Analyzing Exhaust Gas Temperature Management in B58 Turbo Systems

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Turbo EGT Background and Objectives

The B58 turbo engine, developed by BMW, represents a significant advancement in automotive engineering, particularly in the realm of exhaust gas temperature (EGT) management. This innovative power plant has been a cornerstone of BMW's performance lineup since its introduction in 2015, featuring in various models across the BMW and Toyota ranges. The B58's sophisticated EGT management system is crucial for maintaining optimal engine performance, efficiency, and longevity.

The primary objective of EGT management in the B58 turbo system is to balance power output with thermal efficiency. By precisely controlling exhaust gas temperatures, engineers aim to maximize engine performance while preventing damage to critical components such as turbochargers, catalytic converters, and exhaust valves. This delicate balance is essential for meeting stringent emissions regulations without compromising the driving experience that BMW enthusiasts expect.

Historically, EGT management has been a significant challenge in turbocharged engines. As boost pressure increases, so does the temperature of exhaust gases, potentially leading to thermal stress and component failure. The B58 engine addresses this challenge through a combination of advanced materials, precise sensor technology, and sophisticated engine management software.

The evolution of EGT management in turbocharged engines has been driven by several factors, including the push for higher specific power outputs, improved fuel efficiency, and stricter emissions standards. The B58 turbo system represents the culmination of decades of research and development in this field, incorporating lessons learned from previous generations of BMW engines and industry-wide advancements.

One of the key technological trends in EGT management is the integration of predictive algorithms and real-time data analysis. The B58 engine utilizes a network of sensors and advanced control units to continuously monitor and adjust exhaust gas temperatures. This proactive approach allows for more precise control over the combustion process, optimizing performance across a wide range of operating conditions.

Looking forward, the goals for EGT management in the B58 and future turbo systems include further improvements in thermal efficiency, reduced emissions, and enhanced durability. Researchers are exploring innovative cooling technologies, advanced materials with superior heat resistance, and more sophisticated control strategies to push the boundaries of what is possible in turbocharged engine design.

In conclusion, the analysis of EGT management in B58 turbo systems is not just about understanding current technology, but also about anticipating future developments that will shape the automotive industry. As emissions regulations become increasingly stringent and consumer expectations for performance continue to rise, the importance of effective EGT management will only grow, making it a critical area of focus for automotive engineers and researchers.

The primary objective of EGT management in the B58 turbo system is to balance power output with thermal efficiency. By precisely controlling exhaust gas temperatures, engineers aim to maximize engine performance while preventing damage to critical components such as turbochargers, catalytic converters, and exhaust valves. This delicate balance is essential for meeting stringent emissions regulations without compromising the driving experience that BMW enthusiasts expect.

Historically, EGT management has been a significant challenge in turbocharged engines. As boost pressure increases, so does the temperature of exhaust gases, potentially leading to thermal stress and component failure. The B58 engine addresses this challenge through a combination of advanced materials, precise sensor technology, and sophisticated engine management software.

The evolution of EGT management in turbocharged engines has been driven by several factors, including the push for higher specific power outputs, improved fuel efficiency, and stricter emissions standards. The B58 turbo system represents the culmination of decades of research and development in this field, incorporating lessons learned from previous generations of BMW engines and industry-wide advancements.

One of the key technological trends in EGT management is the integration of predictive algorithms and real-time data analysis. The B58 engine utilizes a network of sensors and advanced control units to continuously monitor and adjust exhaust gas temperatures. This proactive approach allows for more precise control over the combustion process, optimizing performance across a wide range of operating conditions.

Looking forward, the goals for EGT management in the B58 and future turbo systems include further improvements in thermal efficiency, reduced emissions, and enhanced durability. Researchers are exploring innovative cooling technologies, advanced materials with superior heat resistance, and more sophisticated control strategies to push the boundaries of what is possible in turbocharged engine design.

In conclusion, the analysis of EGT management in B58 turbo systems is not just about understanding current technology, but also about anticipating future developments that will shape the automotive industry. As emissions regulations become increasingly stringent and consumer expectations for performance continue to rise, the importance of effective EGT management will only grow, making it a critical area of focus for automotive engineers and researchers.

Market Demand for EGT Management

The market demand for Exhaust Gas Temperature (EGT) management in B58 turbo systems has been steadily increasing due to the growing emphasis on engine efficiency, performance, and emissions control. As automotive manufacturers strive to meet stringent environmental regulations while maintaining high-performance standards, effective EGT management has become a critical factor in engine design and optimization.

In the performance vehicle segment, where B58 turbo systems are commonly used, there is a significant demand for advanced EGT management solutions. Enthusiasts and manufacturers alike seek to maximize engine output without compromising reliability or longevity. This has led to a surge in aftermarket products and OEM developments focused on improving EGT control.

