How Direct Injection Enhances B58 Engine Fuel Economy

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 DI Technology Background and Objectives

The B58 engine, developed by BMW, represents a significant advancement in automotive engineering, particularly in the realm of fuel efficiency. This inline-six turbocharged engine, first introduced in 2015, has become a cornerstone of BMW's powertrain strategy, finding its way into various models across the BMW and Toyota lineups. The direct injection (DI) technology employed in the B58 engine plays a crucial role in enhancing its fuel economy, marking a notable evolution from its predecessor, the N55 engine.

Direct injection technology in the B58 engine aims to optimize fuel delivery and combustion processes, ultimately leading to improved fuel efficiency and reduced emissions. By injecting fuel directly into the combustion chamber at high pressure, DI allows for more precise control over the fuel-air mixture, enabling better atomization and more complete combustion. This technology aligns with the broader industry trend towards more efficient and environmentally friendly powertrains, driven by increasingly stringent emissions regulations and consumer demand for fuel-efficient vehicles.

The development of direct injection in the B58 engine builds upon decades of research and innovation in fuel injection systems. From early mechanical injection systems to electronic port fuel injection, the progression to direct injection represents a significant leap in engine technology. The B58's DI system operates at pressures up to 350 bar, allowing for multiple injection events per combustion cycle, which contributes to its enhanced efficiency and performance characteristics.

One of the primary objectives of implementing direct injection in the B58 engine is to achieve a balance between performance and efficiency. BMW engineers aimed to deliver the power and responsiveness expected from a premium sports engine while simultaneously improving fuel economy and reducing emissions. This dual focus reflects the evolving priorities in automotive engineering, where environmental considerations are increasingly shaping technological advancements.

The B58 engine's direct injection system is part of a broader suite of technologies designed to maximize efficiency. These include a twin-scroll turbocharger, variable valve timing, and an advanced cooling system. Together, these features work synergistically to optimize the engine's operation across a wide range of driving conditions, from low-speed urban environments to high-speed highway cruising.

As the automotive industry continues to evolve towards electrification, the role of advanced internal combustion engines like the B58 remains significant. The development and refinement of technologies such as direct injection demonstrate the ongoing potential for improving traditional powertrains, serving as a bridge between conventional vehicles and future electric and hybrid models. The B58 engine, with its sophisticated direct injection system, exemplifies BMW's commitment to pushing the boundaries of internal combustion efficiency while meeting the challenges of a rapidly changing automotive landscape.

Direct injection technology in the B58 engine aims to optimize fuel delivery and combustion processes, ultimately leading to improved fuel efficiency and reduced emissions. By injecting fuel directly into the combustion chamber at high pressure, DI allows for more precise control over the fuel-air mixture, enabling better atomization and more complete combustion. This technology aligns with the broader industry trend towards more efficient and environmentally friendly powertrains, driven by increasingly stringent emissions regulations and consumer demand for fuel-efficient vehicles.

The development of direct injection in the B58 engine builds upon decades of research and innovation in fuel injection systems. From early mechanical injection systems to electronic port fuel injection, the progression to direct injection represents a significant leap in engine technology. The B58's DI system operates at pressures up to 350 bar, allowing for multiple injection events per combustion cycle, which contributes to its enhanced efficiency and performance characteristics.

One of the primary objectives of implementing direct injection in the B58 engine is to achieve a balance between performance and efficiency. BMW engineers aimed to deliver the power and responsiveness expected from a premium sports engine while simultaneously improving fuel economy and reducing emissions. This dual focus reflects the evolving priorities in automotive engineering, where environmental considerations are increasingly shaping technological advancements.

The B58 engine's direct injection system is part of a broader suite of technologies designed to maximize efficiency. These include a twin-scroll turbocharger, variable valve timing, and an advanced cooling system. Together, these features work synergistically to optimize the engine's operation across a wide range of driving conditions, from low-speed urban environments to high-speed highway cruising.

