Exploring Graphene Battery Safety Enhancement Strategies

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Battery Evolution and Safety Goals

Graphene batteries have emerged as a promising technology in the energy storage landscape, offering potential advantages over traditional lithium-ion batteries. The evolution of graphene batteries has been driven by the need for safer, more efficient, and higher-capacity energy storage solutions. This technological progression aims to address the limitations of conventional batteries while leveraging the unique properties of graphene.

The primary safety goals for graphene batteries focus on mitigating risks associated with thermal runaway, electrolyte leakage, and structural integrity. Researchers and engineers are working to develop graphene-based electrodes and electrolytes that can withstand higher temperatures and mechanical stress without compromising performance or safety. Additionally, efforts are being made to enhance the overall stability of the battery system to prevent short circuits and reduce the risk of fire or explosion.

One of the key objectives in graphene battery development is to improve the thermal management capabilities. Graphene's excellent thermal conductivity is being harnessed to dissipate heat more effectively, thereby reducing the likelihood of overheating and thermal runaway. This property is particularly crucial for high-power applications and fast-charging scenarios where heat generation can be significant.

Another important safety goal is the development of solid-state graphene electrolytes. These electrolytes aim to replace the flammable liquid electrolytes used in conventional batteries, significantly reducing the risk of fire and electrolyte leakage. Solid-state graphene electrolytes also have the potential to improve the overall stability and longevity of the battery.

Researchers are also exploring the use of graphene in battery separators to enhance mechanical strength and prevent internal short circuits. The incorporation of graphene in separators can improve their thermal stability and reduce the risk of separator failure under extreme conditions.

The evolution of graphene batteries also includes the development of advanced battery management systems (BMS) that can more accurately monitor and control the battery's state of charge, temperature, and overall health. These systems leverage graphene's unique properties to provide more precise and responsive control, further enhancing safety and performance.

As the technology progresses, there is a growing focus on scalability and manufacturability. Researchers are working on methods to produce graphene-enhanced battery components at scale while maintaining consistent quality and safety standards. This includes developing new manufacturing processes and quality control measures specific to graphene-based materials.

The primary safety goals for graphene batteries focus on mitigating risks associated with thermal runaway, electrolyte leakage, and structural integrity. Researchers and engineers are working to develop graphene-based electrodes and electrolytes that can withstand higher temperatures and mechanical stress without compromising performance or safety. Additionally, efforts are being made to enhance the overall stability of the battery system to prevent short circuits and reduce the risk of fire or explosion.

One of the key objectives in graphene battery development is to improve the thermal management capabilities. Graphene's excellent thermal conductivity is being harnessed to dissipate heat more effectively, thereby reducing the likelihood of overheating and thermal runaway. This property is particularly crucial for high-power applications and fast-charging scenarios where heat generation can be significant.

Another important safety goal is the development of solid-state graphene electrolytes. These electrolytes aim to replace the flammable liquid electrolytes used in conventional batteries, significantly reducing the risk of fire and electrolyte leakage. Solid-state graphene electrolytes also have the potential to improve the overall stability and longevity of the battery.

Researchers are also exploring the use of graphene in battery separators to enhance mechanical strength and prevent internal short circuits. The incorporation of graphene in separators can improve their thermal stability and reduce the risk of separator failure under extreme conditions.

The evolution of graphene batteries also includes the development of advanced battery management systems (BMS) that can more accurately monitor and control the battery's state of charge, temperature, and overall health. These systems leverage graphene's unique properties to provide more precise and responsive control, further enhancing safety and performance.

As the technology progresses, there is a growing focus on scalability and manufacturability. Researchers are working on methods to produce graphene-enhanced battery components at scale while maintaining consistent quality and safety standards. This includes developing new manufacturing processes and quality control measures specific to graphene-based materials.

Market Demand for Safe High-Performance Batteries

The demand for safe, high-performance batteries has been steadily increasing across various industries, driven by the growing adoption of electric vehicles, renewable energy storage systems, and portable electronic devices. As traditional lithium-ion batteries approach their theoretical limits in terms of energy density and safety, there is a pressing need for advanced battery technologies that can offer improved performance without compromising safety.

Graphene-enhanced batteries have emerged as a promising solution to address these market demands. The unique properties of graphene, including its high electrical conductivity, mechanical strength, and thermal management capabilities, make it an ideal material for enhancing battery safety and performance. The automotive industry, in particular, has shown significant interest in graphene batteries due to their potential to extend the range of electric vehicles while reducing charging times and improving overall safety.

