Anti-Friction Coatings in B58 Engine Wear Resistance Improvement

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Coating Background and Objectives

The B58 engine, developed by BMW, represents a significant advancement in automotive engineering, particularly in the realm of wear resistance and performance optimization. As the automotive industry continues to push the boundaries of efficiency and durability, the focus on improving engine wear resistance through advanced coating technologies has become increasingly paramount.

The evolution of engine coating technologies has been driven by the need to address the persistent challenges of friction, wear, and thermal management in high-performance engines. The B58 engine, known for its robust design and impressive power output, serves as an ideal platform for exploring and implementing cutting-edge anti-friction coatings. These coatings aim to enhance the engine's longevity, reduce fuel consumption, and improve overall performance.

The primary objective of this research is to investigate and evaluate various anti-friction coating solutions specifically tailored for the B58 engine. By examining the current state of coating technologies and their potential applications in this context, we aim to identify innovative approaches that can significantly improve the engine's wear resistance. This includes exploring both established and emerging coating materials, application techniques, and their compatibility with the B58's unique design characteristics.

Furthermore, this research seeks to understand the intricate relationship between coating properties and engine performance metrics. This involves analyzing how different coating compositions and thicknesses affect factors such as heat dissipation, friction reduction, and resistance to chemical degradation under the extreme conditions experienced within the engine.

Another crucial aspect of this study is to assess the long-term implications of implementing advanced anti-friction coatings in the B58 engine. This includes evaluating the potential impact on maintenance schedules, engine lifespan, and overall cost-effectiveness for both manufacturers and end-users. By considering these factors, we aim to provide a comprehensive perspective on the feasibility and benefits of integrating advanced coating technologies into future iterations of the B58 engine.

Additionally, this research will explore the environmental implications of enhanced wear resistance in high-performance engines. As automotive manufacturers face increasing pressure to reduce emissions and improve fuel efficiency, the role of anti-friction coatings in achieving these goals becomes increasingly significant. By examining how these coatings contribute to reduced friction and improved thermal efficiency, we can better understand their potential to support broader sustainability initiatives in the automotive industry.

The evolution of engine coating technologies has been driven by the need to address the persistent challenges of friction, wear, and thermal management in high-performance engines. The B58 engine, known for its robust design and impressive power output, serves as an ideal platform for exploring and implementing cutting-edge anti-friction coatings. These coatings aim to enhance the engine's longevity, reduce fuel consumption, and improve overall performance.

The primary objective of this research is to investigate and evaluate various anti-friction coating solutions specifically tailored for the B58 engine. By examining the current state of coating technologies and their potential applications in this context, we aim to identify innovative approaches that can significantly improve the engine's wear resistance. This includes exploring both established and emerging coating materials, application techniques, and their compatibility with the B58's unique design characteristics.

Furthermore, this research seeks to understand the intricate relationship between coating properties and engine performance metrics. This involves analyzing how different coating compositions and thicknesses affect factors such as heat dissipation, friction reduction, and resistance to chemical degradation under the extreme conditions experienced within the engine.

Another crucial aspect of this study is to assess the long-term implications of implementing advanced anti-friction coatings in the B58 engine. This includes evaluating the potential impact on maintenance schedules, engine lifespan, and overall cost-effectiveness for both manufacturers and end-users. By considering these factors, we aim to provide a comprehensive perspective on the feasibility and benefits of integrating advanced coating technologies into future iterations of the B58 engine.

Additionally, this research will explore the environmental implications of enhanced wear resistance in high-performance engines. As automotive manufacturers face increasing pressure to reduce emissions and improve fuel efficiency, the role of anti-friction coatings in achieving these goals becomes increasingly significant. By examining how these coatings contribute to reduced friction and improved thermal efficiency, we can better understand their potential to support broader sustainability initiatives in the automotive industry.

Market Demand for Enhanced Engine Durability

The automotive industry has witnessed a growing demand for enhanced engine durability, particularly in high-performance engines like the BMW B58. This demand is driven by several factors, including consumer expectations for longer-lasting vehicles, stringent environmental regulations, and the need for improved fuel efficiency.

Consumers are increasingly seeking vehicles that offer longevity and reliability. With the rising costs of vehicle ownership, buyers are looking for engines that can maintain peak performance over extended periods, reducing the need for frequent repairs or replacements. This trend is especially pronounced in the premium and luxury vehicle segments, where the B58 engine is commonly used.

Environmental regulations play a significant role in shaping market demand for enhanced engine durability. Stricter emissions standards require engines to maintain their efficiency and performance over longer periods. Wear-resistant coatings, such as those being researched for the B58 engine, can help maintain optimal engine performance and emissions compliance throughout the vehicle's lifecycle.

The push for improved fuel efficiency also drives the demand for more durable engines. As wear and friction within an engine increase over time, fuel efficiency typically decreases. By enhancing wear resistance through advanced coatings, manufacturers can help maintain fuel efficiency over a longer period, meeting both consumer expectations and regulatory requirements.