As the automotive industry continues to evolve towards electrification, the role of advanced internal combustion engines like the B58 remains significant. The development and refinement of technologies such as direct injection demonstrate the ongoing potential for improving traditional powertrains, serving as a bridge between conventional vehicles and future electric and hybrid models. The B58 engine, with its sophisticated direct injection system, exemplifies BMW's commitment to pushing the boundaries of internal combustion efficiency while meeting the challenges of a rapidly changing automotive landscape.

Market Demand for Fuel-Efficient Engines

The global automotive industry is experiencing a significant shift towards fuel-efficient engines, driven by stringent environmental regulations, rising fuel costs, and increasing consumer awareness of carbon footprints. This trend has created a robust market demand for engines that offer improved fuel economy without compromising performance. The B58 engine, with its direct injection technology, is positioned at the forefront of this market evolution.

Consumer preferences are increasingly leaning towards vehicles that deliver better mileage and reduced emissions. A recent survey conducted by J.D. Power revealed that fuel efficiency remains one of the top three factors influencing vehicle purchase decisions across major automotive markets. This consumer sentiment is reflected in the sales figures of vehicles equipped with fuel-efficient engines, which have shown consistent growth over the past five years.

Government regulations worldwide are also playing a crucial role in shaping the market demand for fuel-efficient engines. In the European Union, the implementation of Euro 6d emissions standards has put pressure on automakers to develop engines with lower CO2 emissions. Similarly, the Corporate Average Fuel Economy (CAFE) standards in the United States continue to push for improved fuel efficiency across vehicle fleets.

The B58 engine's direct injection technology addresses these market demands by offering a compelling combination of power and efficiency. This has led to increased adoption of the B58 engine across various BMW models, with sales figures showing a positive trajectory. The engine's ability to meet both performance expectations and fuel economy requirements has made it particularly attractive in the premium segment, where consumers are willing to pay a premium for advanced technology.

Market analysis indicates that the demand for engines like the B58 is not limited to personal vehicles. There is a growing interest in the commercial and fleet sectors, where fuel efficiency directly impacts operational costs. This expansion of market segments presents significant opportunities for engines featuring direct injection technology.

The aftermarket and tuning community have also shown considerable interest in the B58 engine, particularly due to its potential for further optimization. This has created a secondary market for performance upgrades and modifications, further enhancing the engine's appeal and market presence.

Looking ahead, industry forecasts predict a continued growth in the market for fuel-efficient engines. The B58 engine, with its direct injection technology, is well-positioned to capitalize on this trend. As consumers become more environmentally conscious and governments continue to tighten emissions regulations, the demand for engines that can deliver both performance and efficiency is expected to rise, potentially expanding the B58's market share across various vehicle segments and geographical regions.

Consumer preferences are increasingly leaning towards vehicles that deliver better mileage and reduced emissions. A recent survey conducted by J.D. Power revealed that fuel efficiency remains one of the top three factors influencing vehicle purchase decisions across major automotive markets. This consumer sentiment is reflected in the sales figures of vehicles equipped with fuel-efficient engines, which have shown consistent growth over the past five years.

Government regulations worldwide are also playing a crucial role in shaping the market demand for fuel-efficient engines. In the European Union, the implementation of Euro 6d emissions standards has put pressure on automakers to develop engines with lower CO2 emissions. Similarly, the Corporate Average Fuel Economy (CAFE) standards in the United States continue to push for improved fuel efficiency across vehicle fleets.

The B58 engine's direct injection technology addresses these market demands by offering a compelling combination of power and efficiency. This has led to increased adoption of the B58 engine across various BMW models, with sales figures showing a positive trajectory. The engine's ability to meet both performance expectations and fuel economy requirements has made it particularly attractive in the premium segment, where consumers are willing to pay a premium for advanced technology.

