Studying the Effects of Lightweight Materials on B58 Engine Output

AUG 12, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Evolution

The B58 engine, developed by BMW, has undergone significant evolution since its introduction in 2015. This inline-six turbocharged engine has been a cornerstone of BMW's powertrain strategy, featuring in various models across the BMW and Toyota lineups. The engine's development has been driven by the need for increased performance, improved fuel efficiency, and reduced emissions.

Initially introduced with a 3.0-liter displacement, the B58 engine has seen several iterations over the years. The first generation, known as B58B30M0, produced 315-340 horsepower depending on the application. This version set the foundation for future improvements, showcasing BMW's commitment to balancing power and efficiency.

In 2019, BMW introduced an updated version of the B58, designated as B58B30O1. This iteration brought significant enhancements, including a new crankshaft, pistons, and connecting rods. The revisions resulted in increased power output, with some variants producing up to 382 horsepower. The improvements also focused on reducing internal friction and enhancing thermal management.

The latest evolution of the B58 engine, introduced in 2022, further pushes the boundaries of performance and efficiency. This version, found in models like the M340i and Toyota Supra, boasts outputs of up to 382 horsepower and 369 lb-ft of torque. The enhancements include an upgraded turbocharger, revised engine management software, and improved cooling systems.

Throughout its evolution, the B58 engine has incorporated various technological advancements. These include the integration of BMW's Valvetronic variable valve timing system, Double-VANOS variable camshaft timing, and direct fuel injection. These technologies have played crucial roles in optimizing power delivery, fuel efficiency, and emissions performance.

The engine's design has also evolved to accommodate hybrid powertrains, with some variants featuring mild-hybrid technology. This integration of electrification demonstrates BMW's forward-thinking approach to meeting increasingly stringent emissions regulations while maintaining performance standards.

As the automotive industry shifts towards lightweight materials and increased electrification, the B58 engine's evolution is likely to continue. Future iterations may incorporate more advanced materials and manufacturing techniques to further reduce weight and improve efficiency, aligning with the industry's focus on sustainability and performance.

Initially introduced with a 3.0-liter displacement, the B58 engine has seen several iterations over the years. The first generation, known as B58B30M0, produced 315-340 horsepower depending on the application. This version set the foundation for future improvements, showcasing BMW's commitment to balancing power and efficiency.

In 2019, BMW introduced an updated version of the B58, designated as B58B30O1. This iteration brought significant enhancements, including a new crankshaft, pistons, and connecting rods. The revisions resulted in increased power output, with some variants producing up to 382 horsepower. The improvements also focused on reducing internal friction and enhancing thermal management.

The latest evolution of the B58 engine, introduced in 2022, further pushes the boundaries of performance and efficiency. This version, found in models like the M340i and Toyota Supra, boasts outputs of up to 382 horsepower and 369 lb-ft of torque. The enhancements include an upgraded turbocharger, revised engine management software, and improved cooling systems.

Throughout its evolution, the B58 engine has incorporated various technological advancements. These include the integration of BMW's Valvetronic variable valve timing system, Double-VANOS variable camshaft timing, and direct fuel injection. These technologies have played crucial roles in optimizing power delivery, fuel efficiency, and emissions performance.

The engine's design has also evolved to accommodate hybrid powertrains, with some variants featuring mild-hybrid technology. This integration of electrification demonstrates BMW's forward-thinking approach to meeting increasingly stringent emissions regulations while maintaining performance standards.

As the automotive industry shifts towards lightweight materials and increased electrification, the B58 engine's evolution is likely to continue. Future iterations may incorporate more advanced materials and manufacturing techniques to further reduce weight and improve efficiency, aligning with the industry's focus on sustainability and performance.

Market Demand Analysis

The market demand for lightweight materials in B58 engine applications has been steadily increasing in recent years, driven by the automotive industry's push for improved fuel efficiency and reduced emissions. As environmental regulations become more stringent worldwide, manufacturers are seeking innovative solutions to enhance engine performance while reducing overall vehicle weight.

The B58 engine, known for its robust power output and efficiency, has become a popular choice among luxury and performance vehicle manufacturers. However, the growing emphasis on sustainability and eco-friendly transportation has created a significant market opportunity for lightweight materials that can further optimize this engine's capabilities.

Consumer preferences are shifting towards vehicles that offer both performance and fuel economy. This trend has led to a surge in demand for engines that can deliver high power output while maintaining excellent fuel efficiency. Lightweight materials play a crucial role in achieving this balance, as they can reduce the overall weight of the engine without compromising its structural integrity or performance.

The automotive aftermarket sector has also shown considerable interest in lightweight materials for B58 engine modifications. Performance enthusiasts and tuning shops are constantly seeking ways to enhance engine output and reduce weight, creating a niche market for specialized lightweight components.

