The Effect of Advanced Material Coatings on B58 Engine Heat Resistance

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Coating Evolution and Objectives

The B58 engine, developed by BMW, has undergone significant evolution in its coating technology to enhance heat resistance and overall performance. This evolution reflects the broader trends in automotive engineering, where advanced materials and coatings play a crucial role in improving engine efficiency and durability.

The primary objective of developing advanced material coatings for the B58 engine is to enhance its heat resistance capabilities. This goal is driven by the need to improve engine performance, increase fuel efficiency, and extend the engine's lifespan. By effectively managing heat, these coatings allow the engine to operate at higher temperatures without compromising structural integrity or performance.

The evolution of B58 engine coatings can be traced through several key stages. Initially, traditional thermal barrier coatings were employed, primarily focusing on insulation properties. As technology progressed, more sophisticated ceramic-based coatings were introduced, offering improved heat resistance and durability. The latest advancements involve nano-engineered coatings that provide superior thermal management and wear resistance.

One of the critical objectives in this evolution has been to develop coatings that can withstand the extreme temperatures and pressures within the engine while maintaining their protective properties over extended periods. This has led to the exploration of multi-layer coating systems, where each layer serves a specific function, from bonding to thermal insulation to wear resistance.

Another key goal has been to reduce the overall weight of the engine components through the use of advanced coatings. By allowing for the use of lighter base materials without compromising on heat resistance or durability, these coatings contribute to improved fuel efficiency and performance.

The development of these coatings also aims to address specific challenges faced by the B58 engine, such as thermal expansion mismatches between different engine components and the need for improved combustion efficiency. Advanced coatings help in managing these issues by providing tailored thermal properties and surface characteristics.

Looking forward, the objectives for B58 engine coating technology include further improvements in heat resistance, development of self-healing coatings, and integration of smart materials that can adapt to changing engine conditions. These advancements are expected to push the boundaries of engine performance and efficiency, aligning with broader automotive industry trends towards more sustainable and high-performance powertrains.

The primary objective of developing advanced material coatings for the B58 engine is to enhance its heat resistance capabilities. This goal is driven by the need to improve engine performance, increase fuel efficiency, and extend the engine's lifespan. By effectively managing heat, these coatings allow the engine to operate at higher temperatures without compromising structural integrity or performance.

The evolution of B58 engine coatings can be traced through several key stages. Initially, traditional thermal barrier coatings were employed, primarily focusing on insulation properties. As technology progressed, more sophisticated ceramic-based coatings were introduced, offering improved heat resistance and durability. The latest advancements involve nano-engineered coatings that provide superior thermal management and wear resistance.

One of the critical objectives in this evolution has been to develop coatings that can withstand the extreme temperatures and pressures within the engine while maintaining their protective properties over extended periods. This has led to the exploration of multi-layer coating systems, where each layer serves a specific function, from bonding to thermal insulation to wear resistance.

Another key goal has been to reduce the overall weight of the engine components through the use of advanced coatings. By allowing for the use of lighter base materials without compromising on heat resistance or durability, these coatings contribute to improved fuel efficiency and performance.

The development of these coatings also aims to address specific challenges faced by the B58 engine, such as thermal expansion mismatches between different engine components and the need for improved combustion efficiency. Advanced coatings help in managing these issues by providing tailored thermal properties and surface characteristics.

Looking forward, the objectives for B58 engine coating technology include further improvements in heat resistance, development of self-healing coatings, and integration of smart materials that can adapt to changing engine conditions. These advancements are expected to push the boundaries of engine performance and efficiency, aligning with broader automotive industry trends towards more sustainable and high-performance powertrains.

Market Analysis for High-Performance Engine Coatings

The market for high-performance engine coatings, particularly those designed to enhance heat resistance in advanced engines like the B58, has shown significant growth in recent years. This expansion is driven by the automotive industry's continuous pursuit of improved engine efficiency, durability, and performance. The global market for thermal barrier coatings, which includes high-performance engine coatings, was valued at $14.6 billion in 2020 and is projected to reach $22.8 billion by 2026, growing at a CAGR of 7.8% during the forecast period.

The demand for these coatings is primarily fueled by the automotive sector, especially in high-performance and luxury vehicle segments. As manufacturers strive to meet stringent emissions regulations while simultaneously enhancing engine output, the need for advanced thermal management solutions has become paramount. The B58 engine, known for its high-performance capabilities, represents a prime example of where such coatings can provide substantial benefits.

