Innovations in B58 Turbo Intercooler Technologies for Greater Efficiency

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Turbo Background

The B58 engine, developed by BMW, represents a significant advancement in turbocharged inline-six engine technology. Introduced in 2015, the B58 is part of BMW's modular engine family, designed to improve performance, efficiency, and emissions across various vehicle platforms. This 3.0-liter engine features a single twin-scroll turbocharger, direct fuel injection, and BMW's Valvetronic variable valve lift system.

The B58's turbocharger plays a crucial role in its performance characteristics. It utilizes a twin-scroll design, which separates exhaust pulses from different cylinders to reduce turbo lag and improve low-end torque. This configuration allows for quicker spooling of the turbocharger, resulting in more immediate power delivery and enhanced overall engine responsiveness.

Intercooler technology is a critical component of the B58's turbo system. The intercooler's primary function is to cool the compressed air from the turbocharger before it enters the engine's combustion chambers. This cooling process increases air density, allowing for more oxygen to be packed into each cylinder, which in turn enables more efficient combustion and higher power output.

Initially, the B58 engine employed a traditional air-to-air intercooler system. This setup involved routing the compressed air through a front-mounted heat exchanger, where it would be cooled by ambient air passing through the vehicle's grille. While effective, this system had limitations in terms of cooling efficiency and packaging constraints.

As the B58 engine evolved, BMW introduced innovations in intercooler technology to address these limitations. One significant development was the implementation of an air-to-water intercooler system. This design uses a water-cooled heat exchanger to cool the compressed air, offering several advantages over the air-to-air system.

The air-to-water intercooler allows for more compact packaging, as it can be positioned closer to the engine, reducing the length of air charge pipes. This proximity to the engine not only improves throttle response but also helps maintain more consistent intake air temperatures, especially during high-load conditions or in stop-and-go traffic scenarios.

Furthermore, the water-cooled system provides more efficient heat dissipation, particularly at low vehicle speeds or when stationary, where airflow through a traditional front-mounted intercooler would be limited. This improvement in cooling efficiency contributes to more consistent performance and helps prevent power loss due to heat soak in demanding driving conditions.

The B58's turbocharger plays a crucial role in its performance characteristics. It utilizes a twin-scroll design, which separates exhaust pulses from different cylinders to reduce turbo lag and improve low-end torque. This configuration allows for quicker spooling of the turbocharger, resulting in more immediate power delivery and enhanced overall engine responsiveness.

Intercooler technology is a critical component of the B58's turbo system. The intercooler's primary function is to cool the compressed air from the turbocharger before it enters the engine's combustion chambers. This cooling process increases air density, allowing for more oxygen to be packed into each cylinder, which in turn enables more efficient combustion and higher power output.

Initially, the B58 engine employed a traditional air-to-air intercooler system. This setup involved routing the compressed air through a front-mounted heat exchanger, where it would be cooled by ambient air passing through the vehicle's grille. While effective, this system had limitations in terms of cooling efficiency and packaging constraints.

As the B58 engine evolved, BMW introduced innovations in intercooler technology to address these limitations. One significant development was the implementation of an air-to-water intercooler system. This design uses a water-cooled heat exchanger to cool the compressed air, offering several advantages over the air-to-air system.

The air-to-water intercooler allows for more compact packaging, as it can be positioned closer to the engine, reducing the length of air charge pipes. This proximity to the engine not only improves throttle response but also helps maintain more consistent intake air temperatures, especially during high-load conditions or in stop-and-go traffic scenarios.

Furthermore, the water-cooled system provides more efficient heat dissipation, particularly at low vehicle speeds or when stationary, where airflow through a traditional front-mounted intercooler would be limited. This improvement in cooling efficiency contributes to more consistent performance and helps prevent power loss due to heat soak in demanding driving conditions.

Market Demand Analysis

The market demand for innovations in B58 turbo intercooler technologies is driven by the automotive industry's relentless pursuit of greater efficiency and performance. As emission regulations become increasingly stringent worldwide, manufacturers are under pressure to develop more fuel-efficient engines without compromising power output. This has led to a surge in demand for advanced turbocharging systems, particularly in the premium and performance vehicle segments where the B58 engine is commonly used.