Market research indicates that the global automotive lightweight materials market is experiencing substantial growth. This growth is particularly pronounced in regions with strict emissions regulations, such as Europe and North America. The increasing adoption of electric and hybrid vehicles has also indirectly boosted the demand for lightweight materials in conventional engines, as manufacturers strive to maintain competitiveness in terms of performance and efficiency.

The aerospace industry's advancements in lightweight materials have begun to influence the automotive sector, leading to cross-industry collaborations and technology transfers. This synergy has accelerated the development and adoption of innovative lightweight solutions for high-performance engines like the B58.

Economic factors, such as fluctuating fuel prices and raw material costs, continue to impact the market demand for lightweight engine components. However, the long-term benefits of improved fuel efficiency and reduced emissions are expected to sustain the growth trajectory of lightweight materials in B58 engine applications.

As the automotive industry moves towards more sustainable practices, there is an emerging demand for lightweight materials that are not only performance-enhancing but also environmentally friendly and recyclable. This trend is likely to shape future research and development efforts in the field of lightweight materials for B58 engines and similar high-performance power units.

The B58 engine, known for its robust power output and efficiency, has become a popular choice among luxury and performance vehicle manufacturers. However, the growing emphasis on sustainability and eco-friendly transportation has created a significant market opportunity for lightweight materials that can further optimize this engine's capabilities.

Consumer preferences are shifting towards vehicles that offer both performance and fuel economy. This trend has led to a surge in demand for engines that can deliver high power output while maintaining excellent fuel efficiency. Lightweight materials play a crucial role in achieving this balance, as they can reduce the overall weight of the engine without compromising its structural integrity or performance.

The automotive aftermarket sector has also shown considerable interest in lightweight materials for B58 engine modifications. Performance enthusiasts and tuning shops are constantly seeking ways to enhance engine output and reduce weight, creating a niche market for specialized lightweight components.

Market research indicates that the global automotive lightweight materials market is experiencing substantial growth. This growth is particularly pronounced in regions with strict emissions regulations, such as Europe and North America. The increasing adoption of electric and hybrid vehicles has also indirectly boosted the demand for lightweight materials in conventional engines, as manufacturers strive to maintain competitiveness in terms of performance and efficiency.

The aerospace industry's advancements in lightweight materials have begun to influence the automotive sector, leading to cross-industry collaborations and technology transfers. This synergy has accelerated the development and adoption of innovative lightweight solutions for high-performance engines like the B58.

Economic factors, such as fluctuating fuel prices and raw material costs, continue to impact the market demand for lightweight engine components. However, the long-term benefits of improved fuel efficiency and reduced emissions are expected to sustain the growth trajectory of lightweight materials in B58 engine applications.

As the automotive industry moves towards more sustainable practices, there is an emerging demand for lightweight materials that are not only performance-enhancing but also environmentally friendly and recyclable. This trend is likely to shape future research and development efforts in the field of lightweight materials for B58 engines and similar high-performance power units.

Lightweight Materials

Lightweight materials have become a focal point in automotive engineering, particularly in the context of enhancing engine performance. The B58 engine, known for its robust power output, presents an intriguing case study for the application of lightweight materials. These materials, primarily consisting of advanced alloys, composites, and engineered plastics, offer significant potential for reducing overall engine weight while maintaining or even improving structural integrity and performance characteristics.

The integration of lightweight materials in engine design involves a multifaceted approach, considering factors such as thermal efficiency, durability, and cost-effectiveness. For the B58 engine, which is already renowned for its power-to-weight ratio, the implementation of lightweight materials could further optimize its performance metrics. Key areas of focus include the engine block, cylinder heads, pistons, and various internal components.

Advanced aluminum alloys, for instance, have shown promise in reducing engine block weight without compromising strength. These alloys, often reinforced with silicon and copper, offer excellent heat dissipation properties crucial for high-performance engines like the B58. Similarly, titanium alloys are being explored for components such as connecting rods and valves, leveraging their high strength-to-weight ratio and resistance to high temperatures.

Carbon fiber reinforced polymers (CFRP) represent another frontier in lightweight engine materials. While traditionally used in body panels and chassis components, recent advancements have made CFRP viable for certain engine parts. In the context of the B58 engine, CFRP could potentially be utilized in intake manifolds or engine covers, contributing to weight reduction while also providing thermal insulation benefits.

The application of magnesium alloys is another area of interest. Despite challenges related to corrosion resistance and high-temperature stability, magnesium's extremely low density makes it an attractive option for specific engine components. Ongoing research aims to develop magnesium alloys suitable for more demanding engine environments, which could have significant implications for future iterations of engines like the B58.