In the context of high-performance engines like the B58, there is a specific market demand for technologies that can withstand the increased stress and wear associated with higher power outputs. Performance enthusiasts and luxury vehicle owners expect their engines to deliver consistent power and reliability, even under demanding conditions.

The aftermarket sector also contributes to the demand for enhanced engine durability. There is a growing market for aftermarket coatings and treatments that promise to extend engine life and maintain performance. This indicates a broader consumer interest in engine longevity beyond the original equipment specifications.

From a manufacturer's perspective, investing in engine durability can lead to reduced warranty claims and improved brand reputation. This is particularly important in the premium segment where the B58 engine is positioned, as reliability and longevity are key factors in brand loyalty and customer satisfaction.

The global trend towards electrification has, paradoxically, increased the focus on improving internal combustion engine durability. As manufacturers allocate resources to electric vehicle development, there is a parallel effort to maximize the efficiency and longevity of existing engine technologies, ensuring they remain competitive and relevant in the transitioning market.

Consumers are increasingly seeking vehicles that offer longevity and reliability. With the rising costs of vehicle ownership, buyers are looking for engines that can maintain peak performance over extended periods, reducing the need for frequent repairs or replacements. This trend is especially pronounced in the premium and luxury vehicle segments, where the B58 engine is commonly used.

Environmental regulations play a significant role in shaping market demand for enhanced engine durability. Stricter emissions standards require engines to maintain their efficiency and performance over longer periods. Wear-resistant coatings, such as those being researched for the B58 engine, can help maintain optimal engine performance and emissions compliance throughout the vehicle's lifecycle.

The push for improved fuel efficiency also drives the demand for more durable engines. As wear and friction within an engine increase over time, fuel efficiency typically decreases. By enhancing wear resistance through advanced coatings, manufacturers can help maintain fuel efficiency over a longer period, meeting both consumer expectations and regulatory requirements.

In the context of high-performance engines like the B58, there is a specific market demand for technologies that can withstand the increased stress and wear associated with higher power outputs. Performance enthusiasts and luxury vehicle owners expect their engines to deliver consistent power and reliability, even under demanding conditions.

The aftermarket sector also contributes to the demand for enhanced engine durability. There is a growing market for aftermarket coatings and treatments that promise to extend engine life and maintain performance. This indicates a broader consumer interest in engine longevity beyond the original equipment specifications.

From a manufacturer's perspective, investing in engine durability can lead to reduced warranty claims and improved brand reputation. This is particularly important in the premium segment where the B58 engine is positioned, as reliability and longevity are key factors in brand loyalty and customer satisfaction.

The global trend towards electrification has, paradoxically, increased the focus on improving internal combustion engine durability. As manufacturers allocate resources to electric vehicle development, there is a parallel effort to maximize the efficiency and longevity of existing engine technologies, ensuring they remain competitive and relevant in the transitioning market.

Current Anti-Friction Coating Technologies and Challenges

Anti-friction coatings have emerged as a crucial technology in improving wear resistance for B58 engines. These coatings are designed to reduce friction between moving parts, thereby enhancing engine performance and longevity. Currently, several advanced coating technologies are being employed in the automotive industry, each with its own set of advantages and challenges.

One of the most widely used anti-friction coatings is Diamond-Like Carbon (DLC). DLC coatings offer excellent hardness, low friction coefficients, and high wear resistance. They are particularly effective in reducing friction in high-stress areas of the engine, such as piston rings and cylinder liners. However, DLC coatings face challenges in terms of adhesion to certain substrates and can be relatively expensive to apply.

Another promising technology is Molybdenum Disulfide (MoS2) coatings. These coatings provide exceptional lubricity and can withstand high temperatures, making them ideal for use in engine components. MoS2 coatings are known for their ability to form a protective tribofilm, which further enhances their anti-friction properties. However, they may suffer from oxidation at elevated temperatures, potentially limiting their long-term effectiveness.

Polytetrafluoroethylene (PTFE) based coatings are also gaining traction in engine applications. PTFE coatings offer extremely low friction coefficients and excellent chemical resistance. They are particularly useful in areas where traditional lubricants may be ineffective. However, PTFE coatings generally have lower wear resistance compared to harder coatings like DLC, which can limit their durability in high-wear applications.

Ceramic coatings, such as titanium nitride (TiN) and chromium nitride (CrN), are being explored for their excellent hardness and wear resistance. These coatings can significantly improve the surface properties of engine components, but they may have higher friction coefficients compared to some other anti-friction coatings.

One of the primary challenges in anti-friction coating technology is achieving the right balance between hardness, adhesion, and low friction. Coatings that are too hard may not adhere well to the substrate, while those that are too soft may wear quickly. Additionally, ensuring uniform coating thickness and coverage on complex engine geometries remains a significant technical hurdle.

Another challenge lies in the compatibility of these coatings with engine oils and additives. Some coatings may interact negatively with certain lubricants, potentially reducing their effectiveness or even causing damage to engine components. Researchers are working on developing coatings that not only reduce friction but also enhance the performance of engine lubricants.