The consumer electronics sector is another key driver of demand for safe, high-performance batteries. With the increasing power requirements of smartphones, laptops, and wearable devices, manufacturers are seeking battery technologies that can provide longer battery life and faster charging capabilities without the risk of overheating or combustion. Graphene-enhanced batteries offer the potential to meet these requirements, making them highly attractive for next-generation consumer electronics.

In the renewable energy sector, the need for large-scale energy storage solutions has created a substantial market opportunity for advanced battery technologies. Grid-scale energy storage systems require batteries that can withstand frequent charge-discharge cycles, maintain high efficiency, and operate safely over extended periods. Graphene-enhanced batteries show promise in addressing these challenges, potentially enabling more efficient and reliable renewable energy integration.

The aerospace and defense industries also represent significant markets for safe, high-performance batteries. These sectors require batteries that can operate reliably under extreme conditions while maintaining the highest safety standards. Graphene-enhanced batteries, with their improved thermal management and structural integrity, are well-positioned to meet these stringent requirements.

As concerns about battery safety continue to grow, regulatory bodies worldwide are implementing stricter safety standards for battery technologies. This regulatory landscape is further driving the demand for innovative battery solutions that can meet or exceed these safety requirements while delivering enhanced performance. Graphene-enhanced batteries, with their potential for improved safety features, are well-aligned with these evolving regulatory standards.

Graphene-enhanced batteries have emerged as a promising solution to address these market demands. The unique properties of graphene, including its high electrical conductivity, mechanical strength, and thermal management capabilities, make it an ideal material for enhancing battery safety and performance. The automotive industry, in particular, has shown significant interest in graphene batteries due to their potential to extend the range of electric vehicles while reducing charging times and improving overall safety.

The consumer electronics sector is another key driver of demand for safe, high-performance batteries. With the increasing power requirements of smartphones, laptops, and wearable devices, manufacturers are seeking battery technologies that can provide longer battery life and faster charging capabilities without the risk of overheating or combustion. Graphene-enhanced batteries offer the potential to meet these requirements, making them highly attractive for next-generation consumer electronics.

In the renewable energy sector, the need for large-scale energy storage solutions has created a substantial market opportunity for advanced battery technologies. Grid-scale energy storage systems require batteries that can withstand frequent charge-discharge cycles, maintain high efficiency, and operate safely over extended periods. Graphene-enhanced batteries show promise in addressing these challenges, potentially enabling more efficient and reliable renewable energy integration.

The aerospace and defense industries also represent significant markets for safe, high-performance batteries. These sectors require batteries that can operate reliably under extreme conditions while maintaining the highest safety standards. Graphene-enhanced batteries, with their improved thermal management and structural integrity, are well-positioned to meet these stringent requirements.

As concerns about battery safety continue to grow, regulatory bodies worldwide are implementing stricter safety standards for battery technologies. This regulatory landscape is further driving the demand for innovative battery solutions that can meet or exceed these safety requirements while delivering enhanced performance. Graphene-enhanced batteries, with their potential for improved safety features, are well-aligned with these evolving regulatory standards.

Current Challenges in Graphene Battery Safety

Despite the promising potential of graphene batteries, several significant challenges persist in ensuring their safety and reliability. One of the primary concerns is the potential for thermal runaway, a phenomenon where the battery's temperature rapidly increases, leading to fire or explosion. Graphene's high thermal conductivity, while beneficial in many applications, can exacerbate this issue by quickly spreading heat throughout the battery structure.

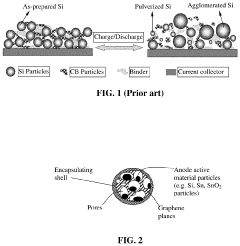

Another critical challenge is the long-term stability of graphene-based electrodes. Over repeated charge-discharge cycles, graphene materials may undergo structural changes, leading to capacity fade and reduced performance. This degradation not only affects the battery's efficiency but also raises safety concerns as unstable electrodes can contribute to internal short circuits or electrolyte decomposition.

The interaction between graphene and electrolytes presents another safety hurdle. Some graphene materials may catalyze unwanted side reactions with the electrolyte, potentially generating gases or forming a solid electrolyte interphase (SEI) layer that is less stable than in conventional lithium-ion batteries. These reactions can lead to pressure build-up within the cell or compromise the protective functions of the SEI layer, increasing the risk of battery failure.

Mechanical integrity is also a significant concern. While graphene is known for its strength, the integration of graphene materials into battery structures can create new vulnerabilities. For instance, the formation of graphene-based composite electrodes may introduce weak points or inhomogeneities that could lead to mechanical failures under stress or during thermal expansion and contraction cycles.

