Exploring Ferrofluid's Application in Emerging Transportation Technologies

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel manipulation in zero gravity, ferrofluids have found their way into various applications, including emerging transportation technologies.

The early stages of ferrofluid development focused on improving stability and magnetic responsiveness. Scientists worked on optimizing the composition of magnetic nanoparticles and carrier fluids to enhance the overall performance. This led to the creation of more stable ferrofluids capable of maintaining their properties over extended periods.

In the 1980s and 1990s, research shifted towards exploring potential applications in various industries. The automotive sector began investigating ferrofluids for use in shock absorbers and damping systems. This period saw the development of magnetorheological fluids, a close cousin of ferrofluids, which found applications in adaptive suspension systems.

The turn of the millennium marked a significant leap in ferrofluid technology. Advancements in nanotechnology allowed for the production of more uniform and smaller magnetic particles, leading to improved ferrofluid performance. This era also saw the emergence of biocompatible ferrofluids, opening up possibilities in biomedical applications and drug delivery systems.

In the context of transportation technologies, the 2000s and 2010s witnessed increased interest in ferrofluids for energy harvesting and efficiency improvement. Researchers began exploring ferrofluid-based energy harvesters that could convert vibrations from vehicles into electrical energy. Additionally, studies on using ferrofluids in cooling systems for electric vehicle batteries gained traction.

Recent years have seen a surge in research focused on smart materials and adaptive systems incorporating ferrofluids. The development of magnetically controlled ferrofluid seals for rotating shafts in electric vehicles has shown promise in improving efficiency and reducing wear. Furthermore, investigations into ferrofluid-based sensors for real-time monitoring of vehicle dynamics and road conditions have opened new avenues for intelligent transportation systems.

The latest frontier in ferrofluid technology for transportation applications involves the integration of artificial intelligence and machine learning. These advanced algorithms are being employed to optimize ferrofluid behavior in real-time, adapting to changing environmental conditions and vehicle dynamics. This synergy between ferrofluids and AI holds the potential to revolutionize various aspects of transportation, from enhanced safety features to improved energy management in electric and hybrid vehicles.

As we look towards the future, the evolution of ferrofluid technology in transportation is likely to focus on sustainability and eco-friendly solutions. Research is underway to develop biodegradable ferrofluids and explore their potential in reducing the environmental impact of transportation systems. The ongoing advancements in material science and nanotechnology continue to push the boundaries of what is possible with ferrofluids, promising exciting innovations in the realm of emerging transportation technologies.

The early stages of ferrofluid development focused on improving stability and magnetic responsiveness. Scientists worked on optimizing the composition of magnetic nanoparticles and carrier fluids to enhance the overall performance. This led to the creation of more stable ferrofluids capable of maintaining their properties over extended periods.

In the 1980s and 1990s, research shifted towards exploring potential applications in various industries. The automotive sector began investigating ferrofluids for use in shock absorbers and damping systems. This period saw the development of magnetorheological fluids, a close cousin of ferrofluids, which found applications in adaptive suspension systems.

The turn of the millennium marked a significant leap in ferrofluid technology. Advancements in nanotechnology allowed for the production of more uniform and smaller magnetic particles, leading to improved ferrofluid performance. This era also saw the emergence of biocompatible ferrofluids, opening up possibilities in biomedical applications and drug delivery systems.

In the context of transportation technologies, the 2000s and 2010s witnessed increased interest in ferrofluids for energy harvesting and efficiency improvement. Researchers began exploring ferrofluid-based energy harvesters that could convert vibrations from vehicles into electrical energy. Additionally, studies on using ferrofluids in cooling systems for electric vehicle batteries gained traction.

Recent years have seen a surge in research focused on smart materials and adaptive systems incorporating ferrofluids. The development of magnetically controlled ferrofluid seals for rotating shafts in electric vehicles has shown promise in improving efficiency and reducing wear. Furthermore, investigations into ferrofluid-based sensors for real-time monitoring of vehicle dynamics and road conditions have opened new avenues for intelligent transportation systems.

The latest frontier in ferrofluid technology for transportation applications involves the integration of artificial intelligence and machine learning. These advanced algorithms are being employed to optimize ferrofluid behavior in real-time, adapting to changing environmental conditions and vehicle dynamics. This synergy between ferrofluids and AI holds the potential to revolutionize various aspects of transportation, from enhanced safety features to improved energy management in electric and hybrid vehicles.

As we look towards the future, the evolution of ferrofluid technology in transportation is likely to focus on sustainability and eco-friendly solutions. Research is underway to develop biodegradable ferrofluids and explore their potential in reducing the environmental impact of transportation systems. The ongoing advancements in material science and nanotechnology continue to push the boundaries of what is possible with ferrofluids, promising exciting innovations in the realm of emerging transportation technologies.