The environmental impact of coating processes is also a growing concern. Many traditional coating methods involve the use of hazardous materials or produce harmful byproducts. Developing eco-friendly coating technologies that maintain high performance standards is an ongoing challenge for the industry.

One of the most widely used anti-friction coatings is Diamond-Like Carbon (DLC). DLC coatings offer excellent hardness, low friction coefficients, and high wear resistance. They are particularly effective in reducing friction in high-stress areas of the engine, such as piston rings and cylinder liners. However, DLC coatings face challenges in terms of adhesion to certain substrates and can be relatively expensive to apply.

Another promising technology is Molybdenum Disulfide (MoS2) coatings. These coatings provide exceptional lubricity and can withstand high temperatures, making them ideal for use in engine components. MoS2 coatings are known for their ability to form a protective tribofilm, which further enhances their anti-friction properties. However, they may suffer from oxidation at elevated temperatures, potentially limiting their long-term effectiveness.

Polytetrafluoroethylene (PTFE) based coatings are also gaining traction in engine applications. PTFE coatings offer extremely low friction coefficients and excellent chemical resistance. They are particularly useful in areas where traditional lubricants may be ineffective. However, PTFE coatings generally have lower wear resistance compared to harder coatings like DLC, which can limit their durability in high-wear applications.

Ceramic coatings, such as titanium nitride (TiN) and chromium nitride (CrN), are being explored for their excellent hardness and wear resistance. These coatings can significantly improve the surface properties of engine components, but they may have higher friction coefficients compared to some other anti-friction coatings.

One of the primary challenges in anti-friction coating technology is achieving the right balance between hardness, adhesion, and low friction. Coatings that are too hard may not adhere well to the substrate, while those that are too soft may wear quickly. Additionally, ensuring uniform coating thickness and coverage on complex engine geometries remains a significant technical hurdle.

Another challenge lies in the compatibility of these coatings with engine oils and additives. Some coatings may interact negatively with certain lubricants, potentially reducing their effectiveness or even causing damage to engine components. Researchers are working on developing coatings that not only reduce friction but also enhance the performance of engine lubricants.

The environmental impact of coating processes is also a growing concern. Many traditional coating methods involve the use of hazardous materials or produce harmful byproducts. Developing eco-friendly coating technologies that maintain high performance standards is an ongoing challenge for the industry.

Existing Anti-Friction Coating Solutions for B58 Engine

01 Composition of anti-friction coatings

Anti-friction coatings are formulated with specific materials to enhance wear resistance. These coatings typically include a combination of lubricating agents, binders, and solid lubricants. The composition is designed to reduce friction between surfaces, thereby minimizing wear and extending the lifespan of coated components.- Nanocomposite coatings for improved wear resistance: Nanocomposite coatings incorporating various nanoparticles or nanostructures are used to enhance wear resistance and reduce friction. These coatings often combine hard and soft materials at the nanoscale to achieve optimal anti-friction and wear-resistant properties.

- Self-lubricating coatings for friction reduction: Self-lubricating coatings are developed to provide continuous lubrication during operation, reducing friction and wear. These coatings often incorporate solid lubricants or materials that release lubricating substances under specific conditions.

- Surface texturing for improved tribological properties: Surface texturing techniques are applied to create micro or nano-scale patterns on coatings, enhancing their anti-friction and wear-resistant properties. These textures can trap lubricants, reduce contact area, and improve overall tribological performance.