Market analysis indicates that the demand for engines like the B58 is not limited to personal vehicles. There is a growing interest in the commercial and fleet sectors, where fuel efficiency directly impacts operational costs. This expansion of market segments presents significant opportunities for engines featuring direct injection technology.

The aftermarket and tuning community have also shown considerable interest in the B58 engine, particularly due to its potential for further optimization. This has created a secondary market for performance upgrades and modifications, further enhancing the engine's appeal and market presence.

Looking ahead, industry forecasts predict a continued growth in the market for fuel-efficient engines. The B58 engine, with its direct injection technology, is well-positioned to capitalize on this trend. As consumers become more environmentally conscious and governments continue to tighten emissions regulations, the demand for engines that can deliver both performance and efficiency is expected to rise, potentially expanding the B58's market share across various vehicle segments and geographical regions.

Current State and Challenges of DI in B58 Engines

The current state of direct injection (DI) in BMW's B58 engine represents a significant advancement in fuel efficiency and performance. The B58 engine, introduced in 2015, utilizes a high-precision direct injection system that has been continuously refined to meet increasingly stringent emissions standards while improving fuel economy.

The direct injection system in the B58 engine operates at pressures up to 350 bar, allowing for precise fuel metering and multiple injection events per combustion cycle. This high-pressure system enables better atomization of fuel, resulting in more complete combustion and reduced emissions. The injectors are centrally mounted in the combustion chamber, optimizing fuel distribution and mixture formation.

One of the key challenges faced by the B58's direct injection system is carbon buildup on intake valves. Unlike port injection engines, where fuel helps clean the valves, direct injection can lead to carbon deposits over time. BMW has addressed this issue by implementing a dual injection system in some variants, combining direct and port injection to mitigate carbon accumulation.

Another challenge is the complexity of the high-pressure fuel system. The B58 engine requires precise control of fuel pressure and timing to maintain optimal performance across various operating conditions. This complexity can lead to increased manufacturing costs and potential reliability concerns in the long term.

The B58 engine's direct injection system also faces the challenge of particulate emissions. While DI improves overall emissions, it can produce higher levels of particulate matter compared to port injection engines. To combat this, BMW has incorporated gasoline particulate filters (GPF) in some markets, adding cost and complexity to the exhaust system.

Fuel quality sensitivity is another consideration for the B58's direct injection system. The high-pressure injectors are more susceptible to damage from impurities in fuel, necessitating the use of high-quality gasoline and potentially more frequent maintenance intervals for the fuel system components.

Despite these challenges, the B58 engine's direct injection system has proven highly effective in enhancing fuel economy. The precise control over fuel delivery allows for lean-burn strategies and improved thermal efficiency. However, balancing these benefits with emission control requirements and long-term reliability remains an ongoing focus for BMW's engineering teams.

The direct injection system in the B58 engine operates at pressures up to 350 bar, allowing for precise fuel metering and multiple injection events per combustion cycle. This high-pressure system enables better atomization of fuel, resulting in more complete combustion and reduced emissions. The injectors are centrally mounted in the combustion chamber, optimizing fuel distribution and mixture formation.

One of the key challenges faced by the B58's direct injection system is carbon buildup on intake valves. Unlike port injection engines, where fuel helps clean the valves, direct injection can lead to carbon deposits over time. BMW has addressed this issue by implementing a dual injection system in some variants, combining direct and port injection to mitigate carbon accumulation.

Another challenge is the complexity of the high-pressure fuel system. The B58 engine requires precise control of fuel pressure and timing to maintain optimal performance across various operating conditions. This complexity can lead to increased manufacturing costs and potential reliability concerns in the long term.

The B58 engine's direct injection system also faces the challenge of particulate emissions. While DI improves overall emissions, it can produce higher levels of particulate matter compared to port injection engines. To combat this, BMW has incorporated gasoline particulate filters (GPF) in some markets, adding cost and complexity to the exhaust system.