Transport Market Demand

The transportation market is experiencing a significant shift towards more efficient, sustainable, and innovative technologies. Ferrofluids, with their unique properties, are poised to play a crucial role in this evolving landscape. The demand for ferrofluid applications in transportation is driven by several key factors, including the need for improved energy efficiency, enhanced safety features, and advanced control systems.

In the automotive sector, there is a growing interest in ferrofluid-based shock absorbers and damping systems. These systems offer superior performance compared to traditional hydraulic systems, providing better ride comfort and handling characteristics. The market for such advanced suspension systems is expected to grow as consumers increasingly prioritize vehicle comfort and safety.

The aerospace industry is another significant driver of ferrofluid demand in transportation. Ferrofluids are being explored for use in adaptive wing designs, where they can be used to alter the shape of aircraft wings in real-time, improving aerodynamics and fuel efficiency. This application aligns with the industry's push towards more fuel-efficient and environmentally friendly aircraft.

In the rail transportation sector, ferrofluids are being investigated for use in magnetic levitation (maglev) systems. While maglev technology is not new, the use of ferrofluids could potentially reduce system complexity and cost, making this high-speed transportation option more viable for wider adoption. The demand for faster, more efficient inter-city transportation is driving research in this area.

The maritime industry is also showing interest in ferrofluid applications, particularly in the development of advanced propulsion systems and hull coatings. Ferrofluid-based propulsion systems could offer improved efficiency and maneuverability, while ferrofluid coatings may reduce drag and improve fuel efficiency.

As the transportation industry continues to embrace electrification, ferrofluids are finding new applications in thermal management systems for electric vehicles (EVs). The ability of ferrofluids to efficiently transfer heat makes them ideal for cooling battery packs and power electronics, addressing one of the key challenges in EV development.

The market demand for ferrofluid applications in transportation is further bolstered by the global push towards smart cities and intelligent transportation systems. Ferrofluids could play a role in developing advanced sensors and actuators for traffic management systems, autonomous vehicles, and smart infrastructure.

While the potential applications of ferrofluids in transportation are promising, it's important to note that many of these technologies are still in the research and development phase. The market demand is currently driven more by potential than by widespread commercial adoption. However, as these technologies mature and prove their efficacy, the demand is expected to grow significantly in the coming years.

In the automotive sector, there is a growing interest in ferrofluid-based shock absorbers and damping systems. These systems offer superior performance compared to traditional hydraulic systems, providing better ride comfort and handling characteristics. The market for such advanced suspension systems is expected to grow as consumers increasingly prioritize vehicle comfort and safety.

The aerospace industry is another significant driver of ferrofluid demand in transportation. Ferrofluids are being explored for use in adaptive wing designs, where they can be used to alter the shape of aircraft wings in real-time, improving aerodynamics and fuel efficiency. This application aligns with the industry's push towards more fuel-efficient and environmentally friendly aircraft.

In the rail transportation sector, ferrofluids are being investigated for use in magnetic levitation (maglev) systems. While maglev technology is not new, the use of ferrofluids could potentially reduce system complexity and cost, making this high-speed transportation option more viable for wider adoption. The demand for faster, more efficient inter-city transportation is driving research in this area.

The maritime industry is also showing interest in ferrofluid applications, particularly in the development of advanced propulsion systems and hull coatings. Ferrofluid-based propulsion systems could offer improved efficiency and maneuverability, while ferrofluid coatings may reduce drag and improve fuel efficiency.

As the transportation industry continues to embrace electrification, ferrofluids are finding new applications in thermal management systems for electric vehicles (EVs). The ability of ferrofluids to efficiently transfer heat makes them ideal for cooling battery packs and power electronics, addressing one of the key challenges in EV development.

The market demand for ferrofluid applications in transportation is further bolstered by the global push towards smart cities and intelligent transportation systems. Ferrofluids could play a role in developing advanced sensors and actuators for traffic management systems, autonomous vehicles, and smart infrastructure.

While the potential applications of ferrofluids in transportation are promising, it's important to note that many of these technologies are still in the research and development phase. The market demand is currently driven more by potential than by widespread commercial adoption. However, as these technologies mature and prove their efficacy, the demand is expected to grow significantly in the coming years.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in emerging transportation technologies, several significant challenges hinder their widespread adoption and application. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these magnetic liquids tend to degrade, with magnetic particles agglomerating or settling out of suspension. This instability can lead to reduced performance and reliability in transportation applications, particularly in systems that require consistent magnetic properties over extended periods.