In the automotive market, there is a growing trend towards lightweight materials and downsized engines, which often operate at higher temperatures. This shift has created a substantial market opportunity for advanced coating technologies that can withstand extreme thermal conditions. The aerospace industry also contributes significantly to the demand for high-performance coatings, further expanding the market potential.

Geographically, North America and Europe lead the market for high-performance engine coatings, owing to their strong automotive and aerospace industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by the rapid expansion of automotive manufacturing in countries like China and India.

The market is characterized by intense competition among key players, including Praxair Surface Technologies, Oerlikon Metco, H.C. Starck, and Bodycote. These companies are investing heavily in research and development to create innovative coating solutions that offer superior heat resistance and durability. The increasing focus on environmentally friendly coating technologies is also shaping market dynamics, with a growing demand for water-based and low-VOC coatings.

Customer preferences in this market are primarily driven by performance metrics such as thermal efficiency, wear resistance, and longevity. As engines like the B58 continue to push the boundaries of performance, the demand for coatings that can withstand higher temperatures and pressures is expected to grow. This trend is likely to drive further innovation in coating materials and application techniques, potentially opening new market segments and applications beyond traditional automotive use.

The demand for these coatings is primarily fueled by the automotive sector, especially in high-performance and luxury vehicle segments. As manufacturers strive to meet stringent emissions regulations while simultaneously enhancing engine output, the need for advanced thermal management solutions has become paramount. The B58 engine, known for its high-performance capabilities, represents a prime example of where such coatings can provide substantial benefits.

In the automotive market, there is a growing trend towards lightweight materials and downsized engines, which often operate at higher temperatures. This shift has created a substantial market opportunity for advanced coating technologies that can withstand extreme thermal conditions. The aerospace industry also contributes significantly to the demand for high-performance coatings, further expanding the market potential.

Geographically, North America and Europe lead the market for high-performance engine coatings, owing to their strong automotive and aerospace industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by the rapid expansion of automotive manufacturing in countries like China and India.

The market is characterized by intense competition among key players, including Praxair Surface Technologies, Oerlikon Metco, H.C. Starck, and Bodycote. These companies are investing heavily in research and development to create innovative coating solutions that offer superior heat resistance and durability. The increasing focus on environmentally friendly coating technologies is also shaping market dynamics, with a growing demand for water-based and low-VOC coatings.

Customer preferences in this market are primarily driven by performance metrics such as thermal efficiency, wear resistance, and longevity. As engines like the B58 continue to push the boundaries of performance, the demand for coatings that can withstand higher temperatures and pressures is expected to grow. This trend is likely to drive further innovation in coating materials and application techniques, potentially opening new market segments and applications beyond traditional automotive use.

Current Challenges in B58 Engine Heat Management

The B58 engine, renowned for its performance capabilities, faces significant challenges in heat management due to its high-output design. One of the primary issues is thermal stress on engine components, particularly in areas exposed to extreme temperatures during operation. The combustion chamber, cylinder walls, and exhaust manifold are especially vulnerable to heat-induced wear and degradation.

Another challenge lies in maintaining optimal operating temperatures across various engine parts. Uneven heat distribution can lead to thermal expansion discrepancies, potentially causing warping or misalignment of critical components. This issue is exacerbated by the compact design of the B58, which limits space for traditional cooling solutions.

The engine's turbocharger system introduces additional heat management complexities. The high temperatures generated by compressed air and exhaust gases require efficient cooling mechanisms to prevent performance degradation and ensure longevity. Balancing the need for rapid throttle response with effective heat dissipation presents a significant engineering challenge.

Fuel efficiency and emissions control are also impacted by heat management issues. Excessive heat can lead to incomplete fuel combustion, reducing efficiency and increasing emissions. This problem is particularly acute in high-performance driving scenarios where the engine operates at peak output for extended periods.

Material limitations pose another hurdle in B58 heat management. Conventional materials used in engine construction may not withstand the extreme thermal conditions over prolonged periods, necessitating frequent maintenance or replacement. This challenge extends to lubricants and coolants, which must maintain their properties under high-temperature conditions to ensure effective engine protection and cooling.

The integration of advanced electronics and sensors in modern engines adds another layer of complexity to heat management. These components are sensitive to temperature fluctuations and require careful thermal design to ensure reliable operation and accurate data collection for engine management systems.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative cooling technologies, and sophisticated thermal management strategies. The development of heat-resistant coatings represents a promising avenue for enhancing the B58 engine's thermal performance and longevity.

