Evaluating mechanical stresses on flexible AMOLED innovations.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Flexibility Evolution

The evolution of AMOLED flexibility represents a significant milestone in display technology, marking a shift from rigid to bendable and foldable screens. This progression has been driven by the increasing demand for more versatile and durable mobile devices, as well as the pursuit of novel form factors in consumer electronics.

The journey began with the introduction of curved AMOLED displays in smartphones around 2013. These early implementations featured subtle curves that improved ergonomics and viewing angles but did not offer true flexibility. The next phase saw the development of bendable displays, which could be flexed to a certain degree without damage. This technology paved the way for devices with screens that could wrap around edges or conform to non-flat surfaces.

A major breakthrough came with the introduction of foldable AMOLED displays in 2019. These screens could be folded in half, enabling smartphones to transform into tablets and vice versa. The initial designs faced challenges related to durability and visible creases at the fold, prompting rapid iterations and improvements in subsequent generations.

Concurrent with these advancements, researchers and manufacturers have been working on rollable AMOLED displays. These screens can be rolled up like a scroll, offering the potential for even more compact devices with large screen real estate. While still in the early stages of commercialization, rollable displays represent the next frontier in AMOLED flexibility.

Throughout this evolution, several key technological improvements have been crucial. The development of ultra-thin glass and advanced polymer substrates has enhanced the durability and flexibility of AMOLED panels. Innovations in encapsulation techniques have improved protection against moisture and oxygen, extending the lifespan of flexible displays. Additionally, advancements in touch sensor integration and pixel structures have ensured that flexible AMOLEDs maintain high performance and image quality despite repeated bending or folding.

The ongoing challenge in AMOLED flexibility lies in balancing mechanical robustness with display performance. As screens become more flexible, they must also withstand the stresses of repeated bending, folding, or rolling without degradation in image quality or functionality. This has led to intensive research into materials science, particularly in the areas of flexible electrodes, barrier layers, and protective coatings.

The journey began with the introduction of curved AMOLED displays in smartphones around 2013. These early implementations featured subtle curves that improved ergonomics and viewing angles but did not offer true flexibility. The next phase saw the development of bendable displays, which could be flexed to a certain degree without damage. This technology paved the way for devices with screens that could wrap around edges or conform to non-flat surfaces.

A major breakthrough came with the introduction of foldable AMOLED displays in 2019. These screens could be folded in half, enabling smartphones to transform into tablets and vice versa. The initial designs faced challenges related to durability and visible creases at the fold, prompting rapid iterations and improvements in subsequent generations.

Concurrent with these advancements, researchers and manufacturers have been working on rollable AMOLED displays. These screens can be rolled up like a scroll, offering the potential for even more compact devices with large screen real estate. While still in the early stages of commercialization, rollable displays represent the next frontier in AMOLED flexibility.

Throughout this evolution, several key technological improvements have been crucial. The development of ultra-thin glass and advanced polymer substrates has enhanced the durability and flexibility of AMOLED panels. Innovations in encapsulation techniques have improved protection against moisture and oxygen, extending the lifespan of flexible displays. Additionally, advancements in touch sensor integration and pixel structures have ensured that flexible AMOLEDs maintain high performance and image quality despite repeated bending or folding.

The ongoing challenge in AMOLED flexibility lies in balancing mechanical robustness with display performance. As screens become more flexible, they must also withstand the stresses of repeated bending, folding, or rolling without degradation in image quality or functionality. This has led to intensive research into materials science, particularly in the areas of flexible electrodes, barrier layers, and protective coatings.

Market Demand Analysis

The flexible AMOLED (Active-Matrix Organic Light-Emitting Diode) display market has been experiencing significant growth in recent years, driven by the increasing demand for innovative and versatile display technologies across various industries. The ability to evaluate and mitigate mechanical stresses on these flexible displays is crucial for their widespread adoption and long-term durability.

Consumer electronics, particularly smartphones and wearable devices, represent the largest market segment for flexible AMOLED displays. The demand for thinner, lighter, and more durable devices with curved or foldable screens has been steadily rising. Major smartphone manufacturers have already introduced foldable devices, and this trend is expected to continue, potentially reshaping the entire mobile device landscape.

Beyond smartphones, there is growing interest in flexible AMOLED technology for automotive applications. As vehicles become more technologically advanced and user-centric, curved displays for dashboards, infotainment systems, and even exterior lighting are gaining traction. The automotive industry's shift towards electric and autonomous vehicles is likely to further accelerate this demand.