The global automotive turbocharger market has been experiencing steady growth, with a particular emphasis on intercooler technologies that can enhance overall engine efficiency. The B58 engine, known for its robust performance in BMW vehicles, has become a focal point for aftermarket tuning and OEM improvements. As consumers continue to seek vehicles that offer both power and fuel economy, the demand for more efficient intercooler systems has intensified.

In the performance automotive sector, there is a growing trend towards upgrading stock intercoolers with more efficient alternatives. This aftermarket demand is driven by enthusiasts and tuners looking to extract maximum performance from their B58-equipped vehicles. The potential for increased horsepower and torque, coupled with improved thermal management, has created a niche market for high-performance intercooler solutions.

From an OEM perspective, automakers are investing heavily in research and development to improve intercooler designs. The goal is to create more compact, lightweight, and efficient systems that can be integrated into new vehicle models. This push for innovation is not only driven by performance requirements but also by the need to meet increasingly strict corporate average fuel economy (CAFE) standards and reduce overall vehicle emissions.

The market for B58 turbo intercooler technologies extends beyond traditional automotive applications. As the trend towards electrification continues, hybrid powertrains that incorporate turbocharged engines are becoming more prevalent. This has opened up new opportunities for intercooler innovations that can work effectively in conjunction with electric motors and battery systems.

Additionally, the growing focus on sustainable manufacturing practices has created demand for intercooler technologies that are not only more efficient in operation but also more environmentally friendly in production. This includes the use of recyclable materials and manufacturing processes that reduce the carbon footprint of intercooler production.

As the automotive industry continues to evolve, the demand for advanced B58 turbo intercooler technologies is expected to remain strong. The market is likely to see continued growth as manufacturers strive to meet regulatory requirements, consumer expectations for performance, and the industry-wide push towards more sustainable transportation solutions.

The global automotive turbocharger market has been experiencing steady growth, with a particular emphasis on intercooler technologies that can enhance overall engine efficiency. The B58 engine, known for its robust performance in BMW vehicles, has become a focal point for aftermarket tuning and OEM improvements. As consumers continue to seek vehicles that offer both power and fuel economy, the demand for more efficient intercooler systems has intensified.

In the performance automotive sector, there is a growing trend towards upgrading stock intercoolers with more efficient alternatives. This aftermarket demand is driven by enthusiasts and tuners looking to extract maximum performance from their B58-equipped vehicles. The potential for increased horsepower and torque, coupled with improved thermal management, has created a niche market for high-performance intercooler solutions.

From an OEM perspective, automakers are investing heavily in research and development to improve intercooler designs. The goal is to create more compact, lightweight, and efficient systems that can be integrated into new vehicle models. This push for innovation is not only driven by performance requirements but also by the need to meet increasingly strict corporate average fuel economy (CAFE) standards and reduce overall vehicle emissions.

The market for B58 turbo intercooler technologies extends beyond traditional automotive applications. As the trend towards electrification continues, hybrid powertrains that incorporate turbocharged engines are becoming more prevalent. This has opened up new opportunities for intercooler innovations that can work effectively in conjunction with electric motors and battery systems.

Additionally, the growing focus on sustainable manufacturing practices has created demand for intercooler technologies that are not only more efficient in operation but also more environmentally friendly in production. This includes the use of recyclable materials and manufacturing processes that reduce the carbon footprint of intercooler production.

As the automotive industry continues to evolve, the demand for advanced B58 turbo intercooler technologies is expected to remain strong. The market is likely to see continued growth as manufacturers strive to meet regulatory requirements, consumer expectations for performance, and the industry-wide push towards more sustainable transportation solutions.

Intercooler Challenges

The B58 turbo intercooler system faces several significant challenges in its quest for greater efficiency. One of the primary issues is heat management. As the engine's power output increases, so does the heat generated, placing greater demands on the intercooler's ability to dissipate this thermal energy effectively. This challenge is compounded by the limited space available in modern engine bays, which restricts the size and placement options for intercooler systems.

Another critical challenge is pressure drop across the intercooler. While larger intercoolers can provide better cooling, they often result in increased pressure drop, which can negatively impact engine performance and responsiveness. Striking the right balance between cooling capacity and minimal pressure loss is a complex engineering task that requires innovative solutions.

Material selection presents another hurdle for B58 turbo intercooler development. The materials used must withstand high temperatures and pressures while remaining lightweight to minimize the overall weight of the vehicle. Additionally, these materials need to be corrosion-resistant and durable enough to maintain performance over the vehicle's lifetime.