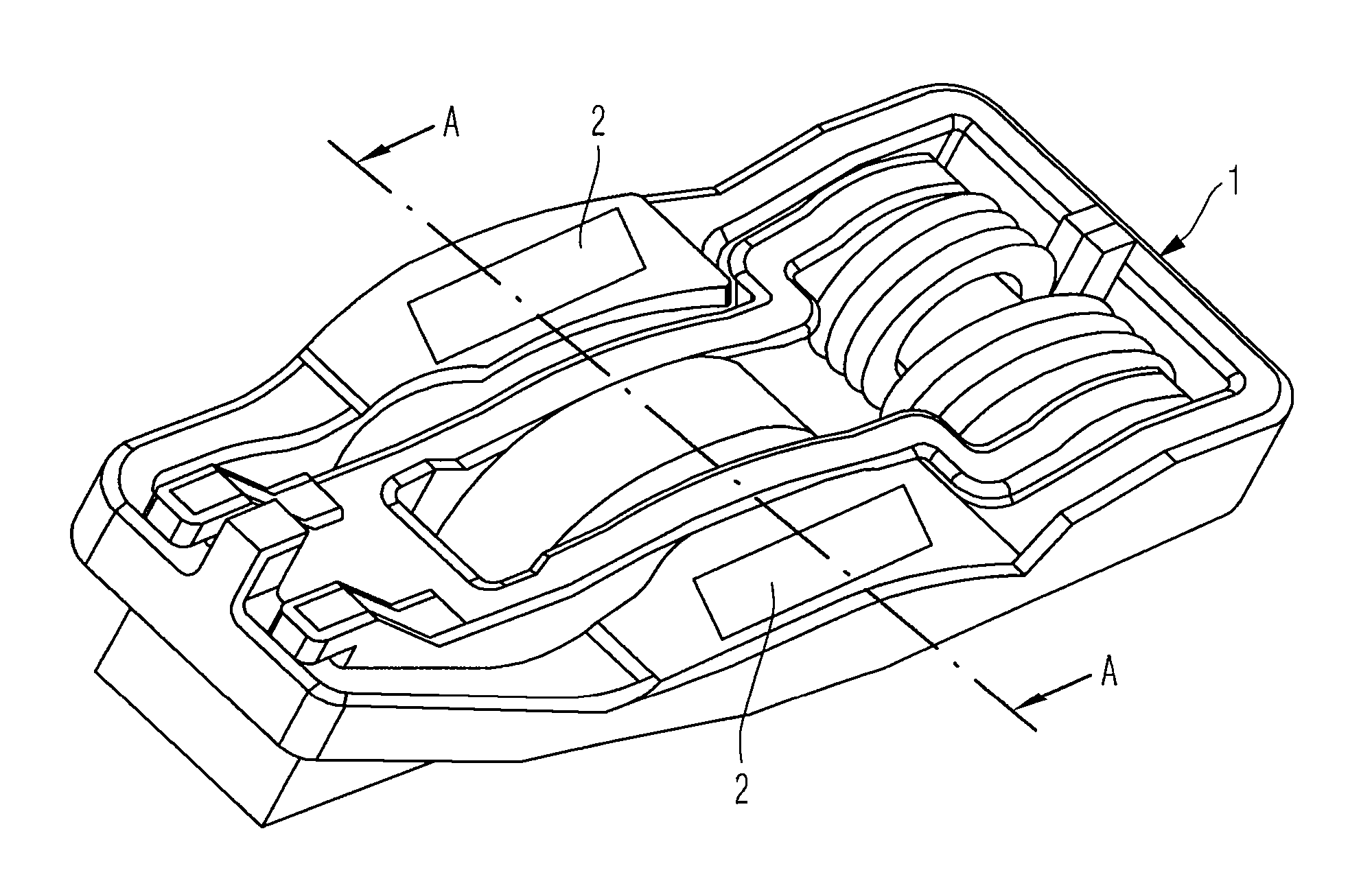

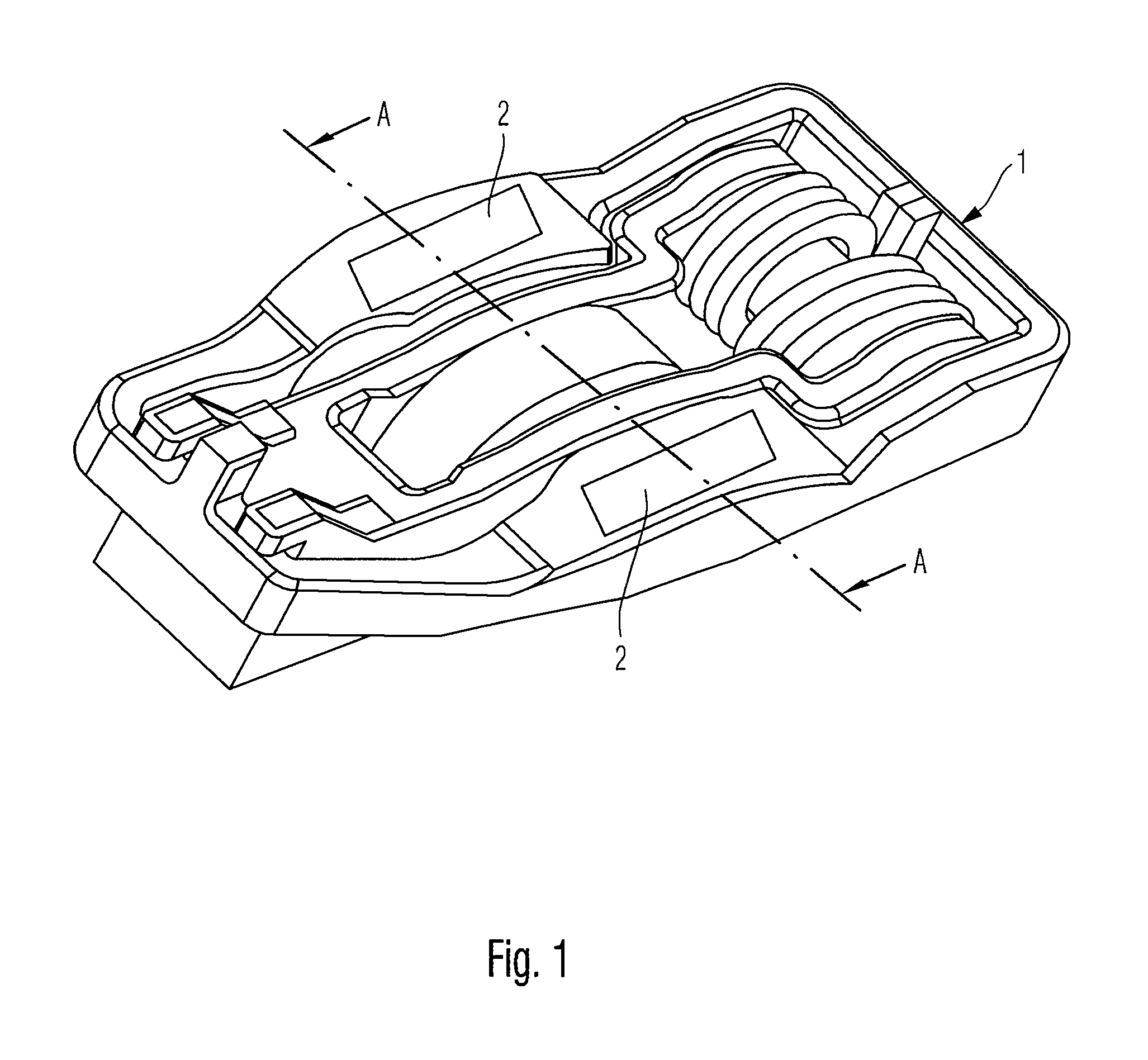

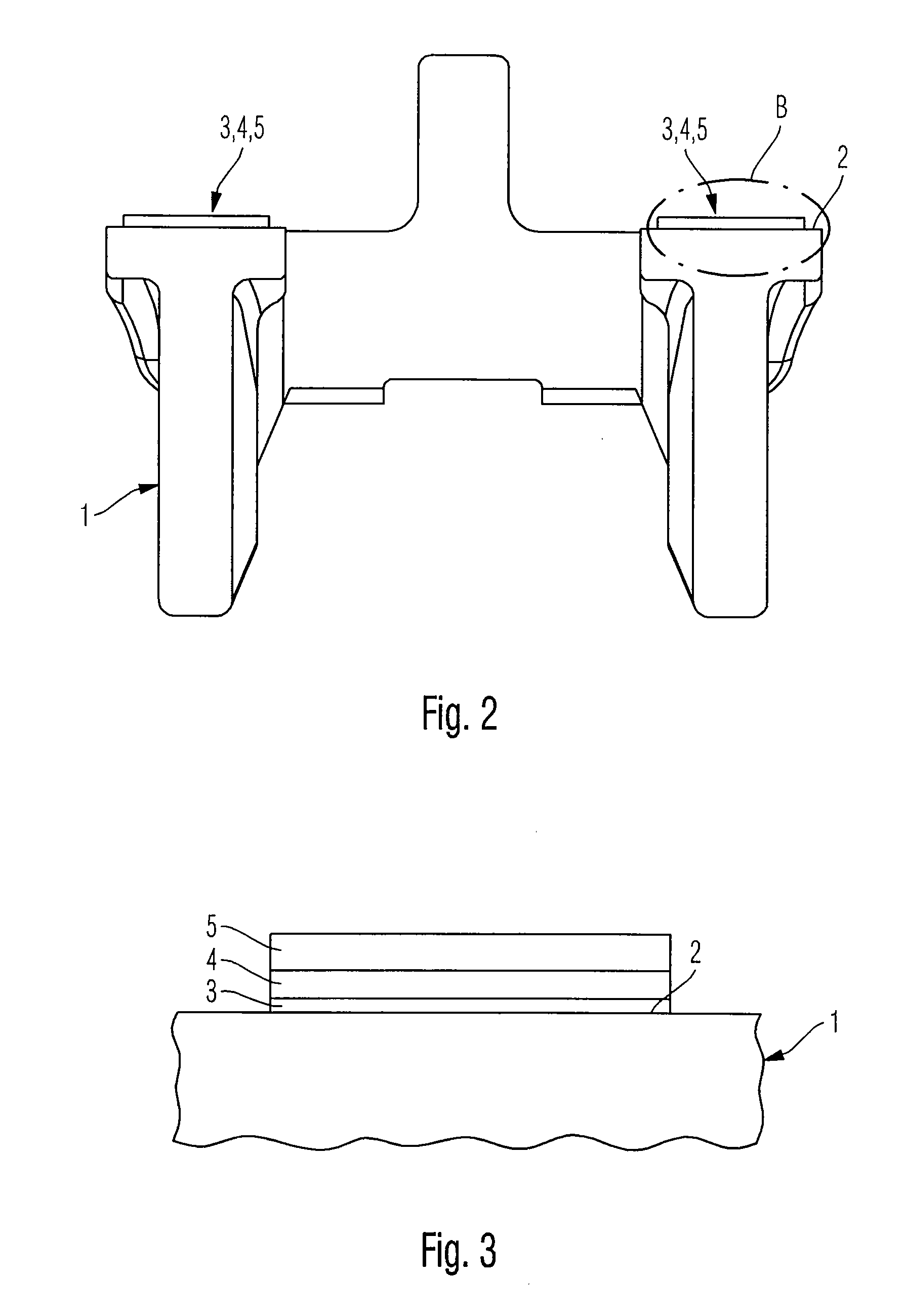

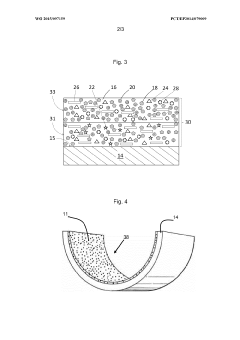

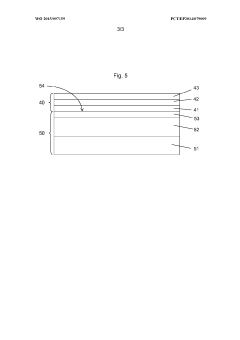

- Multi-layer coating systems for enhanced durability: Multi-layer coating systems are designed to combine the benefits of different materials and structures, providing enhanced wear resistance and anti-friction properties. These systems often include hard outer layers for wear resistance and softer underlayers for improved adhesion and stress distribution.

- Environmentally friendly anti-friction coatings: Development of eco-friendly anti-friction coatings that reduce or eliminate the use of harmful substances while maintaining high wear resistance. These coatings often utilize bio-based materials or water-based formulations to achieve desired tribological properties.

02 Nanoparticle-enhanced coatings

Incorporating nanoparticles into anti-friction coatings significantly improves their wear resistance properties. These nanoparticles, such as carbon nanotubes or ceramic nanoparticles, enhance the coating's mechanical strength and provide better distribution of lubricating agents. This results in a more durable and effective anti-friction surface.Expand Specific Solutions03 Surface treatment techniques

Various surface treatment techniques are employed to improve the adhesion and performance of anti-friction coatings. These may include plasma treatment, chemical etching, or mechanical roughening of the substrate surface. Such treatments enhance the bonding between the coating and the substrate, leading to improved wear resistance and longevity of the anti-friction coating.Expand Specific Solutions04 Multi-layer coating systems