Ceramic matrix composites (CMCs) are also gaining attention for their potential in high-temperature applications within engines. These materials offer exceptional heat resistance and low density, making them candidates for components such as turbine housings in turbochargers, which are integral to the B58's performance.

The integration of lightweight materials in engine design involves a multifaceted approach, considering factors such as thermal efficiency, durability, and cost-effectiveness. For the B58 engine, which is already renowned for its power-to-weight ratio, the implementation of lightweight materials could further optimize its performance metrics. Key areas of focus include the engine block, cylinder heads, pistons, and various internal components.

Advanced aluminum alloys, for instance, have shown promise in reducing engine block weight without compromising strength. These alloys, often reinforced with silicon and copper, offer excellent heat dissipation properties crucial for high-performance engines like the B58. Similarly, titanium alloys are being explored for components such as connecting rods and valves, leveraging their high strength-to-weight ratio and resistance to high temperatures.

Carbon fiber reinforced polymers (CFRP) represent another frontier in lightweight engine materials. While traditionally used in body panels and chassis components, recent advancements have made CFRP viable for certain engine parts. In the context of the B58 engine, CFRP could potentially be utilized in intake manifolds or engine covers, contributing to weight reduction while also providing thermal insulation benefits.

The application of magnesium alloys is another area of interest. Despite challenges related to corrosion resistance and high-temperature stability, magnesium's extremely low density makes it an attractive option for specific engine components. Ongoing research aims to develop magnesium alloys suitable for more demanding engine environments, which could have significant implications for future iterations of engines like the B58.

Ceramic matrix composites (CMCs) are also gaining attention for their potential in high-temperature applications within engines. These materials offer exceptional heat resistance and low density, making them candidates for components such as turbine housings in turbochargers, which are integral to the B58's performance.

Current Solutions

01 Engine output control systems

Advanced control systems are implemented to optimize the B58 engine's output. These systems utilize various sensors and electronic control units to manage fuel injection, ignition timing, and turbocharger operation. By precisely controlling these parameters, the engine can achieve improved performance, fuel efficiency, and emissions control across different operating conditions.- Engine output control systems: Advanced control systems are implemented to optimize the B58 engine's output. These systems utilize various sensors and electronic control units to manage fuel injection, ignition timing, and boost pressure. By precisely controlling these parameters, the engine's performance and efficiency can be maximized across different operating conditions.

- Turbocharging and boost pressure management: The B58 engine employs turbocharging technology to increase power output. Sophisticated boost pressure management systems are used to regulate the turbocharger's performance, ensuring optimal air intake and combustion efficiency. This allows for increased power output while maintaining fuel efficiency and reducing emissions.

- Variable valve timing and lift: Advanced valve control mechanisms are incorporated in the B58 engine to enhance its output. These systems allow for dynamic adjustment of valve timing and lift, optimizing air intake and exhaust flow across different engine speeds and load conditions. This results in improved power delivery, fuel efficiency, and reduced emissions.

- Engine performance monitoring and diagnostics: Sophisticated monitoring and diagnostic systems are integrated into the B58 engine to ensure optimal performance. These systems continuously analyze engine parameters, detect potential issues, and provide real-time feedback for performance optimization. This enables proactive maintenance and helps maintain peak engine output over time.

- Cooling and thermal management: Effective cooling and thermal management systems are crucial for maintaining the B58 engine's output. Advanced cooling technologies are employed to regulate engine temperature under various operating conditions, preventing overheating and ensuring consistent performance. This includes optimized coolant circulation, intercooling for turbocharged air, and efficient heat dissipation mechanisms.

02 Turbocharger technology

The B58 engine incorporates advanced turbocharger technology to enhance output and efficiency. This includes variable geometry turbochargers, twin-scroll designs, or electric assist systems. These technologies help reduce turbo lag, improve low-end torque, and increase overall engine performance across a wide range of RPMs.Expand Specific Solutions03 Valve timing and lift control

Variable valve timing and lift control mechanisms are employed in the B58 engine to optimize output. These systems allow for dynamic adjustment of valve operation based on engine speed and load, resulting in improved power delivery, fuel economy, and emissions performance throughout the engine's operating range.Expand Specific Solutions04 Fuel injection and combustion optimization

The B58 engine utilizes advanced fuel injection systems and combustion chamber designs to maximize output and efficiency. This may include direct injection technology, multiple injection events per cycle, and optimized piston and cylinder head geometries. These features contribute to more complete fuel combustion, reduced emissions, and increased power output.Expand Specific Solutions05 Thermal management and cooling systems

Efficient thermal management and cooling systems are crucial for maintaining optimal B58 engine output. This includes advanced coolant circulation strategies, integrated exhaust manifolds, and intelligent cooling fan control. These systems help maintain ideal operating temperatures, reduce thermal stress on engine components, and contribute to overall performance and longevity.Expand Specific Solutions

Key Industry Players

The study of lightweight materials' effects on B58 engine output is in a mature phase, with significant market potential due to increasing demand for fuel-efficient vehicles. The technology's maturity is evident from the involvement of major automotive players like GM Global Technology Operations, Ford Global Technologies, and BMW (Bayerische Motoren Werke AG). These companies, along with specialized firms such as BorgWarner and Aisin Technical Center of America, are driving innovation in lightweight materials and engine optimization. The competitive landscape is diverse, including traditional automakers, suppliers, and research institutions, indicating a robust ecosystem for technological advancements in this field.