Another critical challenge is the temperature sensitivity of ferrofluids. Many transportation applications involve exposure to extreme temperatures, from the frigid conditions of aerospace to the high heat of automotive engines. Ferrofluids can experience significant changes in their magnetic and rheological properties under these temperature variations, potentially compromising their effectiveness and safety in critical systems.

The scalability of ferrofluid production presents a further hurdle. While small-scale production for research and specialized applications is well-established, scaling up to meet the demands of the transportation industry remains problematic. Ensuring consistent quality and properties in large-scale manufacturing processes is crucial for widespread implementation but currently poses significant technical and economic challenges.

Environmental concerns also play a role in limiting ferrofluid adoption. The nanoparticles used in ferrofluids may pose risks to ecosystems if released into the environment. This raises questions about the long-term environmental impact of ferrofluid-based technologies and the need for robust containment and disposal protocols.

Additionally, the integration of ferrofluids with existing transportation systems presents complex engineering challenges. Adapting current designs to incorporate ferrofluid-based components often requires significant modifications to established systems, which can be costly and time-consuming. This integration challenge is particularly acute in industries with stringent safety and regulatory requirements, such as aviation and automotive manufacturing.

Lastly, there is a notable knowledge gap in understanding the full range of ferrofluid behaviors under the diverse conditions encountered in transportation applications. This lack of comprehensive data on long-term performance, interaction with other materials, and behavior under various operational stresses hampers the development of robust design guidelines and standards for ferrofluid-based systems in transportation.

Another critical challenge is the temperature sensitivity of ferrofluids. Many transportation applications involve exposure to extreme temperatures, from the frigid conditions of aerospace to the high heat of automotive engines. Ferrofluids can experience significant changes in their magnetic and rheological properties under these temperature variations, potentially compromising their effectiveness and safety in critical systems.

The scalability of ferrofluid production presents a further hurdle. While small-scale production for research and specialized applications is well-established, scaling up to meet the demands of the transportation industry remains problematic. Ensuring consistent quality and properties in large-scale manufacturing processes is crucial for widespread implementation but currently poses significant technical and economic challenges.

Environmental concerns also play a role in limiting ferrofluid adoption. The nanoparticles used in ferrofluids may pose risks to ecosystems if released into the environment. This raises questions about the long-term environmental impact of ferrofluid-based technologies and the need for robust containment and disposal protocols.

Additionally, the integration of ferrofluids with existing transportation systems presents complex engineering challenges. Adapting current designs to incorporate ferrofluid-based components often requires significant modifications to established systems, which can be costly and time-consuming. This integration challenge is particularly acute in industries with stringent safety and regulatory requirements, such as aviation and automotive manufacturing.

Lastly, there is a notable knowledge gap in understanding the full range of ferrofluid behaviors under the diverse conditions encountered in transportation applications. This lack of comprehensive data on long-term performance, interaction with other materials, and behavior under various operational stresses hampers the development of robust design guidelines and standards for ferrofluid-based systems in transportation.

Current Ferrofluid Apps

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They typically consist of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