Fuel quality sensitivity is another consideration for the B58's direct injection system. The high-pressure injectors are more susceptible to damage from impurities in fuel, necessitating the use of high-quality gasoline and potentially more frequent maintenance intervals for the fuel system components.

Despite these challenges, the B58 engine's direct injection system has proven highly effective in enhancing fuel economy. The precise control over fuel delivery allows for lean-burn strategies and improved thermal efficiency. However, balancing these benefits with emission control requirements and long-term reliability remains an ongoing focus for BMW's engineering teams.

B58 Engine DI Implementation Strategies

01 Engine design optimization for fuel efficiency

Improving the B58 engine's fuel economy through design optimizations, including enhanced combustion chamber geometry, improved valve timing, and advanced fuel injection systems. These modifications aim to increase thermal efficiency and reduce fuel consumption during operation.- Engine design optimization for fuel efficiency: Improvements in engine design, such as optimizing combustion chamber geometry, valve timing, and fuel injection systems, can significantly enhance the fuel economy of B58 engines. These modifications aim to increase thermal efficiency and reduce energy losses, resulting in better overall fuel consumption.

- Advanced fuel management systems: Implementation of sophisticated fuel management systems, including direct injection and variable fuel pressure control, can improve the B58 engine's fuel economy. These systems allow for precise control of fuel delivery, optimizing combustion and reducing waste.

- Turbocharging and supercharging technologies: Utilizing advanced forced induction technologies, such as twin-scroll turbochargers or electric superchargers, can enhance the B58 engine's power output while maintaining or improving fuel efficiency. These systems allow for downsizing of the engine while maintaining performance.

- Friction reduction techniques: Implementing various friction reduction techniques, such as low-friction coatings, improved bearing designs, and optimized piston ring configurations, can minimize energy losses in the B58 engine. This results in improved fuel economy by reducing parasitic losses within the engine.

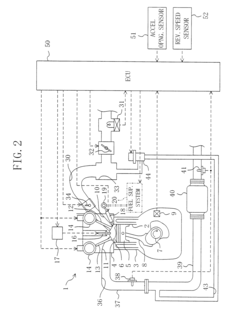

- Engine control and monitoring systems: Developing advanced engine control units (ECUs) and monitoring systems that utilize real-time data and adaptive algorithms can optimize the B58 engine's performance and fuel efficiency. These systems can adjust engine parameters on-the-fly to maintain optimal fuel economy under various operating conditions.

02 Advanced engine control systems

Implementing sophisticated engine control systems that utilize real-time data and adaptive algorithms to optimize fuel injection, ignition timing, and air-fuel mixture. These systems can continuously adjust engine parameters to maintain optimal fuel efficiency across various driving conditions.Expand Specific Solutions03 Friction reduction technologies

Incorporating friction-reducing technologies in the B58 engine, such as advanced lubricants, low-friction coatings, and optimized bearing designs. These improvements help minimize energy losses due to friction, thereby enhancing overall fuel economy.Expand Specific Solutions04 Turbocharging and exhaust energy recovery

Utilizing advanced turbocharging systems and exhaust energy recovery technologies to improve the B58 engine's efficiency. These systems can help extract more power from the same amount of fuel, leading to improved fuel economy without sacrificing performance.Expand Specific Solutions05 Lightweight materials and component design

Employing lightweight materials and innovative component designs to reduce the overall weight of the B58 engine. This approach helps decrease the engine's inertia and friction losses, contributing to improved fuel efficiency and performance.Expand Specific Solutions

Key Players in DI Engine Manufacturing

The direct injection technology for B58 engines is in a mature stage of development, with significant market adoption and ongoing refinement. The market for this technology is substantial, driven by increasing demand for fuel-efficient and high-performance engines in the automotive sector. Key players like BMW, Ford, GM, and Bosch are at the forefront, continuously improving direct injection systems. The technology's maturity is evident in its widespread implementation across various vehicle models, with companies like Mercedes-Benz, Nissan, and Hyundai also actively incorporating and enhancing direct injection in their engine designs to meet stringent fuel economy and emissions standards.