GM Global Technology Operations LLC

Technical Solution: General Motors has been focusing on advanced aluminum alloys and innovative manufacturing processes to reduce engine weight. They've developed a patented process called "Selective Laser Melting" for creating complex, lightweight engine components[13]. This additive manufacturing technique allows for the production of parts with optimized geometries that are not possible with traditional casting methods. GM has applied this technology to create lightweight cylinder heads and engine blocks, achieving weight reductions of up to 40% in some components[14]. Additionally, they've been researching nano-structured aluminum alloys that offer improved strength and heat resistance, allowing for further weight reduction in critical engine parts. GM's studies indicate that these technologies can lead to an overall engine weight reduction of 15-20% while maintaining or even improving performance and durability[15].

Strengths: Significant weight reduction, ability to create complex geometries, and improved performance potential. Weaknesses: High initial investment costs, limited production scalability, and potential challenges in repair and maintenance.

Ford Global Technologies LLC

Technical Solution: Ford has been investigating the use of graphene-enhanced materials in engine components, which could be applicable to high-performance engines like the B58. Their research involves incorporating graphene into polymer composites used for engine covers, front covers, and oil pans. Ford claims that these graphene-enhanced parts are 20% stronger and 30% lighter than traditional components[11]. They've also been exploring the use of nano-cellulose composites for engine components, which offer a renewable and lightweight alternative to conventional materials. Ford's studies suggest that these advanced materials can contribute to a 12-15% reduction in engine weight while also improving noise, vibration, and harshness (NVH) characteristics[12].

Strengths: Significant weight reduction, improved strength-to-weight ratio, and potential for using renewable materials. Weaknesses: High material costs, challenges in large-scale production, and potential recycling issues.

Core Innovations

High-strength mechanical and structural components, and methods of making high-strength components