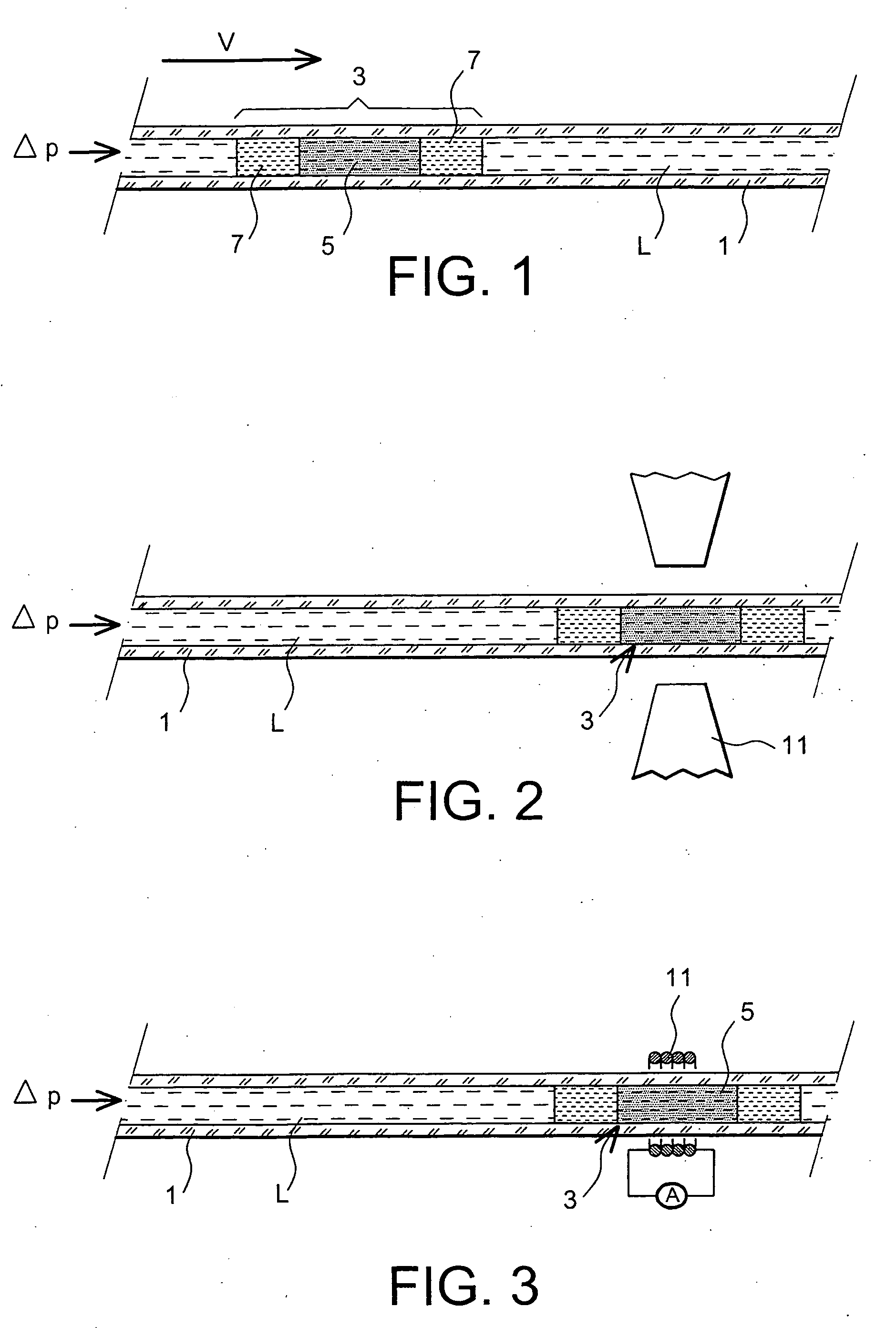

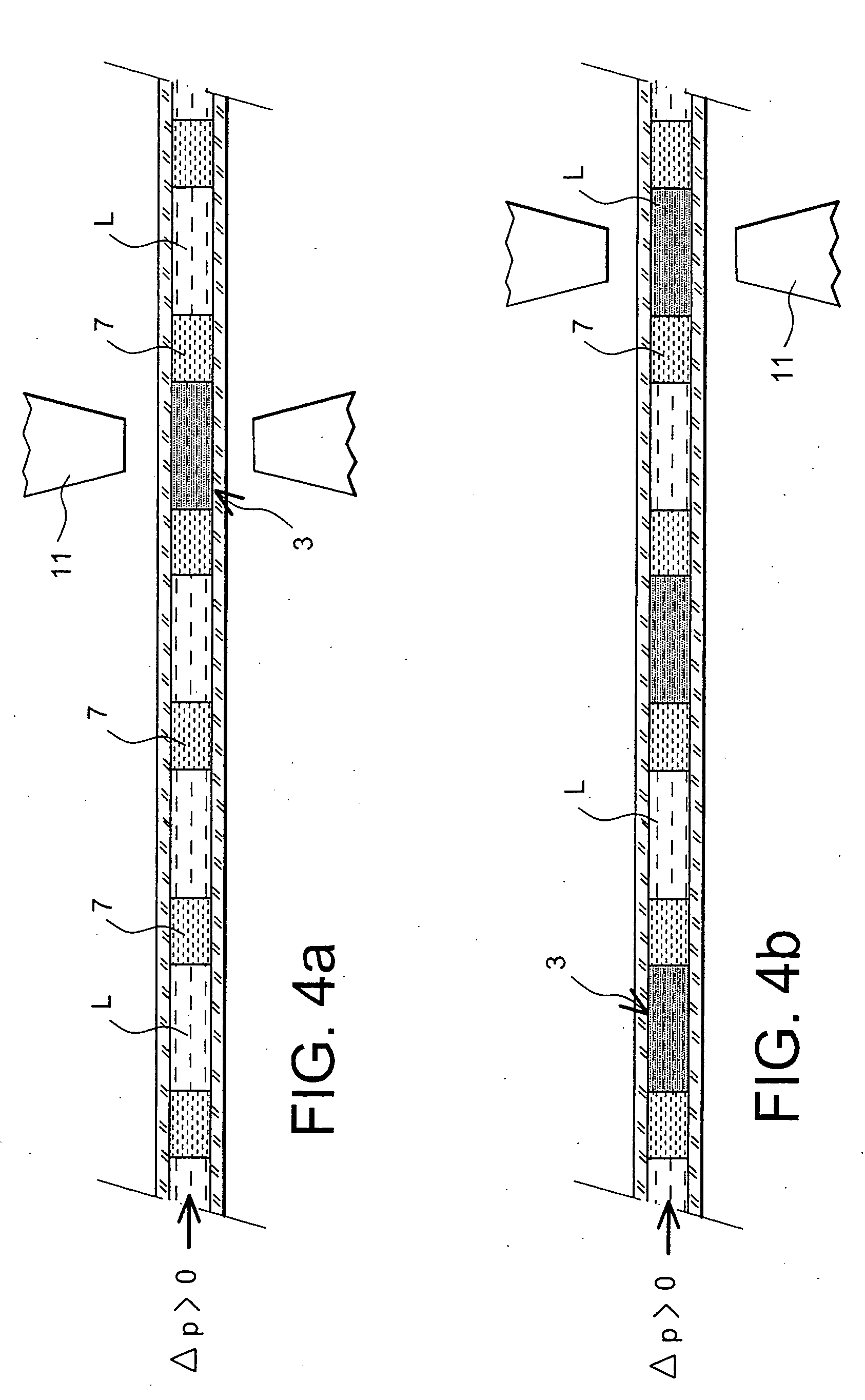

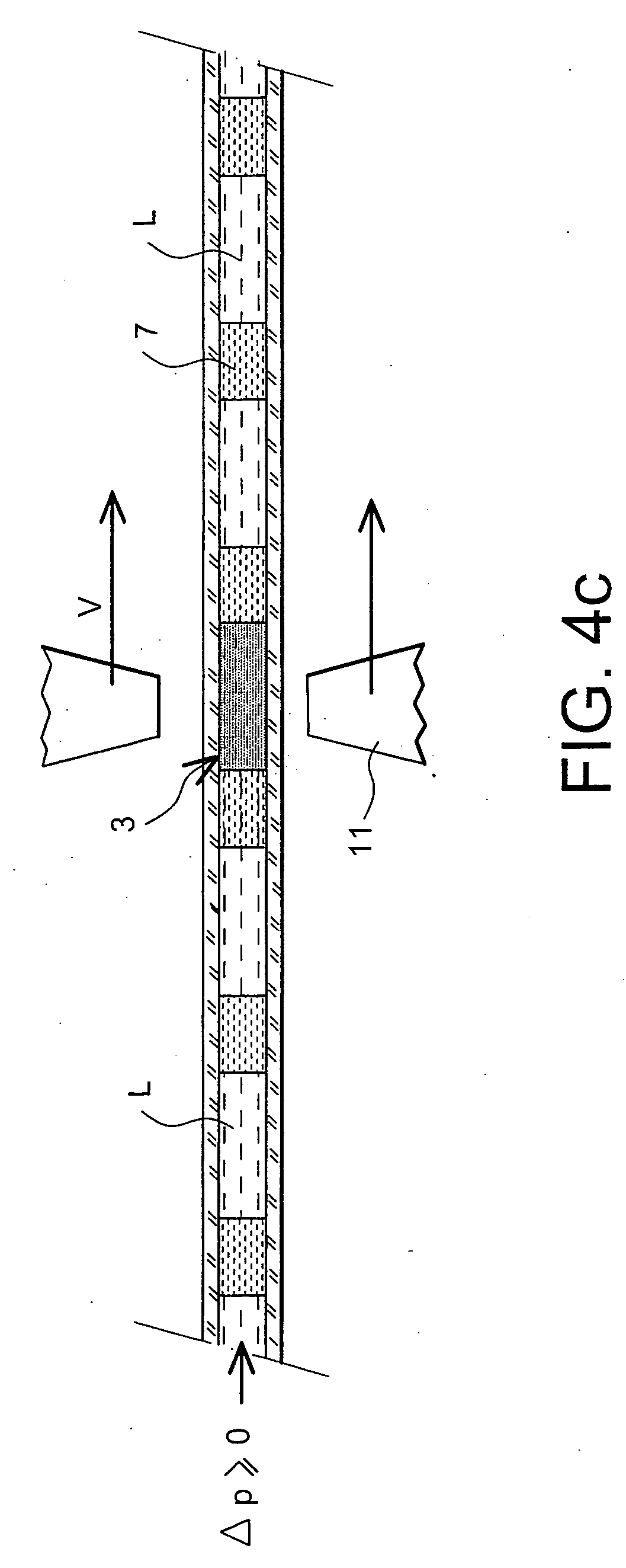

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication systems, particularly in rotating shaft seals. They provide effective sealing against pressure differentials and contaminants while reducing friction. These applications leverage the fluid's ability to be held in place by magnetic fields, creating dynamic seals in various industrial and mechanical systems.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The fluid's movement can be controlled by magnetic fields, allowing for targeted and efficient heat dissipation in various applications.