GM Global Technology Operations LLC

Technical Solution: GM has implemented a direct injection system for their B58-equivalent engines, focusing on optimizing fuel economy through advanced spray-guided technology. Their system employs centrally mounted injectors with multi-hole nozzles, capable of operating at pressures up to 300 bar [4]. GM's direct injection technology incorporates a variable-displacement high-pressure fuel pump, which adjusts fuel supply based on engine demand, reducing parasitic losses [5]. The system also features advanced combustion chamber designs that promote better air-fuel mixing and more complete combustion. GM's direct injection strategy includes sophisticated engine control algorithms that optimize injection timing and duration across various operating conditions, maximizing fuel efficiency [6].

Strengths: Improved fuel atomization, reduced pumping losses, and adaptive fuel delivery. Weaknesses: Increased system cost and potential for carbon buildup on intake valves.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced direct injection systems for B58 engines, focusing on high-pressure fuel injection technology. Their system utilizes piezoelectric injectors capable of multiple injections per combustion cycle, with pressures up to 350 bar [1]. This allows for precise fuel atomization and distribution, resulting in more efficient combustion. Bosch's direct injection technology incorporates sophisticated electronic control units that continuously adjust injection timing and duration based on real-time engine parameters [2]. The system also features a high-pressure fuel pump that maintains optimal fuel pressure across various engine loads, ensuring consistent performance and fuel economy improvements [3].

Strengths: Precise fuel control, improved atomization, and adaptability to various engine conditions. Weaknesses: Higher system complexity and potential for increased maintenance costs.

Core Innovations in B58 DI Fuel Economy

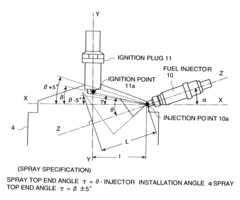

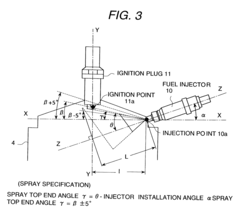

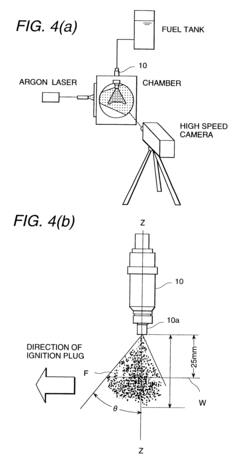

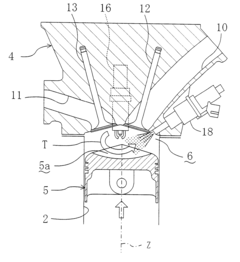

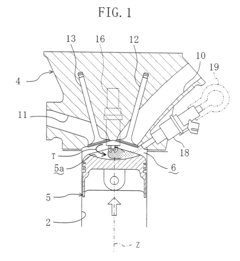

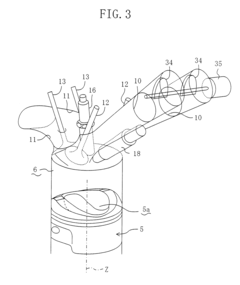

Cylinder injection engine and method of combusting engine

PatentInactiveUS6659075B1

Innovation

- The engine generates a tumble air flow between the ignition plug and fuel injector, carrying fuel spray to the ignition plug, optimizing fuel injection timing and angle to reduce fuel deposition on piston and cylinder walls, and increasing spray density near the ignition plug.

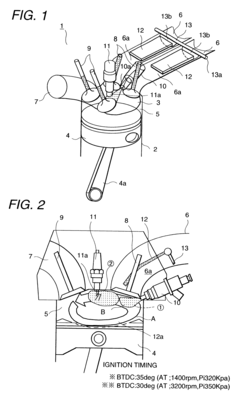

Direct-injection spark ignition engine

PatentInactiveUS6672277B2

Innovation

- A direct-injection spark ignition engine design that generates a tumble flow from the spark plug electrode toward the fuel injection nozzle during the compression stroke, allowing fuel injection to oppose the tumble and promote stratification around the spark plug, thereby reducing fuel adhesion to the piston crown and enhancing flame propagation.