The commercial vehicle sector has also shown increased interest in EGT management for B58 turbo systems. Fleet operators are looking for ways to enhance fuel efficiency and reduce maintenance costs, both of which can be positively impacted by effective temperature control in the exhaust system.

Environmental concerns and regulatory pressures have further fueled the demand for EGT management solutions. As emissions standards become more stringent globally, automotive manufacturers are investing heavily in technologies that can help reduce harmful exhaust emissions. Proper EGT management plays a crucial role in this aspect by ensuring optimal catalytic converter performance and minimizing the formation of pollutants.

The aftermarket tuning industry has experienced a boom in demand for EGT management products compatible with B58 turbo systems. Performance enthusiasts are willing to invest in advanced monitoring and control systems to push their engines to the limit while maintaining safe operating temperatures.

OEMs are responding to this market demand by integrating more sophisticated EGT management systems into their stock configurations. This trend is driven by the need to offer high-performance vehicles that comply with emissions regulations and meet consumer expectations for reliability and longevity.

The racing and motorsport sectors have also contributed to the growing demand for EGT management in B58 turbo systems. Competitive teams are constantly seeking ways to extract maximum performance while ensuring engine durability, making advanced temperature control systems a valuable asset in their pursuit of victory.

As the automotive industry continues to evolve towards electrification, there is an emerging demand for EGT management solutions that can be adapted to hybrid powertrains incorporating B58 turbo systems. This represents a new frontier in temperature management, as engineers work to optimize the interplay between combustion engines and electric motors.

In the performance vehicle segment, where B58 turbo systems are commonly used, there is a significant demand for advanced EGT management solutions. Enthusiasts and manufacturers alike seek to maximize engine output without compromising reliability or longevity. This has led to a surge in aftermarket products and OEM developments focused on improving EGT control.

The commercial vehicle sector has also shown increased interest in EGT management for B58 turbo systems. Fleet operators are looking for ways to enhance fuel efficiency and reduce maintenance costs, both of which can be positively impacted by effective temperature control in the exhaust system.

Environmental concerns and regulatory pressures have further fueled the demand for EGT management solutions. As emissions standards become more stringent globally, automotive manufacturers are investing heavily in technologies that can help reduce harmful exhaust emissions. Proper EGT management plays a crucial role in this aspect by ensuring optimal catalytic converter performance and minimizing the formation of pollutants.

The aftermarket tuning industry has experienced a boom in demand for EGT management products compatible with B58 turbo systems. Performance enthusiasts are willing to invest in advanced monitoring and control systems to push their engines to the limit while maintaining safe operating temperatures.

OEMs are responding to this market demand by integrating more sophisticated EGT management systems into their stock configurations. This trend is driven by the need to offer high-performance vehicles that comply with emissions regulations and meet consumer expectations for reliability and longevity.

The racing and motorsport sectors have also contributed to the growing demand for EGT management in B58 turbo systems. Competitive teams are constantly seeking ways to extract maximum performance while ensuring engine durability, making advanced temperature control systems a valuable asset in their pursuit of victory.

As the automotive industry continues to evolve towards electrification, there is an emerging demand for EGT management solutions that can be adapted to hybrid powertrains incorporating B58 turbo systems. This represents a new frontier in temperature management, as engineers work to optimize the interplay between combustion engines and electric motors.

EGT Challenges in B58 Turbo Systems

The B58 turbo system, a prominent engine configuration in modern high-performance vehicles, faces significant challenges in managing exhaust gas temperature (EGT). These challenges stem from the inherent design of turbocharged engines, which compress intake air to increase power output. As a result, the combustion process generates higher temperatures, placing increased stress on engine components and the exhaust system.

One of the primary EGT challenges in B58 turbo systems is the risk of thermal damage to critical components. The turbocharger, catalytic converter, and exhaust valves are particularly vulnerable to excessive heat. Prolonged exposure to high temperatures can lead to premature wear, reduced efficiency, and potential failure of these components. This necessitates sophisticated thermal management strategies to maintain optimal operating conditions and ensure longevity of the engine.

Another significant challenge is the balance between performance and emissions control. Higher EGTs can improve turbocharger efficiency and overall engine performance. However, they also contribute to increased nitrogen oxide (NOx) emissions, which are strictly regulated in many jurisdictions. Engineers must navigate this delicate balance, implementing solutions that maximize performance while adhering to stringent emissions standards.

The B58's high-output nature exacerbates these challenges. During high-load conditions, such as aggressive acceleration or sustained high-speed operation, EGTs can spike rapidly. This sudden temperature increase poses a risk of thermal shock to components and requires rapid response from the engine management system to prevent damage.

Fuel efficiency considerations also play a role in EGT management. While higher temperatures can improve combustion efficiency, they can also lead to increased fuel consumption if not properly controlled. This creates a complex optimization problem where engineers must balance power output, fuel economy, and component protection.