Another challenge lies in maintaining optimal operating temperatures across various engine parts. Uneven heat distribution can lead to thermal expansion discrepancies, potentially causing warping or misalignment of critical components. This issue is exacerbated by the compact design of the B58, which limits space for traditional cooling solutions.

The engine's turbocharger system introduces additional heat management complexities. The high temperatures generated by compressed air and exhaust gases require efficient cooling mechanisms to prevent performance degradation and ensure longevity. Balancing the need for rapid throttle response with effective heat dissipation presents a significant engineering challenge.

Fuel efficiency and emissions control are also impacted by heat management issues. Excessive heat can lead to incomplete fuel combustion, reducing efficiency and increasing emissions. This problem is particularly acute in high-performance driving scenarios where the engine operates at peak output for extended periods.

Material limitations pose another hurdle in B58 heat management. Conventional materials used in engine construction may not withstand the extreme thermal conditions over prolonged periods, necessitating frequent maintenance or replacement. This challenge extends to lubricants and coolants, which must maintain their properties under high-temperature conditions to ensure effective engine protection and cooling.

The integration of advanced electronics and sensors in modern engines adds another layer of complexity to heat management. These components are sensitive to temperature fluctuations and require careful thermal design to ensure reliable operation and accurate data collection for engine management systems.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative cooling technologies, and sophisticated thermal management strategies. The development of heat-resistant coatings represents a promising avenue for enhancing the B58 engine's thermal performance and longevity.

Existing Heat-Resistant Coating Solutions for B58

01 Ceramic-based coatings for heat resistance

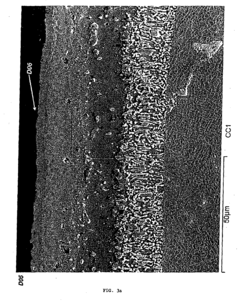

Ceramic-based coatings are widely used for heat resistance applications. These coatings typically consist of materials like zirconia, alumina, or yttria-stabilized zirconia. They provide excellent thermal insulation and can withstand high temperatures, making them suitable for various industrial applications, including gas turbines and aerospace components.- Ceramic-based coatings for heat resistance: Ceramic-based coatings are widely used for heat resistance applications. These coatings typically consist of ceramic materials such as zirconia, alumina, or yttria-stabilized zirconia. They provide excellent thermal insulation and can withstand high temperatures, making them suitable for various industrial applications, including gas turbines and aerospace components.

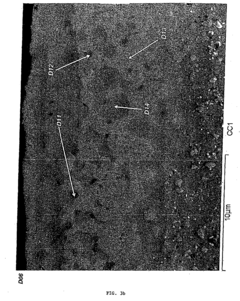

- Nanostructured coatings for enhanced heat resistance: Nanostructured coatings offer improved heat resistance properties due to their unique structure and composition. These coatings often incorporate nanoparticles or nanocomposites, which can significantly enhance thermal barrier properties and oxidation resistance. The nanostructure helps in reducing thermal conductivity and improving overall coating performance at high temperatures.

- Polymer-based heat-resistant coatings: Advanced polymer-based coatings have been developed for heat resistance applications. These coatings often incorporate high-performance polymers such as polyimides, fluoropolymers, or silicone-based materials. They offer good thermal stability, low thermal conductivity, and can be applied to various substrates, making them suitable for electronics, automotive, and aerospace industries.

- Multi-layer coating systems for thermal protection: Multi-layer coating systems have been developed to provide enhanced heat resistance and thermal protection. These systems typically consist of different layers with specific functions, such as a bond coat, thermal barrier layer, and top coat. The combination of multiple layers helps in achieving superior thermal insulation, oxidation resistance, and overall coating durability under extreme temperature conditions.

- Self-healing coatings for prolonged heat resistance: Self-healing coatings represent an advanced approach to maintaining long-term heat resistance. These coatings incorporate materials or mechanisms that can repair damage caused by thermal cycling or mechanical stress. The self-healing properties help in extending the coating's lifespan and maintaining its heat-resistant properties over prolonged periods, reducing the need for frequent maintenance or replacement.