The design of the intercooler's internal structure is also a significant challenge. Optimizing the flow path of the charged air through the intercooler to maximize heat transfer efficiency while minimizing turbulence and pressure drop requires advanced computational fluid dynamics (CFD) modeling and extensive testing.

Integration with other engine systems poses yet another challenge. The intercooler must work in harmony with the turbocharger, engine control unit, and other components to ensure optimal performance across various operating conditions. This integration becomes increasingly complex as engines become more sophisticated and incorporate advanced technologies such as variable geometry turbochargers or electric compressors.

Lastly, cost considerations present a significant challenge in intercooler development. While high-performance materials and advanced designs can offer substantial efficiency gains, they often come at a premium. Balancing performance improvements with cost-effectiveness is crucial for widespread adoption in production vehicles.

Addressing these challenges requires a multidisciplinary approach, combining expertise in thermodynamics, materials science, fluid dynamics, and automotive engineering. Innovations in areas such as 3D printing for complex geometries, advanced composite materials, and smart cooling systems that adapt to driving conditions may hold the key to overcoming these hurdles and achieving greater efficiency in B58 turbo intercooler technologies.

Another critical challenge is pressure drop across the intercooler. While larger intercoolers can provide better cooling, they often result in increased pressure drop, which can negatively impact engine performance and responsiveness. Striking the right balance between cooling capacity and minimal pressure loss is a complex engineering task that requires innovative solutions.

Material selection presents another hurdle for B58 turbo intercooler development. The materials used must withstand high temperatures and pressures while remaining lightweight to minimize the overall weight of the vehicle. Additionally, these materials need to be corrosion-resistant and durable enough to maintain performance over the vehicle's lifetime.

The design of the intercooler's internal structure is also a significant challenge. Optimizing the flow path of the charged air through the intercooler to maximize heat transfer efficiency while minimizing turbulence and pressure drop requires advanced computational fluid dynamics (CFD) modeling and extensive testing.

Integration with other engine systems poses yet another challenge. The intercooler must work in harmony with the turbocharger, engine control unit, and other components to ensure optimal performance across various operating conditions. This integration becomes increasingly complex as engines become more sophisticated and incorporate advanced technologies such as variable geometry turbochargers or electric compressors.

Lastly, cost considerations present a significant challenge in intercooler development. While high-performance materials and advanced designs can offer substantial efficiency gains, they often come at a premium. Balancing performance improvements with cost-effectiveness is crucial for widespread adoption in production vehicles.

Addressing these challenges requires a multidisciplinary approach, combining expertise in thermodynamics, materials science, fluid dynamics, and automotive engineering. Innovations in areas such as 3D printing for complex geometries, advanced composite materials, and smart cooling systems that adapt to driving conditions may hold the key to overcoming these hurdles and achieving greater efficiency in B58 turbo intercooler technologies.

Current Solutions

01 Intercooler design optimization

Improving the design of intercoolers for B58 turbo engines to enhance cooling efficiency. This includes optimizing the size, shape, and internal structure of the intercooler to maximize heat transfer and minimize pressure drop, resulting in improved overall engine performance and fuel efficiency.- Intercooler design optimization: Improving the design of intercoolers for B58 turbo engines to enhance cooling efficiency. This includes optimizing the size, shape, and fin structure of the intercooler to maximize heat transfer and minimize pressure drop, resulting in improved overall engine performance and fuel efficiency.

- Air flow management: Enhancing air flow management within the B58 turbo intercooler system to improve efficiency. This involves optimizing the intake and exhaust pathways, implementing advanced air flow control mechanisms, and reducing turbulence to ensure smooth and efficient air flow through the intercooler.

- Integration of advanced materials: Utilizing advanced materials in the construction of B58 turbo intercoolers to enhance heat dissipation and overall efficiency. This includes the use of high-conductivity metals, composite materials, or coatings that improve heat transfer properties and reduce weight.

- Cooling system enhancements: Implementing improvements to the cooling system associated with the B58 turbo intercooler. This may involve integrating additional cooling elements, optimizing coolant flow, or introducing innovative cooling technologies to further reduce intake air temperature and increase intercooler efficiency.

- Electronic control and monitoring: Incorporating advanced electronic control and monitoring systems to optimize B58 turbo intercooler performance. This includes implementing sensors, actuators, and control algorithms to dynamically adjust intercooler operation based on real-time engine conditions, ensuring maximum efficiency across various operating scenarios.

