Exploring Turbo Wastegate Actuation Technologies in B58 Engines

AUG 12, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Turbo Background

The B58 engine, developed by BMW, represents a significant advancement in turbocharged inline-six engine technology. Introduced in 2015, this 3.0-liter powerplant has become a cornerstone of BMW's performance lineup, featuring in various models across the BMW and Toyota ranges. The B58's turbocharging system is a key component of its design, contributing significantly to its power output and efficiency.

At the heart of the B58's turbocharging system is a single twin-scroll turbocharger. This design choice allows for improved exhaust gas separation and reduced turbo lag compared to traditional single-scroll turbos. The twin-scroll configuration effectively divides the exhaust flow from the cylinders, maintaining exhaust pulse energy and improving turbine efficiency.

The turbocharger in the B58 engine is integrated into the exhaust manifold, forming part of the engine's overall architecture. This integration offers several advantages, including reduced weight, improved packaging, and enhanced thermal management. The close coupling of the turbocharger to the engine also contributes to faster catalyst light-off times, aiding in emissions reduction.

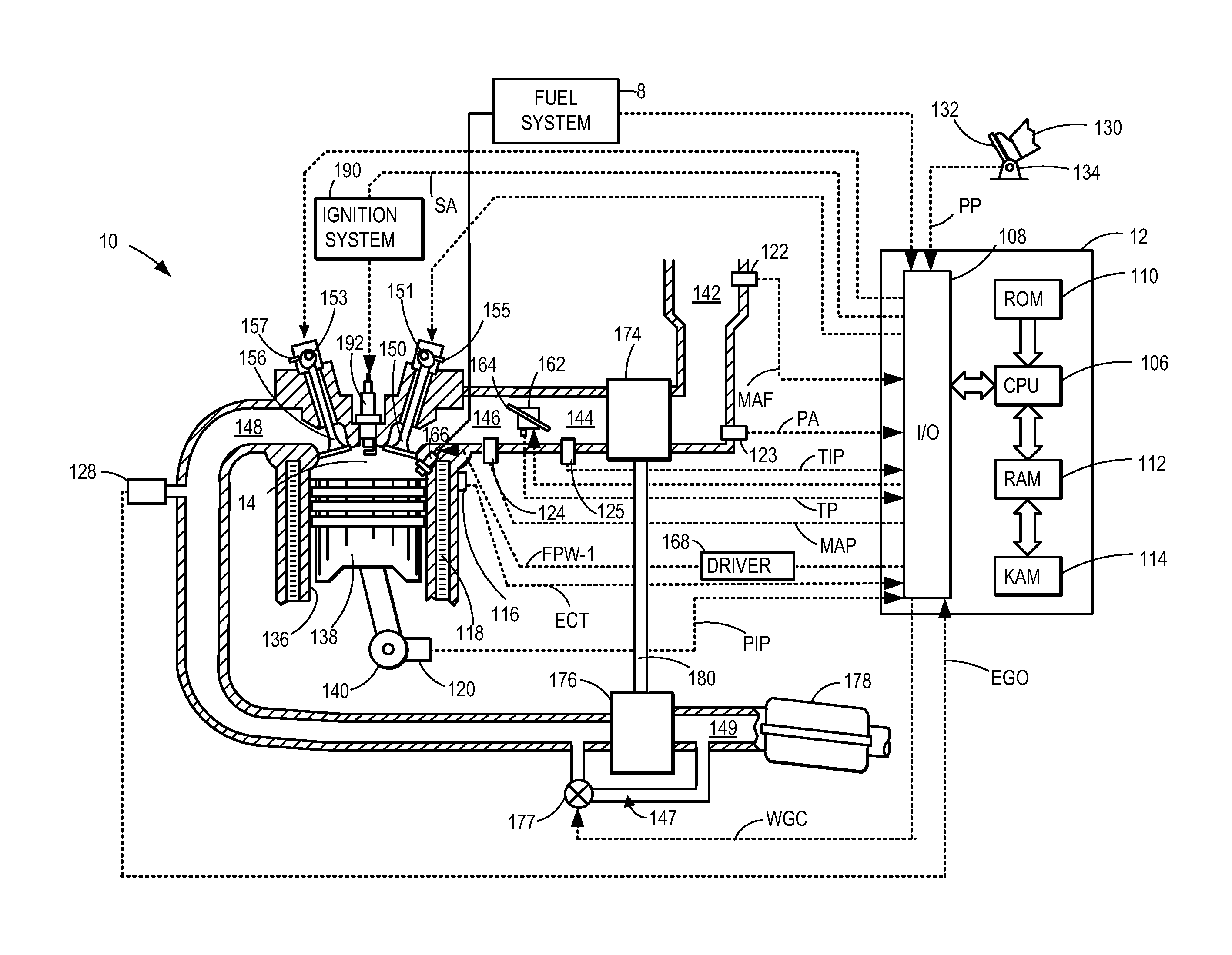

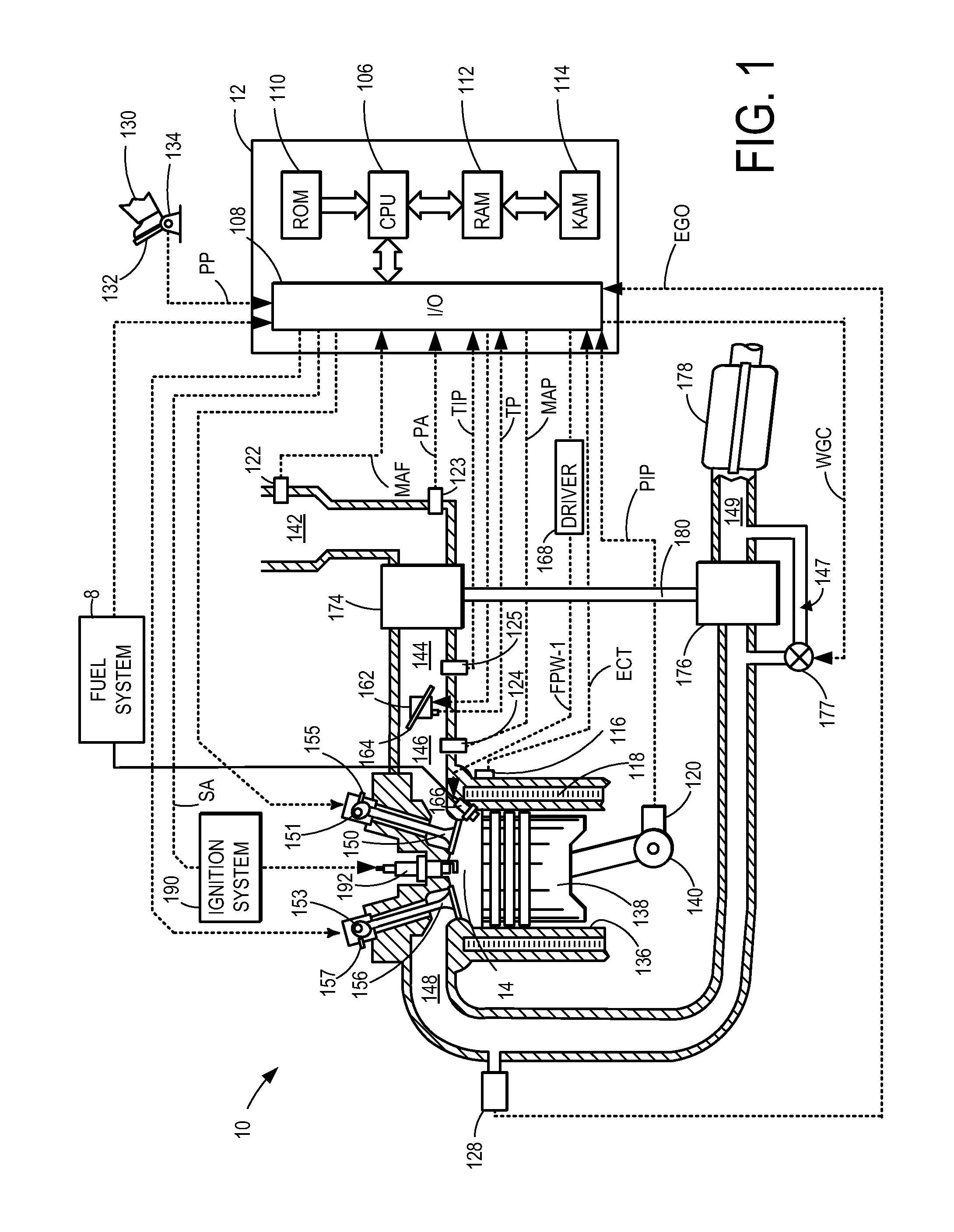

A crucial element of the B58's turbocharging system is its wastegate mechanism. The wastegate plays a vital role in regulating boost pressure by controlling the flow of exhaust gases to the turbine wheel. In the B58, the wastegate is electronically actuated, allowing for precise control over boost pressure across various operating conditions.

The electronic wastegate actuation in the B58 engine represents a departure from traditional pneumatic systems. This shift towards electronic control enables more rapid and accurate adjustments to boost pressure, contributing to improved engine response and overall performance. The electronic wastegate actuator works in conjunction with the engine's ECU to optimize boost levels based on factors such as engine load, ambient conditions, and driver input.

