Exploring Ferrofluid's Application in Dynamic System Designs

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution in their composition, properties, and applications. Initially conceived for fuel control in zero-gravity environments, these magnetic liquids have since found diverse uses across multiple industries. The technology's progression has been marked by advancements in nanoparticle synthesis, surfactant chemistry, and carrier fluid optimization.

Early ferrofluids faced challenges in stability and magnetic response, limiting their practical applications. However, continuous research efforts have led to the development of more stable and responsive formulations. The introduction of new magnetic materials, such as cobalt and manganese ferrite nanoparticles, has expanded the range of achievable magnetic properties, enabling finer control and broader applicability in dynamic systems.

The evolution of ferrofluid technology has been closely tied to advancements in nanotechnology and materials science. Improved manufacturing processes have resulted in more uniform particle size distributions and enhanced magnetic properties. This has opened up new possibilities for ferrofluids in areas such as adaptive optics, biomedical applications, and energy harvesting systems.

Recent years have seen a surge in research focused on smart materials and responsive systems, with ferrofluids playing a crucial role. The ability to manipulate ferrofluids using external magnetic fields has led to innovative designs in dynamic sealing, damping systems, and thermal management solutions. The integration of ferrofluids with other smart materials, such as shape memory alloys and piezoelectric materials, has further expanded their potential in adaptive and self-regulating systems.

The primary objectives in ferrofluid technology development are centered around enhancing their stability, responsiveness, and versatility. Researchers aim to create ferrofluids with improved long-term stability, resistance to aggregation, and maintained magnetic properties under various environmental conditions. Another key goal is to develop ferrofluids with faster response times and more precise control over their behavior in dynamic systems.

Furthermore, there is a growing emphasis on developing environmentally friendly and biocompatible ferrofluids, particularly for medical and consumer applications. This includes the exploration of non-toxic carrier fluids and biodegradable surfactants. The ultimate objective is to create multifunctional ferrofluids that can simultaneously respond to multiple stimuli, such as magnetic fields, temperature, and pH, enabling more complex and adaptive system designs.

Early ferrofluids faced challenges in stability and magnetic response, limiting their practical applications. However, continuous research efforts have led to the development of more stable and responsive formulations. The introduction of new magnetic materials, such as cobalt and manganese ferrite nanoparticles, has expanded the range of achievable magnetic properties, enabling finer control and broader applicability in dynamic systems.

The evolution of ferrofluid technology has been closely tied to advancements in nanotechnology and materials science. Improved manufacturing processes have resulted in more uniform particle size distributions and enhanced magnetic properties. This has opened up new possibilities for ferrofluids in areas such as adaptive optics, biomedical applications, and energy harvesting systems.

Recent years have seen a surge in research focused on smart materials and responsive systems, with ferrofluids playing a crucial role. The ability to manipulate ferrofluids using external magnetic fields has led to innovative designs in dynamic sealing, damping systems, and thermal management solutions. The integration of ferrofluids with other smart materials, such as shape memory alloys and piezoelectric materials, has further expanded their potential in adaptive and self-regulating systems.

The primary objectives in ferrofluid technology development are centered around enhancing their stability, responsiveness, and versatility. Researchers aim to create ferrofluids with improved long-term stability, resistance to aggregation, and maintained magnetic properties under various environmental conditions. Another key goal is to develop ferrofluids with faster response times and more precise control over their behavior in dynamic systems.

Furthermore, there is a growing emphasis on developing environmentally friendly and biocompatible ferrofluids, particularly for medical and consumer applications. This includes the exploration of non-toxic carrier fluids and biodegradable surfactants. The ultimate objective is to create multifunctional ferrofluids that can simultaneously respond to multiple stimuli, such as magnetic fields, temperature, and pH, enabling more complex and adaptive system designs.

