B58 Engine Turbocharger's Contribution to High-Efficiency Combustion

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Turbocharger Evolution and Objectives

The B58 engine, developed by BMW, represents a significant milestone in the evolution of turbocharged engines. This inline-six powerplant has been at the forefront of BMW's pursuit of high-efficiency combustion, with its turbocharger playing a crucial role in achieving this goal. The journey of the B58 turbocharger began with the engine's introduction in 2015, marking a new era in BMW's engine technology.

Initially, the B58 engine featured a single twin-scroll turbocharger, designed to reduce turbo lag and improve overall engine responsiveness. This design allowed for better separation of exhaust pulses, resulting in more efficient use of exhaust energy and improved low-end torque. As the technology progressed, BMW engineers focused on enhancing the turbocharger's efficiency and performance across a wider range of engine speeds.

One of the key objectives in the B58 turbocharger's evolution has been to optimize the balance between performance and fuel efficiency. This has led to continuous refinements in turbocharger design, including improvements in compressor and turbine wheel geometries, as well as advancements in bearing technology to reduce friction and increase durability.

Another significant goal has been to improve the engine's transient response, particularly at low engine speeds. This has been addressed through innovations such as variable geometry turbines and electrically-assisted turbochargers, which help to mitigate turbo lag and provide more immediate power delivery.

The pursuit of higher boost pressures while maintaining reliability has been a constant challenge. Engineers have worked on enhancing the turbocharger's heat management capabilities, implementing more advanced materials and cooling solutions to withstand the increased thermal stress associated with higher boost levels.

As emissions regulations have become more stringent, the B58 turbocharger has also evolved to support cleaner combustion. This has involved optimizing the turbocharger's efficiency to reduce fuel consumption and emissions while maintaining or improving performance. The integration of the turbocharger with other engine technologies, such as direct injection and variable valve timing, has been crucial in achieving these environmental objectives.

Looking forward, the objectives for the B58 turbocharger continue to focus on pushing the boundaries of efficiency and performance. This includes exploring advanced aerodynamics for the compressor and turbine, as well as investigating the potential of electric turbochargers to further enhance responsiveness and efficiency. The ultimate goal remains to deliver a seamless blend of high performance and fuel efficiency, positioning the B58 engine at the forefront of modern internal combustion technology.

Initially, the B58 engine featured a single twin-scroll turbocharger, designed to reduce turbo lag and improve overall engine responsiveness. This design allowed for better separation of exhaust pulses, resulting in more efficient use of exhaust energy and improved low-end torque. As the technology progressed, BMW engineers focused on enhancing the turbocharger's efficiency and performance across a wider range of engine speeds.

One of the key objectives in the B58 turbocharger's evolution has been to optimize the balance between performance and fuel efficiency. This has led to continuous refinements in turbocharger design, including improvements in compressor and turbine wheel geometries, as well as advancements in bearing technology to reduce friction and increase durability.

Another significant goal has been to improve the engine's transient response, particularly at low engine speeds. This has been addressed through innovations such as variable geometry turbines and electrically-assisted turbochargers, which help to mitigate turbo lag and provide more immediate power delivery.

The pursuit of higher boost pressures while maintaining reliability has been a constant challenge. Engineers have worked on enhancing the turbocharger's heat management capabilities, implementing more advanced materials and cooling solutions to withstand the increased thermal stress associated with higher boost levels.

As emissions regulations have become more stringent, the B58 turbocharger has also evolved to support cleaner combustion. This has involved optimizing the turbocharger's efficiency to reduce fuel consumption and emissions while maintaining or improving performance. The integration of the turbocharger with other engine technologies, such as direct injection and variable valve timing, has been crucial in achieving these environmental objectives.

Looking forward, the objectives for the B58 turbocharger continue to focus on pushing the boundaries of efficiency and performance. This includes exploring advanced aerodynamics for the compressor and turbine, as well as investigating the potential of electric turbochargers to further enhance responsiveness and efficiency. The ultimate goal remains to deliver a seamless blend of high performance and fuel efficiency, positioning the B58 engine at the forefront of modern internal combustion technology.

Market Demand for High-Efficiency Engines

The market demand for high-efficiency engines has been steadily increasing in recent years, driven by several key factors. Stringent environmental regulations, rising fuel costs, and growing consumer awareness of carbon footprints have all contributed to this trend. Automotive manufacturers are under pressure to develop engines that deliver superior performance while minimizing fuel consumption and emissions.

