The Effect of B58 Engine on BMW's Portfolio Hybridization

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Evolution

The B58 engine, introduced by BMW in 2015, represents a significant milestone in the company's engine development history. This inline-six turbocharged engine has undergone several iterations, each marking a step forward in performance, efficiency, and adaptability to hybrid systems.

The initial B58B30M0 variant, launched in the F30 340i, set the foundation for future developments. It featured a closed-deck design, which improved cylinder stability and allowed for higher boost pressures. This design choice proved crucial for the engine's longevity and its ability to handle increased power outputs in subsequent versions.

In 2018, BMW introduced the B58B30O1, an updated version that incorporated several refinements. This iteration saw improvements in the turbocharger design, resulting in reduced lag and enhanced responsiveness. The engine management system was also optimized, allowing for better fuel efficiency without compromising performance.

The B58B30M1 variant, introduced in 2019, marked a significant leap in the engine's evolution. This version incorporated a water-cooled exhaust manifold integrated into the cylinder head, which not only improved thermal management but also enhanced the engine's suitability for hybrid applications. The addition of a gasoline particulate filter further improved emissions performance, aligning the engine with increasingly stringent environmental regulations.

2020 saw the introduction of the B58B30O2, which featured further refinements in fuel injection technology and turbocharger design. This version demonstrated BMW's commitment to continually improving the engine's performance and efficiency, even as the automotive industry began shifting towards electrification.

The latest iteration, the B58B30T0, represents the pinnacle of the B58 engine's evolution. Introduced in 2022, this variant incorporates advanced technologies such as a 48V mild-hybrid system, showcasing BMW's strategy to bridge the gap between traditional combustion engines and full electrification. The integration of the mild-hybrid system not only improves fuel efficiency but also enhances performance by providing additional torque during acceleration.

Throughout its evolution, the B58 engine has maintained its core characteristics of smooth power delivery and refined operation, hallmarks of BMW's inline-six engines. The engine's adaptability to hybrid systems has played a crucial role in BMW's portfolio hybridization strategy, allowing the company to offer a range of vehicles that combine the traditional driving dynamics BMW is known for with improved efficiency and reduced emissions.

The B58's evolution demonstrates BMW's commitment to continuous improvement and adaptation to changing market demands and regulatory requirements. By progressively enhancing the engine's performance, efficiency, and compatibility with hybrid systems, BMW has positioned the B58 as a versatile powerplant capable of meeting diverse customer needs while supporting the company's transition towards a more electrified future.

The initial B58B30M0 variant, launched in the F30 340i, set the foundation for future developments. It featured a closed-deck design, which improved cylinder stability and allowed for higher boost pressures. This design choice proved crucial for the engine's longevity and its ability to handle increased power outputs in subsequent versions.

In 2018, BMW introduced the B58B30O1, an updated version that incorporated several refinements. This iteration saw improvements in the turbocharger design, resulting in reduced lag and enhanced responsiveness. The engine management system was also optimized, allowing for better fuel efficiency without compromising performance.

The B58B30M1 variant, introduced in 2019, marked a significant leap in the engine's evolution. This version incorporated a water-cooled exhaust manifold integrated into the cylinder head, which not only improved thermal management but also enhanced the engine's suitability for hybrid applications. The addition of a gasoline particulate filter further improved emissions performance, aligning the engine with increasingly stringent environmental regulations.

2020 saw the introduction of the B58B30O2, which featured further refinements in fuel injection technology and turbocharger design. This version demonstrated BMW's commitment to continually improving the engine's performance and efficiency, even as the automotive industry began shifting towards electrification.

The latest iteration, the B58B30T0, represents the pinnacle of the B58 engine's evolution. Introduced in 2022, this variant incorporates advanced technologies such as a 48V mild-hybrid system, showcasing BMW's strategy to bridge the gap between traditional combustion engines and full electrification. The integration of the mild-hybrid system not only improves fuel efficiency but also enhances performance by providing additional torque during acceleration.

Throughout its evolution, the B58 engine has maintained its core characteristics of smooth power delivery and refined operation, hallmarks of BMW's inline-six engines. The engine's adaptability to hybrid systems has played a crucial role in BMW's portfolio hybridization strategy, allowing the company to offer a range of vehicles that combine the traditional driving dynamics BMW is known for with improved efficiency and reduced emissions.