Market Demand for Ferrofluid-based Dynamic Systems

The market demand for ferrofluid-based dynamic systems has been steadily growing across various industries, driven by the unique properties and versatile applications of ferrofluids. These magnetic liquids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, offer a combination of fluid and magnetic characteristics that make them highly attractive for innovative system designs.

In the automotive sector, ferrofluid-based dynamic systems are gaining traction for their potential in improving vehicle performance and efficiency. Adaptive suspension systems utilizing ferrofluids can provide real-time adjustments to road conditions, enhancing ride comfort and handling. The market for such advanced suspension technologies is expected to expand as automakers seek to differentiate their products and meet increasing consumer demands for smoother, more responsive driving experiences.

The aerospace industry represents another significant market for ferrofluid applications in dynamic systems. Ferrofluid-based dampers and vibration control mechanisms are being explored for their ability to mitigate structural vibrations in aircraft and spacecraft. This demand is driven by the need for lightweight, efficient solutions that can withstand extreme conditions while improving overall system performance and longevity.

In the field of renewable energy, particularly wind power, ferrofluid-based systems are showing promise in enhancing the efficiency of wind turbines. By incorporating ferrofluids into turbine bearings and seals, manufacturers can reduce friction, improve heat dissipation, and extend component lifespans. As the global push for clean energy intensifies, the demand for such innovative solutions in wind turbine design is expected to grow substantially.

The medical device industry is also exploring ferrofluid applications in dynamic systems, particularly for targeted drug delivery and minimally invasive surgical procedures. Ferrofluid-based actuators and control systems offer precise manipulation capabilities at the microscale, opening up new possibilities for medical interventions. This market segment is poised for significant growth as healthcare providers seek more advanced, less invasive treatment options.

Consumer electronics represent another burgeoning market for ferrofluid-based dynamic systems. Haptic feedback devices utilizing ferrofluids are being developed to enhance user interfaces in smartphones, gaming controllers, and virtual reality systems. The demand for more immersive and responsive user experiences is driving innovation in this area, with ferrofluid-based solutions offering unique tactile sensations that traditional mechanical systems cannot match.

As research and development in ferrofluid technology continue to advance, new applications and market opportunities are likely to emerge. The versatility of ferrofluids in dynamic system designs positions them as a key enabling technology across multiple industries, with potential for significant market growth in the coming years. However, challenges such as long-term stability, scalability, and cost-effectiveness will need to be addressed to fully realize the market potential of ferrofluid-based dynamic systems.

In the automotive sector, ferrofluid-based dynamic systems are gaining traction for their potential in improving vehicle performance and efficiency. Adaptive suspension systems utilizing ferrofluids can provide real-time adjustments to road conditions, enhancing ride comfort and handling. The market for such advanced suspension technologies is expected to expand as automakers seek to differentiate their products and meet increasing consumer demands for smoother, more responsive driving experiences.

The aerospace industry represents another significant market for ferrofluid applications in dynamic systems. Ferrofluid-based dampers and vibration control mechanisms are being explored for their ability to mitigate structural vibrations in aircraft and spacecraft. This demand is driven by the need for lightweight, efficient solutions that can withstand extreme conditions while improving overall system performance and longevity.

In the field of renewable energy, particularly wind power, ferrofluid-based systems are showing promise in enhancing the efficiency of wind turbines. By incorporating ferrofluids into turbine bearings and seals, manufacturers can reduce friction, improve heat dissipation, and extend component lifespans. As the global push for clean energy intensifies, the demand for such innovative solutions in wind turbine design is expected to grow substantially.

The medical device industry is also exploring ferrofluid applications in dynamic systems, particularly for targeted drug delivery and minimally invasive surgical procedures. Ferrofluid-based actuators and control systems offer precise manipulation capabilities at the microscale, opening up new possibilities for medical interventions. This market segment is poised for significant growth as healthcare providers seek more advanced, less invasive treatment options.