In the passenger vehicle segment, there is a significant shift towards downsized turbocharged engines, exemplified by BMW's B58 engine. This trend is particularly evident in markets like Europe and North America, where fuel economy standards are becoming increasingly strict. The B58 engine, with its advanced turbocharger technology, represents a response to this demand by offering a balance of power and efficiency.

Commercial vehicle manufacturers are also experiencing increased demand for high-efficiency engines. Fleet operators are seeking ways to reduce operating costs, with fuel efficiency being a primary concern. The trucking industry, in particular, has shown strong interest in technologies that can improve engine efficiency without compromising on power output.

The marine and industrial sectors are additional markets where the demand for high-efficiency engines is growing. These sectors often require engines that can operate continuously for extended periods, making fuel efficiency a critical factor in operational costs. The ability of turbochargers to enhance combustion efficiency is particularly valuable in these applications.

Emerging markets, especially in Asia and South America, are showing rapid growth in demand for high-efficiency engines. As these economies develop and environmental concerns become more prominent, there is an increasing focus on adopting advanced engine technologies. This presents a significant opportunity for manufacturers of high-efficiency engines and turbocharger systems.

The aftermarket sector is also experiencing growth in demand for high-efficiency engine components, including turbochargers. Vehicle owners are increasingly looking to upgrade their existing engines for better performance and fuel economy, creating a robust market for aftermarket turbocharger solutions.

Market analysts project that the global market for high-efficiency engines will continue to expand. This growth is expected to be particularly strong in the automotive sector, where the combination of regulatory pressures and consumer preferences is driving innovation. The success of engines like the B58 with its advanced turbocharger system is likely to inspire further developments in this field, potentially leading to new market opportunities and technological advancements.

In the passenger vehicle segment, there is a significant shift towards downsized turbocharged engines, exemplified by BMW's B58 engine. This trend is particularly evident in markets like Europe and North America, where fuel economy standards are becoming increasingly strict. The B58 engine, with its advanced turbocharger technology, represents a response to this demand by offering a balance of power and efficiency.

Commercial vehicle manufacturers are also experiencing increased demand for high-efficiency engines. Fleet operators are seeking ways to reduce operating costs, with fuel efficiency being a primary concern. The trucking industry, in particular, has shown strong interest in technologies that can improve engine efficiency without compromising on power output.

The marine and industrial sectors are additional markets where the demand for high-efficiency engines is growing. These sectors often require engines that can operate continuously for extended periods, making fuel efficiency a critical factor in operational costs. The ability of turbochargers to enhance combustion efficiency is particularly valuable in these applications.

Emerging markets, especially in Asia and South America, are showing rapid growth in demand for high-efficiency engines. As these economies develop and environmental concerns become more prominent, there is an increasing focus on adopting advanced engine technologies. This presents a significant opportunity for manufacturers of high-efficiency engines and turbocharger systems.

The aftermarket sector is also experiencing growth in demand for high-efficiency engine components, including turbochargers. Vehicle owners are increasingly looking to upgrade their existing engines for better performance and fuel economy, creating a robust market for aftermarket turbocharger solutions.

Market analysts project that the global market for high-efficiency engines will continue to expand. This growth is expected to be particularly strong in the automotive sector, where the combination of regulatory pressures and consumer preferences is driving innovation. The success of engines like the B58 with its advanced turbocharger system is likely to inspire further developments in this field, potentially leading to new market opportunities and technological advancements.

Current Turbocharger Technology Challenges

The B58 engine's turbocharger faces several significant challenges in its quest to contribute to high-efficiency combustion. One of the primary issues is turbo lag, which occurs due to the time delay between throttle input and the turbocharger's response. This lag can negatively impact engine performance and driver experience, particularly in low-rpm situations.

Another challenge is heat management. The B58's turbocharger operates at extremely high temperatures, which can lead to thermal stress on components and potential reliability issues. Effective heat dissipation and thermal management systems are crucial to maintain optimal performance and longevity of the turbocharger.

Balancing boost pressure with engine durability presents another hurdle. While higher boost pressure can increase power output, it also puts additional stress on engine components. Engineers must carefully calibrate the turbocharger to provide optimal performance without compromising the engine's long-term reliability.