The B58's evolution demonstrates BMW's commitment to continuous improvement and adaptation to changing market demands and regulatory requirements. By progressively enhancing the engine's performance, efficiency, and compatibility with hybrid systems, BMW has positioned the B58 as a versatile powerplant capable of meeting diverse customer needs while supporting the company's transition towards a more electrified future.

Hybrid Market Demand

The hybrid vehicle market has experienced significant growth in recent years, driven by increasing environmental concerns, stricter emissions regulations, and advancements in hybrid technology. This trend has created a substantial demand for hybrid vehicles across various segments, including luxury and performance cars where BMW operates.

Consumer preferences have shifted towards more fuel-efficient and environmentally friendly vehicles, with hybrid models becoming increasingly popular. Market research indicates that hybrid vehicle sales have been growing at a compound annual growth rate (CAGR) of over 10% globally, with projections suggesting continued strong growth in the coming years.

In the premium segment where BMW competes, the demand for hybrid vehicles has been particularly strong. Luxury car buyers are increasingly seeking vehicles that combine performance with sustainability, making hybrid powertrains an attractive option. This shift in consumer preferences has prompted many premium automakers, including BMW's direct competitors, to expand their hybrid offerings.

The integration of the B58 engine into BMW's hybrid portfolio represents a strategic response to this market demand. The B58, known for its performance capabilities, can be effectively combined with electric motors to create powerful yet efficient hybrid powertrains. This approach allows BMW to cater to customers who desire both the driving dynamics associated with BMW and the fuel efficiency and reduced emissions of hybrid technology.

Market analysis suggests that hybrid vehicles are no longer viewed as a compromise in terms of performance, especially in the premium segment. Consumers are increasingly recognizing that hybrid powertrains can enhance vehicle performance while also providing improved fuel economy. This perception shift has expanded the potential market for hybrid vehicles, particularly among performance-oriented buyers who might have previously been hesitant to consider hybrid options.

The demand for hybrid vehicles is also influenced by government policies and regulations. Many countries have implemented incentives for hybrid vehicle purchases and set stringent emissions targets, further driving market growth. These regulatory factors are particularly relevant in key markets for BMW, such as Europe and China, where emissions standards are becoming increasingly strict.

Furthermore, the hybrid market demand extends beyond personal vehicles to fleet sales. Corporate and government fleets are increasingly adopting hybrid vehicles to meet sustainability goals and reduce operating costs. This trend presents additional opportunities for BMW's hybrid portfolio, especially in markets where fleet sales constitute a significant portion of premium vehicle sales.

As the automotive industry continues to evolve towards electrification, the hybrid market serves as a crucial transition phase. Many consumers view hybrid vehicles as a stepping stone towards full electric vehicles, appreciating the combination of familiar internal combustion technology with the benefits of electrification. This transitional role further enhances the market demand for hybrid vehicles in the near to medium term.

Consumer preferences have shifted towards more fuel-efficient and environmentally friendly vehicles, with hybrid models becoming increasingly popular. Market research indicates that hybrid vehicle sales have been growing at a compound annual growth rate (CAGR) of over 10% globally, with projections suggesting continued strong growth in the coming years.

In the premium segment where BMW competes, the demand for hybrid vehicles has been particularly strong. Luxury car buyers are increasingly seeking vehicles that combine performance with sustainability, making hybrid powertrains an attractive option. This shift in consumer preferences has prompted many premium automakers, including BMW's direct competitors, to expand their hybrid offerings.

The integration of the B58 engine into BMW's hybrid portfolio represents a strategic response to this market demand. The B58, known for its performance capabilities, can be effectively combined with electric motors to create powerful yet efficient hybrid powertrains. This approach allows BMW to cater to customers who desire both the driving dynamics associated with BMW and the fuel efficiency and reduced emissions of hybrid technology.

Market analysis suggests that hybrid vehicles are no longer viewed as a compromise in terms of performance, especially in the premium segment. Consumers are increasingly recognizing that hybrid powertrains can enhance vehicle performance while also providing improved fuel economy. This perception shift has expanded the potential market for hybrid vehicles, particularly among performance-oriented buyers who might have previously been hesitant to consider hybrid options.

The demand for hybrid vehicles is also influenced by government policies and regulations. Many countries have implemented incentives for hybrid vehicle purchases and set stringent emissions targets, further driving market growth. These regulatory factors are particularly relevant in key markets for BMW, such as Europe and China, where emissions standards are becoming increasingly strict.