BMW's implementation of turbo technology in the B58 engine also includes measures to mitigate turbo lag. These include the use of a low-inertia turbine wheel and optimized exhaust manifold design. Additionally, the engine's Valvetronic variable valve lift system and Double-VANOS variable camshaft timing contribute to improved low-end torque and overall engine responsiveness.

The B58's turbocharging system is complemented by direct fuel injection and an advanced cooling system. These technologies work in concert to maximize power output while maintaining efficiency and reliability. The result is an engine capable of producing over 300 horsepower in its base form, with higher-output versions exceeding 380 horsepower in some applications.

At the heart of the B58's turbocharging system is a single twin-scroll turbocharger. This design choice allows for improved exhaust gas separation and reduced turbo lag compared to traditional single-scroll turbos. The twin-scroll configuration effectively divides the exhaust flow from the cylinders, maintaining exhaust pulse energy and improving turbine efficiency.

The turbocharger in the B58 engine is integrated into the exhaust manifold, forming part of the engine's overall architecture. This integration offers several advantages, including reduced weight, improved packaging, and enhanced thermal management. The close coupling of the turbocharger to the engine also contributes to faster catalyst light-off times, aiding in emissions reduction.

A crucial element of the B58's turbocharging system is its wastegate mechanism. The wastegate plays a vital role in regulating boost pressure by controlling the flow of exhaust gases to the turbine wheel. In the B58, the wastegate is electronically actuated, allowing for precise control over boost pressure across various operating conditions.

The electronic wastegate actuation in the B58 engine represents a departure from traditional pneumatic systems. This shift towards electronic control enables more rapid and accurate adjustments to boost pressure, contributing to improved engine response and overall performance. The electronic wastegate actuator works in conjunction with the engine's ECU to optimize boost levels based on factors such as engine load, ambient conditions, and driver input.

BMW's implementation of turbo technology in the B58 engine also includes measures to mitigate turbo lag. These include the use of a low-inertia turbine wheel and optimized exhaust manifold design. Additionally, the engine's Valvetronic variable valve lift system and Double-VANOS variable camshaft timing contribute to improved low-end torque and overall engine responsiveness.

The B58's turbocharging system is complemented by direct fuel injection and an advanced cooling system. These technologies work in concert to maximize power output while maintaining efficiency and reliability. The result is an engine capable of producing over 300 horsepower in its base form, with higher-output versions exceeding 380 horsepower in some applications.

Market Demand Analysis

The market demand for advanced turbo wastegate actuation technologies in B58 engines has been steadily increasing, driven by the automotive industry's push for improved engine performance, fuel efficiency, and emissions control. As stringent environmental regulations continue to shape the automotive landscape, manufacturers are seeking innovative solutions to optimize engine output while meeting emission standards.

The B58 engine, developed by BMW, has gained significant popularity in the premium sports car segment due to its robust performance and efficiency. This has created a growing market for aftermarket and OEM upgrades, particularly in turbo wastegate actuation systems. The demand is further fueled by enthusiasts and tuners looking to extract maximum performance from their vehicles.

In recent years, there has been a noticeable shift towards electrification in the automotive industry. However, this transition has not diminished the demand for advanced internal combustion engine technologies. Instead, it has intensified the need for more sophisticated turbocharging systems, including improved wastegate actuation, to bridge the gap between traditional powertrains and fully electric vehicles.

The market for turbo wastegate actuation technologies in B58 engines extends beyond personal vehicles. Commercial and industrial applications, such as in high-performance boats and specialized machinery, are also driving demand. This diversification of applications has expanded the potential market size and opened new avenues for technological innovation.

Geographically, the demand is particularly strong in regions with a high concentration of premium vehicle manufacturers and performance-oriented consumers. North America, Europe, and parts of Asia have shown significant interest in these technologies, with emerging markets also beginning to contribute to the growing demand.

The aftermarket sector plays a crucial role in driving innovation and demand for advanced wastegate actuation technologies. Tuning companies and performance parts manufacturers are constantly seeking new ways to enhance engine output, creating a vibrant ecosystem of products and services around B58 engines and similar powerplants.

As the automotive industry continues to evolve, the demand for more precise, responsive, and durable wastegate actuation systems is expected to grow. This trend is likely to persist as long as internal combustion engines remain a significant part of the automotive landscape, with potential for further growth in hybrid powertrain applications where efficient turbocharging can complement electric propulsion systems.

The B58 engine, developed by BMW, has gained significant popularity in the premium sports car segment due to its robust performance and efficiency. This has created a growing market for aftermarket and OEM upgrades, particularly in turbo wastegate actuation systems. The demand is further fueled by enthusiasts and tuners looking to extract maximum performance from their vehicles.