Lastly, the compact design of modern engine bays presents spatial constraints for implementing traditional EGT management solutions. The limited space available for heat shielding, insulation, and cooling systems necessitates innovative approaches to thermal management within the confines of the engine compartment.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, sophisticated engine control algorithms, and innovative cooling technologies. As the automotive industry continues to push the boundaries of performance and efficiency, effective EGT management in systems like the B58 turbo remains a critical area of focus for engineers and researchers.

One of the primary EGT challenges in B58 turbo systems is the risk of thermal damage to critical components. The turbocharger, catalytic converter, and exhaust valves are particularly vulnerable to excessive heat. Prolonged exposure to high temperatures can lead to premature wear, reduced efficiency, and potential failure of these components. This necessitates sophisticated thermal management strategies to maintain optimal operating conditions and ensure longevity of the engine.

Another significant challenge is the balance between performance and emissions control. Higher EGTs can improve turbocharger efficiency and overall engine performance. However, they also contribute to increased nitrogen oxide (NOx) emissions, which are strictly regulated in many jurisdictions. Engineers must navigate this delicate balance, implementing solutions that maximize performance while adhering to stringent emissions standards.

The B58's high-output nature exacerbates these challenges. During high-load conditions, such as aggressive acceleration or sustained high-speed operation, EGTs can spike rapidly. This sudden temperature increase poses a risk of thermal shock to components and requires rapid response from the engine management system to prevent damage.

Fuel efficiency considerations also play a role in EGT management. While higher temperatures can improve combustion efficiency, they can also lead to increased fuel consumption if not properly controlled. This creates a complex optimization problem where engineers must balance power output, fuel economy, and component protection.

Lastly, the compact design of modern engine bays presents spatial constraints for implementing traditional EGT management solutions. The limited space available for heat shielding, insulation, and cooling systems necessitates innovative approaches to thermal management within the confines of the engine compartment.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, sophisticated engine control algorithms, and innovative cooling technologies. As the automotive industry continues to push the boundaries of performance and efficiency, effective EGT management in systems like the B58 turbo remains a critical area of focus for engineers and researchers.

Current B58 EGT Management Solutions

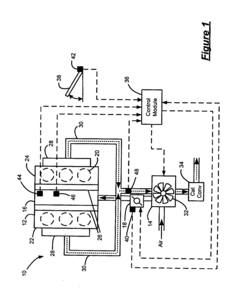

01 Exhaust gas temperature control in turbo systems

B58 turbo systems employ various methods to control exhaust gas temperature. These methods include adjusting fuel injection timing, modifying air-fuel ratios, and implementing cooling systems to manage heat in the exhaust stream. Effective temperature control is crucial for maintaining engine efficiency, reducing emissions, and preventing damage to turbocharger components.- Exhaust gas temperature control in turbo systems: Various methods are employed to control and manage exhaust gas temperature in turbo systems. These may include adjusting fuel injection timing, modifying turbocharger geometry, or implementing cooling systems to prevent overheating and maintain optimal performance.

- Turbocharger design for improved exhaust gas management: Innovative turbocharger designs focus on enhancing exhaust gas flow and temperature management. This may involve optimizing turbine blade geometry, implementing variable geometry systems, or using advanced materials to withstand high temperatures.

- Exhaust gas temperature sensors and monitoring systems: Advanced sensors and monitoring systems are utilized to accurately measure and track exhaust gas temperatures in B58 turbo systems. These systems provide real-time data for engine management and help prevent damage from excessive temperatures.

- Cooling strategies for exhaust gas temperature reduction: Various cooling strategies are implemented to reduce exhaust gas temperatures in B58 turbo systems. These may include intercoolers, water injection systems, or advanced heat exchangers to lower temperatures and improve overall engine efficiency.