PatentInactiveUS20070084527A1

Innovation

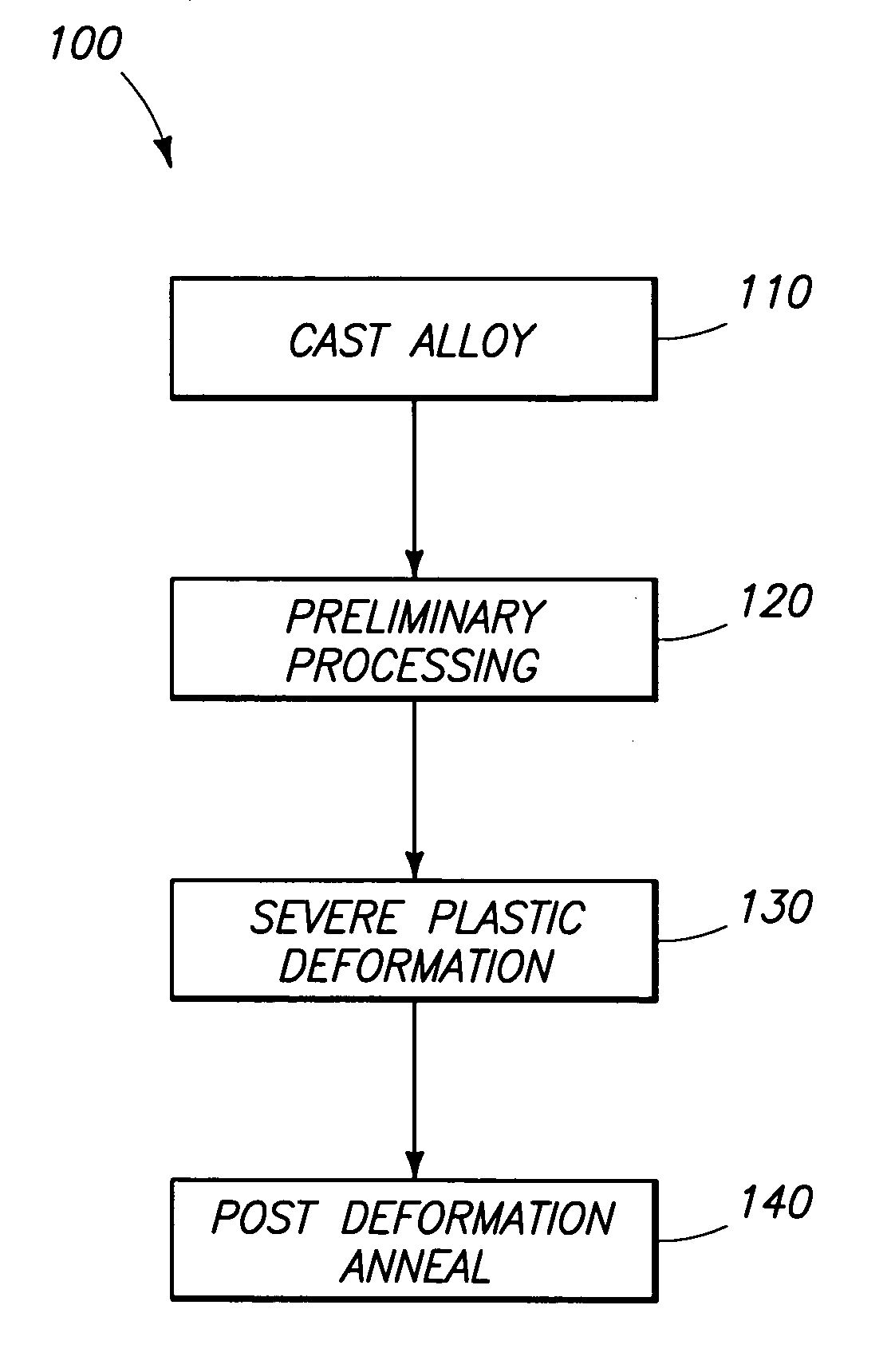

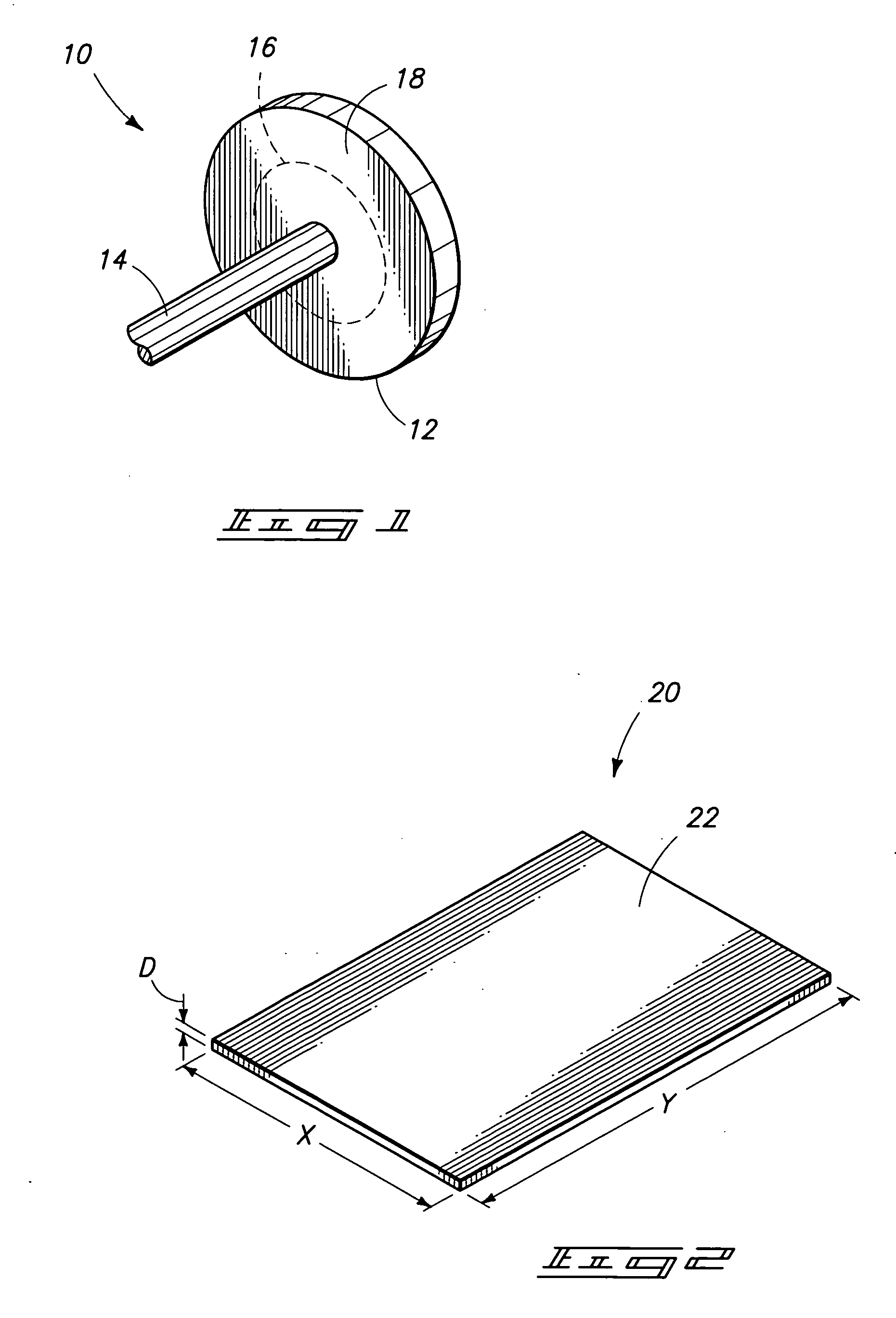

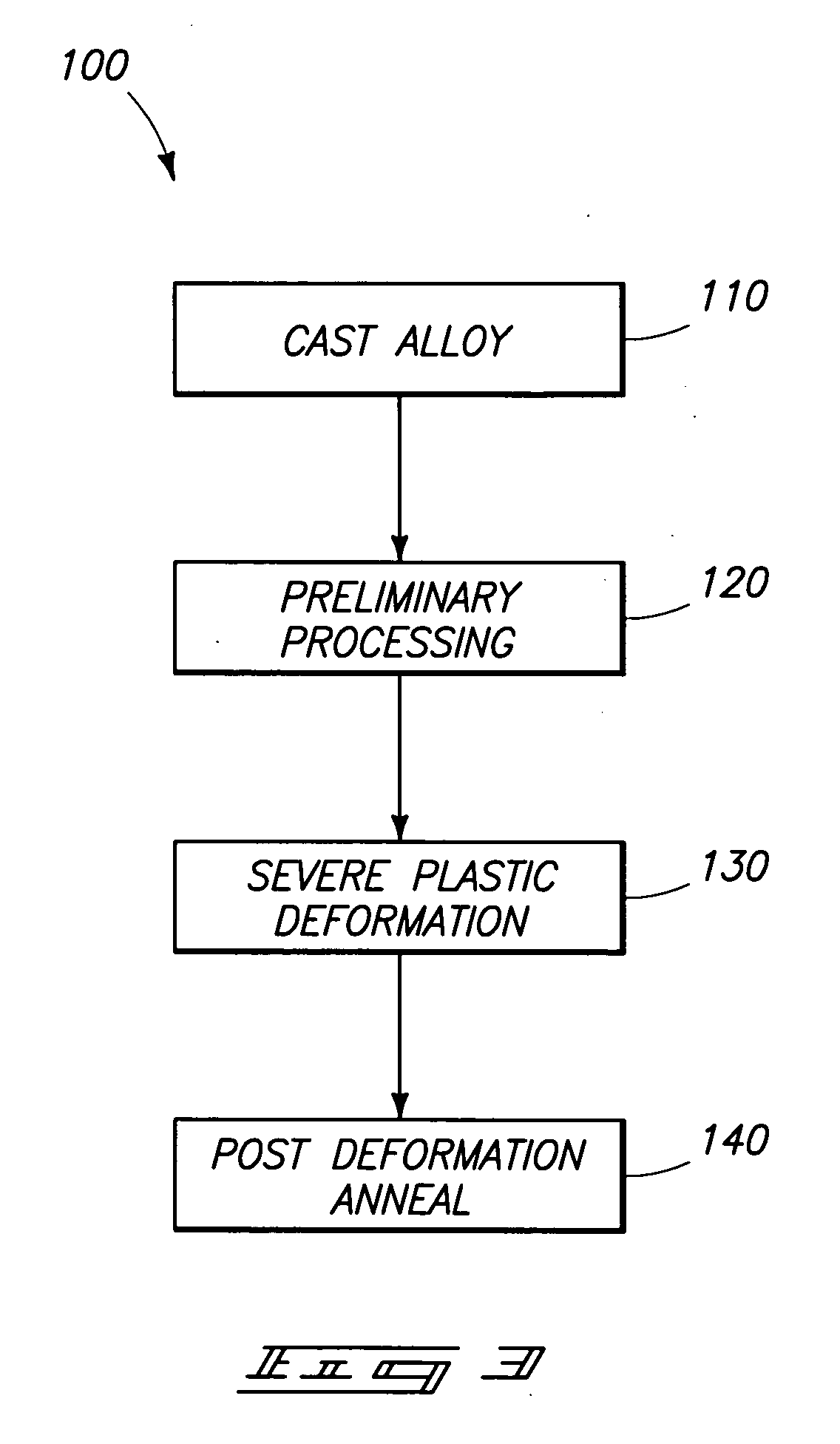

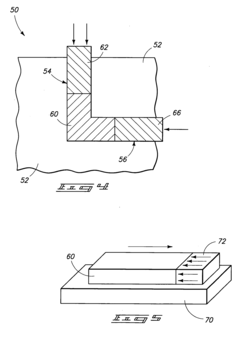

- The use of equal channel angular extrusion (ECAE) in combination with heat treatments and thermo-mechanical processing to refine grain size and control precipitate formation, resulting in high-strength lightweight materials with improved yield strength, hardness, and fatigue properties, while avoiding cast defects and non-uniform deformation.