Furthermore, the potential for graphene nanoparticles to penetrate cell separators poses a unique safety risk. If graphene particles migrate through the separator, they could create conductive pathways between electrodes, leading to internal short circuits. This risk is particularly pronounced given graphene's high electrical conductivity and the ultra-thin nature of advanced separators used to maximize energy density.

Lastly, the scalability of safe graphene battery production remains a challenge. Ensuring consistent quality and safety features across large-scale manufacturing processes is crucial but difficult, given the complex nature of graphene materials and their integration into battery systems. Variations in graphene quality, dispersion, or electrode fabrication could lead to inconsistent safety performance across produced batteries, complicating quality control and reliability assurance efforts.

Another critical challenge is the long-term stability of graphene-based electrodes. Over repeated charge-discharge cycles, graphene materials may undergo structural changes, leading to capacity fade and reduced performance. This degradation not only affects the battery's efficiency but also raises safety concerns as unstable electrodes can contribute to internal short circuits or electrolyte decomposition.

The interaction between graphene and electrolytes presents another safety hurdle. Some graphene materials may catalyze unwanted side reactions with the electrolyte, potentially generating gases or forming a solid electrolyte interphase (SEI) layer that is less stable than in conventional lithium-ion batteries. These reactions can lead to pressure build-up within the cell or compromise the protective functions of the SEI layer, increasing the risk of battery failure.

Mechanical integrity is also a significant concern. While graphene is known for its strength, the integration of graphene materials into battery structures can create new vulnerabilities. For instance, the formation of graphene-based composite electrodes may introduce weak points or inhomogeneities that could lead to mechanical failures under stress or during thermal expansion and contraction cycles.

Furthermore, the potential for graphene nanoparticles to penetrate cell separators poses a unique safety risk. If graphene particles migrate through the separator, they could create conductive pathways between electrodes, leading to internal short circuits. This risk is particularly pronounced given graphene's high electrical conductivity and the ultra-thin nature of advanced separators used to maximize energy density.

Lastly, the scalability of safe graphene battery production remains a challenge. Ensuring consistent quality and safety features across large-scale manufacturing processes is crucial but difficult, given the complex nature of graphene materials and their integration into battery systems. Variations in graphene quality, dispersion, or electrode fabrication could lead to inconsistent safety performance across produced batteries, complicating quality control and reliability assurance efforts.

Existing Graphene Battery Safety Solutions

01 Thermal management for safety

Graphene's excellent thermal conductivity is utilized in battery designs to enhance heat dissipation and prevent thermal runaway. This improves the overall safety of graphene batteries by reducing the risk of overheating and potential fire hazards. Advanced thermal management systems incorporating graphene materials help maintain optimal operating temperatures and increase battery longevity.- Thermal management for graphene batteries: Implementing effective thermal management systems in graphene batteries is crucial for safety. This includes the use of heat dissipation materials, cooling mechanisms, and temperature monitoring systems to prevent overheating and thermal runaway, which can lead to battery failure or fire hazards.

- Electrolyte optimization for graphene batteries: Developing and using specialized electrolytes that are compatible with graphene electrodes can enhance the safety of graphene batteries. These electrolytes may include additives or compounds that improve stability, reduce flammability, and prevent unwanted reactions between the electrolyte and graphene components.

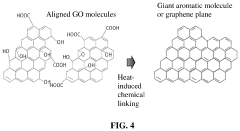

- Structural design for improved safety: Incorporating advanced structural designs in graphene batteries can enhance their safety profile. This may include the use of protective layers, separator materials, or encapsulation techniques that prevent short circuits, contain potential leaks, and improve overall mechanical stability of the battery.

- Safety monitoring and control systems: Implementing sophisticated monitoring and control systems in graphene batteries can significantly improve their safety. These systems may include sensors for detecting abnormal conditions, voltage and current regulators, and intelligent management systems that can shut down the battery or adjust its operation in case of potential safety risks.

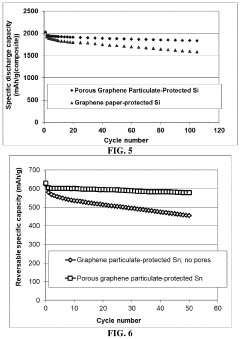

- Graphene material modifications for enhanced safety: Modifying the graphene material used in batteries through various treatments or combinations with other materials can improve safety characteristics. This may include functionalization of graphene, creating composite materials, or developing hybrid structures that enhance stability and reduce the risk of uncontrolled reactions.