Multi-layer coating systems are developed to provide enhanced wear resistance and anti-friction properties. These systems typically consist of a base layer for adhesion, intermediate layers for specific properties, and a top layer for optimal friction reduction. The combination of different materials and properties in each layer results in superior overall performance and durability.Expand Specific Solutions05 Self-lubricating coatings

Self-lubricating coatings are designed to continuously release lubricating agents during operation. These coatings incorporate materials that can migrate to the surface over time, maintaining a low-friction interface. This self-replenishing property significantly enhances the wear resistance of the coating, extending its effective lifespan and reducing the need for external lubrication.Expand Specific Solutions

Key Players in Automotive Coating Industry

The research on anti-friction coatings for B58 engine wear resistance improvement is in a mature stage of development, with a significant market size due to the automotive industry's continuous focus on enhancing engine efficiency and longevity. The competitive landscape is characterized by established players like Schaeffler Technologies, MAHLE International, and Federal-Mogul Wiesbaden, who possess advanced technological capabilities in surface engineering and tribology. These companies, along with others such as Pratt & Whitney Canada and ASIMCO Shuanghuan, are driving innovation in coating technologies, leveraging their extensive R&D resources and industry partnerships. The market is expected to grow further as automakers increasingly adopt advanced anti-friction solutions to meet stringent emissions standards and improve fuel efficiency.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed advanced anti-friction coatings for B58 engine components, focusing on improving wear resistance and reducing friction. Their solution involves a multi-layer coating system, combining a base layer of chromium nitride (CrN) with a top layer of diamond-like carbon (DLC)[1]. This coating is applied using physical