- Damping and vibration control: The unique properties of ferrofluids make them effective in damping and vibration control applications. They can be used in shock absorbers, inertial dampers, and acoustic devices. The fluid's response to magnetic fields allows for adaptive damping systems that can adjust to different conditions and frequencies.

- Sensing and measurement applications: Ferrofluids are employed in various sensing and measurement devices. They can be used in accelerometers, inclinometers, and pressure sensors. The fluid's response to magnetic fields and its ability to change shape or position under different conditions make it suitable for precise measurements in diverse fields, including aerospace and automotive industries.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly for electronic devices. They can be used in cooling systems where their magnetic properties allow for enhanced heat transfer and precise control of fluid flow, improving overall cooling efficiency.Expand Specific Solutions04 Sensor and actuator technologies

Ferrofluids are utilized in various sensor and actuator applications. Their unique magnetic properties allow for the development of highly sensitive position sensors, accelerometers, and other devices that can respond to magnetic fields or mechanical forces.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have potential applications in medicine and biomedical research. They can be used for targeted drug delivery, magnetic hyperthermia treatment of cancer, and as contrast agents in magnetic resonance imaging (MRI). The ability to control these fluids using external magnetic fields makes them valuable for minimally invasive procedures.Expand Specific Solutions

Key Industry Players

The application of ferrofluid in emerging transportation technologies is in an early development stage, with a growing market potential as the automotive and aerospace industries explore innovative solutions. The technology's maturity is still evolving, with key players like Teledyne Scientific & Imaging LLC, Western Digital Corp., and Ferrotec (USA) Corp. leading research and development efforts. Universities such as Arizona State University and Yale University are contributing to fundamental research, while companies like Boeing Co. and LORD Corp. are exploring practical applications. The competitive landscape is diverse, involving both established corporations and specialized firms, indicating a dynamic and expanding field with opportunities for technological breakthroughs and market growth.

Western Digital Corp.

Technical Solution: While primarily known for data storage solutions, Western Digital has been exploring ferrofluid applications in emerging transportation technologies, particularly in the realm of autonomous vehicles and advanced driver assistance systems (ADAS). They have developed ferrofluid-based inertial measurement units (IMUs) that offer improved accuracy and reliability for vehicle navigation and stability control systems[9]. Western Digital's research also extends to using ferrofluids in next-generation data storage devices designed for harsh automotive environments, leveraging the fluid's unique properties to enhance shock resistance and thermal management[10]. Their work aims to address the growing data processing and storage needs of connected and autonomous vehicles.

Strengths: Expertise in precision engineering and data systems relevant to modern vehicles. Weaknesses: Limited direct experience in traditional automotive applications.

Ferrotec (USA) Corp.

Technical Solution: Ferrotec has developed advanced ferrofluid-based sealing systems for rotating shafts in transportation applications. Their technology utilizes the unique properties of ferrofluids to create a hermetic seal that can withstand high rotational speeds and pressure differentials. The company has implemented nano-engineered ferrofluids with improved thermal stability and magnetic responsiveness, allowing for enhanced performance in extreme conditions often encountered in transportation systems[1][3]. Ferrotec's ferrofluid seals have been successfully applied in electric vehicle powertrains, reducing friction and improving overall efficiency.

Strengths: Expertise in ferrofluid engineering, proven track record in transportation applications. Weaknesses: Potential limitations in scaling production for mass market adoption.

Core Ferrofluid Patents

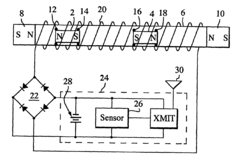

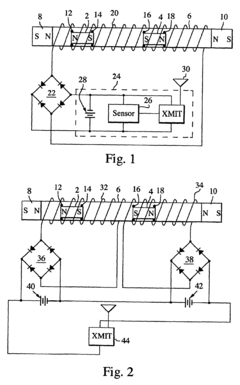

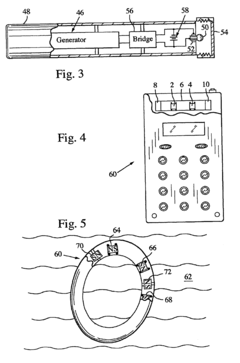

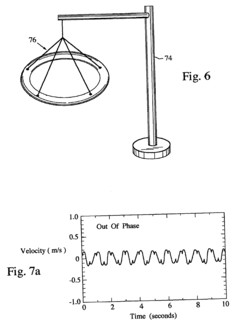

Multiple magnet transducer

PatentInactiveUS6768230B2

Innovation

- The implementation of ultra-low friction ferrofluid bearings between magnets and a support structure, allowing for horizontal orientation and enabling multiple oscillation modes that respond to various types of motion, including gentle and random movements, by using multiple magnets in polar opposition with a common axis.