The healthcare and medical device sector also presents significant opportunities for flexible AMOLED displays. Wearable health monitors, smart medical devices, and advanced diagnostic equipment can benefit from the technology's flexibility and energy efficiency. As telemedicine and remote patient monitoring become more prevalent, the demand for portable, durable display solutions is expected to increase.

In the retail and advertising sectors, flexible AMOLED displays offer new possibilities for dynamic and eye-catching signage. The ability to create curved or uniquely shaped displays opens up creative avenues for product showcases, interactive advertisements, and immersive brand experiences.

The aerospace and defense industries are exploring flexible AMOLED technologies for cockpit displays, heads-up displays, and wearable equipment for military personnel. The lightweight and adaptable nature of these displays makes them particularly suitable for environments where space and weight constraints are critical.

As the Internet of Things (IoT) continues to expand, there is a growing need for flexible display solutions in smart home devices, industrial control systems, and urban infrastructure. These applications require displays that can be integrated into various form factors and withstand diverse environmental conditions.

The market demand for flexible AMOLED innovations is closely tied to advancements in evaluating and mitigating mechanical stresses. As manufacturers push the boundaries of flexibility and durability, the ability to accurately assess and predict the performance of these displays under various stress conditions becomes paramount. This drives the need for sophisticated testing methodologies, simulation tools, and materials science innovations to ensure the reliability and longevity of flexible AMOLED products across all market segments.

Consumer electronics, particularly smartphones and wearable devices, represent the largest market segment for flexible AMOLED displays. The demand for thinner, lighter, and more durable devices with curved or foldable screens has been steadily rising. Major smartphone manufacturers have already introduced foldable devices, and this trend is expected to continue, potentially reshaping the entire mobile device landscape.

Beyond smartphones, there is growing interest in flexible AMOLED technology for automotive applications. As vehicles become more technologically advanced and user-centric, curved displays for dashboards, infotainment systems, and even exterior lighting are gaining traction. The automotive industry's shift towards electric and autonomous vehicles is likely to further accelerate this demand.

The healthcare and medical device sector also presents significant opportunities for flexible AMOLED displays. Wearable health monitors, smart medical devices, and advanced diagnostic equipment can benefit from the technology's flexibility and energy efficiency. As telemedicine and remote patient monitoring become more prevalent, the demand for portable, durable display solutions is expected to increase.

In the retail and advertising sectors, flexible AMOLED displays offer new possibilities for dynamic and eye-catching signage. The ability to create curved or uniquely shaped displays opens up creative avenues for product showcases, interactive advertisements, and immersive brand experiences.

The aerospace and defense industries are exploring flexible AMOLED technologies for cockpit displays, heads-up displays, and wearable equipment for military personnel. The lightweight and adaptable nature of these displays makes them particularly suitable for environments where space and weight constraints are critical.

As the Internet of Things (IoT) continues to expand, there is a growing need for flexible display solutions in smart home devices, industrial control systems, and urban infrastructure. These applications require displays that can be integrated into various form factors and withstand diverse environmental conditions.

The market demand for flexible AMOLED innovations is closely tied to advancements in evaluating and mitigating mechanical stresses. As manufacturers push the boundaries of flexibility and durability, the ability to accurately assess and predict the performance of these displays under various stress conditions becomes paramount. This drives the need for sophisticated testing methodologies, simulation tools, and materials science innovations to ensure the reliability and longevity of flexible AMOLED products across all market segments.

Mechanical Stress Challenges

Flexible AMOLED displays face significant mechanical stress challenges due to their inherent bendable nature. These stresses can lead to various issues, including delamination, cracking, and performance degradation. The primary sources of mechanical stress in flexible AMOLED innovations include bending, folding, and repeated flexing during normal usage.

One of the most critical challenges is the differential stress experienced by various layers within the AMOLED structure. The organic light-emitting layers, thin-film transistors (TFTs), and encapsulation layers all have different mechanical properties, leading to stress concentration at interfaces. This can result in delamination or cracking, particularly at the edges of the display or along fold lines.

Another significant challenge is the fatigue stress induced by repeated bending cycles. As users fold and unfold their devices, the AMOLED display undergoes numerous stress-strain cycles. This cyclic loading can lead to the accumulation of microcracks and defects, ultimately compromising the display's integrity and performance over time.

The encapsulation layer, crucial for protecting the organic materials from moisture and oxygen, is particularly vulnerable to mechanical stress. Cracks or defects in this layer can lead to rapid degradation of the OLED materials, resulting in dark spots or non-functional areas of the display. Balancing the need for effective encapsulation with flexibility remains a significant engineering challenge.