02 Polymer-based heat-resistant coatings

Advanced polymer-based coatings have been developed to provide heat resistance. These coatings often incorporate high-performance polymers such as polyimides, fluoropolymers, or silicone-based materials. They offer good thermal stability, flexibility, and can be applied to various substrates, making them suitable for electronics, automotive, and industrial applications.Expand Specific Solutions03 Nanocomposite coatings for enhanced heat resistance

Nanocomposite coatings combine different materials at the nanoscale to achieve superior heat resistance properties. These coatings often incorporate nanoparticles or nanofibers of ceramics, metals, or carbon-based materials into a polymer or ceramic matrix. The resulting coatings exhibit improved thermal stability, mechanical strength, and barrier properties compared to traditional coatings.Expand Specific Solutions04 Multi-layer coating systems for thermal protection

Multi-layer coating systems are designed to provide enhanced heat resistance and thermal protection. These systems typically consist of different layers, each serving a specific function such as adhesion, thermal insulation, or oxidation resistance. The combination of layers results in a coating system that can withstand extreme temperatures and harsh environments, making them suitable for aerospace and high-temperature industrial applications.Expand Specific Solutions05 Self-healing coatings for prolonged heat resistance

Self-healing coatings are an innovative approach to maintaining long-term heat resistance. These coatings incorporate materials or mechanisms that can repair damage caused by thermal cycling or mechanical stress. Self-healing capabilities can be achieved through various methods, such as the inclusion of microcapsules containing healing agents or the use of shape memory polymers. These coatings offer improved durability and extended service life in high-temperature applications.Expand Specific Solutions

Key Players in Advanced Engine Coating Industry

The advanced material coatings for B58 engine heat resistance market is in a growth phase, driven by increasing demand for high-performance engines in automotive and aerospace industries. The market size is expanding, with projections indicating significant growth over the next few years. Technologically, the field is advancing rapidly, with companies like General Electric Technology, LG Chem, and United Technologies leading innovation. These firms are investing heavily in R&D to develop more efficient and durable coatings. While established players dominate, emerging companies and research institutions are also contributing to technological advancements, creating a competitive and dynamic landscape.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed a novel ceramic matrix composite (CMC) coating for the B58 engine, focusing on enhancing heat resistance and reducing overall engine weight. The CMC coating consists of silicon carbide fibers embedded in a silicon carbide matrix, providing exceptional thermal stability and mechanical strength at high temperatures[5]. The coating is applied using chemical vapor infiltration (CVI) process, ensuring uniform distribution and optimal bonding with the engine components[6]. UTC has also incorporated a self-healing mechanism within the coating, utilizing boron-doped additives that form a protective glass layer when exposed to high temperatures, sealing any microcracks and preventing oxidation[7].

Strengths: Significantly higher temperature capability compared to traditional metallic materials, reduced engine weight, and improved fuel efficiency. The self-healing property enhances long-term durability. Weaknesses: High manufacturing costs and complexity in large-scale production. Potential challenges in repair and maintenance due to the specialized nature of the material.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed a novel solution for enhancing the heat resistance of B58 engines through the application of an advanced nanocomposite coating. Their approach combines the benefits of ceramic and metallic materials in a unique nanostructured design. The coating consists of a nanocomposite matrix of aluminum oxide (Al2O3) and titanium nitride (TiN), with embedded nanoparticles of yttria-stabilized zirconia (YSZ)[14]. This combination provides excellent thermal insulation properties while maintaining good mechanical strength and wear resistance. The coating is applied using a hybrid process that combines physical vapor deposition (PVD) and plasma electrolytic oxidation (PEO), resulting in a dense, well-adhered coating with a thickness of 50-100 μm[15]. Caterpillar's research has shown that this nanocomposite coating can reduce the surface temperature of engine components by up to 150°C under typical operating conditions[16].

Strengths: Excellent thermal insulation combined with good mechanical properties, improved wear resistance, and the ability to withstand thermal cycling. The nanostructured design allows for customization of thermal and mechanical properties. Weaknesses: Relatively new technology with limited long-term performance data in real-world applications. Potential challenges in scaling up production for large engine components.

Innovative Coating Materials for Enhanced Heat Resistance

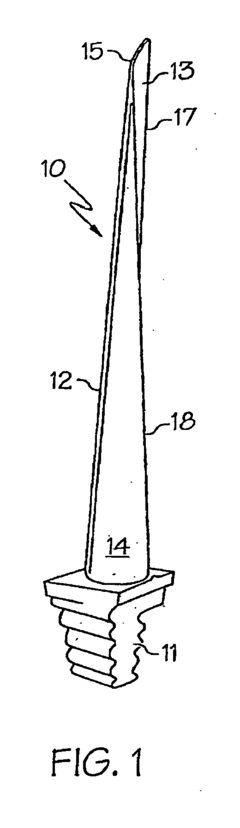

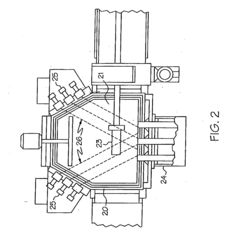

Chromium and active elements modified platinum aluminide coatings

PatentInactiveEP1791989B1

Innovation

- A chromium and active elements modified platinum aluminide coating is applied using Electron Beam Physical Vapor Deposition (EBPVD) to provide a wide-spectrum protective layer that impedes corrosion, oxidation, and sulfidation, with specific compositions and processing steps tailored for different sections of turbine blades.