Emissions Regulations Impact on DI Development

The development of direct injection (DI) technology in engines like the BMW B58 has been significantly influenced by increasingly stringent emissions regulations worldwide. These regulations have played a crucial role in shaping the direction of DI technology, pushing manufacturers to innovate and improve fuel economy while reducing harmful emissions.

In the European Union, the introduction of Euro 6 standards in 2014 set strict limits on nitrogen oxides (NOx) and particulate matter emissions. This prompted engine manufacturers to focus on optimizing DI systems to achieve better fuel atomization and more precise fuel delivery. The B58 engine's DI system was designed to meet these stringent requirements, incorporating high-pressure fuel injectors and advanced injection timing strategies.

Similarly, in the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind the adoption of DI technology. These standards require automakers to achieve specific fleet-wide fuel economy targets, which has led to the widespread implementation of DI systems in engines like the B58. The precise fuel control offered by DI allows for improved fuel efficiency, helping manufacturers meet these regulatory requirements.

China's emissions regulations have also had a significant impact on DI development. The country's rapid implementation of stringent emissions standards, such as China 6, has forced automakers to accelerate their DI technology advancements. This has resulted in the B58 engine incorporating advanced DI features to comply with these regulations in the Chinese market.

The global push for reduced CO2 emissions has been another key factor in DI development. Many countries have implemented carbon dioxide emission targets, which have driven engine manufacturers to focus on improving overall engine efficiency. The B58's DI system plays a crucial role in achieving these targets by enabling more precise fuel metering and improved combustion efficiency.

Particulate matter emissions have become a growing concern in recent years, leading to the introduction of particulate filters in gasoline engines. This development has further influenced DI technology, with manufacturers like BMW refining their injection strategies to minimize particulate formation at the source. The B58 engine's DI system has been optimized to reduce particulate emissions while maintaining performance and fuel economy.

As emissions regulations continue to evolve, DI technology in engines like the B58 is expected to advance further. Future developments may include even higher injection pressures, more sophisticated injection patterns, and integration with other technologies such as electrification to meet increasingly stringent emissions standards while enhancing fuel economy.

In the European Union, the introduction of Euro 6 standards in 2014 set strict limits on nitrogen oxides (NOx) and particulate matter emissions. This prompted engine manufacturers to focus on optimizing DI systems to achieve better fuel atomization and more precise fuel delivery. The B58 engine's DI system was designed to meet these stringent requirements, incorporating high-pressure fuel injectors and advanced injection timing strategies.

Similarly, in the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind the adoption of DI technology. These standards require automakers to achieve specific fleet-wide fuel economy targets, which has led to the widespread implementation of DI systems in engines like the B58. The precise fuel control offered by DI allows for improved fuel efficiency, helping manufacturers meet these regulatory requirements.

China's emissions regulations have also had a significant impact on DI development. The country's rapid implementation of stringent emissions standards, such as China 6, has forced automakers to accelerate their DI technology advancements. This has resulted in the B58 engine incorporating advanced DI features to comply with these regulations in the Chinese market.

The global push for reduced CO2 emissions has been another key factor in DI development. Many countries have implemented carbon dioxide emission targets, which have driven engine manufacturers to focus on improving overall engine efficiency. The B58's DI system plays a crucial role in achieving these targets by enabling more precise fuel metering and improved combustion efficiency.

Particulate matter emissions have become a growing concern in recent years, leading to the introduction of particulate filters in gasoline engines. This development has further influenced DI technology, with manufacturers like BMW refining their injection strategies to minimize particulate formation at the source. The B58 engine's DI system has been optimized to reduce particulate emissions while maintaining performance and fuel economy.