02 Structural integrity and mechanical stability

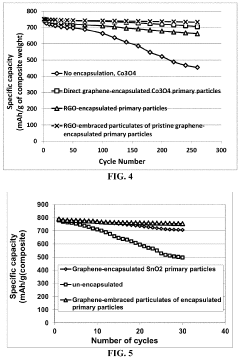

Graphene's exceptional mechanical properties are leveraged to enhance the structural integrity of battery components. This includes reinforcing electrode materials and separators, which improves the overall durability and safety of the battery. The increased mechanical stability helps prevent internal short circuits and reduces the risk of physical damage during operation or in case of impact.Expand Specific Solutions03 Electrolyte additives and modifications

Graphene-based additives or modifications to the electrolyte are explored to enhance battery safety. These additives can improve the stability of the electrolyte, reduce flammability, and prevent the formation of dendrites. Such modifications contribute to safer battery operation by mitigating risks associated with electrolyte decomposition and short circuits.Expand Specific Solutions04 Advanced electrode designs

Innovative electrode designs incorporating graphene materials are developed to enhance safety. These designs may include structured electrodes that improve ion transport, reduce internal resistance, and prevent capacity fade. The advanced electrode architectures contribute to more stable and safer battery performance over extended cycles.Expand Specific Solutions05 Safety monitoring and control systems

Integration of graphene-based sensors and monitoring systems in batteries to enhance safety. These systems can detect abnormal conditions such as overcharging, over-discharging, or internal short circuits in real-time. Advanced control mechanisms utilizing graphene's properties are implemented to prevent safety hazards and optimize battery performance.Expand Specific Solutions

Key Players in Graphene Battery Development

The graphene battery safety enhancement market is in its early growth stage, characterized by intense research and development efforts across academia and industry. The market size is expanding rapidly, driven by increasing demand for safer and more efficient energy storage solutions. While the technology is promising, it is still evolving towards full commercial maturity. Key players like Samsung SDI, Toray Industries, and NIO Technology are investing heavily in graphene battery research, with companies such as Honeycomb Battery Co. and Nanotek Instruments focusing specifically on graphene-based energy storage solutions. Universities like Northwestern and Guangxi University are contributing significant research to advance the technology. The competitive landscape is diverse, with both established electronics giants and specialized startups vying for market share in this emerging field.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a graphene-based separator technology for lithium-ion batteries that significantly enhances safety and performance. Their approach involves creating a thin, porous graphene oxide membrane that serves as an advanced separator between the cathode and anode[7]. This graphene-based separator demonstrates superior thermal stability and mechanical strength compared to conventional polyolefin separators. Toray's technology also incorporates a flame-retardant coating on the graphene oxide separator, further improving the battery's safety under extreme conditions[8]. The company has also explored the use of graphene in electrode materials, developing a graphene-wrapped silicon anode that shows improved cycling stability and capacity retention[9].

Strengths: Enhanced thermal stability, improved mechanical strength, and flame-retardant properties. Weaknesses: Potential increase in production complexity and cost.

Northwestern University

Technical Solution: Northwestern University researchers have developed a novel graphene-based battery safety enhancement strategy focusing on the electrolyte. Their approach involves creating a graphene oxide-based composite electrolyte that forms a protective layer on the electrode surfaces during cycling[10]. This layer acts as a barrier against dendrite formation and helps prevent short circuits. The team has also explored the use of 3D graphene structures as a host for silicon anodes, which significantly improves the mechanical stability and cycling performance of high-capacity silicon-based batteries[11]. Additionally, Northwestern researchers have developed a graphene-based "heat shield" that can be integrated into the battery structure to prevent thermal runaway propagation between cells in a battery pack[12].

Strengths: Addresses multiple safety concerns (dendrite formation, thermal runaway), and improves cycling stability. Weaknesses: May require significant changes to existing battery manufacturing processes.

Innovative Safety Mechanisms for Graphene Batteries

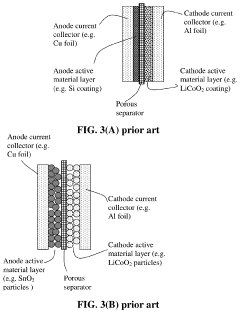

Process for producing porous graphene particulate-protected anode active materials for lithium batteries