The B58 engine's turbocharger also faces challenges in terms of efficiency across a wide range of operating conditions. Achieving high efficiency at both low and high engine speeds is difficult, as the turbocharger's design must accommodate varying exhaust gas flow rates and temperatures.

Emissions control is another critical challenge. The turbocharger must be designed to work in harmony with the engine's emissions control systems, ensuring that the B58 meets increasingly stringent environmental regulations without sacrificing performance.

Size and packaging constraints pose additional difficulties. The B58 engine compartment has limited space, requiring compact turbocharger designs that don't compromise on performance or thermal management capabilities.

Noise, vibration, and harshness (NVH) considerations also present challenges. The turbocharger can contribute to increased engine noise and vibration, which must be mitigated to maintain the premium feel expected in vehicles equipped with the B58 engine.

Lastly, cost-effectiveness remains a constant challenge. Implementing advanced turbocharger technologies to address the aforementioned issues while keeping production costs reasonable requires innovative engineering solutions and careful material selection.

Overcoming these challenges is crucial for the B58 engine's turbocharger to maximize its contribution to high-efficiency combustion, ensuring optimal performance, reliability, and environmental compliance in modern automotive applications.

Another challenge is heat management. The B58's turbocharger operates at extremely high temperatures, which can lead to thermal stress on components and potential reliability issues. Effective heat dissipation and thermal management systems are crucial to maintain optimal performance and longevity of the turbocharger.

Balancing boost pressure with engine durability presents another hurdle. While higher boost pressure can increase power output, it also puts additional stress on engine components. Engineers must carefully calibrate the turbocharger to provide optimal performance without compromising the engine's long-term reliability.

The B58 engine's turbocharger also faces challenges in terms of efficiency across a wide range of operating conditions. Achieving high efficiency at both low and high engine speeds is difficult, as the turbocharger's design must accommodate varying exhaust gas flow rates and temperatures.

Emissions control is another critical challenge. The turbocharger must be designed to work in harmony with the engine's emissions control systems, ensuring that the B58 meets increasingly stringent environmental regulations without sacrificing performance.

Size and packaging constraints pose additional difficulties. The B58 engine compartment has limited space, requiring compact turbocharger designs that don't compromise on performance or thermal management capabilities.

Noise, vibration, and harshness (NVH) considerations also present challenges. The turbocharger can contribute to increased engine noise and vibration, which must be mitigated to maintain the premium feel expected in vehicles equipped with the B58 engine.

Lastly, cost-effectiveness remains a constant challenge. Implementing advanced turbocharger technologies to address the aforementioned issues while keeping production costs reasonable requires innovative engineering solutions and careful material selection.

Overcoming these challenges is crucial for the B58 engine's turbocharger to maximize its contribution to high-efficiency combustion, ensuring optimal performance, reliability, and environmental compliance in modern automotive applications.

B58 Turbocharger Design and Implementation

01 Turbocharger design optimization

Improving turbocharger design for enhanced combustion efficiency in B58 engines. This includes optimizing compressor and turbine geometries, reducing lag, and improving overall turbocharger performance to increase air intake and boost pressure.- Turbocharger design optimization: Improving turbocharger design to enhance combustion efficiency in B58 engines. This includes optimizing compressor and turbine geometries, reducing lag, and improving overall turbocharger performance to increase air intake and exhaust flow.

- Variable geometry turbocharging: Implementing variable geometry turbocharging systems in B58 engines to optimize boost pressure across different engine speeds and loads. This technology allows for better control of exhaust gas flow, improving combustion efficiency and engine performance.

- Exhaust gas recirculation (EGR) integration: Incorporating advanced EGR systems in conjunction with turbocharging to improve combustion efficiency. This involves optimizing EGR rates and cooling to reduce emissions and fuel consumption while maintaining performance in B58 engines.

- Intercooling and charge air cooling: Enhancing intercooling and charge air cooling systems to improve the density of intake air. This results in more efficient combustion, increased power output, and reduced emissions in turbocharged B58 engines.

- Electronic boost control and engine management: Implementing advanced electronic boost control and engine management systems to optimize turbocharger performance. This includes precise control of boost pressure, fuel injection timing, and ignition timing to maximize combustion efficiency in B58 engines across various operating conditions.