Method for moving a fluid of interest in a capillary tube and fluidic microsystem

PatentInactiveUS20040241693A1

Innovation

- A method involving a ferrofluid train with a slug of ferrofluid and a slug of immiscible liquid, controlled by a magnetic field generated externally, is introduced into the capillary channel to manage the displacement of analyte fluids, using ionic ferrofluids and hydrophobic capillary channels to prevent contamination and ensure accurate flow control.

Environmental Impact

The application of ferrofluids in emerging transportation technologies presents both opportunities and challenges from an environmental perspective. As these magnetic nanofluids gain traction in various transport systems, it is crucial to assess their potential environmental impacts throughout their lifecycle.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can enhance efficiency and performance in transportation applications. However, their production process involves the use of potentially harmful chemicals and energy-intensive manufacturing techniques. The synthesis of magnetic nanoparticles often requires the use of strong acids, bases, and organic solvents, which can contribute to air and water pollution if not properly managed.

In terms of operational environmental impact, ferrofluids used in transportation systems may have both positive and negative effects. On the positive side, their ability to improve energy efficiency in various applications, such as in advanced suspension systems or magnetic seals, could lead to reduced fuel consumption and lower greenhouse gas emissions. Additionally, their use in lubricants and coolants may extend the lifespan of mechanical components, potentially reducing waste generation from worn-out parts.

However, concerns arise regarding the potential release of nanoparticles into the environment during the use phase. While ferrofluids are designed to be contained within closed systems, wear and tear or accidental leaks could result in the dispersion of magnetic nanoparticles. The long-term effects of these nanoparticles on ecosystems and human health are not yet fully understood, necessitating further research and careful monitoring.

End-of-life management of ferrofluid-containing components presents another environmental challenge. Proper disposal and recycling procedures must be developed to prevent the release of nanoparticles into landfills or water systems. The recovery of valuable magnetic materials from used ferrofluids could contribute to resource conservation but may require energy-intensive separation processes.

To mitigate potential environmental risks, ongoing research is focused on developing more environmentally friendly synthesis methods for ferrofluids, such as using green chemistry principles and renewable precursors. Additionally, efforts are being made to improve containment systems and develop effective filtration technologies to capture any escaped nanoparticles during use or disposal.

As the adoption of ferrofluid-based technologies in transportation increases, it is essential to conduct comprehensive life cycle assessments to fully understand their environmental footprint. This holistic approach will help identify areas for improvement and guide the development of sustainable practices in the production, use, and disposal of ferrofluids in emerging transportation technologies.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can enhance efficiency and performance in transportation applications. However, their production process involves the use of potentially harmful chemicals and energy-intensive manufacturing techniques. The synthesis of magnetic nanoparticles often requires the use of strong acids, bases, and organic solvents, which can contribute to air and water pollution if not properly managed.

In terms of operational environmental impact, ferrofluids used in transportation systems may have both positive and negative effects. On the positive side, their ability to improve energy efficiency in various applications, such as in advanced suspension systems or magnetic seals, could lead to reduced fuel consumption and lower greenhouse gas emissions. Additionally, their use in lubricants and coolants may extend the lifespan of mechanical components, potentially reducing waste generation from worn-out parts.

However, concerns arise regarding the potential release of nanoparticles into the environment during the use phase. While ferrofluids are designed to be contained within closed systems, wear and tear or accidental leaks could result in the dispersion of magnetic nanoparticles. The long-term effects of these nanoparticles on ecosystems and human health are not yet fully understood, necessitating further research and careful monitoring.

End-of-life management of ferrofluid-containing components presents another environmental challenge. Proper disposal and recycling procedures must be developed to prevent the release of nanoparticles into landfills or water systems. The recovery of valuable magnetic materials from used ferrofluids could contribute to resource conservation but may require energy-intensive separation processes.

To mitigate potential environmental risks, ongoing research is focused on developing more environmentally friendly synthesis methods for ferrofluids, such as using green chemistry principles and renewable precursors. Additionally, efforts are being made to improve containment systems and develop effective filtration technologies to capture any escaped nanoparticles during use or disposal.