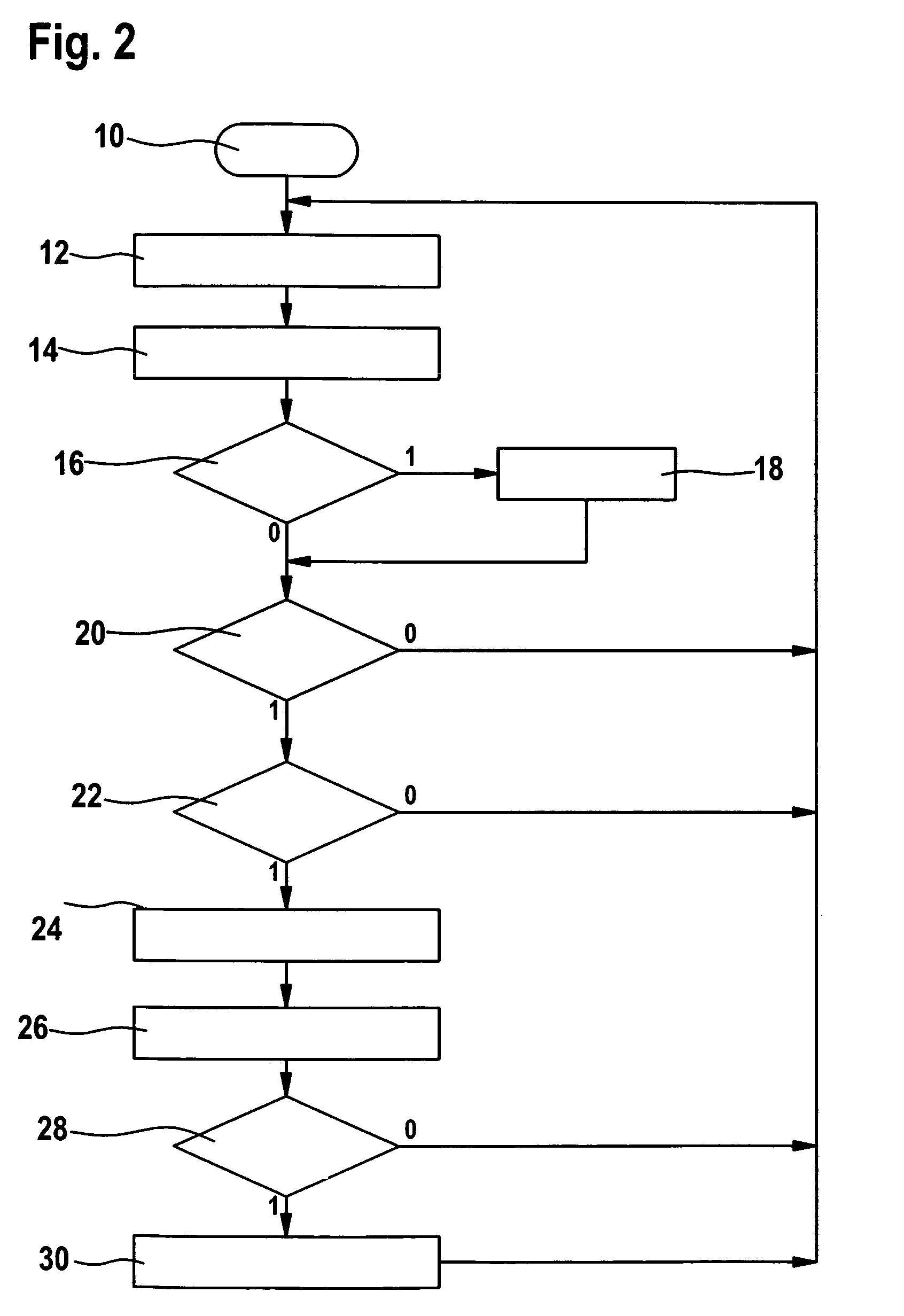

- Engine management systems for optimizing exhaust gas temperature: Sophisticated engine management systems are developed to optimize exhaust gas temperature in B58 turbo systems. These systems may adjust various parameters such as fuel injection, ignition timing, and boost pressure to maintain ideal exhaust gas temperatures across different operating conditions.

02 Turbocharger design for improved thermal management

Advanced turbocharger designs in B58 systems focus on enhancing thermal management. This includes the use of heat-resistant materials, optimized turbine geometry, and improved bearing systems. These design features help to withstand high exhaust gas temperatures and maintain turbocharger performance and longevity.Expand Specific Solutions03 Exhaust gas recirculation (EGR) integration

B58 turbo systems often incorporate exhaust gas recirculation (EGR) to manage exhaust gas temperatures. EGR helps reduce peak combustion temperatures, which in turn lowers exhaust gas temperatures. This integration contributes to improved emissions control and engine efficiency while mitigating the thermal stress on turbocharger components.Expand Specific Solutions04 Sensor technology for exhaust gas temperature monitoring

Advanced sensor technologies are employed in B58 turbo systems to accurately monitor exhaust gas temperatures. These sensors provide real-time data to the engine control unit, allowing for precise adjustments to engine parameters and turbocharger operation. This continuous monitoring helps maintain optimal performance and protects the system from thermal damage.Expand Specific Solutions05 Intercooling and aftercooling systems

B58 turbo systems often utilize intercooling and aftercooling systems to manage exhaust gas temperatures. These cooling systems help reduce the temperature of the compressed air before it enters the engine, which in turn lowers exhaust gas temperatures. This approach improves engine efficiency, reduces thermal stress on components, and enhances overall system performance.Expand Specific Solutions

Key Players in Turbo EGT Management

The exhaust gas temperature management in B58 turbo systems represents a competitive landscape in the advanced automotive technology sector. This field is currently in a growth phase, with increasing market size driven by the demand for more efficient and powerful engines. The technology is reaching maturity, with major players like Ford Global Technologies, Cummins, GM Global Technology Operations, and Robert Bosch GmbH leading the way. These companies are investing heavily in research and development to optimize exhaust gas temperature control, enhancing engine performance and fuel efficiency. The market is characterized by intense competition among established automotive manufacturers and specialized powertrain companies, with emerging players like Achates Power bringing innovative solutions to the table.