Furthermore, the hybrid market demand extends beyond personal vehicles to fleet sales. Corporate and government fleets are increasingly adopting hybrid vehicles to meet sustainability goals and reduce operating costs. This trend presents additional opportunities for BMW's hybrid portfolio, especially in markets where fleet sales constitute a significant portion of premium vehicle sales.

As the automotive industry continues to evolve towards electrification, the hybrid market serves as a crucial transition phase. Many consumers view hybrid vehicles as a stepping stone towards full electric vehicles, appreciating the combination of familiar internal combustion technology with the benefits of electrification. This transitional role further enhances the market demand for hybrid vehicles in the near to medium term.

B58 Hybridization Challenges

The hybridization of BMW's B58 engine presents several significant challenges that must be addressed to successfully integrate this powerful inline-six engine into the company's electrified portfolio. One of the primary obstacles is the engine's size and weight. The B58, known for its robust performance, is relatively large and heavy compared to smaller, more compact engines typically used in hybrid systems. This poses difficulties in packaging and weight distribution, potentially affecting the vehicle's overall balance and handling characteristics.

Another challenge lies in the thermal management of the hybrid system. The B58 engine generates considerable heat during operation, and when combined with the additional heat produced by electric motors and batteries in a hybrid setup, it creates a complex thermal environment. Efficient cooling systems must be developed to maintain optimal operating temperatures for both the combustion engine and the electrical components, ensuring reliability and performance across various driving conditions.

The integration of the B58 engine with electric motors also presents challenges in terms of power delivery and control. Balancing the power output between the combustion engine and electric motors to achieve smooth, seamless operation requires sophisticated control algorithms and hardware. This includes developing advanced transmission systems capable of handling the combined torque from both power sources while maintaining efficiency and drivability.

Furthermore, the B58's high-performance nature may conflict with the fuel efficiency goals typically associated with hybrid vehicles. While the engine is relatively efficient for its power output, it still consumes more fuel than smaller engines commonly used in hybrids. Engineers must find ways to optimize the engine's efficiency in hybrid applications without compromising its performance characteristics that BMW customers expect.

Emissions regulations pose another significant challenge. As global emissions standards become increasingly stringent, integrating a powerful combustion engine like the B58 into a hybrid system requires innovative solutions to meet these regulations. This may involve advanced exhaust after-treatment systems, precise engine management, and optimized hybrid operating strategies to minimize emissions across all driving modes.

Lastly, the cost implications of hybridizing the B58 engine are substantial. The development of bespoke hybrid components, such as electric motors and battery systems that can complement the engine's performance, requires significant investment. Additionally, the complexity of the hybrid system may increase production costs, potentially impacting the final price point of vehicles equipped with this powertrain.

Another challenge lies in the thermal management of the hybrid system. The B58 engine generates considerable heat during operation, and when combined with the additional heat produced by electric motors and batteries in a hybrid setup, it creates a complex thermal environment. Efficient cooling systems must be developed to maintain optimal operating temperatures for both the combustion engine and the electrical components, ensuring reliability and performance across various driving conditions.

The integration of the B58 engine with electric motors also presents challenges in terms of power delivery and control. Balancing the power output between the combustion engine and electric motors to achieve smooth, seamless operation requires sophisticated control algorithms and hardware. This includes developing advanced transmission systems capable of handling the combined torque from both power sources while maintaining efficiency and drivability.

Furthermore, the B58's high-performance nature may conflict with the fuel efficiency goals typically associated with hybrid vehicles. While the engine is relatively efficient for its power output, it still consumes more fuel than smaller engines commonly used in hybrids. Engineers must find ways to optimize the engine's efficiency in hybrid applications without compromising its performance characteristics that BMW customers expect.

Emissions regulations pose another significant challenge. As global emissions standards become increasingly stringent, integrating a powerful combustion engine like the B58 into a hybrid system requires innovative solutions to meet these regulations. This may involve advanced exhaust after-treatment systems, precise engine management, and optimized hybrid operating strategies to minimize emissions across all driving modes.

Lastly, the cost implications of hybridizing the B58 engine are substantial. The development of bespoke hybrid components, such as electric motors and battery systems that can complement the engine's performance, requires significant investment. Additionally, the complexity of the hybrid system may increase production costs, potentially impacting the final price point of vehicles equipped with this powertrain.