Consumer electronics represent another burgeoning market for ferrofluid-based dynamic systems. Haptic feedback devices utilizing ferrofluids are being developed to enhance user interfaces in smartphones, gaming controllers, and virtual reality systems. The demand for more immersive and responsive user experiences is driving innovation in this area, with ferrofluid-based solutions offering unique tactile sensations that traditional mechanical systems cannot match.

As research and development in ferrofluid technology continue to advance, new applications and market opportunities are likely to emerge. The versatility of ferrofluids in dynamic system designs positions them as a key enabling technology across multiple industries, with potential for significant market growth in the coming years. However, challenges such as long-term stability, scalability, and cost-effectiveness will need to be addressed to fully realize the market potential of ferrofluid-based dynamic systems.

Current Challenges in Ferrofluid Applications

Despite the promising potential of ferrofluids in dynamic system designs, several significant challenges currently hinder their widespread application and commercialization. These challenges span across multiple domains, including material properties, system integration, and long-term stability.

One of the primary obstacles is the limited temperature range in which ferrofluids maintain their unique properties. Most commercially available ferrofluids lose their magnetic responsiveness at temperatures above 100°C, restricting their use in high-temperature environments such as automotive or aerospace applications. This thermal limitation also affects the fluid's viscosity and magnetic susceptibility, potentially compromising system performance in dynamic conditions.

Another critical challenge lies in the long-term stability of ferrofluids. Over time, these fluids tend to experience particle agglomeration and sedimentation, leading to a degradation of their magnetic properties and overall performance. This instability issue is particularly problematic in applications requiring prolonged operation or those subject to frequent start-stop cycles, as it can result in system failure or reduced efficiency.

The precise control of ferrofluid behavior in complex dynamic systems presents another significant hurdle. While the basic principles of ferrohydrodynamics are well understood, predicting and manipulating ferrofluid responses in intricate, multi-variable environments remains challenging. This difficulty in achieving fine-tuned control limits the precision and reliability of ferrofluid-based systems, especially in applications requiring high accuracy or rapid response times.

Scaling up ferrofluid production for industrial applications also poses considerable challenges. Current synthesis methods are often costly and time-consuming, making large-scale production economically unfeasible for many potential applications. Additionally, ensuring consistent quality and properties across large batches of ferrofluids remains a significant technical challenge, impacting the reproducibility and reliability of ferrofluid-based systems.

The environmental and health impacts of ferrofluids are also areas of concern. The nanoparticles used in ferrofluids may pose potential risks to human health and ecosystems if not properly contained or disposed of. This raises questions about the long-term sustainability and safety of ferrofluid applications, particularly in consumer products or environmental sensing systems.

Lastly, the integration of ferrofluids with existing technologies and manufacturing processes presents its own set of challenges. Many industries lack the specialized equipment and expertise needed to effectively incorporate ferrofluids into their products or processes. This knowledge gap, combined with the need for custom-designed components to accommodate ferrofluid properties, creates significant barriers to adoption in various sectors.

One of the primary obstacles is the limited temperature range in which ferrofluids maintain their unique properties. Most commercially available ferrofluids lose their magnetic responsiveness at temperatures above 100°C, restricting their use in high-temperature environments such as automotive or aerospace applications. This thermal limitation also affects the fluid's viscosity and magnetic susceptibility, potentially compromising system performance in dynamic conditions.

Another critical challenge lies in the long-term stability of ferrofluids. Over time, these fluids tend to experience particle agglomeration and sedimentation, leading to a degradation of their magnetic properties and overall performance. This instability issue is particularly problematic in applications requiring prolonged operation or those subject to frequent start-stop cycles, as it can result in system failure or reduced efficiency.

The precise control of ferrofluid behavior in complex dynamic systems presents another significant hurdle. While the basic principles of ferrohydrodynamics are well understood, predicting and manipulating ferrofluid responses in intricate, multi-variable environments remains challenging. This difficulty in achieving fine-tuned control limits the precision and reliability of ferrofluid-based systems, especially in applications requiring high accuracy or rapid response times.