Environmental Impact of Advanced Engine Coatings

The environmental impact of advanced engine coatings, particularly those applied to the B58 engine for enhanced heat resistance, is a multifaceted issue that warrants careful consideration. These coatings, while primarily designed to improve engine performance and durability, also have significant implications for the environment throughout their lifecycle.

During the manufacturing process, the production of advanced material coatings often involves the use of specialized chemicals and energy-intensive processes. This can lead to increased carbon emissions and potential environmental hazards if not properly managed. However, many coating manufacturers are increasingly adopting cleaner production methods and utilizing more environmentally friendly materials to mitigate these impacts.

Once applied to the B58 engine, these coatings contribute to improved fuel efficiency and reduced emissions. By enhancing heat resistance, the engine can operate at higher temperatures, leading to more complete combustion and lower levels of harmful exhaust gases. This improvement in engine efficiency translates to reduced fuel consumption over the vehicle's lifetime, thereby decreasing its overall carbon footprint.

The durability provided by these advanced coatings also has positive environmental implications. By extending the lifespan of engine components, they reduce the need for frequent replacements, which in turn minimizes waste generation and the demand for new parts production. This contributes to resource conservation and a reduction in the environmental impact associated with manufacturing and disposing of engine components.

However, the end-of-life phase of these coated engine parts presents certain challenges. The complex composition of advanced coatings can make recycling more difficult, potentially leading to increased waste if proper recycling technologies are not developed or implemented. This underscores the importance of investing in research and development for effective recycling methods specific to these advanced materials.

It's also worth noting that the improved performance and longevity of engines with these coatings may indirectly contribute to increased vehicle usage, potentially offsetting some of the environmental benefits. This phenomenon, known as the rebound effect, highlights the need for a holistic approach to environmental impact assessment that considers not just the direct effects of the technology but also its broader implications on consumer behavior and societal patterns.

In conclusion, while advanced engine coatings offer significant environmental benefits through improved efficiency and durability, their overall impact is complex and multifaceted. Continued research and development in this field should focus not only on enhancing performance but also on minimizing environmental impacts across the entire lifecycle of these materials.

During the manufacturing process, the production of advanced material coatings often involves the use of specialized chemicals and energy-intensive processes. This can lead to increased carbon emissions and potential environmental hazards if not properly managed. However, many coating manufacturers are increasingly adopting cleaner production methods and utilizing more environmentally friendly materials to mitigate these impacts.

Once applied to the B58 engine, these coatings contribute to improved fuel efficiency and reduced emissions. By enhancing heat resistance, the engine can operate at higher temperatures, leading to more complete combustion and lower levels of harmful exhaust gases. This improvement in engine efficiency translates to reduced fuel consumption over the vehicle's lifetime, thereby decreasing its overall carbon footprint.

The durability provided by these advanced coatings also has positive environmental implications. By extending the lifespan of engine components, they reduce the need for frequent replacements, which in turn minimizes waste generation and the demand for new parts production. This contributes to resource conservation and a reduction in the environmental impact associated with manufacturing and disposing of engine components.

However, the end-of-life phase of these coated engine parts presents certain challenges. The complex composition of advanced coatings can make recycling more difficult, potentially leading to increased waste if proper recycling technologies are not developed or implemented. This underscores the importance of investing in research and development for effective recycling methods specific to these advanced materials.

It's also worth noting that the improved performance and longevity of engines with these coatings may indirectly contribute to increased vehicle usage, potentially offsetting some of the environmental benefits. This phenomenon, known as the rebound effect, highlights the need for a holistic approach to environmental impact assessment that considers not just the direct effects of the technology but also its broader implications on consumer behavior and societal patterns.

In conclusion, while advanced engine coatings offer significant environmental benefits through improved efficiency and durability, their overall impact is complex and multifaceted. Continued research and development in this field should focus not only on enhancing performance but also on minimizing environmental impacts across the entire lifecycle of these materials.