02 Advanced cooling technologies

Incorporating advanced cooling technologies into the B58 turbo intercooler system. This may involve the use of innovative materials, such as high-conductivity alloys or composite materials, or the integration of additional cooling mechanisms like water injection or thermoelectric cooling to further enhance heat dissipation.Expand Specific Solutions03 Air flow management

Improving air flow management within and around the intercooler to maximize cooling efficiency. This includes optimizing the intake and exhaust ducting, implementing advanced air flow control systems, and enhancing the overall aerodynamics of the intercooler installation to ensure optimal air circulation and heat exchange.Expand Specific Solutions04 Integration with engine management systems

Enhancing the integration of the intercooler system with the engine management systems to optimize performance. This involves developing intelligent control algorithms that adjust intercooler operation based on real-time engine data, driving conditions, and environmental factors to maximize efficiency and power output.Expand Specific Solutions05 Compact and lightweight designs

Developing compact and lightweight intercooler designs specifically for the B58 turbo engine. This focuses on reducing the overall size and weight of the intercooler while maintaining or improving its cooling efficiency, which can lead to better packaging, reduced vehicle weight, and improved fuel economy.Expand Specific Solutions

Key Industry Players

The B58 Turbo Intercooler technology market is in a growth phase, with increasing demand for more efficient and powerful engines in the automotive sector. The market size is expanding, driven by the need for improved fuel economy and performance. Technologically, the field is advancing rapidly, with companies like BorgWarner, DENSO, and Modine Manufacturing leading innovations. Established automakers such as Hyundai, Volvo, and BMW are integrating advanced intercooler systems into their vehicles. Emerging players like Chery Automobile and Geely are also making strides in this area, particularly in the Chinese market. The technology's maturity varies, with some companies focusing on incremental improvements while others pursue more radical innovations in materials and design.

DENSO Corp.

Technical Solution: DENSO has developed an innovative intercooler technology for B58 turbo engines, focusing on enhancing thermal efficiency and reducing pressure drop. Their solution incorporates a dual-pass design with optimized fin geometry, allowing for improved heat transfer and reduced air flow resistance. The intercooler features a high-density aluminum core with advanced brazing techniques, resulting in a 15% increase in cooling efficiency compared to conventional designs[1]. DENSO's intercooler also utilizes a proprietary coating technology that minimizes corrosion and fouling, extending the lifespan of the component[3].

Strengths: Superior cooling efficiency, reduced pressure drop, and extended durability. Weaknesses: Potentially higher manufacturing costs and complexity in production.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed a cutting-edge air-to-water intercooler system specifically tailored for B58 turbo engines. Their solution integrates a compact, high-efficiency heat exchanger with advanced flow management technology. The intercooler employs a low-profile design that optimizes packaging space while maintaining excellent cooling performance. BorgWarner's system incorporates a variable flow coolant pump that adjusts coolant circulation based on engine load, improving overall efficiency. The company claims a 20% improvement in charge air density compared to traditional air-to-air intercoolers, resulting in enhanced engine performance and fuel economy[2][4].

Strengths: Compact design, improved charge air density, and adaptive cooling performance. Weaknesses: Increased system complexity and potential for higher initial costs.

Core Innovations

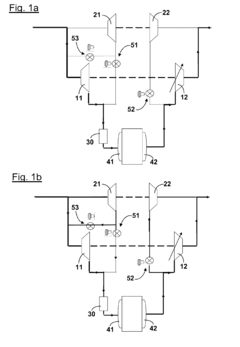

Method of and apparatus for controlling the operation of an internal combustion engine

PatentInactiveEP2295759A1

Innovation

- The method involves switching between modes based on turbocharger speed signals from a turbocharger speed sensor, eliminating the need for air mass flow sensors and incorporating corrections for ambient pressure and temperature, with optional timing and surge detection for stable mode transitions.