As the adoption of ferrofluid-based technologies in transportation increases, it is essential to conduct comprehensive life cycle assessments to fully understand their environmental footprint. This holistic approach will help identify areas for improvement and guide the development of sustainable practices in the production, use, and disposal of ferrofluids in emerging transportation technologies.

Safety Regulations

The integration of ferrofluids in emerging transportation technologies necessitates a comprehensive framework of safety regulations to ensure public safety and environmental protection. As ferrofluids become more prevalent in various transportation applications, regulatory bodies must establish and enforce stringent guidelines to address potential risks associated with their use.

One primary concern is the containment and disposal of ferrofluids. Regulations should mandate proper sealing and encapsulation of ferrofluid-based components to prevent leakage or spillage during normal operation and in the event of accidents. Additionally, guidelines for the safe disposal of ferrofluid-containing devices at the end of their lifecycle must be implemented to mitigate environmental contamination.

Electromagnetic compatibility (EMC) is another crucial aspect of safety regulations. As ferrofluids are responsive to magnetic fields, strict standards should be set to ensure that ferrofluid-based systems do not interfere with other electronic components or sensitive equipment in transportation vehicles. This includes establishing acceptable limits for electromagnetic emissions and susceptibility.

Health and safety considerations for workers involved in the manufacturing, installation, and maintenance of ferrofluid-based transportation technologies must also be addressed. Regulations should outline proper handling procedures, personal protective equipment requirements, and exposure limits to minimize potential health risks associated with ferrofluid contact or inhalation.

Given the potential use of ferrofluids in critical transportation systems, regulations must address reliability and fail-safe mechanisms. Standards should be established for regular inspections, maintenance protocols, and performance testing to ensure the continued safe operation of ferrofluid-based components throughout their service life.

Environmental impact assessments should be mandated for large-scale implementations of ferrofluid technologies in transportation infrastructure. This includes evaluating potential effects on local ecosystems, groundwater, and air quality, as well as establishing monitoring protocols to detect and mitigate any adverse environmental impacts.

As ferrofluid applications in transportation evolve, safety regulations must remain adaptable. Regulatory bodies should establish mechanisms for periodic review and updates to safety standards, incorporating new research findings and addressing emerging risks associated with advanced ferrofluid technologies.

Lastly, international cooperation and harmonization of safety regulations will be crucial as ferrofluid-based transportation technologies cross borders. Collaborative efforts between regulatory agencies worldwide can help establish consistent safety standards and facilitate the global adoption of these innovative technologies while ensuring uniform safety measures across different regions.

One primary concern is the containment and disposal of ferrofluids. Regulations should mandate proper sealing and encapsulation of ferrofluid-based components to prevent leakage or spillage during normal operation and in the event of accidents. Additionally, guidelines for the safe disposal of ferrofluid-containing devices at the end of their lifecycle must be implemented to mitigate environmental contamination.

Electromagnetic compatibility (EMC) is another crucial aspect of safety regulations. As ferrofluids are responsive to magnetic fields, strict standards should be set to ensure that ferrofluid-based systems do not interfere with other electronic components or sensitive equipment in transportation vehicles. This includes establishing acceptable limits for electromagnetic emissions and susceptibility.

Health and safety considerations for workers involved in the manufacturing, installation, and maintenance of ferrofluid-based transportation technologies must also be addressed. Regulations should outline proper handling procedures, personal protective equipment requirements, and exposure limits to minimize potential health risks associated with ferrofluid contact or inhalation.

Given the potential use of ferrofluids in critical transportation systems, regulations must address reliability and fail-safe mechanisms. Standards should be established for regular inspections, maintenance protocols, and performance testing to ensure the continued safe operation of ferrofluid-based components throughout their service life.

Environmental impact assessments should be mandated for large-scale implementations of ferrofluid technologies in transportation infrastructure. This includes evaluating potential effects on local ecosystems, groundwater, and air quality, as well as establishing monitoring protocols to detect and mitigate any adverse environmental impacts.

As ferrofluid applications in transportation evolve, safety regulations must remain adaptable. Regulatory bodies should establish mechanisms for periodic review and updates to safety standards, incorporating new research findings and addressing emerging risks associated with advanced ferrofluid technologies.

Lastly, international cooperation and harmonization of safety regulations will be crucial as ferrofluid-based transportation technologies cross borders. Collaborative efforts between regulatory agencies worldwide can help establish consistent safety standards and facilitate the global adoption of these innovative technologies while ensuring uniform safety measures across different regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!