Method of manufacturing high-conductivity wear resistant surface on a soft substrate

PatentActiveUS20160311071A1

Innovation

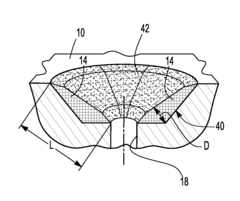

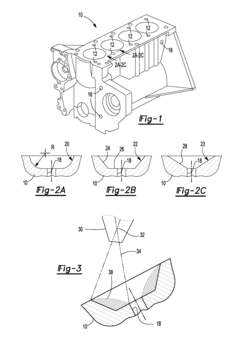

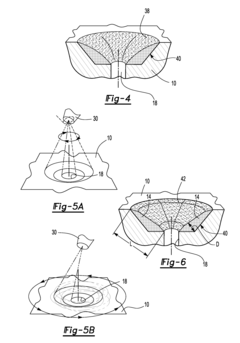

- A method involving direct metal deposition of a second composition with enhanced heat conductivity onto a preheated engine head, creating a melt pool that forms a valve seat with improved durability and thermal properties, utilizing a source of directed heat energy and a specific alloy composition that matches or exceeds the heat conductivity of the engine head material.

Performance Metrics

The performance metrics for studying the effects of lightweight materials on B58 engine output encompass a range of key indicators that evaluate the engine's efficiency, power, and overall performance. These metrics provide crucial data for assessing the impact of incorporating lightweight materials into the engine design.

One of the primary performance metrics is the power-to-weight ratio, which measures the engine's power output relative to its mass. By utilizing lightweight materials, the B58 engine's overall weight can be reduced, potentially leading to a higher power-to-weight ratio. This improvement can result in enhanced acceleration and better overall vehicle performance.

Fuel efficiency is another critical metric to consider. The use of lightweight materials can contribute to reduced engine weight, which may lead to improved fuel economy. Measuring fuel consumption under various driving conditions and comparing it to the standard B58 engine configuration will provide valuable insights into the effectiveness of lightweight materials in enhancing efficiency.

Thermal efficiency is an essential metric that evaluates the engine's ability to convert fuel energy into mechanical work. Lightweight materials with superior thermal properties may contribute to better heat management within the engine, potentially improving its thermal efficiency. This can be measured through exhaust gas temperature analysis and overall engine temperature monitoring.

Emissions performance is a crucial metric, especially in the context of increasingly stringent environmental regulations. The incorporation of lightweight materials may impact the engine's emissions profile, potentially leading to reduced CO2 and other pollutant emissions. Comprehensive emissions testing under various operating conditions is necessary to quantify these effects.

Durability and longevity metrics are also vital in assessing the viability of lightweight materials in the B58 engine. These metrics include wear resistance, fatigue strength, and overall component lifespan. Long-term testing and accelerated wear simulations can provide insights into how lightweight materials perform over extended periods of use.

Noise, vibration, and harshness (NVH) characteristics are important performance metrics that affect the overall driving experience. The use of lightweight materials may alter the engine's NVH profile, potentially leading to changes in sound quality and vibration levels. Sophisticated acoustic and vibration analysis techniques are employed to measure and evaluate these characteristics.

Lastly, performance under extreme conditions, such as high-temperature environments or during high-load operations, must be thoroughly evaluated. This includes metrics like thermal expansion, material stability, and performance consistency across a wide range of operating conditions. These assessments are crucial for ensuring that the lightweight materials can withstand the demanding requirements of a high-performance engine like the B58.

One of the primary performance metrics is the power-to-weight ratio, which measures the engine's power output relative to its mass. By utilizing lightweight materials, the B58 engine's overall weight can be reduced, potentially leading to a higher power-to-weight ratio. This improvement can result in enhanced acceleration and better overall vehicle performance.

Fuel efficiency is another critical metric to consider. The use of lightweight materials can contribute to reduced engine weight, which may lead to improved fuel economy. Measuring fuel consumption under various driving conditions and comparing it to the standard B58 engine configuration will provide valuable insights into the effectiveness of lightweight materials in enhancing efficiency.

Thermal efficiency is an essential metric that evaluates the engine's ability to convert fuel energy into mechanical work. Lightweight materials with superior thermal properties may contribute to better heat management within the engine, potentially improving its thermal efficiency. This can be measured through exhaust gas temperature analysis and overall engine temperature monitoring.