In recent years, there has been a noticeable shift towards electrification in the automotive industry. However, this transition has not diminished the demand for advanced internal combustion engine technologies. Instead, it has intensified the need for more sophisticated turbocharging systems, including improved wastegate actuation, to bridge the gap between traditional powertrains and fully electric vehicles.

The market for turbo wastegate actuation technologies in B58 engines extends beyond personal vehicles. Commercial and industrial applications, such as in high-performance boats and specialized machinery, are also driving demand. This diversification of applications has expanded the potential market size and opened new avenues for technological innovation.

Geographically, the demand is particularly strong in regions with a high concentration of premium vehicle manufacturers and performance-oriented consumers. North America, Europe, and parts of Asia have shown significant interest in these technologies, with emerging markets also beginning to contribute to the growing demand.

The aftermarket sector plays a crucial role in driving innovation and demand for advanced wastegate actuation technologies. Tuning companies and performance parts manufacturers are constantly seeking new ways to enhance engine output, creating a vibrant ecosystem of products and services around B58 engines and similar powerplants.

As the automotive industry continues to evolve, the demand for more precise, responsive, and durable wastegate actuation systems is expected to grow. This trend is likely to persist as long as internal combustion engines remain a significant part of the automotive landscape, with potential for further growth in hybrid powertrain applications where efficient turbocharging can complement electric propulsion systems.

Wastegate Tech Status

The current state of wastegate actuation technology in B58 engines reflects a blend of traditional and advanced approaches. Pneumatic actuation remains prevalent, utilizing engine vacuum or boost pressure to control the wastegate position. This system offers simplicity and reliability but may lack the precision of more modern solutions.

Electronically controlled pneumatic actuators represent an evolutionary step, combining the robustness of pneumatic systems with enhanced control capabilities. These systems employ solenoid valves to modulate the pneumatic pressure, allowing for more nuanced wastegate management and improved boost control across various operating conditions.

Electric actuators have gained traction in recent years, offering superior precision and responsiveness. These systems use electric motors to directly control the wastegate position, enabling rapid adjustments and fine-tuned boost management. The B58 engine has seen implementations of electric wastegate actuators in some variants, showcasing the industry's shift towards more advanced control strategies.

Hydraulic actuation systems, while less common in B58 applications, present another alternative. These systems leverage engine oil pressure to control wastegate movement, offering potential advantages in terms of durability and integration with existing engine systems.

The integration of wastegate control with engine management systems has become increasingly sophisticated. Modern B58 engines utilize complex algorithms and real-time data from various sensors to optimize wastegate operation, balancing performance, efficiency, and emissions requirements.

Advancements in materials science have also influenced wastegate technology. High-temperature alloys and coatings are being employed to enhance durability and performance under extreme operating conditions, addressing historical challenges related to thermal stress and wear.

Dual wastegate configurations have been explored in some B58 variants, offering potential benefits in terms of boost control precision and turbocharger efficiency across a broader operating range. This approach, while more complex, aligns with the trend towards increasingly sophisticated turbocharging systems.

The ongoing development of wastegate actuation technologies in B58 engines reflects a broader industry focus on enhancing turbocharger performance, efficiency, and emissions control. As regulations become more stringent and performance expectations rise, the evolution of wastegate technology continues to play a crucial role in engine development strategies.

Electronically controlled pneumatic actuators represent an evolutionary step, combining the robustness of pneumatic systems with enhanced control capabilities. These systems employ solenoid valves to modulate the pneumatic pressure, allowing for more nuanced wastegate management and improved boost control across various operating conditions.

Electric actuators have gained traction in recent years, offering superior precision and responsiveness. These systems use electric motors to directly control the wastegate position, enabling rapid adjustments and fine-tuned boost management. The B58 engine has seen implementations of electric wastegate actuators in some variants, showcasing the industry's shift towards more advanced control strategies.

Hydraulic actuation systems, while less common in B58 applications, present another alternative. These systems leverage engine oil pressure to control wastegate movement, offering potential advantages in terms of durability and integration with existing engine systems.

The integration of wastegate control with engine management systems has become increasingly sophisticated. Modern B58 engines utilize complex algorithms and real-time data from various sensors to optimize wastegate operation, balancing performance, efficiency, and emissions requirements.

Advancements in materials science have also influenced wastegate technology. High-temperature alloys and coatings are being employed to enhance durability and performance under extreme operating conditions, addressing historical challenges related to thermal stress and wear.

Dual wastegate configurations have been explored in some B58 variants, offering potential benefits in terms of boost control precision and turbocharger efficiency across a broader operating range. This approach, while more complex, aligns with the trend towards increasingly sophisticated turbocharging systems.