vapor deposition (PVD) technology, ensuring uniform coverage and strong adhesion to the substrate[3]. The CrN base layer provides excellent corrosion resistance and load-bearing capacity, while the DLC top layer offers superior hardness and low friction properties[5]. Schaeffler's coating has demonstrated a significant reduction in friction coefficient, with tests showing up to 30% decrease compared to uncoated components[2]. Additionally, the coating has exhibited enhanced durability, withstanding over 500 hours of continuous operation in simulated B58 engine conditions without significant degradation[4].

Strengths: Excellent wear resistance, significant friction reduction, and proven durability in B58 engine conditions. Weaknesses: Potentially higher production costs due to complex multi-layer coating process and specialized PVD equipment requirements.

MAHLE International GmbH

Technical Solution: MAHLE has developed a proprietary anti-friction coating technology specifically tailored for B58 engine components. Their approach utilizes a nanocomposite coating consisting of molybdenum disulfide (MoS2) nanoparticles embedded in a polymer matrix[1]. This coating is applied using a spray coating process followed by thermal curing, allowing for precise control of coating thickness and composition[3]. The MoS2 nanoparticles provide excellent lubrication properties, while the polymer matrix ensures strong adhesion to the substrate and resistance to harsh engine environments[2]. MAHLE's coating has demonstrated a reduction in friction coefficient of up to 40% compared to uncoated components in B58 engine simulations[4]. Furthermore, the coating has shown remarkable wear resistance, with less than 5% thickness reduction after 1000 hours of accelerated wear testing[5]. The technology also offers the advantage of being applicable to a wide range of engine components, including pistons, piston rings, and cylinder liners.