B58 Hybrid Solutions

01 Portfolio optimization for engine hybridization

This approach involves optimizing investment portfolios to support the development and implementation of hybrid engine technologies. It includes strategies for allocating resources, managing risks, and maximizing returns in the context of transitioning to hybrid powertrains for the B58 engine.- Portfolio optimization for hybrid engine systems: This approach involves optimizing investment portfolios for hybrid engine systems, particularly focusing on the B58 engine. It includes strategies for balancing risk and return in the context of hybrid technology development, considering factors such as market trends, technological advancements, and regulatory requirements in the automotive industry.

- Data analysis and machine learning for engine hybridization: Utilizing advanced data analysis techniques and machine learning algorithms to support decision-making in B58 engine hybridization. This includes processing large datasets related to engine performance, fuel efficiency, and emissions to identify optimal hybridization strategies and predict market trends.

- Financial modeling for hybrid engine projects: Developing comprehensive financial models to assess the viability and profitability of B58 engine hybridization projects. This involves forecasting costs, revenues, and return on investment, as well as evaluating different financing options and risk management strategies specific to hybrid engine development.

- Intellectual property management for hybrid technologies: Strategies for managing and leveraging intellectual property related to B58 engine hybridization. This includes patent portfolio analysis, licensing strategies, and identifying potential collaboration opportunities with other companies or research institutions in the field of hybrid engine technology.

- Supply chain optimization for hybrid engine components: Developing efficient supply chain strategies for sourcing and managing components specific to B58 hybrid engine systems. This involves supplier selection, inventory management, and logistics optimization to ensure smooth production and cost-effectiveness in the transition to hybrid technologies.

02 Data analysis and decision-making for engine hybridization

This focuses on utilizing data analytics and decision support systems to guide the hybridization process of the B58 engine. It involves analyzing market trends, technological advancements, and performance metrics to inform strategic decisions in hybrid engine development.Expand Specific Solutions03 Financial modeling for hybrid engine projects

This involves creating financial models and forecasts specifically tailored to hybrid engine projects. It includes cost-benefit analysis, ROI projections, and funding strategies to support the transition of the B58 engine portfolio to hybrid technologies.Expand Specific Solutions04 Intellectual property management for hybrid technologies

This focuses on managing and leveraging intellectual property related to hybrid engine technologies. It includes strategies for patent portfolio management, licensing agreements, and protecting innovations in the hybridization of the B58 engine.Expand Specific Solutions05 Supply chain and manufacturing adaptation for hybrid engines

This involves restructuring and optimizing supply chains and manufacturing processes to accommodate the production of hybrid B58 engines. It includes strategies for sourcing new components, retooling production lines, and managing inventory for hybrid engine production.Expand Specific Solutions

Automotive Hybrid Players

The automotive industry's hybridization efforts, particularly focusing on BMW's B58 engine, are in a transitional phase. The market for hybrid vehicles is expanding rapidly, driven by increasing environmental concerns and stricter emissions regulations. The technology's maturity varies among manufacturers, with companies like Toyota, Honda, and BMW leading the charge. BMW's B58 engine represents a significant advancement in hybrid powertrain technology, showcasing the company's commitment to electrification. Other major players like Volkswagen, Nissan, and Ford are also making strides in hybrid technology, creating a competitive landscape. The market size for hybrid vehicles is projected to grow substantially in the coming years, as automakers continue to invest in research and development to improve efficiency and performance.

GM Global Technology Operations LLC

Technical Solution: While GM does not use the B58 engine, the company has developed its own approach to portfolio hybridization. GM's strategy focuses on its Ultium platform, a flexible battery and drive unit system designed to support a wide range of electric and hybrid vehicles[5]. The Ultium platform allows GM to produce everything from compact cars to full-size trucks and SUVs with varying levels of electrification. For hybrid applications, GM often pairs its efficient gasoline engines with electric motors, similar to BMW's approach with the B58. GM's latest hybrid systems, such as those used in the Chevrolet Tahoe and GMC Yukon, combine a 3.0L Duramax turbo-diesel engine with electric motors, offering improved fuel economy and performance[6]. This approach demonstrates GM's commitment to hybridization across its vehicle lineup, albeit with a different technological foundation compared to BMW's B58-based strategy.

Strengths: Flexible platform for various vehicle types, scalable electrification. Weaknesses: Less focus on high-performance hybrid powertrains compared to BMW's B58 approach.