Scaling up ferrofluid production for industrial applications also poses considerable challenges. Current synthesis methods are often costly and time-consuming, making large-scale production economically unfeasible for many potential applications. Additionally, ensuring consistent quality and properties across large batches of ferrofluids remains a significant technical challenge, impacting the reproducibility and reliability of ferrofluid-based systems.

The environmental and health impacts of ferrofluids are also areas of concern. The nanoparticles used in ferrofluids may pose potential risks to human health and ecosystems if not properly contained or disposed of. This raises questions about the long-term sustainability and safety of ferrofluid applications, particularly in consumer products or environmental sensing systems.

Lastly, the integration of ferrofluids with existing technologies and manufacturing processes presents its own set of challenges. Many industries lack the specialized equipment and expertise needed to effectively incorporate ferrofluids into their products or processes. This knowledge gap, combined with the need for custom-designed components to accommodate ferrofluid properties, creates significant barriers to adoption in various sectors.

Existing Ferrofluid Dynamic System Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, minimal leakage, and long service life. These properties make them ideal for use in various industrial and mechanical systems.

- Magnetic field-responsive devices: Ferrofluids are utilized in various devices that respond to magnetic fields. These include sensors, actuators, and damping systems. The ability of ferrofluids to change their physical properties in response to magnetic fields allows for the creation of adaptive and controllable systems with applications in automotive, aerospace, and other industries.

- Heat transfer and thermal management: Ferrofluids have unique heat transfer properties that make them useful in thermal management applications. They can be used to enhance heat dissipation in electronic devices, improve the efficiency of cooling systems, and enable novel thermal control mechanisms. The magnetic properties of ferrofluids allow for directed heat transfer under the influence of magnetic fields.

- Measurement and instrumentation: Ferrofluids are employed in various measurement and instrumentation applications. They can be used in liquid level sensors, accelerometers, and other devices that rely on the movement or displacement of magnetic fluids. The unique properties of ferrofluids enable the development of sensitive and accurate measurement systems for a wide range of industrial and scientific applications.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide effective sealing against pressure differentials and contaminants while reducing friction. These properties make them valuable in various industries, including electronics, aerospace, and automotive.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly for electronic devices. Their unique properties allow for efficient heat transfer and cooling when subjected to magnetic fields. This makes them useful in cooling systems for high-performance electronics and in managing thermal issues in various industrial applications.Expand Specific Solutions04 Magnetic field sensing and measurement

Ferrofluids are utilized in various sensing and measurement applications involving magnetic fields. Their response to magnetic fields allows for the development of sensitive instruments for detecting and measuring magnetic field strength and direction. This has applications in scientific research, industrial processes, and navigation systems.Expand Specific Solutions05 Novel applications and emerging technologies

Ferrofluids are finding new applications in emerging technologies. These include use in microfluidic devices, adaptive optics, energy harvesting systems, and biomedical applications such as targeted drug delivery and magnetic hyperthermia for cancer treatment. Ongoing research continues to expand the potential uses of ferrofluids in various fields.Expand Specific Solutions

Key Players in Ferrofluid Industry

The ferrofluid application market in dynamic system designs is in a growth phase, with increasing interest across various industries. The market size is expanding as more companies recognize the potential of ferrofluids in enhancing system performance. Technologically, ferrofluids are advancing, but still have room for further development and optimization. Key players like Ferrotec and Western Digital are driving innovation, while academic institutions such as Chongqing University and Arizona State University contribute to fundamental research. The involvement of diverse entities, from specialized companies to large corporations like Halliburton and Caterpillar, indicates a broadening application scope and growing market maturity.

Ferrotec (USA) Corp.