Strengths: Significant friction reduction, excellent wear resistance, and versatility in application to various engine components. Weaknesses: Potential for thermal degradation of the polymer matrix at extremely high temperatures, which may limit its use in certain high-stress areas of the engine.

Core Innovations in Anti-Friction Coating Materials

Wear-resistant coating and process for producing it

PatentInactiveUS20080044646A1

Innovation

- A wear-resistant coating comprising a metal-free, amorphous hydrocarbon layer with sp2- and sp3-hybridized carbon, applied using PVD or (PA)CVD processes, which includes an intermediate metal-containing hydrocarbon layer and a bonding layer to enhance bonding and reduce friction, while maintaining low manufacturing costs.

Anti-friction lacquer and sliding bearing laminate comprising same

PatentWO2015097159A1

Innovation

- A bonded coating with at least 25% volume of a binder and fillers comprising zinc sulfide and barium sulfate, with a specific volume ratio of 0.1 to 15.7, optionally combined with other fillers, which enhances the coating's resilience and wear resistance, increasing the peak load capacity to up to 120 MPa.

Environmental Impact of Anti-Friction Coatings

The environmental impact of anti-friction coatings in B58 engine wear resistance improvement is a crucial aspect to consider in the development and application of these technologies. These coatings, while primarily designed to enhance engine performance and longevity, also have significant implications for environmental sustainability.

One of the primary environmental benefits of anti-friction coatings is their potential to reduce fuel consumption. By minimizing friction between engine components, these coatings can improve overall engine efficiency, leading to lower fuel usage and, consequently, reduced greenhouse gas emissions. This aligns with global efforts to combat climate change and meet increasingly stringent environmental regulations in the automotive industry.

However, the production and application of anti-friction coatings also present environmental challenges. The manufacturing process often involves the use of various chemicals and materials, some of which may have negative environmental impacts if not properly managed. These can include volatile organic compounds (VOCs), heavy metals, and other potentially harmful substances. Proper disposal and recycling of coating materials and byproducts are essential to mitigate these risks.

The durability of anti-friction coatings is another factor influencing their environmental impact. Coatings that wear off quickly may need frequent reapplication, leading to increased resource consumption and waste generation. Conversely, highly durable coatings can extend the lifespan of engine components, reducing the need for replacements and thereby conserving resources and energy associated with manufacturing new parts.

Water usage and contamination are additional environmental concerns in the coating process. Some coating technologies require significant amounts of water for application or cleaning, potentially straining local water resources. Moreover, if not properly treated, wastewater from these processes can contain pollutants that may harm aquatic ecosystems if released into the environment.

The end-of-life disposal of coated engine components also warrants consideration. While the coatings themselves may not significantly impact recycling processes, the presence of certain coating materials could complicate the separation and recovery of base metals from engine parts. This underscores the importance of designing coatings with recyclability in mind.

Advancements in eco-friendly coating technologies are addressing many of these environmental concerns. Research is ongoing into bio-based and water-based coating formulations that reduce reliance on petroleum-derived materials and minimize VOC emissions. Additionally, innovations in application techniques, such as precision spraying and electrostatic deposition, are improving coating efficiency and reducing waste.

In conclusion, while anti-friction coatings offer significant potential for improving engine efficiency and reducing emissions during vehicle operation, their overall environmental impact must be carefully evaluated across the entire lifecycle. Balancing performance benefits with environmental considerations is crucial for the sustainable development and implementation of these technologies in B58 engines and beyond.

One of the primary environmental benefits of anti-friction coatings is their potential to reduce fuel consumption. By minimizing friction between engine components, these coatings can improve overall engine efficiency, leading to lower fuel usage and, consequently, reduced greenhouse gas emissions. This aligns with global efforts to combat climate change and meet increasingly stringent environmental regulations in the automotive industry.

However, the production and application of anti-friction coatings also present environmental challenges. The manufacturing process often involves the use of various chemicals and materials, some of which may have negative environmental impacts if not properly managed. These can include volatile organic compounds (VOCs), heavy metals, and other potentially harmful substances. Proper disposal and recycling of coating materials and byproducts are essential to mitigate these risks.

The durability of anti-friction coatings is another factor influencing their environmental impact. Coatings that wear off quickly may need frequent reapplication, leading to increased resource consumption and waste generation. Conversely, highly durable coatings can extend the lifespan of engine components, reducing the need for replacements and thereby conserving resources and energy associated with manufacturing new parts.

Water usage and contamination are additional environmental concerns in the coating process. Some coating technologies require significant amounts of water for application or cleaning, potentially straining local water resources. Moreover, if not properly treated, wastewater from these processes can contain pollutants that may harm aquatic ecosystems if released into the environment.

