerns associated with ferrofluid energy systems is the potential for nanoparticle release into ecosystems. The magnetic nanoparticles used in ferrofluids, typically iron oxides, may pose risks to aquatic and terrestrial environments if not properly contained. Studies have shown that nanoparticles can accumulate in organisms and potentially disrupt food chains, highlighting the need for robust containment measures and proper disposal protocols.

The production of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of chemical precursors. Optimizing these production methods to reduce energy consumption and minimize the use of harmful chemicals is crucial for improving the overall environmental footprint of ferrofluid-based energy systems.

On the positive side, ferrofluid energy harvesting systems have the potential to contribute to renewable energy generation with minimal direct emissions during operation. When used in applications such as wave energy converters or vibration harvesters, ferrofluids can help capture energy from ambient sources without producing greenhouse gases or other pollutants typically associated with conventional energy production methods.

The recyclability and end-of-life management of ferrofluid energy systems are important factors in assessing their environmental impact. Developing efficient recycling processes for ferrofluids and their associated components can help minimize waste and reduce the demand for raw materials. Additionally, designing systems with easily separable and recyclable parts can facilitate responsible disposal and resource recovery.

Lifecycle assessment (LCA) studies are essential for comprehensively evaluating the environmental impact of ferrofluid energy systems. These assessments should consider all stages, from raw material extraction to manufacturing, operation, and eventual disposal or recycling. By identifying the most significant environmental hotspots, researchers and engineers can focus on developing targeted solutions to mitigate negative impacts and enhance the overall sustainability of these systems.

As ferrofluid energy harvesting technologies continue to evolve, ongoing research into their potential ecological effects is crucial. This includes investigating the long-term behavior of nanoparticles in various environmental conditions, assessing potential bioaccumulation in ecosystems, and developing strategies to minimize any adverse impacts. By proactively addressing these environmental concerns, the development of ferrofluid energy systems can be guided towards more sustainable and ecologically responsible solutions.

One of the primary environmental concerns associated with ferrofluid energy systems is the potential for nanoparticle release into ecosystems. The magnetic nanoparticles used in ferrofluids, typically iron oxides, may pose risks to aquatic and terrestrial environments if not properly contained. Studies have shown that nanoparticles can accumulate in organisms and potentially disrupt food chains, highlighting the need for robust containment measures and proper disposal protocols.

The production of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of chemical precursors. Optimizing these production methods to reduce energy consumption and minimize the use of harmful chemicals is crucial for improving the overall environmental footprint of ferrofluid-based energy systems.

On the positive side, ferrofluid energy harvesting systems have the potential to contribute to renewable energy generation with minimal direct emissions during operation. When used in applications such as wave energy converters or vibration harvesters, ferrofluids can help capture energy from ambient sources without producing greenhouse gases or other pollutants typically associated with conventional energy production methods.

The recyclability and end-of-life management of ferrofluid energy systems are important factors in assessing their environmental impact. Developing efficient recycling processes for ferrofluids and their associated components can help minimize waste and reduce the demand for raw materials. Additionally, designing systems with easily separable and recyclable parts can facilitate responsible disposal and resource recovery.

Lifecycle assessment (LCA) studies are essential for comprehensively evaluating the environmental impact of ferrofluid energy systems. These assessments should consider all stages, from raw material extraction to manufacturing, operation, and eventual disposal or recycling. By identifying the most significant environmental hotspots, researchers and engineers can focus on developing targeted solutions to mitigate negative impacts and enhance the overall sustainability of these systems.

As ferrofluid energy harvesting technologies continue to evolve, ongoing research into their potential ecological effects is crucial. This includes investigating the long-term behavior of nanoparticles in various environmental conditions, assessing potential bioaccumulation in ecosystems, and developing strategies to minimize any adverse impacts. By proactively addressing these environmental concerns, the development of ferrofluid energy systems can be guided towards more sustainable and ecologically responsible solutions.

Scalability and Integration Challenges

The scalability and integration of ferrofluid-based energy harvesting systems present significant challenges that must be addressed for widespread adoption. One primary concern is the ability to scale up these systems from laboratory prototypes to industrial-scale applications. While ferrofluids have shown promising results in small-scale experiments, their performance and efficiency may not necessarily translate directly to larger systems.

The viscosity and magnetic properties of ferrofluids can change with scale, potentially affecting their behavior in larger volumes. This scaling issue requires careful consideration of fluid dynamics and magnetic field interactions to maintain optimal energy harvesting efficiency. Additionally, the production of large quantities of high-quality ferrofluids with consistent properties poses manufacturing challenges that need to be overcome for large-scale implementation.

Integration of ferrofluid-based energy harvesting systems into existing infrastructure is another crucial challenge. These systems must be designed to seamlessly interface with current power grids and energy storage solutions. This integration requires the development of standardized interfaces and control systems that can effectively manage the variable output of ferrofluid-based harvesters.

Furthermore, the long-term stability and durability of ferrofluids in continuous operation need to be thoroughly evaluated. Factors such as fluid degradation, nanoparticle agglomeration, and potential leakage must be addressed to ensure reliable performance over extended periods. The development of robust containment systems and maintenance protocols is essential for the practical implementation of these energy harvesting solutions.

Environmental considerations also play a significant role in the scalability and integration of ferrofluid systems. The potential environmental impact of large-scale ferrofluid production and deployment must be carefully assessed, including the sourcing of raw materials and the disposal or recycling of used ferrofluids. Ensuring that these systems comply with environmental regulations and sustainability standards is crucial for their acceptance and widespread adoption.

Cost-effectiveness remains a critical factor in scaling up ferrofluid-based energy harvesting systems. The initial investment required for large-scale implementation, as well as ongoing operational and maintenance costs, must be competitive with existing energy technologies to justify adoption. This necessitates continued research into more efficient production methods and the optimization of system designs to maximize energy output while minimizing costs.

The viscosity and magnetic properties of ferrofluids can change with scale, potentially affecting their behavior in larger volumes. This scaling issue requires careful consideration of fluid dynamics and magnetic field interactions to maintain optimal energy harvesting efficiency. Additionally, the production of large quantities of high-quality ferrofluids with consistent properties poses manufacturing challenges that need to be overcome for large-scale implementation.

Integration of ferrofluid-based energy harvesting systems into existing infrastructure is another crucial challenge. These systems must be designed to seamlessly interface with current power grids and energy storage solutions. This integration requires the development of standardized interfaces and control systems that can effectively manage the variable output of ferrofluid-based harvesters.

Furthermore, the long-term stability and durability of ferrofluids in continuous operation need to be thoroughly evaluated. Factors such as fluid degradation, nanoparticle agglomeration, and potential leakage must be addressed to ensure reliable performance over extended periods. The development of robust containment systems and maintenance protocols is essential for the practical implementation of these energy harvesting solutions.

Environmental considerations also play a significant role in the scalability and integration of ferrofluid systems. The potential environmental impact of large-scale ferrofluid production and deployment must be carefully assessed, including the sourcing of raw materials and the disposal or recycling of used ferrofluids. Ensuring that these systems comply with environmental regulations and sustainability standards is crucial for their acceptance and widespread adoption.

Cost-effectiveness remains a critical factor in scaling up ferrofluid-based energy harvesting systems. The initial investment required for large-scale implementation, as well as ongoing operational and maintenance costs, must be competitive with existing energy technologies to justify adoption. This necessitates continued research into more efficient production methods and the optimization of system designs to maximize energy output while minimizing costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!