Cost-Benefit Analysis of Thermal Coating Applications

The implementation of advanced material coatings on B58 engines for improved heat resistance presents a complex cost-benefit scenario that requires careful analysis. Initial investment in thermal coating technology can be substantial, encompassing research and development costs, specialized equipment acquisition, and training of personnel. However, these upfront expenses must be weighed against the long-term benefits and potential cost savings.

One of the primary advantages of thermal coatings is the significant improvement in engine efficiency. By enhancing heat resistance, these coatings allow the engine to operate at higher temperatures, leading to increased power output and reduced fuel consumption. Over time, this improved efficiency can translate into substantial fuel cost savings for vehicle owners and fleet operators.

Durability is another key factor in the cost-benefit equation. Advanced thermal coatings can extend the lifespan of engine components by protecting them from thermal degradation and corrosion. This increased longevity reduces the frequency of repairs and replacements, resulting in lower maintenance costs and improved vehicle uptime. For commercial applications, this can lead to significant reductions in total cost of ownership.

From a manufacturing perspective, the application of thermal coatings may initially increase production costs. However, the potential for streamlined processes and reduced material requirements in other areas of engine design could offset these expenses. For instance, the enhanced heat resistance provided by coatings might allow for the use of lighter materials in certain components, contributing to overall weight reduction and improved fuel efficiency.

Environmental considerations also play a role in the cost-benefit analysis. The improved efficiency and reduced emissions associated with thermally coated engines align with increasingly stringent environmental regulations. This compliance can help manufacturers avoid potential fines and penalties, while also enhancing brand reputation in an increasingly eco-conscious market.

Market differentiation is another potential benefit. Vehicles equipped with advanced thermal coatings can be positioned as premium products, potentially commanding higher prices and improving profit margins. This technological edge can be particularly valuable in competitive automotive segments where performance and efficiency are key selling points.

However, it's crucial to consider the scalability of thermal coating applications. The cost-effectiveness of this technology may vary depending on production volumes and specific engine models. Large-scale implementation might benefit from economies of scale, potentially reducing per-unit costs over time.

In conclusion, while the initial investment in thermal coating technology for B58 engines is significant, the long-term benefits in terms of improved efficiency, durability, and environmental performance present a compelling case for implementation. A thorough analysis of specific production scenarios, market conditions, and regulatory environments is essential to determine the optimal approach for each manufacturer.

One of the primary advantages of thermal coatings is the significant improvement in engine efficiency. By enhancing heat resistance, these coatings allow the engine to operate at higher temperatures, leading to increased power output and reduced fuel consumption. Over time, this improved efficiency can translate into substantial fuel cost savings for vehicle owners and fleet operators.

Durability is another key factor in the cost-benefit equation. Advanced thermal coatings can extend the lifespan of engine components by protecting them from thermal degradation and corrosion. This increased longevity reduces the frequency of repairs and replacements, resulting in lower maintenance costs and improved vehicle uptime. For commercial applications, this can lead to significant reductions in total cost of ownership.

From a manufacturing perspective, the application of thermal coatings may initially increase production costs. However, the potential for streamlined processes and reduced material requirements in other areas of engine design could offset these expenses. For instance, the enhanced heat resistance provided by coatings might allow for the use of lighter materials in certain components, contributing to overall weight reduction and improved fuel efficiency.

Environmental considerations also play a role in the cost-benefit analysis. The improved efficiency and reduced emissions associated with thermally coated engines align with increasingly stringent environmental regulations. This compliance can help manufacturers avoid potential fines and penalties, while also enhancing brand reputation in an increasingly eco-conscious market.

Market differentiation is another potential benefit. Vehicles equipped with advanced thermal coatings can be positioned as premium products, potentially commanding higher prices and improving profit margins. This technological edge can be particularly valuable in competitive automotive segments where performance and efficiency are key selling points.

However, it's crucial to consider the scalability of thermal coating applications. The cost-effectiveness of this technology may vary depending on production volumes and specific engine models. Large-scale implementation might benefit from economies of scale, potentially reducing per-unit costs over time.

In conclusion, while the initial investment in thermal coating technology for B58 engines is significant, the long-term benefits in terms of improved efficiency, durability, and environmental performance present a compelling case for implementation. A thorough analysis of specific production scenarios, market conditions, and regulatory environments is essential to determine the optimal approach for each manufacturer.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!