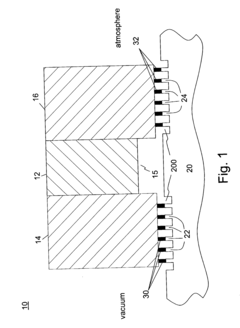

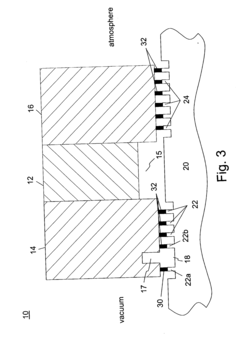

Technical Solution: Ferrotec has developed advanced ferrofluid-based sealing systems for dynamic applications. Their technology utilizes the unique properties of ferrofluids to create hermetic seals in rotating equipment. The company's ferrofluid seals consist of a permanent magnet, pole pieces, and a ferrofluid that is magnetically held in place[1]. This design allows for near-zero leakage rates and minimal friction, making it ideal for use in vacuum systems, semiconductor manufacturing equipment, and hard disk drives[2]. Ferrotec has also explored the use of ferrofluids in thermal management solutions, leveraging the fluid's heat transfer capabilities to enhance cooling in electronic devices[3].

Strengths: Expertise in ferrofluid manufacturing and application; proven track record in sealing technology. Weaknesses: Limited diversification beyond sealing and thermal management applications.

Western Digital Corp.

Technical Solution: Western Digital has incorporated ferrofluid technology into their hard disk drive (HDD) designs to improve performance and reliability. The company uses ferrofluid-based seals to create a barrier between the spinning disk and the external environment, preventing contamination and maintaining internal pressure[4]. This technology has enabled Western Digital to increase storage densities and reduce power consumption in their HDDs. Additionally, the company has explored the use of ferrofluids in spindle motor bearings to reduce friction and enhance drive longevity[5]. Western Digital's research has also focused on optimizing ferrofluid compositions to withstand the high temperatures and speeds encountered in modern HDDs[6].

Strengths: Extensive experience in integrating ferrofluids into mass-produced consumer electronics; strong R&D capabilities. Weaknesses: Application focus primarily limited to data storage devices.

Core Innovations in Ferrofluid Technology

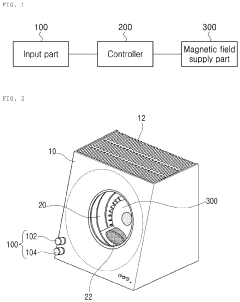

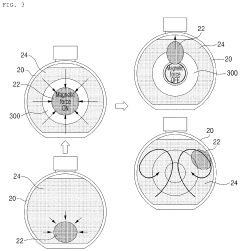

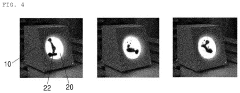

Ferrofluid display control device

PatentPendingUS20230161185A1

Innovation

- A ferrofluid display control device featuring a transparent storage container with different specific gravities of ferrofluid and liquid, an input part for selecting frequency ranges, a controller for generating magnetic field control signals, and a single electromagnet to create directional and random movements of the ferrofluid in response to sound frequencies.

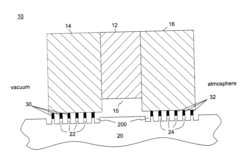

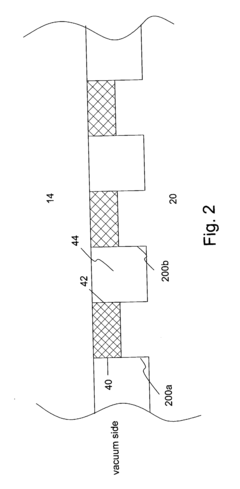

Ferrofluid seal incorporating multiple types of ferrofluid

PatentInactiveUS20040173972A1

Innovation

- A multi-stage ferrofluid seal apparatus utilizing multiple types of ferrofluids, where each type is optimized for specific stages based on environmental conditions, such as low evaporation rate and high viscosity for vacuum stages and lower viscosity and higher oxidation resistance for atmospheric stages, to balance performance requirements and reduce torque and heat generation.