The ongoing development of wastegate actuation technologies in B58 engines reflects a broader industry focus on enhancing turbocharger performance, efficiency, and emissions control. As regulations become more stringent and performance expectations rise, the evolution of wastegate technology continues to play a crucial role in engine development strategies.

Current Solutions

01 Electric actuators for turbo wastegates

Electric actuators are used to control turbo wastegates, offering precise and rapid control of boost pressure. These systems typically include an electric motor, gearing, and a position sensor to accurately regulate wastegate opening and closing. Electric actuators provide improved response times and can be easily integrated with engine management systems for optimized performance.- Electric actuators for turbo wastegates: Electric actuators are used to control turbo wastegates, offering precise and rapid control of boost pressure. These systems typically use electric motors or solenoids to adjust the wastegate position, allowing for improved engine performance and efficiency. Electric actuators can be integrated with engine management systems for optimal control.

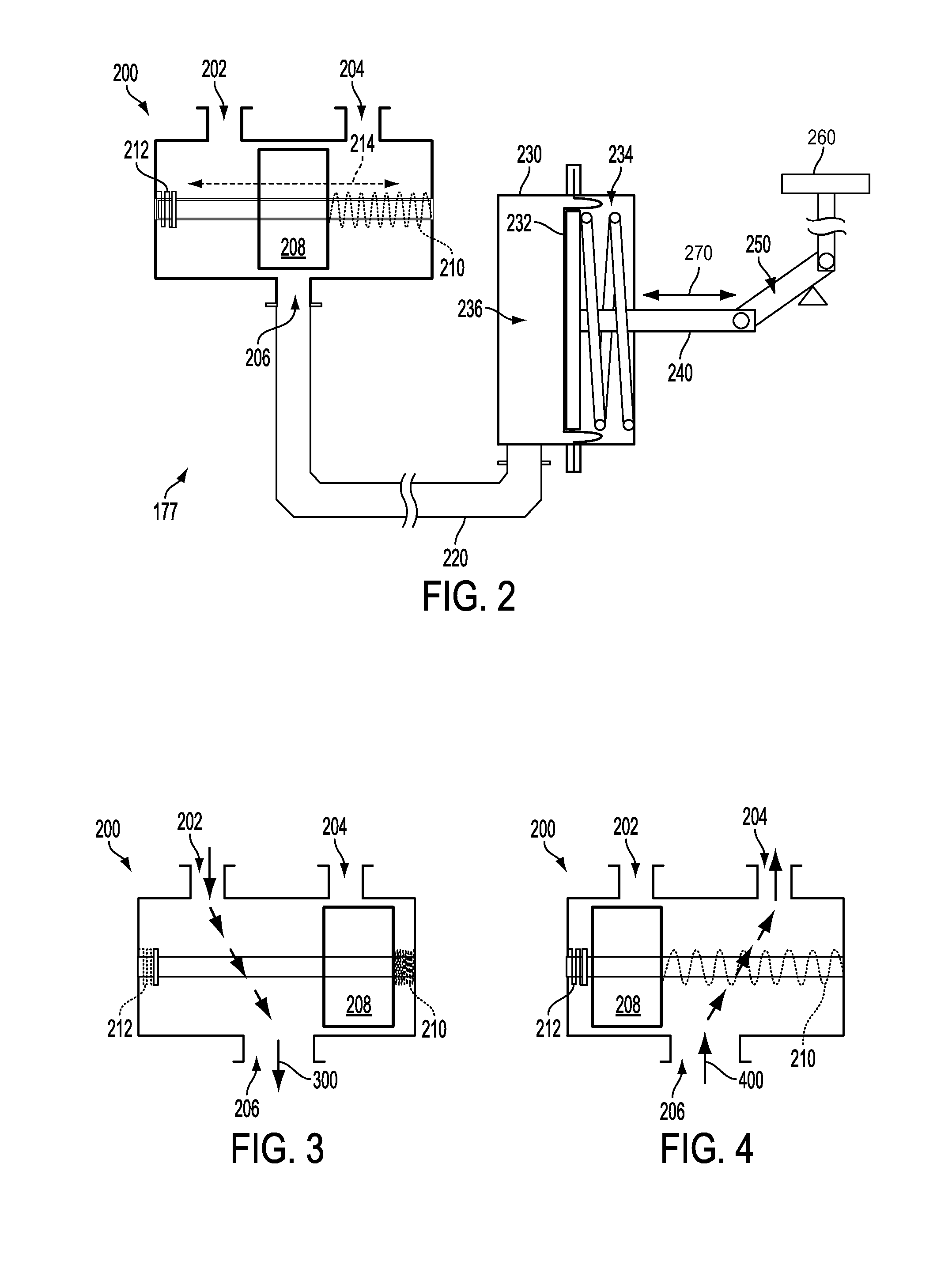

- Pneumatic wastegate actuation systems: Pneumatic systems utilize pressure differentials to actuate turbo wastegates. These systems often employ diaphragms or pistons connected to the wastegate valve, which respond to changes in boost pressure. Pneumatic actuators can be simple and reliable, but may offer less precise control compared to electric systems.