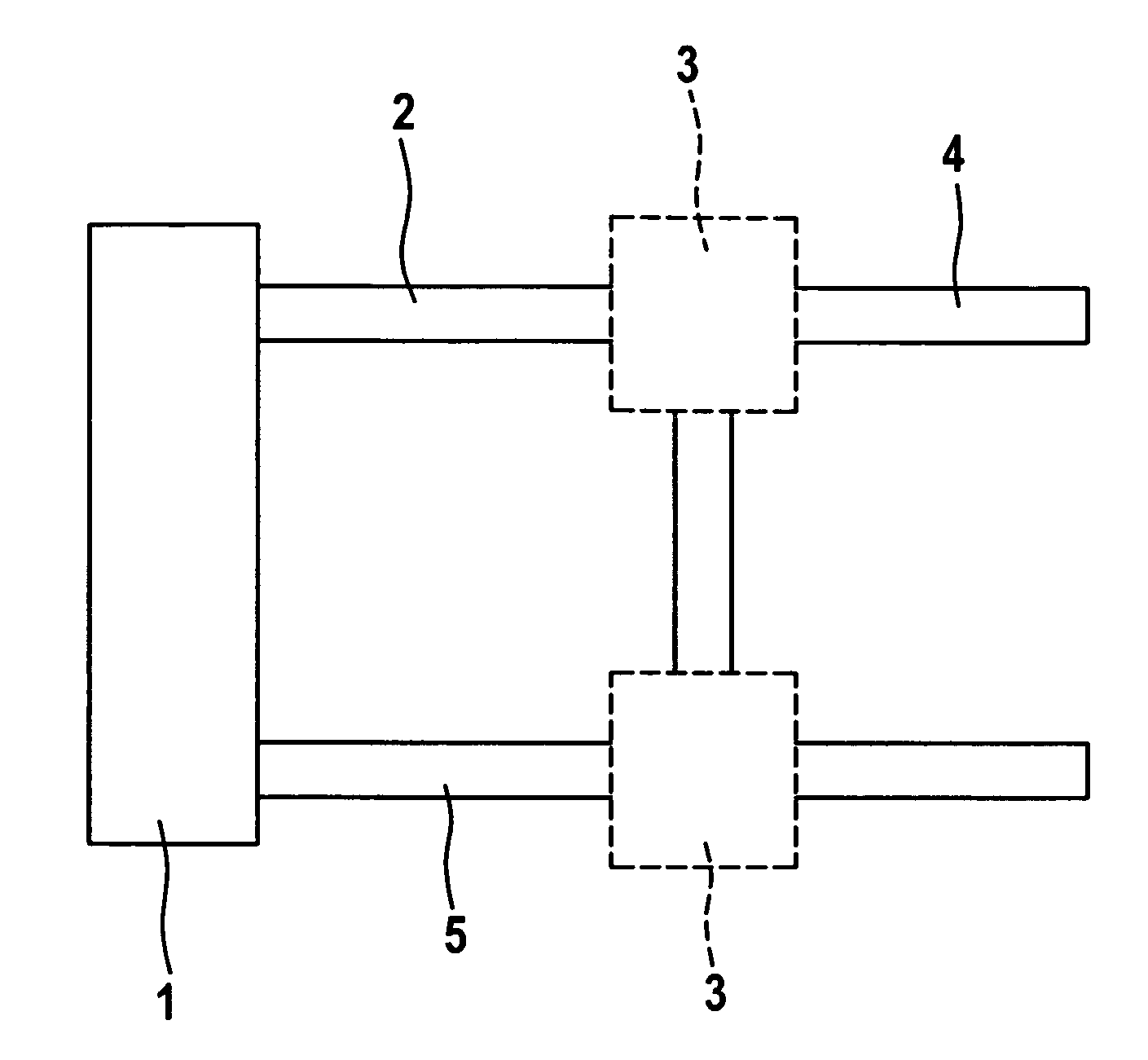

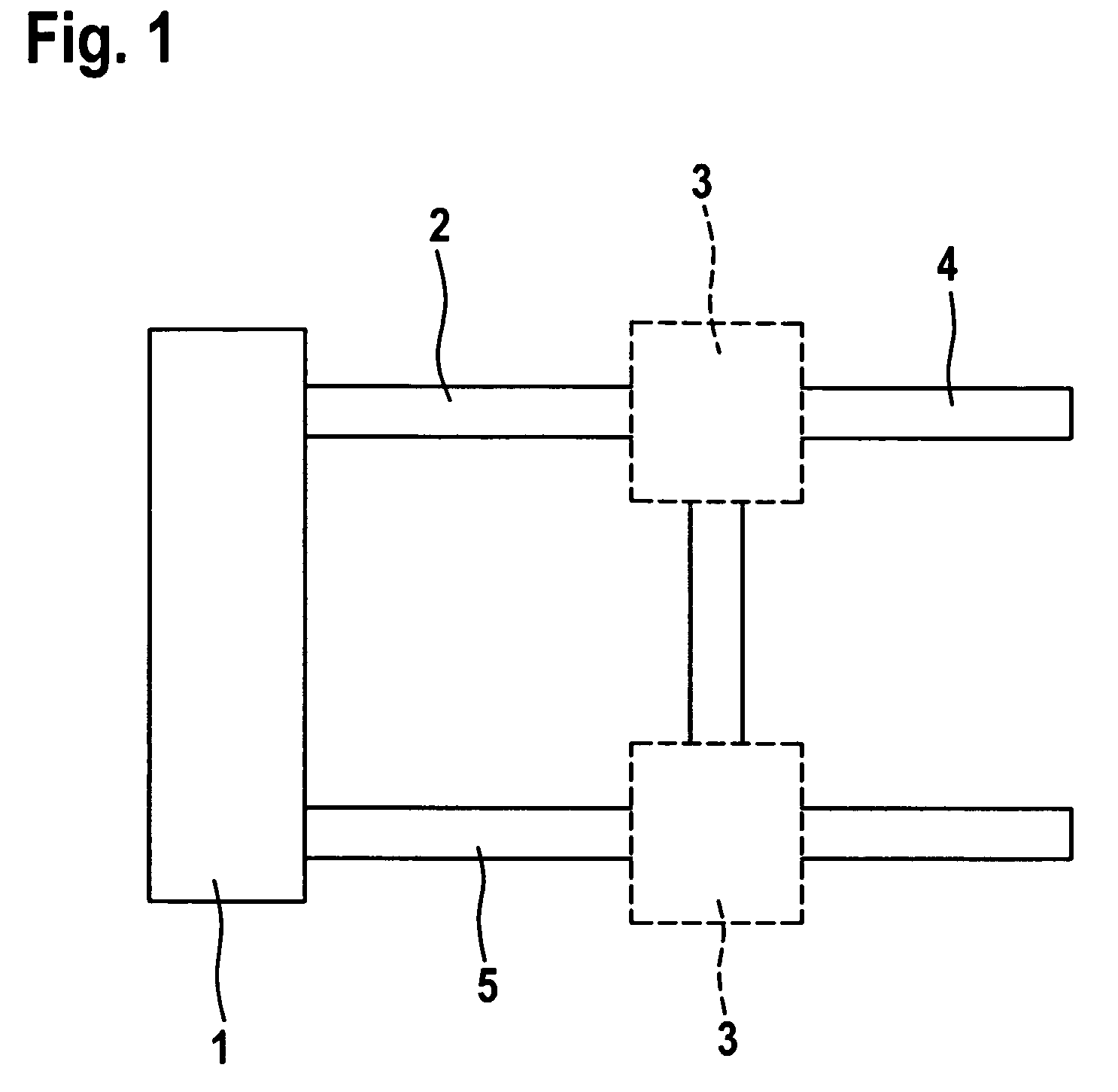

GM Global Technology Operations LLC

Technical Solution: GM has implemented an innovative Exhaust Gas Temperature Management system for their B58 turbo engines. The system utilizes a twin-scroll turbocharger design, which separates exhaust pulses for improved efficiency[4]. GM's approach also includes an active thermal management system that rapidly warms up the engine and catalytic converter to reduce cold-start emissions[5]. The EGTM system incorporates an electrically assisted turbocharger, allowing for quicker response times and better low-end torque[6]. Additionally, GM has developed a proprietary exhaust manifold design that optimizes exhaust flow and helps maintain ideal temperatures across a wide range of operating conditions[7].

Strengths: Rapid engine warm-up, improved low-end performance, reduced turbo lag. Weaknesses: Increased system complexity, potential reliability concerns with electrical components.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced Exhaust Gas Temperature Management (EGTM) system for B58 turbo engines. This system utilizes a combination of hardware and software solutions to optimize exhaust gas temperatures. The hardware includes a variable geometry turbocharger (VGT) and an electronically controlled wastegate[1]. The software employs predictive algorithms to anticipate engine load changes and adjust the turbocharger accordingly. Bosch's system also incorporates a dual-loop exhaust gas recirculation (EGR) system, which helps to reduce peak combustion temperatures and NOx emissions[2]. The EGTM system is integrated with Bosch's engine control unit (ECU) for precise control and real-time adjustments based on various sensor inputs[3].