Environmental Impact of Ferrofluid Usage

The environmental impact of ferrofluid usage in dynamic system designs is a crucial consideration for sustainable technological development. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable in various applications. However, their potential environmental consequences must be carefully evaluated.

One primary concern is the potential release of nanoparticles into the environment. These particles, typically made of iron oxides, could accumulate in soil and water systems if not properly contained. The long-term effects of such accumulation on ecosystems and human health are not yet fully understood, necessitating further research and monitoring.

The production process of ferrofluids also raises environmental concerns. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. Proper waste management and treatment protocols are essential to mitigate the risk of environmental contamination during manufacturing.

Disposal of ferrofluid-containing devices presents another challenge. As these systems reach the end of their lifecycle, proper recycling and disposal methods must be developed to prevent the release of nanoparticles into landfills or water sources. This requires the establishment of specialized recycling facilities and guidelines for the safe handling of ferrofluid waste.

On the positive side, ferrofluids can contribute to environmental sustainability in certain applications. For instance, their use in energy harvesting systems and efficient cooling mechanisms can lead to reduced energy consumption and improved overall system efficiency. This indirect environmental benefit should be weighed against potential risks.

The potential for bioaccumulation of ferrofluid nanoparticles in living organisms is an area that requires further investigation. While initial studies suggest limited toxicity, the long-term effects of chronic exposure to these materials in various ecosystems remain uncertain. Comprehensive ecological risk assessments are necessary to fully understand the potential impacts on food chains and biodiversity.

To address these environmental concerns, ongoing research is focused on developing more environmentally friendly ferrofluid formulations. This includes exploring biodegradable carrier fluids and investigating the use of less toxic magnetic materials. Additionally, efforts are being made to improve containment technologies and develop closed-loop systems that minimize the risk of environmental release.

As the application of ferrofluids in dynamic systems continues to expand, it is crucial to implement robust environmental monitoring programs. These should include regular assessments of soil, water, and air quality in areas where ferrofluid-based technologies are deployed. Such proactive measures will help identify and address any potential environmental issues before they become significant problems.

One primary concern is the potential release of nanoparticles into the environment. These particles, typically made of iron oxides, could accumulate in soil and water systems if not properly contained. The long-term effects of such accumulation on ecosystems and human health are not yet fully understood, necessitating further research and monitoring.

The production process of ferrofluids also raises environmental concerns. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. Proper waste management and treatment protocols are essential to mitigate the risk of environmental contamination during manufacturing.

Disposal of ferrofluid-containing devices presents another challenge. As these systems reach the end of their lifecycle, proper recycling and disposal methods must be developed to prevent the release of nanoparticles into landfills or water sources. This requires the establishment of specialized recycling facilities and guidelines for the safe handling of ferrofluid waste.

On the positive side, ferrofluids can contribute to environmental sustainability in certain applications. For instance, their use in energy harvesting systems and efficient cooling mechanisms can lead to reduced energy consumption and improved overall system efficiency. This indirect environmental benefit should be weighed against potential risks.

The potential for bioaccumulation of ferrofluid nanoparticles in living organisms is an area that requires further investigation. While initial studies suggest limited toxicity, the long-term effects of chronic exposure to these materials in various ecosystems remain uncertain. Comprehensive ecological risk assessments are necessary to fully understand the potential impacts on food chains and biodiversity.

To address these environmental concerns, ongoing research is focused on developing more environmentally friendly ferrofluid formulations. This includes exploring biodegradable carrier fluids and investigating the use of less toxic magnetic materials. Additionally, efforts are being made to improve containment technologies and develop closed-loop systems that minimize the risk of environmental release.