- Hydraulic wastegate actuation mechanisms: Hydraulic actuators use fluid pressure to control wastegate position. These systems can provide high force and precise control, making them suitable for high-performance applications. Hydraulic actuators may be integrated with engine oil systems or use dedicated hydraulic circuits for operation.

- Electronic wastegate control strategies: Advanced electronic control strategies are employed to optimize wastegate actuation. These may include closed-loop control systems, adaptive algorithms, and integration with other engine management functions. Electronic control can improve response times, reduce turbo lag, and enhance overall engine performance and efficiency.

- Integrated turbocharger and wastegate designs: Some turbocharger designs incorporate integrated wastegate systems, which can improve packaging, reduce weight, and enhance overall system efficiency. These integrated designs may feature specially designed actuators or leverage existing turbocharger components for wastegate control.

02 Pneumatic wastegate actuators

Pneumatic actuators utilize pressure differentials to control wastegate operation. These systems often incorporate diaphragms or pistons that respond to changes in boost pressure or vacuum signals from the engine. Pneumatic actuators are known for their simplicity and reliability, making them a common choice in many turbocharger applications.Expand Specific Solutions03 Hydraulic wastegate actuation systems

Hydraulic actuators use fluid pressure to control wastegate movement. These systems can provide high force output and precise control, often utilizing engine oil pressure or a dedicated hydraulic circuit. Hydraulic actuators can offer advantages in terms of packaging and durability in high-temperature environments.Expand Specific Solutions04 Integrated wastegate actuator designs

Integrated wastegate actuator designs incorporate the actuator mechanism directly into the turbocharger housing or compressor cover. This approach can reduce overall system complexity, improve packaging, and potentially enhance response times. Integrated designs may use various actuation methods, including electric, pneumatic, or hydraulic systems.Expand Specific Solutions05 Smart wastegate control systems

Advanced wastegate control systems utilize sensors, electronic control units, and sophisticated algorithms to optimize turbocharger performance. These systems can adapt to changing engine conditions, driver inputs, and environmental factors to provide precise boost control. Smart control systems may incorporate features such as predictive control, self-learning capabilities, and integration with other vehicle systems for improved efficiency and performance.Expand Specific Solutions

Key Industry Players

The turbo wastegate actuation technology market for B58 engines is in a growth phase, with increasing demand driven by the automotive industry's focus on engine efficiency and performance. The market size is expanding as more vehicle manufacturers adopt advanced turbocharging systems. Technologically, the field is evolving rapidly, with companies like BorgWarner, Garrett Motion, and Continental Automotive leading innovation. These firms are developing sophisticated electronic wastegate actuators and integrated turbocharger systems. Other key players such as Honeywell and Mitsubishi Heavy Industries are also contributing to technological advancements, pushing the boundaries of wastegate control precision and responsiveness.

Garrett Transportation I, Inc.

Technical Solution: Garrett Transportation has developed advanced electric wastegate actuators for B58 engines, utilizing a brushless DC motor for precise control. Their system incorporates a position sensor for real-time feedback, enabling dynamic adjustment of the wastegate position. The actuator is designed with a high-temperature resistant housing and sealed bearings to withstand harsh underhood environments. Garrett's solution also features an integrated control module that communicates with the engine ECU via CAN bus, allowing for adaptive boost control strategies[1][3]. The actuator's response time is less than 100 milliseconds, ensuring rapid boost pressure adjustments for optimal engine performance across various driving conditions.

Strengths: Precise control, fast response time, and durability in harsh environments. Weaknesses: Potentially higher cost compared to pneumatic systems and increased complexity in the control system.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a hybrid electro-pneumatic wastegate actuator system for B58 engines. This innovative approach combines the reliability of traditional pneumatic actuators with the precision of electric control. The system uses a small electric motor to modulate the pneumatic pressure applied to the wastegate, allowing for finer control than purely pneumatic systems. Honeywell's actuator incorporates a dual-spring design for fail-safe operation and a high-temperature resistant diaphragm. The electric component is controlled by a dedicated microprocessor that interfaces with the engine management system, enabling advanced boost control algorithms[2][5]. This hybrid system can achieve a position accuracy of ±0.5 mm and a response time of approximately 150 milliseconds.