PatentActiveUS20200127288A1

Innovation

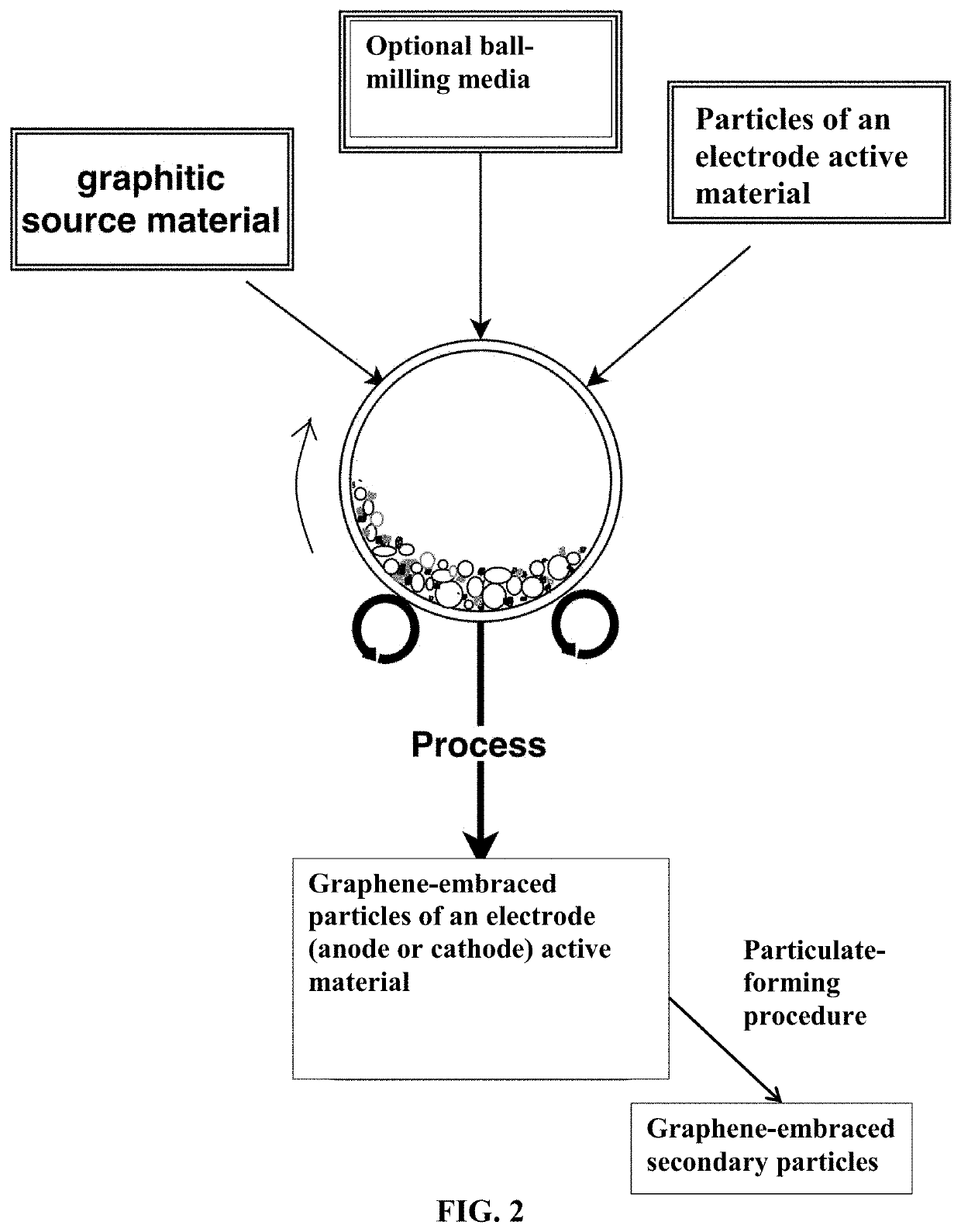

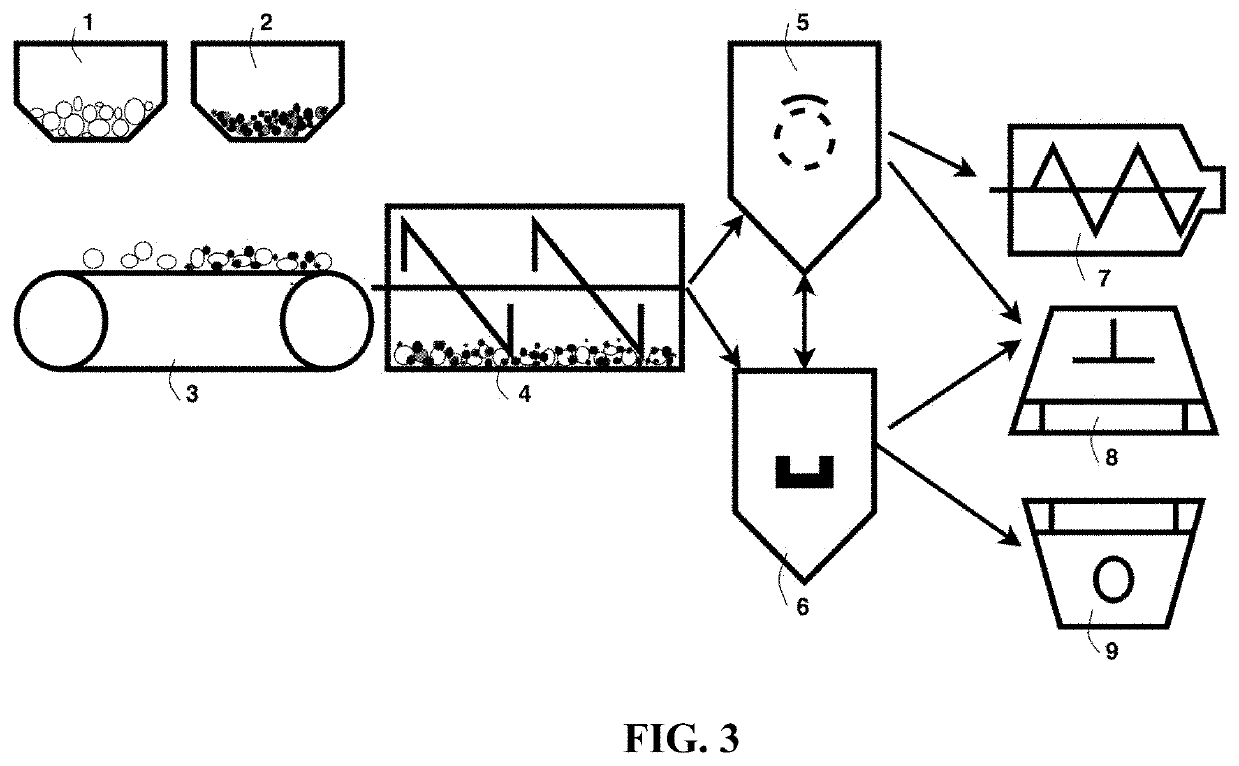

- The development of porous graphene particulates with anode active material particles lodged in their pores, where the particulates have a thin encapsulating layer of conducting material and a 3D network of electron-conducting pathways, allowing for volume expansion accommodation without significant volume change of the anode electrode.

Multi-level graphene-protected anode active material particles for fast-charging lithium-ion batteries

PatentInactiveUS20190379039A1

Innovation

- The use of graphene-embraced particulates, where primary particles of anode or cathode active materials are encapsulated with multiple sheets of graphene, providing mechanical protection and enhanced conductivity, and optionally combined with a conductive additive, to form a composite that improves cycle stability and high-rate capability.

Environmental Impact of Graphene Battery Production

The production of graphene batteries presents both opportunities and challenges in terms of environmental impact. While these batteries offer potential advantages in energy storage and efficiency, their manufacturing process requires careful consideration of ecological factors.