As the application of ferrofluids in dynamic systems continues to expand, it is crucial to implement robust environmental monitoring programs. These should include regular assessments of soil, water, and air quality in areas where ferrofluid-based technologies are deployed. Such proactive measures will help identify and address any potential environmental issues before they become significant problems.

Ferrofluid Safety and Handling Protocols

Ferrofluid safety and handling protocols are crucial aspects of working with this unique magnetic liquid in dynamic system designs. The primary concern when dealing with ferrofluids is the potential health hazards associated with nanoparticle exposure. To mitigate these risks, proper personal protective equipment (PPE) must be worn at all times, including chemical-resistant gloves, safety goggles, and lab coats. Additionally, respiratory protection may be necessary when working with large quantities or in poorly ventilated areas.

Proper storage of ferrofluids is essential to maintain their stability and prevent contamination. They should be kept in sealed containers away from strong magnetic fields, extreme temperatures, and direct sunlight. It is important to note that ferrofluids can stain surfaces and clothing, so spill containment measures should be in place during handling and experimentation.

When incorporating ferrofluids into dynamic system designs, engineers must consider the potential for leakage or dispersion. Containment systems should be designed to prevent the release of ferrofluid into the environment or other parts of the system. Regular maintenance and inspection protocols should be established to ensure the integrity of seals and containment mechanisms.

Disposal of ferrofluids requires special attention due to their magnetic properties and nanoparticle content. They should not be disposed of in regular waste streams or poured down drains. Instead, proper chemical waste disposal procedures must be followed, often involving specialized waste management services.

In research and development settings, it is crucial to establish clear handling procedures and train all personnel involved in ferrofluid experiments. This includes proper techniques for transferring, measuring, and manipulating ferrofluids to minimize the risk of spills or exposure. Emergency response plans should be in place to address accidental releases or exposures, including specific decontamination procedures.

When scaling up ferrofluid applications for industrial use, additional safety considerations come into play. This may involve the implementation of automated handling systems to reduce direct human contact with large quantities of ferrofluid. Environmental impact assessments should be conducted to evaluate potential risks associated with large-scale ferrofluid use and to develop appropriate containment and disposal strategies.

Lastly, ongoing research into the long-term effects of ferrofluid exposure on human health and the environment is essential. As new information becomes available, safety protocols should be updated accordingly to ensure the responsible development and application of ferrofluid technology in dynamic system designs.

Proper storage of ferrofluids is essential to maintain their stability and prevent contamination. They should be kept in sealed containers away from strong magnetic fields, extreme temperatures, and direct sunlight. It is important to note that ferrofluids can stain surfaces and clothing, so spill containment measures should be in place during handling and experimentation.

When incorporating ferrofluids into dynamic system designs, engineers must consider the potential for leakage or dispersion. Containment systems should be designed to prevent the release of ferrofluid into the environment or other parts of the system. Regular maintenance and inspection protocols should be established to ensure the integrity of seals and containment mechanisms.

Disposal of ferrofluids requires special attention due to their magnetic properties and nanoparticle content. They should not be disposed of in regular waste streams or poured down drains. Instead, proper chemical waste disposal procedures must be followed, often involving specialized waste management services.

In research and development settings, it is crucial to establish clear handling procedures and train all personnel involved in ferrofluid experiments. This includes proper techniques for transferring, measuring, and manipulating ferrofluids to minimize the risk of spills or exposure. Emergency response plans should be in place to address accidental releases or exposures, including specific decontamination procedures.

When scaling up ferrofluid applications for industrial use, additional safety considerations come into play. This may involve the implementation of automated handling systems to reduce direct human contact with large quantities of ferrofluid. Environmental impact assessments should be conducted to evaluate potential risks associated with large-scale ferrofluid use and to develop appropriate containment and disposal strategies.

Lastly, ongoing research into the long-term effects of ferrofluid exposure on human health and the environment is essential. As new information becomes available, safety protocols should be updated accordingly to ensure the responsible development and application of ferrofluid technology in dynamic system designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!