Strengths: Combines benefits of both pneumatic and electric systems, fail-safe design, and compatibility with existing pneumatic setups. Weaknesses: More complex than pure electric or pneumatic systems, potentially higher maintenance requirements.

Core Innovations

Wastegate control system and method

PatentInactiveEP2340367A2

Innovation

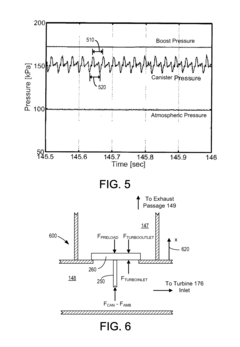

- A wastegate control system that incorporates a control unit communicating with throttle angle, intake charge humidity, engine speed, ambient pressure, ignition timing, and knock sensors to dynamically adjust the wastegate operation, ensuring optimal boost pressure and power delivery based on real-time sensor data.

Turbocharger control

PatentActiveUS20110314807A1

Innovation

- The solution involves using the boost pressure generated by the turbocharger to actuate the wastegate, with the range of actuation varying based on interrelationships between boost pressure, turbine inlet pressure, turbine outlet pressure, and atmospheric pressure, and freezing the integral term when the wastegate actuator is commanded outside this range to prevent integrator windup.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the automotive industry and driving technological advancements in engine design. These regulations aim to reduce harmful emissions and improve air quality, with a particular focus on carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter.

In the context of B58 engines and turbo wastegate actuation technologies, emissions regulations play a crucial role in shaping the development and implementation of these systems. The B58 engine, known for its high performance and efficiency, must meet strict emissions standards while maintaining its power output and fuel economy.

One of the primary challenges faced by B58 engines is the need to balance performance with emissions control. Turbo wastegate actuation technologies are essential in this regard, as they help regulate boost pressure and exhaust gas flow, directly impacting engine efficiency and emissions output. Advanced wastegate control systems can optimize engine performance across various operating conditions, ensuring compliance with emissions standards without sacrificing power.

The European Union's Euro 6 standards and the United States' EPA Tier 3 regulations have set ambitious targets for reducing vehicle emissions. These standards have pushed manufacturers to innovate in areas such as exhaust gas recirculation (EGR), selective catalytic reduction (SCR), and particulate filters. For B58 engines, this has led to the development of more sophisticated wastegate actuation systems that can respond rapidly to changing engine conditions and emissions requirements.

Real-world driving emissions (RDE) tests have further complicated the regulatory landscape, requiring engines to perform efficiently and cleanly under a wide range of driving conditions. This has increased the importance of precise wastegate control to manage boost pressure and exhaust gas flow effectively in various real-world scenarios.

The push towards electrification and hybrid powertrains has also influenced emissions regulations and, consequently, the development of turbo wastegate actuation technologies. As manufacturers explore mild hybrid and plug-in hybrid variants of high-performance engines like the B58, wastegate systems must be adapted to work seamlessly with electric assist technologies and regenerative braking systems.

Looking ahead, future emissions regulations are expected to become even more stringent, potentially including stricter limits on CO2 emissions and the introduction of new pollutants to be regulated. This will likely drive further innovation in turbo wastegate actuation technologies, with a focus on improving precision, response time, and integration with other engine management systems.

In the context of B58 engines and turbo wastegate actuation technologies, emissions regulations play a crucial role in shaping the development and implementation of these systems. The B58 engine, known for its high performance and efficiency, must meet strict emissions standards while maintaining its power output and fuel economy.

One of the primary challenges faced by B58 engines is the need to balance performance with emissions control. Turbo wastegate actuation technologies are essential in this regard, as they help regulate boost pressure and exhaust gas flow, directly impacting engine efficiency and emissions output. Advanced wastegate control systems can optimize engine performance across various operating conditions, ensuring compliance with emissions standards without sacrificing power.

The European Union's Euro 6 standards and the United States' EPA Tier 3 regulations have set ambitious targets for reducing vehicle emissions. These standards have pushed manufacturers to innovate in areas such as exhaust gas recirculation (EGR), selective catalytic reduction (SCR), and particulate filters. For B58 engines, this has led to the development of more sophisticated wastegate actuation systems that can respond rapidly to changing engine conditions and emissions requirements.

Real-world driving emissions (RDE) tests have further complicated the regulatory landscape, requiring engines to perform efficiently and cleanly under a wide range of driving conditions. This has increased the importance of precise wastegate control to manage boost pressure and exhaust gas flow effectively in various real-world scenarios.

The push towards electrification and hybrid powertrains has also influenced emissions regulations and, consequently, the development of turbo wastegate actuation technologies. As manufacturers explore mild hybrid and plug-in hybrid variants of high-performance engines like the B58, wastegate systems must be adapted to work seamlessly with electric assist technologies and regenerative braking systems.