Emissions performance is a crucial metric, especially in the context of increasingly stringent environmental regulations. The incorporation of lightweight materials may impact the engine's emissions profile, potentially leading to reduced CO2 and other pollutant emissions. Comprehensive emissions testing under various operating conditions is necessary to quantify these effects.

Durability and longevity metrics are also vital in assessing the viability of lightweight materials in the B58 engine. These metrics include wear resistance, fatigue strength, and overall component lifespan. Long-term testing and accelerated wear simulations can provide insights into how lightweight materials perform over extended periods of use.

Noise, vibration, and harshness (NVH) characteristics are important performance metrics that affect the overall driving experience. The use of lightweight materials may alter the engine's NVH profile, potentially leading to changes in sound quality and vibration levels. Sophisticated acoustic and vibration analysis techniques are employed to measure and evaluate these characteristics.

Lastly, performance under extreme conditions, such as high-temperature environments or during high-load operations, must be thoroughly evaluated. This includes metrics like thermal expansion, material stability, and performance consistency across a wide range of operating conditions. These assessments are crucial for ensuring that the lightweight materials can withstand the demanding requirements of a high-performance engine like the B58.

Environmental Impact

The adoption of lightweight materials in the B58 engine design has significant environmental implications. These materials, such as aluminum alloys, carbon fiber composites, and high-strength steels, contribute to reduced vehicle weight, which directly impacts fuel efficiency and emissions. As vehicles become lighter, they require less energy to accelerate and maintain speed, resulting in lower fuel consumption and decreased greenhouse gas emissions.

The production processes for lightweight materials often involve advanced manufacturing techniques that can be more energy-intensive than traditional methods. However, the long-term environmental benefits of using these materials in engines typically outweigh the initial production costs. For instance, the reduced weight of the B58 engine leads to improved fuel economy over the vehicle's lifetime, potentially offsetting the environmental impact of material production.

Lightweight materials also contribute to the overall sustainability of the automotive industry. By reducing the amount of raw materials required for engine production, manufacturers can decrease their reliance on finite resources. This shift towards more efficient material usage aligns with circular economy principles and supports long-term environmental conservation efforts.

The durability and recyclability of lightweight materials used in the B58 engine are crucial factors in assessing their environmental impact. Many of these materials, particularly aluminum alloys, are highly recyclable, which reduces the need for virgin material extraction and processing. This recyclability aspect contributes to a more sustainable life cycle for the engine and the vehicle as a whole.

Furthermore, the use of lightweight materials in the B58 engine can lead to improved performance characteristics, such as better acceleration and handling. These enhancements may result in more efficient driving patterns, potentially reducing overall emissions in real-world conditions. The reduced inertia of lighter engine components can also contribute to more responsive and efficient engine operation, further optimizing fuel consumption and emissions.

As environmental regulations become increasingly stringent, the adoption of lightweight materials in engines like the B58 becomes more critical. These materials play a vital role in helping manufacturers meet emissions standards and fuel efficiency targets set by various regulatory bodies worldwide. The environmental benefits extend beyond the individual vehicle level, contributing to broader efforts to combat climate change and reduce the automotive industry's carbon footprint.

The production processes for lightweight materials often involve advanced manufacturing techniques that can be more energy-intensive than traditional methods. However, the long-term environmental benefits of using these materials in engines typically outweigh the initial production costs. For instance, the reduced weight of the B58 engine leads to improved fuel economy over the vehicle's lifetime, potentially offsetting the environmental impact of material production.

Lightweight materials also contribute to the overall sustainability of the automotive industry. By reducing the amount of raw materials required for engine production, manufacturers can decrease their reliance on finite resources. This shift towards more efficient material usage aligns with circular economy principles and supports long-term environmental conservation efforts.

The durability and recyclability of lightweight materials used in the B58 engine are crucial factors in assessing their environmental impact. Many of these materials, particularly aluminum alloys, are highly recyclable, which reduces the need for virgin material extraction and processing. This recyclability aspect contributes to a more sustainable life cycle for the engine and the vehicle as a whole.

Furthermore, the use of lightweight materials in the B58 engine can lead to improved performance characteristics, such as better acceleration and handling. These enhancements may result in more efficient driving patterns, potentially reducing overall emissions in real-world conditions. The reduced inertia of lighter engine components can also contribute to more responsive and efficient engine operation, further optimizing fuel consumption and emissions.

As environmental regulations become increasingly stringent, the adoption of lightweight materials in engines like the B58 becomes more critical. These materials play a vital role in helping manufacturers meet emissions standards and fuel efficiency targets set by various regulatory bodies worldwide. The environmental benefits extend beyond the individual vehicle level, contributing to broader efforts to combat climate change and reduce the automotive industry's carbon footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!