Bayerische Motoren Werke AG

Technical Solution: BMW's B58 engine plays a crucial role in the company's portfolio hybridization strategy. This 3.0-liter inline-six turbocharged engine is designed with a modular approach, allowing for easy integration with electric motors in hybrid powertrains[1]. The B58 engine features advanced technologies such as a closed-deck design, water-to-air intercooler, and twin-scroll turbocharger, which contribute to its high performance and efficiency[2]. In hybrid applications, the B58 is often paired with an electric motor, creating a powerful yet fuel-efficient powertrain. This combination allows BMW to offer vehicles with impressive performance characteristics while meeting increasingly stringent emissions regulations[3]. The B58 engine's adaptability enables BMW to implement various levels of hybridization across its portfolio, from mild hybrids to plug-in hybrid electric vehicles (PHEVs), thus providing a flexible platform for the company's electrification efforts[4].

Strengths: High performance, modular design for easy hybridization, fuel efficiency. Weaknesses: Complexity may lead to higher production costs, potential for increased weight in hybrid configurations.

B58 Hybrid Innovations

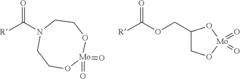

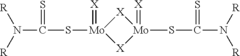

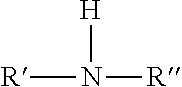

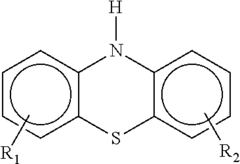

Ultra low phosphorus lubricant compositions

PatentActiveUS20170081608A1

Innovation

- A novel lubricant composition with a combination of an organomolybdenum compound, alkylated diphenylamine, hindered phenol, and dithiocarbamate, which maintains low phosphorus and molybdenum levels, providing excellent fuel economy, corrosion protection, and reduced phosphorus volatility.

Emissions Regulations

Emissions regulations have become increasingly stringent worldwide, significantly impacting the automotive industry and driving manufacturers to innovate in engine technology and vehicle electrification. These regulations aim to reduce greenhouse gas emissions and improve air quality, with a particular focus on carbon dioxide (CO2) emissions from passenger vehicles.

In the European Union, the current CO2 emission standards for new passenger cars require a fleet-wide average of 95 grams of CO2 per kilometer. This target is set to become even more stringent in the coming years, with proposed reductions of 15% by 2025 and 37.5% by 2030, compared to 2021 levels. Similar trends are observed in other major markets, including the United States, China, and Japan.

These regulations have a direct impact on BMW's portfolio hybridization strategy, particularly concerning the B58 engine. As a high-performance inline-six engine, the B58 has been a cornerstone of BMW's powertrain lineup. However, its relatively high fuel consumption and emissions output pose challenges in meeting increasingly strict regulatory requirements.

To address these challenges, BMW has been exploring various hybridization options for the B58 engine. Mild hybrid systems, which incorporate a small electric motor and battery, can provide additional power and improve fuel efficiency without significantly altering the engine's core design. More advanced plug-in hybrid configurations, combining the B58 engine with larger electric motors and batteries, offer extended electric-only driving ranges and substantially reduced emissions.

The integration of the B58 engine into hybrid powertrains allows BMW to leverage its existing technology while meeting emissions targets. This approach enables the company to maintain its reputation for performance and driving dynamics while gradually transitioning towards electrification. However, the effectiveness of this strategy depends on the specific hybrid system employed and its ability to reduce overall vehicle emissions.

As emissions regulations continue to evolve, BMW may need to further refine its hybridization strategy for the B58 engine. This could involve more advanced electrification technologies, such as improved battery chemistry or more efficient electric motors. Additionally, the company may need to consider the long-term viability of internal combustion engines like the B58 in markets with the most stringent emissions standards, potentially leading to a shift towards fully electric powertrains in certain vehicle segments.

In the European Union, the current CO2 emission standards for new passenger cars require a fleet-wide average of 95 grams of CO2 per kilometer. This target is set to become even more stringent in the coming years, with proposed reductions of 15% by 2025 and 37.5% by 2030, compared to 2021 levels. Similar trends are observed in other major markets, including the United States, China, and Japan.

These regulations have a direct impact on BMW's portfolio hybridization strategy, particularly concerning the B58 engine. As a high-performance inline-six engine, the B58 has been a cornerstone of BMW's powertrain lineup. However, its relatively high fuel consumption and emissions output pose challenges in meeting increasingly strict regulatory requirements.