Thermal stress is another factor that compounds the mechanical stress issues. As AMOLED displays operate, they generate heat, which can cause thermal expansion and contraction. This thermal cycling, combined with mechanical bending, creates complex stress patterns that can accelerate material fatigue and failure.

The choice of substrate material also plays a crucial role in managing mechanical stress. While plastic substrates offer excellent flexibility, they may not provide the same level of dimensional stability as glass, potentially leading to alignment issues in the TFT backplane or color filters over time.

Addressing these mechanical stress challenges requires a multidisciplinary approach. Materials science innovations are needed to develop more resilient and flexible materials for each layer of the AMOLED stack. Structural engineering principles must be applied to optimize the overall display architecture for stress distribution. Additionally, advanced simulation and modeling techniques are essential for predicting stress patterns and failure modes under various usage scenarios.

One of the most critical challenges is the differential stress experienced by various layers within the AMOLED structure. The organic light-emitting layers, thin-film transistors (TFTs), and encapsulation layers all have different mechanical properties, leading to stress concentration at interfaces. This can result in delamination or cracking, particularly at the edges of the display or along fold lines.

Another significant challenge is the fatigue stress induced by repeated bending cycles. As users fold and unfold their devices, the AMOLED display undergoes numerous stress-strain cycles. This cyclic loading can lead to the accumulation of microcracks and defects, ultimately compromising the display's integrity and performance over time.

The encapsulation layer, crucial for protecting the organic materials from moisture and oxygen, is particularly vulnerable to mechanical stress. Cracks or defects in this layer can lead to rapid degradation of the OLED materials, resulting in dark spots or non-functional areas of the display. Balancing the need for effective encapsulation with flexibility remains a significant engineering challenge.

Thermal stress is another factor that compounds the mechanical stress issues. As AMOLED displays operate, they generate heat, which can cause thermal expansion and contraction. This thermal cycling, combined with mechanical bending, creates complex stress patterns that can accelerate material fatigue and failure.

The choice of substrate material also plays a crucial role in managing mechanical stress. While plastic substrates offer excellent flexibility, they may not provide the same level of dimensional stability as glass, potentially leading to alignment issues in the TFT backplane or color filters over time.

Addressing these mechanical stress challenges requires a multidisciplinary approach. Materials science innovations are needed to develop more resilient and flexible materials for each layer of the AMOLED stack. Structural engineering principles must be applied to optimize the overall display architecture for stress distribution. Additionally, advanced simulation and modeling techniques are essential for predicting stress patterns and failure modes under various usage scenarios.

Current Stress Evaluation Methods

01 Flexible AMOLED display structure

Flexible AMOLED displays are designed with specific structures to withstand mechanical stresses. These structures often include flexible substrates, thin-film encapsulation layers, and specialized pixel arrangements that can bend without breaking. The design aims to distribute stress evenly across the display, preventing damage during flexing or folding operations.- Flexible AMOLED display structure: Flexible AMOLED displays are designed with specific structures to withstand mechanical stresses. These structures often include flexible substrates, thin-film encapsulation layers, and specialized pixel arrangements that can bend without compromising display performance. The design aims to distribute stress evenly across the display, preventing damage during flexing or folding operations.

- Stress reduction techniques: Various techniques are employed to reduce mechanical stresses in flexible AMOLED displays. These may include the use of stress-relieving layers, optimized material choices, and strategic placement of components. Some designs incorporate buffer layers or utilize specific patterns in the display structure to absorb and distribute stress, thereby enhancing the overall durability of the flexible display.

- Folding and bending mechanisms: Specialized mechanisms are developed to manage mechanical stresses during folding or bending operations of flexible AMOLED displays. These mechanisms may include hinges, support structures, or dynamic stress distribution systems that protect the display during repeated folding or bending actions. The goal is to maintain display integrity and functionality while allowing for flexible form factors.

- Material innovations: Advanced materials play a crucial role in addressing mechanical stresses in flexible AMOLED displays. Researchers and manufacturers are developing new materials with enhanced flexibility, durability, and stress resistance. These may include novel polymers, composite materials, or nano-engineered substances that can withstand repeated bending and folding while maintaining optimal display characteristics.

- Testing and quality control methods: Specialized testing and quality control methods are implemented to evaluate the resilience of flexible AMOLED displays to mechanical stresses. These may include automated bending tests, stress simulations, and long-term durability assessments. Advanced imaging and analysis techniques are used to detect potential weak points or stress concentrations, allowing for continuous improvement in display design and manufacturing processes.