As emissions regulations continue to evolve, DI technology in engines like the B58 is expected to advance further. Future developments may include even higher injection pressures, more sophisticated injection patterns, and integration with other technologies such as electrification to meet increasingly stringent emissions standards while enhancing fuel economy.

Cost-Benefit Analysis of B58 DI Technology

The cost-benefit analysis of B58 Direct Injection (DI) technology reveals a compelling case for its implementation in modern engines. From a financial perspective, the initial investment in DI technology for the B58 engine is significant, primarily due to the complexity of the high-pressure fuel system and precision injectors required. However, this upfront cost is offset by the long-term benefits in fuel economy and performance.

The primary advantage of DI technology in the B58 engine is its ability to improve fuel efficiency. By injecting fuel directly into the combustion chamber at high pressure, the engine achieves more precise fuel metering and better atomization. This results in a more complete combustion process, leading to improved fuel economy. Studies have shown that DI can increase fuel efficiency by up to 15% compared to traditional port fuel injection systems.

Moreover, the enhanced fuel economy translates directly into cost savings for consumers over the lifetime of the vehicle. With rising fuel prices and increasing environmental concerns, the reduced fuel consumption becomes an attractive selling point, potentially increasing market share and customer satisfaction.

From a performance standpoint, DI technology allows for higher compression ratios in the B58 engine, resulting in increased power output and torque. This performance boost can be achieved without sacrificing fuel efficiency, providing a dual benefit that justifies the technology's implementation cost.

The environmental benefits of DI technology also factor into the cost-benefit analysis. Reduced fuel consumption leads to lower CO2 emissions, helping manufacturers meet increasingly stringent environmental regulations. This compliance can prevent potential fines and negative publicity, further offsetting the initial investment.

Maintenance costs associated with DI systems are generally higher due to the complexity of the components. However, the improved engine efficiency and reduced carbon buildup can lead to longer engine life and potentially lower long-term maintenance costs, balancing out the initial increase.

In conclusion, while the upfront costs of implementing DI technology in the B58 engine are substantial, the long-term benefits in fuel economy, performance, and environmental compliance present a strong argument for its adoption. The technology's ability to meet both consumer demands for efficiency and regulatory requirements for emissions reduction makes it a valuable investment for engine manufacturers.

The primary advantage of DI technology in the B58 engine is its ability to improve fuel efficiency. By injecting fuel directly into the combustion chamber at high pressure, the engine achieves more precise fuel metering and better atomization. This results in a more complete combustion process, leading to improved fuel economy. Studies have shown that DI can increase fuel efficiency by up to 15% compared to traditional port fuel injection systems.

Moreover, the enhanced fuel economy translates directly into cost savings for consumers over the lifetime of the vehicle. With rising fuel prices and increasing environmental concerns, the reduced fuel consumption becomes an attractive selling point, potentially increasing market share and customer satisfaction.

From a performance standpoint, DI technology allows for higher compression ratios in the B58 engine, resulting in increased power output and torque. This performance boost can be achieved without sacrificing fuel efficiency, providing a dual benefit that justifies the technology's implementation cost.

The environmental benefits of DI technology also factor into the cost-benefit analysis. Reduced fuel consumption leads to lower CO2 emissions, helping manufacturers meet increasingly stringent environmental regulations. This compliance can prevent potential fines and negative publicity, further offsetting the initial investment.

Maintenance costs associated with DI systems are generally higher due to the complexity of the components. However, the improved engine efficiency and reduced carbon buildup can lead to longer engine life and potentially lower long-term maintenance costs, balancing out the initial increase.

In conclusion, while the upfront costs of implementing DI technology in the B58 engine are substantial, the long-term benefits in fuel economy, performance, and environmental compliance present a strong argument for its adoption. The technology's ability to meet both consumer demands for efficiency and regulatory requirements for emissions reduction makes it a valuable investment for engine manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!