Strengths: Precise control of exhaust gas temperatures, reduced emissions, improved fuel efficiency. Weaknesses: Complex system requiring sophisticated calibration, potentially higher initial cost.

Core EGT Control Innovations for B58

Engine turbine temperature control system

PatentInactiveUS20060080959A1

Innovation

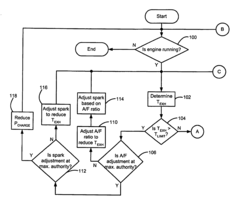

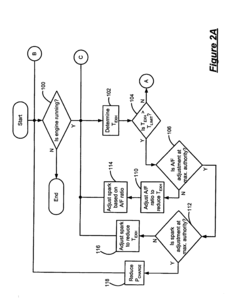

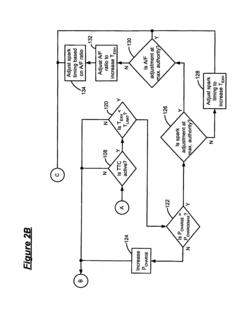

- A turbine temperature control (TTC) system that utilizes sensors to monitor exhaust gas temperature and adjusts engine parameters like air-to-fuel ratio and spark timing, as well as charge pressure, to maintain the temperature within safe operating limits, thereby protecting the turbocharger components.

Method for determining the exhaust gas temperature of an internal combustion engine

PatentInactiveUS8019563B2

Innovation

- A method that involves measuring lambda values and using them to calculate exhaust gas temperature, comparing calculated values with measured values, and adapting a functional relationship between lambda values and temperature to improve accuracy, incorporating additional parameters like rotational speed and oil temperature, and using interpolation/extrapolation to refine calculations, especially during steady-state operations.

Emissions Regulations Impact on EGT

Emissions regulations have significantly impacted exhaust gas temperature (EGT) management in modern automotive engines, particularly in turbocharged systems like the BMW B58. These regulations, aimed at reducing harmful emissions and improving air quality, have necessitated more sophisticated approaches to EGT control.

The introduction of stringent emissions standards, such as Euro 6 and Tier 3, has placed increased pressure on manufacturers to optimize engine performance while minimizing pollutants. This has led to a greater focus on EGT management as a critical factor in achieving these goals. Higher EGTs can lead to increased NOx emissions, which are strictly regulated under these standards.

To comply with these regulations, manufacturers have implemented various strategies for EGT management. One key approach is the use of advanced turbocharger designs that can withstand higher temperatures. This allows for more efficient operation at higher EGTs without compromising durability or emissions performance.

Another significant development is the integration of exhaust gas recirculation (EGR) systems. EGR helps to lower combustion temperatures, thereby reducing NOx formation. However, this can also impact EGT, requiring careful balancing to maintain optimal engine performance and emissions compliance.

The use of variable geometry turbochargers (VGTs) has also become more prevalent as a result of emissions regulations. VGTs allow for more precise control of boost pressure and EGT across a wider range of operating conditions, helping to optimize both performance and emissions.

Advanced engine control units (ECUs) and software have been developed to manage these complex systems. These ECUs continuously monitor and adjust various parameters, including fuel injection timing, air-fuel ratio, and turbocharger operation, to maintain optimal EGTs while meeting emissions targets.

The impact of emissions regulations on EGT management has also driven innovation in materials science. High-temperature resistant materials and coatings are now used in exhaust systems and turbochargers to withstand the increased thermal stress associated with more aggressive EGT management strategies.

Furthermore, the push for lower emissions has led to the adoption of particulate filters and catalytic converters, which can affect exhaust backpressure and, consequently, EGT. This has required even more sophisticated EGT management techniques to ensure these aftertreatment systems operate effectively without compromising engine performance or durability.

In conclusion, emissions regulations have been a driving force behind significant advancements in EGT management technology. These developments have resulted in more efficient, cleaner-running engines that can meet stringent emissions standards while still delivering the performance expected by consumers.

The introduction of stringent emissions standards, such as Euro 6 and Tier 3, has placed increased pressure on manufacturers to optimize engine performance while minimizing pollutants. This has led to a greater focus on EGT management as a critical factor in achieving these goals. Higher EGTs can lead to increased NOx emissions, which are strictly regulated under these standards.

To comply with these regulations, manufacturers have implemented various strategies for EGT management. One key approach is the use of advanced turbocharger designs that can withstand higher temperatures. This allows for more efficient operation at higher EGTs without compromising durability or emissions performance.

Another significant development is the integration of exhaust gas recirculation (EGR) systems. EGR helps to lower combustion temperatures, thereby reducing NOx formation. However, this can also impact EGT, requiring careful balancing to maintain optimal engine performance and emissions compliance.

The use of variable geometry turbochargers (VGTs) has also become more prevalent as a result of emissions regulations. VGTs allow for more precise control of boost pressure and EGT across a wider range of operating conditions, helping to optimize both performance and emissions.