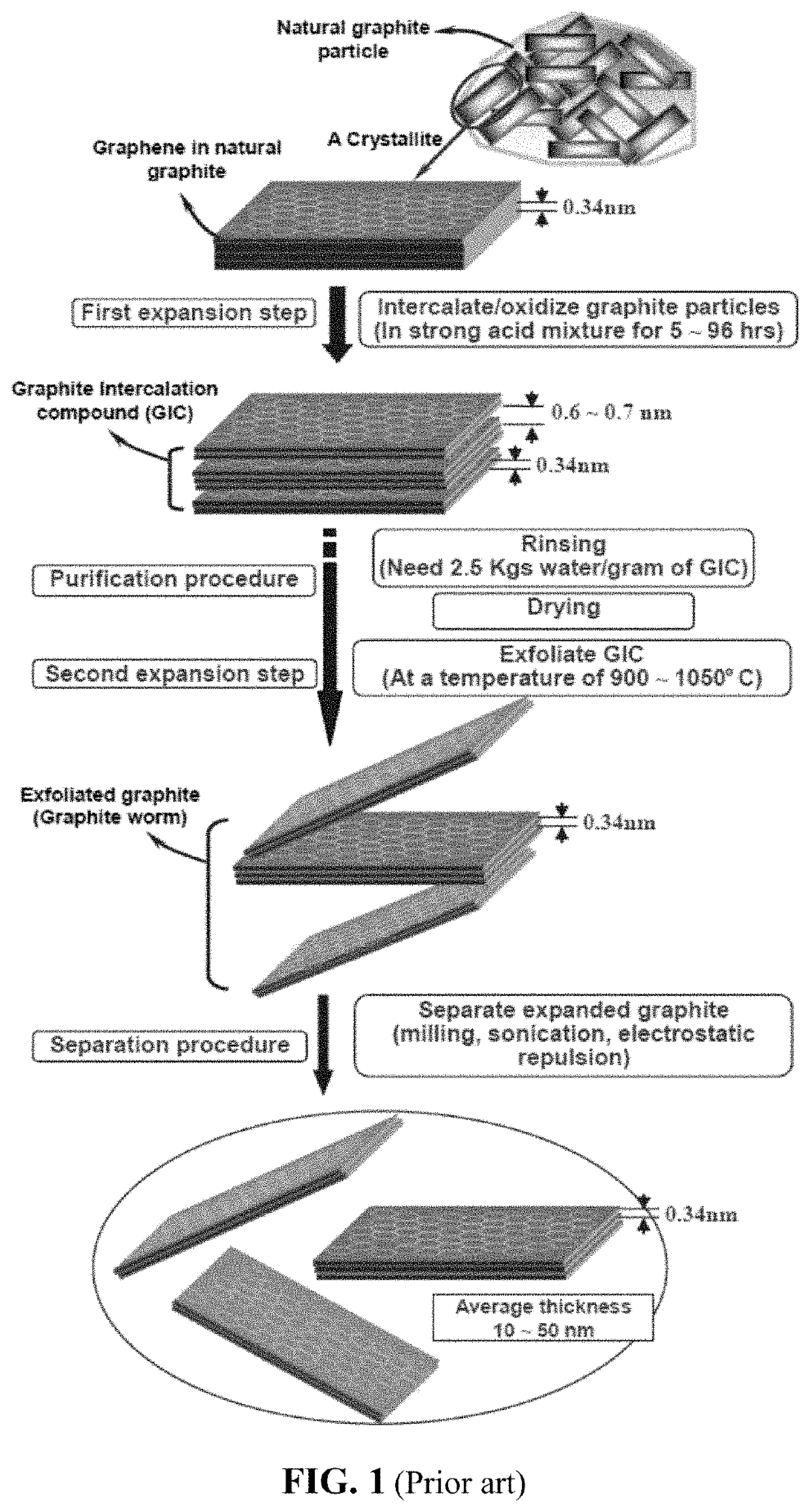

Graphene production typically involves chemical vapor deposition or exfoliation methods, which can be energy-intensive and may generate hazardous byproducts. The use of strong acids and solvents in some production processes raises concerns about potential environmental contamination if not properly managed. However, advancements in green synthesis methods, such as electrochemical exfoliation and biomass-derived graphene production, are showing promise in reducing the environmental footprint.

Water usage is another critical factor in graphene battery production. The purification and processing of graphene often require significant amounts of water, which can strain local water resources in areas of production. Implementing closed-loop water systems and developing water-efficient production techniques are essential steps in mitigating this impact.

The extraction and processing of raw materials for graphene batteries, including lithium, cobalt, and other metals, also contribute to the overall environmental impact. Mining operations can lead to habitat destruction, soil erosion, and water pollution. Sustainable sourcing practices and the development of recycling technologies for these materials are crucial for reducing the long-term environmental burden.

Energy consumption during the manufacturing process is a significant concern. The high temperatures required for certain graphene production methods contribute to increased carbon emissions. Transitioning to renewable energy sources for powering production facilities can help offset these emissions and improve the overall sustainability of graphene battery manufacturing.

On the positive side, graphene batteries have the potential to enhance the efficiency and lifespan of energy storage systems, which could lead to reduced waste from battery disposal. Their improved performance characteristics may also contribute to the wider adoption of electric vehicles and renewable energy systems, indirectly benefiting the environment by reducing reliance on fossil fuels.

As the technology advances, life cycle assessments of graphene batteries are becoming increasingly important. These studies help identify areas for improvement in the production process and guide the development of more environmentally friendly manufacturing techniques. Ongoing research into biodegradable graphene composites and eco-friendly electrolytes also holds promise for further reducing the environmental impact of these batteries.

Graphene production typically involves chemical vapor deposition or exfoliation methods, which can be energy-intensive and may generate hazardous byproducts. The use of strong acids and solvents in some production processes raises concerns about potential environmental contamination if not properly managed. However, advancements in green synthesis methods, such as electrochemical exfoliation and biomass-derived graphene production, are showing promise in reducing the environmental footprint.