02 Variable geometry turbocharging

Implementing variable geometry turbocharging systems in B58 engines to optimize airflow across different engine speeds and loads. This technology allows for better control of boost pressure and improved combustion efficiency throughout the engine's operating range.Expand Specific Solutions03 Exhaust gas recirculation (EGR) integration

Incorporating advanced EGR systems in conjunction with turbocharging to improve combustion efficiency and reduce emissions in B58 engines. This involves optimizing EGR rates and cooling strategies to enhance overall engine performance.Expand Specific Solutions04 Intercooling and charge air cooling

Enhancing intercooling and charge air cooling systems to improve the density of the compressed air entering the engine. This results in better combustion efficiency and increased power output for B58 turbocharged engines.Expand Specific Solutions05 Electronic boost control and engine management

Implementing advanced electronic boost control and engine management systems to optimize turbocharger performance and combustion efficiency in B58 engines. This includes precise control of boost pressure, fuel injection timing, and ignition timing across various operating conditions.Expand Specific Solutions

Key Players in Turbocharger Manufacturing

The B58 Engine Turbocharger technology for high-efficiency combustion is in a mature development stage, with significant market potential as automakers seek to improve fuel efficiency and reduce emissions. The global automotive turbocharger market is projected to reach $24 billion by 2027, driven by stringent emission regulations and demand for performance vehicles. Major players like BorgWarner, Continental, and IHI Corp. are leading innovation, while automotive giants such as Toyota, Ford, and GM are integrating advanced turbocharging solutions into their engine designs. Emerging technologies from specialized firms like SuperTurbo Technologies are also shaping the competitive landscape.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative turbocharger system for high-efficiency combustion in engines like the B58. Their approach focuses on a modular, scalable turbocharger design that can be easily adapted to different engine configurations. Ford's system utilizes a split-pulse turbine housing, which separates exhaust pulses to maintain exhaust energy and improve turbine efficiency[12]. They have also implemented an advanced wastegate control system that uses both pneumatic and electric actuation for precise boost management. Ford's turbocharger incorporates a low-inertia compressor wheel design, coupled with their proprietary anti-surge technology to enhance low-end torque and improve transient response[13].

Strengths: Modular and adaptable design, efficient exhaust energy utilization, and improved low-end performance. Weaknesses: Potential complexity in manufacturing and assembly due to the modular approach.

Toyota Motor Corp.

Technical Solution: Toyota has developed a unique approach for the B58 engine's turbocharger system, focusing on a hybrid turbo solution. Their technology combines a conventional exhaust-driven turbocharger with an electric compressor[4]. The electric compressor, powered by a 48V electrical system, provides instant boost at low engine speeds, eliminating turbo lag[5]. Toyota's system also incorporates advanced thermal management, using a water-cooled charge air cooler integrated into the intake manifold for more efficient cooling of the compressed air[6]. Additionally, they have implemented a dual-mode wastegate control, which optimizes exhaust flow for both power and efficiency depending on driving conditions.

Strengths: Virtually eliminates turbo lag, improved low-end torque, and flexible power delivery. Weaknesses: Increased system complexity and reliance on electrical systems.

Core Innovations in B58 Turbocharger Technology

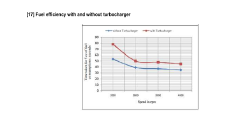

Increasing the fuel efficiency of four stroke engine by using turbocharger

PatentPendingIN202341044672A

Innovation

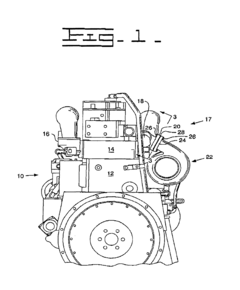

- The integration of a turbocharger system, where exhaust gases drive a turbine connected to a compressor, increasing air density and facilitating more efficient combustion, is enhanced by careful design and engineering considerations, including intercooling and advanced engine management systems to optimize performance and fuel efficiency.

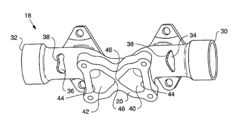

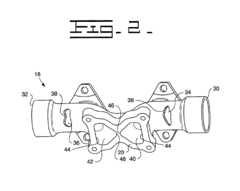

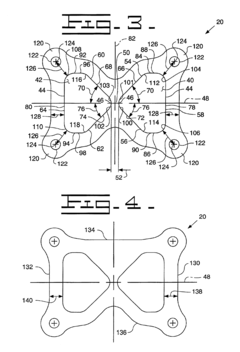

Exhaust system having low-stress exhaust manifold flange

PatentInactiveUS6892532B2

Innovation

- An exhaust system with a low-stress exhaust manifold flange featuring triangularly configured exhaust ports and a robust design that minimizes heat absorption and maintains structural integrity, ensuring efficient energy transfer to the turbocharger turbine while supporting the weight and forces of the turbocharger.