Advanced engine control units (ECUs) and software have been developed to manage these complex systems. These ECUs continuously monitor and adjust various parameters, including fuel injection timing, air-fuel ratio, and turbocharger operation, to maintain optimal EGTs while meeting emissions targets.

The impact of emissions regulations on EGT management has also driven innovation in materials science. High-temperature resistant materials and coatings are now used in exhaust systems and turbochargers to withstand the increased thermal stress associated with more aggressive EGT management strategies.

Furthermore, the push for lower emissions has led to the adoption of particulate filters and catalytic converters, which can affect exhaust backpressure and, consequently, EGT. This has required even more sophisticated EGT management techniques to ensure these aftertreatment systems operate effectively without compromising engine performance or durability.

In conclusion, emissions regulations have been a driving force behind significant advancements in EGT management technology. These developments have resulted in more efficient, cleaner-running engines that can meet stringent emissions standards while still delivering the performance expected by consumers.

B58 EGT Management Cost-Benefit Analysis

The cost-benefit analysis of B58 EGT management systems reveals a complex interplay of factors that influence both the financial and performance aspects of turbo system implementation. Initial investment costs for advanced EGT management technologies can be substantial, including expenses for research and development, specialized sensors, and sophisticated control algorithms. However, these upfront costs are often offset by long-term benefits in engine efficiency, reliability, and compliance with stringent emissions regulations.

From a performance perspective, effective EGT management in B58 turbo systems contributes significantly to overall engine output and longevity. By precisely controlling exhaust gas temperatures, these systems allow for more aggressive turbocharging without compromising engine integrity. This results in improved power delivery and potentially better fuel economy, which can translate to cost savings for end-users over the vehicle's lifetime.

The implementation of advanced EGT management also yields benefits in terms of reduced maintenance costs. By preventing excessive thermal stress on engine components, particularly in the turbocharger and exhaust system, the frequency of repairs and replacements can be minimized. This not only reduces direct maintenance expenses but also enhances customer satisfaction through improved vehicle reliability.

Environmental considerations play a crucial role in the cost-benefit equation. Stricter emissions standards worldwide are driving the need for more sophisticated EGT management systems. While compliance with these regulations incurs additional costs, it also opens up market opportunities in regions with stringent environmental policies. Furthermore, the potential for carbon credits or other environmental incentives can provide additional financial benefits for manufacturers implementing advanced EGT management technologies.

The scalability of EGT management solutions across different vehicle models and engine configurations presents another important factor in the cost-benefit analysis. Developing a versatile system that can be adapted to various B58 turbo applications allows for economies of scale, potentially reducing per-unit costs as production volumes increase. This scalability also enables faster time-to-market for new vehicle models, providing a competitive advantage in the rapidly evolving automotive industry.

In conclusion, while the initial investment in advanced B58 EGT management systems can be significant, the long-term benefits in terms of performance, reliability, compliance, and potential market expansion generally outweigh the costs. As technology continues to evolve and production scales up, the cost-benefit ratio is likely to improve further, making sophisticated EGT management an increasingly attractive proposition for automotive manufacturers.

From a performance perspective, effective EGT management in B58 turbo systems contributes significantly to overall engine output and longevity. By precisely controlling exhaust gas temperatures, these systems allow for more aggressive turbocharging without compromising engine integrity. This results in improved power delivery and potentially better fuel economy, which can translate to cost savings for end-users over the vehicle's lifetime.

The implementation of advanced EGT management also yields benefits in terms of reduced maintenance costs. By preventing excessive thermal stress on engine components, particularly in the turbocharger and exhaust system, the frequency of repairs and replacements can be minimized. This not only reduces direct maintenance expenses but also enhances customer satisfaction through improved vehicle reliability.

Environmental considerations play a crucial role in the cost-benefit equation. Stricter emissions standards worldwide are driving the need for more sophisticated EGT management systems. While compliance with these regulations incurs additional costs, it also opens up market opportunities in regions with stringent environmental policies. Furthermore, the potential for carbon credits or other environmental incentives can provide additional financial benefits for manufacturers implementing advanced EGT management technologies.

The scalability of EGT management solutions across different vehicle models and engine configurations presents another important factor in the cost-benefit analysis. Developing a versatile system that can be adapted to various B58 turbo applications allows for economies of scale, potentially reducing per-unit costs as production volumes increase. This scalability also enables faster time-to-market for new vehicle models, providing a competitive advantage in the rapidly evolving automotive industry.

In conclusion, while the initial investment in advanced B58 EGT management systems can be significant, the long-term benefits in terms of performance, reliability, compliance, and potential market expansion generally outweigh the costs. As technology continues to evolve and production scales up, the cost-benefit ratio is likely to improve further, making sophisticated EGT management an increasingly attractive proposition for automotive manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!