Looking ahead, future emissions regulations are expected to become even more stringent, potentially including stricter limits on CO2 emissions and the introduction of new pollutants to be regulated. This will likely drive further innovation in turbo wastegate actuation technologies, with a focus on improving precision, response time, and integration with other engine management systems.

Performance Metrics

Performance metrics play a crucial role in evaluating the effectiveness of turbo wastegate actuation technologies in B58 engines. These metrics provide quantifiable data to assess the impact of different actuation systems on engine performance, efficiency, and overall driving experience.

One of the primary performance metrics is boost pressure control. The ability of the wastegate actuator to precisely regulate boost pressure directly affects engine power output and responsiveness. Advanced actuation technologies aim to achieve faster response times and more accurate boost control across various operating conditions. This is typically measured in terms of boost pressure rise time, overshoot, and stability under transient conditions.

Fuel efficiency is another critical metric influenced by wastegate actuation. Improved control over the exhaust gas flow can lead to optimized engine breathing and reduced pumping losses. This is often quantified through brake specific fuel consumption (BSFC) measurements, which indicate the amount of fuel consumed per unit of power output. Lower BSFC values suggest higher overall engine efficiency.

Emissions performance is increasingly important in modern engine design. Wastegate actuation technologies that enable more precise control of exhaust gas recirculation (EGR) and catalytic converter temperatures can significantly impact emissions levels. Key metrics include CO2, NOx, and particulate matter emissions, measured across various drive cycles and operating conditions.

Driveability and throttle response are subjective yet crucial performance metrics. Advanced wastegate actuation systems can contribute to smoother power delivery and reduced turbo lag. These improvements are often assessed through acceleration tests, particularly in the low to mid-range RPM bands where turbocharger responsiveness is most noticeable.

Durability and reliability metrics are essential for evaluating long-term performance. This includes cycle life testing of the actuator mechanism, thermal stability under extreme conditions, and resistance to wear and contamination. Mean time between failures (MTBF) and failure mode analysis provide valuable insights into the robustness of different actuation technologies.

Noise, vibration, and harshness (NVH) characteristics are increasingly important in premium vehicle applications. Wastegate actuation can influence exhaust note and overall engine refinement. Metrics such as sound pressure levels at various frequencies and vibration amplitudes are used to quantify NVH performance.

Finally, packaging efficiency and weight are critical metrics, particularly in compact engine designs like the B58. The size, weight, and integration complexity of wastegate actuation systems can impact overall engine design and vehicle dynamics. These factors are typically assessed through CAD analysis and physical prototyping stages.

One of the primary performance metrics is boost pressure control. The ability of the wastegate actuator to precisely regulate boost pressure directly affects engine power output and responsiveness. Advanced actuation technologies aim to achieve faster response times and more accurate boost control across various operating conditions. This is typically measured in terms of boost pressure rise time, overshoot, and stability under transient conditions.

Fuel efficiency is another critical metric influenced by wastegate actuation. Improved control over the exhaust gas flow can lead to optimized engine breathing and reduced pumping losses. This is often quantified through brake specific fuel consumption (BSFC) measurements, which indicate the amount of fuel consumed per unit of power output. Lower BSFC values suggest higher overall engine efficiency.

Emissions performance is increasingly important in modern engine design. Wastegate actuation technologies that enable more precise control of exhaust gas recirculation (EGR) and catalytic converter temperatures can significantly impact emissions levels. Key metrics include CO2, NOx, and particulate matter emissions, measured across various drive cycles and operating conditions.

Driveability and throttle response are subjective yet crucial performance metrics. Advanced wastegate actuation systems can contribute to smoother power delivery and reduced turbo lag. These improvements are often assessed through acceleration tests, particularly in the low to mid-range RPM bands where turbocharger responsiveness is most noticeable.

Durability and reliability metrics are essential for evaluating long-term performance. This includes cycle life testing of the actuator mechanism, thermal stability under extreme conditions, and resistance to wear and contamination. Mean time between failures (MTBF) and failure mode analysis provide valuable insights into the robustness of different actuation technologies.

Noise, vibration, and harshness (NVH) characteristics are increasingly important in premium vehicle applications. Wastegate actuation can influence exhaust note and overall engine refinement. Metrics such as sound pressure levels at various frequencies and vibration amplitudes are used to quantify NVH performance.

Finally, packaging efficiency and weight are critical metrics, particularly in compact engine designs like the B58. The size, weight, and integration complexity of wastegate actuation systems can impact overall engine design and vehicle dynamics. These factors are typically assessed through CAD analysis and physical prototyping stages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!