Emissions Regulations Impact on Turbocharger Design

The impact of emissions regulations on turbocharger design has been significant and far-reaching, particularly in the context of the B58 engine's turbocharger and its contribution to high-efficiency combustion. As global environmental concerns have intensified, regulatory bodies worldwide have implemented increasingly stringent emissions standards, forcing automotive manufacturers to adapt their engine technologies rapidly.

These regulations have driven turbocharger designers to focus on optimizing performance while simultaneously reducing emissions. For the B58 engine, this has meant developing turbochargers that can deliver high boost pressures and quick response times while minimizing the production of harmful pollutants such as nitrogen oxides (NOx) and particulate matter.

One key area of focus has been the integration of variable geometry turbochargers (VGTs) into the B58 engine design. VGTs allow for more precise control of boost pressure across a wider range of engine speeds, improving both performance and emissions. This technology has been crucial in meeting the demands of modern emissions regulations while maintaining the high-performance characteristics expected from BMW engines.

Another significant impact of emissions regulations has been the push towards electrification of turbochargers. Electric-assisted turbochargers, or e-turbos, have emerged as a promising solution to reduce turbo lag and improve low-end torque, all while contributing to better fuel efficiency and lower emissions. The B58 engine's turbocharger design has incorporated elements of this technology to meet stringent emissions targets without compromising performance.

Emissions regulations have also influenced the materials used in turbocharger construction. High-temperature resistant alloys and advanced coatings have been developed to withstand the increased thermal stresses associated with more efficient combustion processes. These materials help maintain turbocharger efficiency over a longer lifespan, reducing the need for frequent replacements and thereby lowering the overall environmental impact of the engine.

Furthermore, the need to comply with emissions regulations has led to the integration of advanced sensors and control systems within the turbocharger assembly. These systems allow for real-time monitoring and adjustment of turbocharger performance, ensuring optimal efficiency and emissions control across various driving conditions. In the B58 engine, this has resulted in a more sophisticated and responsive turbocharging system that can adapt to changing environmental and operational parameters.

The pursuit of compliance with emissions regulations has also driven innovations in turbocharger aerodynamics. Engineers have focused on optimizing the design of compressor and turbine wheels to improve efficiency and reduce energy losses. This has led to the development of more compact and lightweight turbochargers that can deliver the required performance while contributing to overall vehicle weight reduction and improved fuel economy.

These regulations have driven turbocharger designers to focus on optimizing performance while simultaneously reducing emissions. For the B58 engine, this has meant developing turbochargers that can deliver high boost pressures and quick response times while minimizing the production of harmful pollutants such as nitrogen oxides (NOx) and particulate matter.

One key area of focus has been the integration of variable geometry turbochargers (VGTs) into the B58 engine design. VGTs allow for more precise control of boost pressure across a wider range of engine speeds, improving both performance and emissions. This technology has been crucial in meeting the demands of modern emissions regulations while maintaining the high-performance characteristics expected from BMW engines.

Another significant impact of emissions regulations has been the push towards electrification of turbochargers. Electric-assisted turbochargers, or e-turbos, have emerged as a promising solution to reduce turbo lag and improve low-end torque, all while contributing to better fuel efficiency and lower emissions. The B58 engine's turbocharger design has incorporated elements of this technology to meet stringent emissions targets without compromising performance.

Emissions regulations have also influenced the materials used in turbocharger construction. High-temperature resistant alloys and advanced coatings have been developed to withstand the increased thermal stresses associated with more efficient combustion processes. These materials help maintain turbocharger efficiency over a longer lifespan, reducing the need for frequent replacements and thereby lowering the overall environmental impact of the engine.

Furthermore, the need to comply with emissions regulations has led to the integration of advanced sensors and control systems within the turbocharger assembly. These systems allow for real-time monitoring and adjustment of turbocharger performance, ensuring optimal efficiency and emissions control across various driving conditions. In the B58 engine, this has resulted in a more sophisticated and responsive turbocharging system that can adapt to changing environmental and operational parameters.