Water usage is another critical factor in graphene battery production. The purification and processing of graphene often require significant amounts of water, which can strain local water resources in areas of production. Implementing closed-loop water systems and developing water-efficient production techniques are essential steps in mitigating this impact.

The extraction and processing of raw materials for graphene batteries, including lithium, cobalt, and other metals, also contribute to the overall environmental impact. Mining operations can lead to habitat destruction, soil erosion, and water pollution. Sustainable sourcing practices and the development of recycling technologies for these materials are crucial for reducing the long-term environmental burden.

Energy consumption during the manufacturing process is a significant concern. The high temperatures required for certain graphene production methods contribute to increased carbon emissions. Transitioning to renewable energy sources for powering production facilities can help offset these emissions and improve the overall sustainability of graphene battery manufacturing.

On the positive side, graphene batteries have the potential to enhance the efficiency and lifespan of energy storage systems, which could lead to reduced waste from battery disposal. Their improved performance characteristics may also contribute to the wider adoption of electric vehicles and renewable energy systems, indirectly benefiting the environment by reducing reliance on fossil fuels.

As the technology advances, life cycle assessments of graphene batteries are becoming increasingly important. These studies help identify areas for improvement in the production process and guide the development of more environmentally friendly manufacturing techniques. Ongoing research into biodegradable graphene composites and eco-friendly electrolytes also holds promise for further reducing the environmental impact of these batteries.

Regulatory Framework for Advanced Battery Technologies

The regulatory framework for advanced battery technologies, including graphene batteries, is evolving to keep pace with rapid technological advancements. Governments and international organizations are developing comprehensive guidelines to ensure the safety, reliability, and environmental sustainability of these emerging energy storage solutions.

In the United States, the Department of Energy (DOE) has established the Battery and Critical Materials Hub to coordinate research efforts and develop standards for next-generation batteries. The Environmental Protection Agency (EPA) oversees the disposal and recycling of battery materials, while the Consumer Product Safety Commission (CPSC) regulates battery safety in consumer products.

The European Union has implemented the Battery Directive, which sets stringent requirements for battery manufacturing, collection, and recycling. This directive is currently being updated to address the specific challenges posed by advanced battery technologies, including graphene-based systems. The European Commission's Strategic Action Plan on Batteries aims to create a competitive and sustainable battery ecosystem in Europe.

In Asia, countries like China, Japan, and South Korea have implemented their own regulatory frameworks to support the development and commercialization of advanced battery technologies. China's New Energy Vehicle (NEV) policy includes specific provisions for battery safety and performance standards.

International organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are developing global standards for advanced battery technologies. These standards address issues such as safety testing protocols, performance metrics, and interoperability requirements.

Specific to graphene batteries, regulatory bodies are focusing on several key areas. These include the potential environmental and health impacts of graphene nanoparticles, the long-term stability and safety of graphene-enhanced electrodes, and the recyclability of graphene-containing battery components.

As the technology matures, regulators are likely to implement more specific guidelines for graphene battery manufacturing, testing, and disposal. This may include requirements for advanced safety features, such as improved thermal management systems and enhanced structural integrity to prevent short circuits and thermal runaway.

In the United States, the Department of Energy (DOE) has established the Battery and Critical Materials Hub to coordinate research efforts and develop standards for next-generation batteries. The Environmental Protection Agency (EPA) oversees the disposal and recycling of battery materials, while the Consumer Product Safety Commission (CPSC) regulates battery safety in consumer products.

The European Union has implemented the Battery Directive, which sets stringent requirements for battery manufacturing, collection, and recycling. This directive is currently being updated to address the specific challenges posed by advanced battery technologies, including graphene-based systems. The European Commission's Strategic Action Plan on Batteries aims to create a competitive and sustainable battery ecosystem in Europe.

In Asia, countries like China, Japan, and South Korea have implemented their own regulatory frameworks to support the development and commercialization of advanced battery technologies. China's New Energy Vehicle (NEV) policy includes specific provisions for battery safety and performance standards.

International organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are developing global standards for advanced battery technologies. These standards address issues such as safety testing protocols, performance metrics, and interoperability requirements.

Specific to graphene batteries, regulatory bodies are focusing on several key areas. These include the potential environmental and health impacts of graphene nanoparticles, the long-term stability and safety of graphene-enhanced electrodes, and the recyclability of graphene-containing battery components.

As the technology matures, regulators are likely to implement more specific guidelines for graphene battery manufacturing, testing, and disposal. This may include requirements for advanced safety features, such as improved thermal management systems and enhanced structural integrity to prevent short circuits and thermal runaway.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!