02 Stress reduction in bending areas

To reduce mechanical stress in bending areas, various techniques are employed. These may include using neutral plane designs, incorporating stress-absorbing materials, or implementing specialized pixel layouts in folding zones. Such methods help to minimize strain on critical components and extend the lifespan of flexible displays.Expand Specific Solutions03 Encapsulation and protection layers

Flexible AMOLEDs utilize advanced encapsulation and protection layers to shield sensitive components from mechanical stresses and environmental factors. These layers may include organic and inorganic materials in alternating stacks, providing a balance between flexibility and barrier properties. The goal is to prevent moisture and oxygen ingress while maintaining the display's ability to flex.Expand Specific Solutions04 Stress distribution and compensation

Techniques for distributing and compensating for mechanical stresses in flexible AMOLEDs are crucial. These may involve the use of stress-relief patterns, strategically placed buffer layers, or dynamic compensation circuits that adjust for stress-induced changes in electrical properties. Such approaches help maintain display performance and longevity under various bending conditions.Expand Specific Solutions05 Testing and quality control for mechanical stress

Specialized testing and quality control methods are developed for flexible AMOLEDs to ensure their resilience to mechanical stresses. These may include cyclic bending tests, stress simulation models, and real-time monitoring systems. Such procedures help identify weak points in the display structure and validate the effectiveness of stress mitigation strategies.Expand Specific Solutions

Key AMOLED Manufacturers

The flexible AMOLED market is in a growth phase, with increasing demand for bendable displays in smartphones, wearables, and other devices. The global market size for flexible AMOLED displays is projected to expand significantly in the coming years. Technologically, flexible AMOLED is maturing but still faces challenges in mass production and durability. Key players like Samsung Display, BOE Technology, and LG Display are investing heavily in R&D to overcome mechanical stress issues and improve yield rates. Companies such as Corning and 3M are also contributing to advancements in flexible substrate materials. While established firms lead the market, emerging players like Royole and Visionox are making strides in flexible display technology, intensifying competition in this rapidly evolving sector.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive approach to evaluating mechanical stresses on flexible AMOLED displays. Their method incorporates multi-scale modeling, from atomistic simulations to continuum mechanics, to understand stress behavior at various levels[2]. BOE utilizes advanced characterization techniques such as high-resolution X-ray diffraction and nano-indentation to measure residual stresses and mechanical properties of individual layers in the display stack[4]. They have also implemented a real-time monitoring system that uses embedded strain sensors to track stress levels during device operation and folding cycles, allowing for predictive maintenance and improved reliability[6].

Strengths: Large-scale production capabilities, strong presence in the Chinese market, and growing international partnerships. Weaknesses: Relatively newer entrant in flexible AMOLED technology compared to some competitors, potentially playing catch-up in some advanced techniques.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed innovative flexible AMOLED displays with advanced mechanical stress evaluation techniques. They utilize a combination of finite element analysis (FEA) and experimental testing to assess stress distribution across the flexible panels[1]. Their approach involves creating detailed 3D models of the display structure, including all layers such as the thin-film transistor (TFT) array, organic light-emitting diodes (OLEDs), and encapsulation layers. These models are then subjected to simulated bending and folding scenarios to identify potential weak points and areas of high stress concentration[3]. Samsung also employs in-situ strain measurement techniques during actual device operation to validate their simulation results and refine their models[5].

Strengths: Industry-leading expertise in AMOLED technology, extensive R&D resources, and a track record of successful commercialization. Weaknesses: High production costs and potential for supply chain disruptions due to complex manufacturing processes.

Core Stress Mitigation Patents

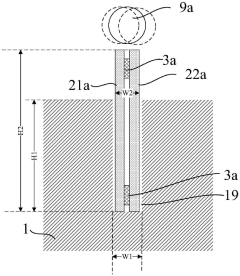

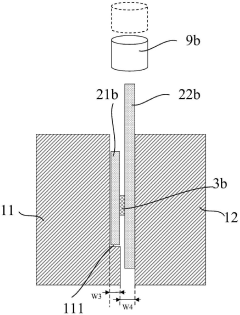

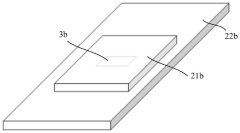

Testing device and testing method

PatentPendingCN117760671A

Innovation

- A test device is designed, including a jig, an indenter, a clamping mechanism and a displacement measurement component, to measure the lateral impact resistance and lateral load performance of glass glue. The state of the glass glue is observed through impact and pressure application. Adjust the indenter position and applied pressure until a change in state is observed or stopping conditions are met.