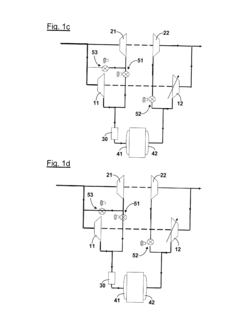

Intercooler system

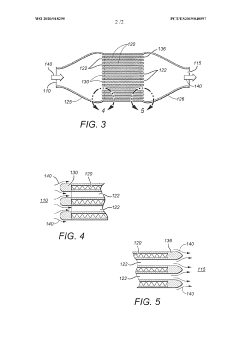

PatentWO2020018295A1

Innovation

- An intercooler design featuring an intercooler core with alternating air flow and charge flow passageways, contoured end tanks, and strategically placed partitions to promote laminar flow and minimize turbulence, along with fin configurations for enhanced heat transfer, maximizing airflow and heat removal.

Environmental Impact

The environmental impact of B58 turbo intercooler technologies is a critical consideration in the pursuit of greater efficiency. As automotive manufacturers strive to meet increasingly stringent emissions regulations, the development of more efficient intercooler systems plays a crucial role in reducing the overall environmental footprint of turbocharged engines.

One of the primary environmental benefits of advanced B58 turbo intercooler technologies is the potential for improved fuel efficiency. By enhancing the cooling capacity of the intercooler, these innovations allow for more efficient combustion processes, resulting in reduced fuel consumption and lower carbon dioxide emissions. This improvement in fuel economy directly contributes to the reduction of greenhouse gas emissions, aligning with global efforts to combat climate change.

Furthermore, innovative intercooler designs can lead to a decrease in the use of environmentally harmful materials. Traditional intercoolers often rely on aluminum, which has a significant environmental impact during production. New technologies may incorporate alternative materials or manufacturing processes that reduce the overall ecological footprint of intercooler production.

The optimization of intercooler efficiency also contributes to the longevity of engine components. By maintaining more stable operating temperatures, these advanced systems can reduce wear and tear on engine parts, potentially extending the lifespan of vehicles. This increased durability translates to fewer replacements and repairs, ultimately reducing the demand for new parts and the associated environmental costs of manufacturing and disposal.

Another environmental consideration is the potential for improved air quality. More efficient intercooling can lead to more complete combustion, potentially reducing the emission of particulate matter and other harmful pollutants. This is particularly relevant in urban areas where air quality is a significant concern and can have direct impacts on public health.

The development of compact and lightweight intercooler designs can also contribute to overall vehicle weight reduction. Lighter vehicles require less energy to operate, further enhancing fuel efficiency and reducing emissions. Additionally, the use of advanced materials and design techniques in intercooler manufacturing may open up possibilities for easier recycling and end-of-life management of these components.

As the automotive industry continues to shift towards electrification, the role of efficient intercooler technologies in hybrid powertrains becomes increasingly important. These systems can contribute to the overall efficiency of hybrid vehicles, bridging the gap between traditional combustion engines and fully electric powertrains, and supporting the gradual transition to more environmentally friendly transportation solutions.

One of the primary environmental benefits of advanced B58 turbo intercooler technologies is the potential for improved fuel efficiency. By enhancing the cooling capacity of the intercooler, these innovations allow for more efficient combustion processes, resulting in reduced fuel consumption and lower carbon dioxide emissions. This improvement in fuel economy directly contributes to the reduction of greenhouse gas emissions, aligning with global efforts to combat climate change.

Furthermore, innovative intercooler designs can lead to a decrease in the use of environmentally harmful materials. Traditional intercoolers often rely on aluminum, which has a significant environmental impact during production. New technologies may incorporate alternative materials or manufacturing processes that reduce the overall ecological footprint of intercooler production.

The optimization of intercooler efficiency also contributes to the longevity of engine components. By maintaining more stable operating temperatures, these advanced systems can reduce wear and tear on engine parts, potentially extending the lifespan of vehicles. This increased durability translates to fewer replacements and repairs, ultimately reducing the demand for new parts and the associated environmental costs of manufacturing and disposal.

Another environmental consideration is the potential for improved air quality. More efficient intercooling can lead to more complete combustion, potentially reducing the emission of particulate matter and other harmful pollutants. This is particularly relevant in urban areas where air quality is a significant concern and can have direct impacts on public health.

The development of compact and lightweight intercooler designs can also contribute to overall vehicle weight reduction. Lighter vehicles require less energy to operate, further enhancing fuel efficiency and reducing emissions. Additionally, the use of advanced materials and design techniques in intercooler manufacturing may open up possibilities for easier recycling and end-of-life management of these components.