The end-of-life disposal of coated engine components also warrants consideration. While the coatings themselves may not significantly impact recycling processes, the presence of certain coating materials could complicate the separation and recovery of base metals from engine parts. This underscores the importance of designing coatings with recyclability in mind.

Advancements in eco-friendly coating technologies are addressing many of these environmental concerns. Research is ongoing into bio-based and water-based coating formulations that reduce reliance on petroleum-derived materials and minimize VOC emissions. Additionally, innovations in application techniques, such as precision spraying and electrostatic deposition, are improving coating efficiency and reducing waste.

In conclusion, while anti-friction coatings offer significant potential for improving engine efficiency and reducing emissions during vehicle operation, their overall environmental impact must be carefully evaluated across the entire lifecycle. Balancing performance benefits with environmental considerations is crucial for the sustainable development and implementation of these technologies in B58 engines and beyond.

Cost-Benefit Analysis of Advanced Coating Technologies

The implementation of advanced coating technologies in the B58 engine for wear resistance improvement requires a thorough cost-benefit analysis to determine its economic viability. This analysis encompasses both the direct costs associated with the application of anti-friction coatings and the long-term benefits derived from enhanced engine performance and durability.

Initial investment costs for advanced coating technologies are significant, including the acquisition of specialized equipment, materials, and the training of personnel. The coating process itself may require modifications to existing production lines, potentially leading to temporary disruptions in manufacturing. However, these upfront expenses should be weighed against the potential for reduced warranty claims and increased customer satisfaction resulting from improved engine longevity.

Operational costs may see a slight increase due to the additional step in the manufacturing process and the need for more skilled labor. However, this is often offset by the reduced material costs in other areas of engine production, as coated components may allow for the use of less expensive base materials without compromising performance.

The benefits of implementing anti-friction coatings are multifaceted. Improved wear resistance leads to extended engine life, reducing the frequency of repairs and replacements. This translates to lower maintenance costs for end-users and enhanced brand reputation for the manufacturer. Additionally, the reduction in friction can contribute to improved fuel efficiency, a critical factor in today's environmentally conscious market.

From a marketing perspective, the use of advanced coating technologies can be a significant differentiator in a competitive automotive market. The ability to promote engines with superior durability and performance characteristics can justify premium pricing strategies, potentially increasing profit margins.

Long-term cost savings are expected through reduced warranty claims and decreased need for post-sale servicing. The improved reliability of coated engine components can lead to fewer recalls and warranty-related expenses, which can be substantial for automotive manufacturers.

Environmental considerations also play a role in the cost-benefit analysis. The extended lifespan of engines with anti-friction coatings contributes to resource conservation and waste reduction. This aligns with increasingly stringent environmental regulations and can potentially lead to tax incentives or improved corporate sustainability ratings.

In conclusion, while the initial investment in advanced coating technologies for the B58 engine is substantial, the long-term benefits in terms of improved performance, reduced maintenance costs, and enhanced market positioning suggest a favorable return on investment. A detailed financial model considering all these factors over the projected lifespan of the engine would provide a more precise assessment of the technology's economic viability.

Initial investment costs for advanced coating technologies are significant, including the acquisition of specialized equipment, materials, and the training of personnel. The coating process itself may require modifications to existing production lines, potentially leading to temporary disruptions in manufacturing. However, these upfront expenses should be weighed against the potential for reduced warranty claims and increased customer satisfaction resulting from improved engine longevity.

Operational costs may see a slight increase due to the additional step in the manufacturing process and the need for more skilled labor. However, this is often offset by the reduced material costs in other areas of engine production, as coated components may allow for the use of less expensive base materials without compromising performance.

The benefits of implementing anti-friction coatings are multifaceted. Improved wear resistance leads to extended engine life, reducing the frequency of repairs and replacements. This translates to lower maintenance costs for end-users and enhanced brand reputation for the manufacturer. Additionally, the reduction in friction can contribute to improved fuel efficiency, a critical factor in today's environmentally conscious market.

From a marketing perspective, the use of advanced coating technologies can be a significant differentiator in a competitive automotive market. The ability to promote engines with superior durability and performance characteristics can justify premium pricing strategies, potentially increasing profit margins.

Long-term cost savings are expected through reduced warranty claims and decreased need for post-sale servicing. The improved reliability of coated engine components can lead to fewer recalls and warranty-related expenses, which can be substantial for automotive manufacturers.

Environmental considerations also play a role in the cost-benefit analysis. The extended lifespan of engines with anti-friction coatings contributes to resource conservation and waste reduction. This aligns with increasingly stringent environmental regulations and can potentially lead to tax incentives or improved corporate sustainability ratings.

In conclusion, while the initial investment in advanced coating technologies for the B58 engine is substantial, the long-term benefits in terms of improved performance, reduced maintenance costs, and enhanced market positioning suggest a favorable return on investment. A detailed financial model considering all these factors over the projected lifespan of the engine would provide a more precise assessment of the technology's economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!