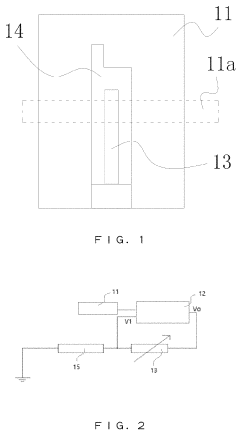

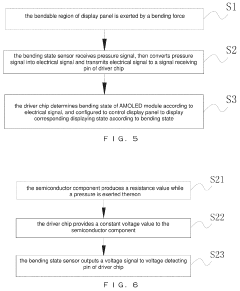

Active-matrix organic light emitting diode module operable in bendable states and displaying method thereof

PatentActiveUS20190355299A1

Innovation

- An AMOLED module with a bending state sensor and driver chip, where the sensor receives pressure signals and converts them into electrical signals to directly control the display panel's state, reducing the reliance on the main control chip for determining and processing bending states.

Materials Science Advancements

The field of flexible AMOLED (Active-Matrix Organic Light-Emitting Diode) displays has seen significant advancements in materials science, which have been crucial in addressing the mechanical stresses inherent in these innovative devices. These advancements have primarily focused on developing materials that can withstand repeated bending and folding while maintaining optimal display performance.

One of the key areas of progress has been in the development of flexible substrate materials. Traditional glass substrates have been replaced with more pliable alternatives such as polyimide films. These films offer excellent thermal stability, low coefficient of thermal expansion, and high mechanical strength, making them ideal for flexible displays. Recent research has also explored the use of ultra-thin glass that can be made flexible through special processing techniques, potentially offering the best of both worlds in terms of flexibility and barrier properties.

Advancements in organic light-emitting materials have also played a crucial role. New classes of organic semiconductors have been synthesized that exhibit improved mechanical properties while maintaining high electroluminescence efficiency. These materials can withstand the strain associated with bending and folding without significant degradation in their light-emitting properties.

The development of flexible encapsulation technologies has been another critical area of materials science innovation. Thin-film encapsulation (TFE) techniques have evolved to provide better protection against moisture and oxygen ingress, which are particularly challenging for flexible displays. Multi-layer structures combining inorganic and organic materials have shown promising results in maintaining barrier properties under mechanical stress.

Innovations in electrode materials have also contributed significantly to the resilience of flexible AMOLEDs. Indium tin oxide (ITO), the traditional transparent electrode material, is brittle and prone to cracking under bending stress. New materials such as silver nanowires, carbon nanotubes, and graphene have emerged as potential alternatives, offering superior flexibility and conductivity.

Furthermore, advancements in adhesive and bonding materials have improved the overall structural integrity of flexible displays. These materials ensure that the various layers of the display remain cohesive under mechanical stress, preventing delamination and other structural failures.

The development of self-healing materials represents a cutting-edge area of research in this field. These materials have the potential to automatically repair minor damage caused by repeated bending or folding, thereby extending the lifespan of flexible displays.

One of the key areas of progress has been in the development of flexible substrate materials. Traditional glass substrates have been replaced with more pliable alternatives such as polyimide films. These films offer excellent thermal stability, low coefficient of thermal expansion, and high mechanical strength, making them ideal for flexible displays. Recent research has also explored the use of ultra-thin glass that can be made flexible through special processing techniques, potentially offering the best of both worlds in terms of flexibility and barrier properties.

Advancements in organic light-emitting materials have also played a crucial role. New classes of organic semiconductors have been synthesized that exhibit improved mechanical properties while maintaining high electroluminescence efficiency. These materials can withstand the strain associated with bending and folding without significant degradation in their light-emitting properties.

The development of flexible encapsulation technologies has been another critical area of materials science innovation. Thin-film encapsulation (TFE) techniques have evolved to provide better protection against moisture and oxygen ingress, which are particularly challenging for flexible displays. Multi-layer structures combining inorganic and organic materials have shown promising results in maintaining barrier properties under mechanical stress.

Innovations in electrode materials have also contributed significantly to the resilience of flexible AMOLEDs. Indium tin oxide (ITO), the traditional transparent electrode material, is brittle and prone to cracking under bending stress. New materials such as silver nanowires, carbon nanotubes, and graphene have emerged as potential alternatives, offering superior flexibility and conductivity.