As the automotive industry continues to shift towards electrification, the role of efficient intercooler technologies in hybrid powertrains becomes increasingly important. These systems can contribute to the overall efficiency of hybrid vehicles, bridging the gap between traditional combustion engines and fully electric powertrains, and supporting the gradual transition to more environmentally friendly transportation solutions.

Performance Metrics

Performance metrics play a crucial role in evaluating the effectiveness of B58 turbo intercooler technologies. These metrics provide quantifiable data to assess the efficiency gains and overall performance improvements achieved through innovative intercooler designs. One of the primary performance indicators is the intercooler's heat rejection capacity, which measures the amount of heat energy removed from the compressed air. This metric is typically expressed in kilowatts (kW) and directly impacts the engine's power output and fuel efficiency.

Pressure drop across the intercooler is another critical performance metric. It quantifies the resistance to airflow caused by the intercooler, measured in kilopascals (kPa) or pounds per square inch (psi). A lower pressure drop indicates better overall system efficiency, as it reduces the workload on the turbocharger and minimizes power losses. Intercooler effectiveness, expressed as a percentage, is a key metric that compares the actual temperature reduction achieved by the intercooler to the theoretical maximum temperature reduction possible.

Charge air density improvement is a vital performance metric that directly correlates with engine power output. It measures the increase in air density achieved by the intercooler, typically expressed as a percentage. Higher charge air density allows for more oxygen to be packed into the combustion chamber, resulting in improved combustion efficiency and increased power output. The intercooler's thermal efficiency, calculated as the ratio of heat energy removed to the energy input, provides insights into the overall effectiveness of the heat exchange process.

Transient response characteristics are essential performance metrics for B58 turbo intercooler systems. These metrics evaluate how quickly the intercooler can respond to sudden changes in boost pressure and airflow, ensuring optimal performance during acceleration and varying load conditions. Response time, measured in milliseconds, quantifies the intercooler's ability to rapidly cool incoming air and maintain consistent charge air temperatures.

Durability and longevity metrics are also crucial for assessing the overall performance of B58 turbo intercooler technologies. These include factors such as thermal cycling resistance, corrosion resistance, and structural integrity under high-pressure conditions. Long-term performance stability, measured through extended testing periods, ensures that the intercooler maintains its efficiency and effectiveness over the vehicle's lifespan.

By comprehensively analyzing these performance metrics, engineers and researchers can accurately evaluate the effectiveness of innovative B58 turbo intercooler technologies. This data-driven approach enables the identification of areas for improvement and guides the development of more efficient and high-performing intercooler systems for enhanced engine performance and fuel economy.

Pressure drop across the intercooler is another critical performance metric. It quantifies the resistance to airflow caused by the intercooler, measured in kilopascals (kPa) or pounds per square inch (psi). A lower pressure drop indicates better overall system efficiency, as it reduces the workload on the turbocharger and minimizes power losses. Intercooler effectiveness, expressed as a percentage, is a key metric that compares the actual temperature reduction achieved by the intercooler to the theoretical maximum temperature reduction possible.

Charge air density improvement is a vital performance metric that directly correlates with engine power output. It measures the increase in air density achieved by the intercooler, typically expressed as a percentage. Higher charge air density allows for more oxygen to be packed into the combustion chamber, resulting in improved combustion efficiency and increased power output. The intercooler's thermal efficiency, calculated as the ratio of heat energy removed to the energy input, provides insights into the overall effectiveness of the heat exchange process.

Transient response characteristics are essential performance metrics for B58 turbo intercooler systems. These metrics evaluate how quickly the intercooler can respond to sudden changes in boost pressure and airflow, ensuring optimal performance during acceleration and varying load conditions. Response time, measured in milliseconds, quantifies the intercooler's ability to rapidly cool incoming air and maintain consistent charge air temperatures.

Durability and longevity metrics are also crucial for assessing the overall performance of B58 turbo intercooler technologies. These include factors such as thermal cycling resistance, corrosion resistance, and structural integrity under high-pressure conditions. Long-term performance stability, measured through extended testing periods, ensures that the intercooler maintains its efficiency and effectiveness over the vehicle's lifespan.

By comprehensively analyzing these performance metrics, engineers and researchers can accurately evaluate the effectiveness of innovative B58 turbo intercooler technologies. This data-driven approach enables the identification of areas for improvement and guides the development of more efficient and high-performing intercooler systems for enhanced engine performance and fuel economy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!