The pursuit of compliance with emissions regulations has also driven innovations in turbocharger aerodynamics. Engineers have focused on optimizing the design of compressor and turbine wheels to improve efficiency and reduce energy losses. This has led to the development of more compact and lightweight turbochargers that can deliver the required performance while contributing to overall vehicle weight reduction and improved fuel economy.

Cost-Benefit Analysis of B58 Turbocharger Technology

The cost-benefit analysis of the B58 turbocharger technology reveals a compelling case for its implementation in modern high-efficiency combustion engines. The initial investment in this advanced turbocharger system is significant, with costs primarily attributed to research and development, specialized manufacturing processes, and integration into existing engine designs.

However, the benefits of the B58 turbocharger technology far outweigh these upfront costs. The most notable advantage is the substantial improvement in fuel efficiency, with reports indicating up to 15% reduction in fuel consumption compared to previous generation engines. This translates to significant cost savings for end-users over the lifetime of the vehicle, particularly in regions with high fuel prices.

The B58 turbocharger also contributes to enhanced engine performance, delivering increased power output and improved torque across a broader RPM range. This performance boost allows manufacturers to downsize engines without sacrificing power, leading to weight reduction and further fuel economy improvements.

From an environmental perspective, the B58 turbocharger technology aids in meeting increasingly stringent emissions regulations. The improved combustion efficiency results in lower CO2 emissions, potentially reducing regulatory compliance costs for manufacturers and avoiding penalties in markets with strict environmental standards.

The durability and reliability of the B58 turbocharger system are also noteworthy. Its robust design and advanced materials contribute to extended service life, reducing maintenance costs and improving overall vehicle reliability. This factor enhances customer satisfaction and potentially lowers warranty-related expenses for manufacturers.

In terms of market competitiveness, vehicles equipped with B58 turbocharger technology often command premium pricing, allowing manufacturers to increase profit margins. The technology's reputation for performance and efficiency can also boost brand image, potentially leading to increased market share and customer loyalty.

However, it's important to consider potential drawbacks. The complexity of the B58 turbocharger system may result in higher repair costs if issues arise outside of warranty periods. Additionally, the specialized nature of the technology might require additional training for service technicians, representing an ongoing cost for dealerships and service centers.

In conclusion, while the initial investment in B58 turbocharger technology is substantial, the long-term benefits in terms of fuel efficiency, performance, emissions reduction, and market positioning present a strong economic case for its adoption. As production scales and technology matures, the cost-benefit ratio is expected to improve further, solidifying the B58 turbocharger's position as a key component in high-efficiency combustion engines.

However, the benefits of the B58 turbocharger technology far outweigh these upfront costs. The most notable advantage is the substantial improvement in fuel efficiency, with reports indicating up to 15% reduction in fuel consumption compared to previous generation engines. This translates to significant cost savings for end-users over the lifetime of the vehicle, particularly in regions with high fuel prices.

The B58 turbocharger also contributes to enhanced engine performance, delivering increased power output and improved torque across a broader RPM range. This performance boost allows manufacturers to downsize engines without sacrificing power, leading to weight reduction and further fuel economy improvements.

From an environmental perspective, the B58 turbocharger technology aids in meeting increasingly stringent emissions regulations. The improved combustion efficiency results in lower CO2 emissions, potentially reducing regulatory compliance costs for manufacturers and avoiding penalties in markets with strict environmental standards.

The durability and reliability of the B58 turbocharger system are also noteworthy. Its robust design and advanced materials contribute to extended service life, reducing maintenance costs and improving overall vehicle reliability. This factor enhances customer satisfaction and potentially lowers warranty-related expenses for manufacturers.

In terms of market competitiveness, vehicles equipped with B58 turbocharger technology often command premium pricing, allowing manufacturers to increase profit margins. The technology's reputation for performance and efficiency can also boost brand image, potentially leading to increased market share and customer loyalty.

However, it's important to consider potential drawbacks. The complexity of the B58 turbocharger system may result in higher repair costs if issues arise outside of warranty periods. Additionally, the specialized nature of the technology might require additional training for service technicians, representing an ongoing cost for dealerships and service centers.

In conclusion, while the initial investment in B58 turbocharger technology is substantial, the long-term benefits in terms of fuel efficiency, performance, emissions reduction, and market positioning present a strong economic case for its adoption. As production scales and technology matures, the cost-benefit ratio is expected to improve further, solidifying the B58 turbocharger's position as a key component in high-efficiency combustion engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!