Furthermore, advancements in adhesive and bonding materials have improved the overall structural integrity of flexible displays. These materials ensure that the various layers of the display remain cohesive under mechanical stress, preventing delamination and other structural failures.

The development of self-healing materials represents a cutting-edge area of research in this field. These materials have the potential to automatically repair minor damage caused by repeated bending or folding, thereby extending the lifespan of flexible displays.

Durability Testing Standards

Durability testing standards for flexible AMOLED innovations are crucial in evaluating their mechanical stress resistance and long-term reliability. These standards encompass a range of rigorous tests designed to simulate real-world conditions and assess the performance of flexible displays under various stresses.

One of the primary testing methods is the bend test, which evaluates the display's ability to withstand repeated flexing without degradation. This test typically involves cycling the display through a specified number of bends at different radii, often ranging from 1mm to 5mm. The number of cycles can vary from thousands to millions, depending on the intended application and durability requirements.

Another critical standard is the folding endurance test, which assesses the display's ability to withstand repeated folding and unfolding actions. This test is particularly relevant for foldable devices and involves folding the display along a predetermined axis for a specified number of cycles, often exceeding 200,000 folds.

Impact resistance testing is also a key component of durability standards. This involves subjecting the flexible AMOLED to controlled impacts using standardized equipment, such as a drop tower or pendulum impact tester. The test evaluates the display's ability to maintain functionality and structural integrity after sudden shocks or impacts.

Environmental stress testing forms another crucial aspect of durability standards. These tests expose the flexible AMOLED to extreme temperatures, humidity levels, and rapid temperature changes to assess its performance and longevity under varying environmental conditions. Typical temperature ranges for these tests span from -40°C to 85°C, with humidity levels up to 95% RH.

Abrasion resistance testing is conducted to evaluate the display's susceptibility to scratches and wear. This often involves using standardized abrasion tools and materials to simulate repeated contact with various surfaces, assessing both the visual and functional impacts on the display.

Pressure sensitivity tests are also included in durability standards, measuring the display's response to applied pressure and its ability to maintain functionality under different levels of force. This is particularly important for touch-sensitive flexible displays.

Lastly, accelerated aging tests are employed to predict the long-term durability of flexible AMOLEDs. These tests subject the displays to intensified conditions that simulate years of use within a shorter timeframe, allowing manufacturers to estimate the product's lifespan and identify potential failure modes.

These comprehensive durability testing standards ensure that flexible AMOLED innovations can withstand the mechanical stresses encountered in real-world applications, providing consumers with reliable and long-lasting display technologies.

One of the primary testing methods is the bend test, which evaluates the display's ability to withstand repeated flexing without degradation. This test typically involves cycling the display through a specified number of bends at different radii, often ranging from 1mm to 5mm. The number of cycles can vary from thousands to millions, depending on the intended application and durability requirements.

Another critical standard is the folding endurance test, which assesses the display's ability to withstand repeated folding and unfolding actions. This test is particularly relevant for foldable devices and involves folding the display along a predetermined axis for a specified number of cycles, often exceeding 200,000 folds.

Impact resistance testing is also a key component of durability standards. This involves subjecting the flexible AMOLED to controlled impacts using standardized equipment, such as a drop tower or pendulum impact tester. The test evaluates the display's ability to maintain functionality and structural integrity after sudden shocks or impacts.

Environmental stress testing forms another crucial aspect of durability standards. These tests expose the flexible AMOLED to extreme temperatures, humidity levels, and rapid temperature changes to assess its performance and longevity under varying environmental conditions. Typical temperature ranges for these tests span from -40°C to 85°C, with humidity levels up to 95% RH.

Abrasion resistance testing is conducted to evaluate the display's susceptibility to scratches and wear. This often involves using standardized abrasion tools and materials to simulate repeated contact with various surfaces, assessing both the visual and functional impacts on the display.

Pressure sensitivity tests are also included in durability standards, measuring the display's response to applied pressure and its ability to maintain functionality under different levels of force. This is particularly important for touch-sensitive flexible displays.

Lastly, accelerated aging tests are employed to predict the long-term durability of flexible AMOLEDs. These tests subject the displays to intensified conditions that simulate years of use within a shorter timeframe, allowing manufacturers to estimate the product's lifespan and identify potential failure modes.

These comprehensive durability testing standards ensure that flexible AMOLED innovations can withstand the mechanical stresses encountered in real-world applications, providing consumers with reliable and long-lasting display technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!