To address these challenges, BMW has been exploring various hybridization options for the B58 engine. Mild hybrid systems, which incorporate a small electric motor and battery, can provide additional power and improve fuel efficiency without significantly altering the engine's core design. More advanced plug-in hybrid configurations, combining the B58 engine with larger electric motors and batteries, offer extended electric-only driving ranges and substantially reduced emissions.

The integration of the B58 engine into hybrid powertrains allows BMW to leverage its existing technology while meeting emissions targets. This approach enables the company to maintain its reputation for performance and driving dynamics while gradually transitioning towards electrification. However, the effectiveness of this strategy depends on the specific hybrid system employed and its ability to reduce overall vehicle emissions.

As emissions regulations continue to evolve, BMW may need to further refine its hybridization strategy for the B58 engine. This could involve more advanced electrification technologies, such as improved battery chemistry or more efficient electric motors. Additionally, the company may need to consider the long-term viability of internal combustion engines like the B58 in markets with the most stringent emissions standards, potentially leading to a shift towards fully electric powertrains in certain vehicle segments.

B58 Production Impact

The introduction of the B58 engine has significantly impacted BMW's production strategies and portfolio hybridization efforts. This inline-six turbocharged engine, first introduced in 2015, has become a cornerstone of BMW's powertrain lineup, influencing the company's approach to vehicle electrification and production planning.

The B58 engine's versatility and performance characteristics have allowed BMW to streamline its production processes across multiple vehicle platforms. By utilizing this engine in various models, from the 3 Series to the X7, BMW has achieved economies of scale in manufacturing. This standardization has led to increased production efficiency and reduced costs, enabling the company to allocate more resources towards hybrid and electric vehicle development.

The engine's compatibility with mild hybrid systems has played a crucial role in BMW's gradual transition towards electrification. The integration of 48-volt mild hybrid technology with the B58 engine has allowed BMW to offer improved fuel efficiency and reduced emissions across its model range without completely overhauling its production lines. This approach has provided a bridge between traditional internal combustion engines and fully electric powertrains, allowing BMW to meet increasingly stringent emissions regulations while maintaining its core brand identity.

The production impact of the B58 engine extends beyond BMW's own facilities. The engine's widespread use has influenced the company's supply chain management, with suppliers adapting their production capabilities to meet the demand for B58-specific components. This has created a ripple effect throughout the automotive industry, as other manufacturers observe and potentially emulate BMW's successful engine strategy.

Furthermore, the B58 engine's production has influenced BMW's global manufacturing footprint. The engine is produced in various locations worldwide, including Germany and Austria, allowing BMW to optimize its production network and reduce transportation costs. This decentralized production approach has enhanced the company's ability to respond to regional market demands and fluctuations in global supply chains.

As BMW continues to expand its electrified vehicle offerings, the production of the B58 engine serves as a critical balancing act. The company must carefully manage the transition from conventional powertrains to electric drivetrains while maintaining profitability and meeting customer demand. The B58's ongoing production provides BMW with the flexibility to gradually shift its portfolio towards hybridization and full electrification without abruptly disrupting its existing production infrastructure.

The B58 engine's versatility and performance characteristics have allowed BMW to streamline its production processes across multiple vehicle platforms. By utilizing this engine in various models, from the 3 Series to the X7, BMW has achieved economies of scale in manufacturing. This standardization has led to increased production efficiency and reduced costs, enabling the company to allocate more resources towards hybrid and electric vehicle development.

The engine's compatibility with mild hybrid systems has played a crucial role in BMW's gradual transition towards electrification. The integration of 48-volt mild hybrid technology with the B58 engine has allowed BMW to offer improved fuel efficiency and reduced emissions across its model range without completely overhauling its production lines. This approach has provided a bridge between traditional internal combustion engines and fully electric powertrains, allowing BMW to meet increasingly stringent emissions regulations while maintaining its core brand identity.

The production impact of the B58 engine extends beyond BMW's own facilities. The engine's widespread use has influenced the company's supply chain management, with suppliers adapting their production capabilities to meet the demand for B58-specific components. This has created a ripple effect throughout the automotive industry, as other manufacturers observe and potentially emulate BMW's successful engine strategy.

Furthermore, the B58 engine's production has influenced BMW's global manufacturing footprint. The engine is produced in various locations worldwide, including Germany and Austria, allowing BMW to optimize its production network and reduce transportation costs. This decentralized production approach has enhanced the company's ability to respond to regional market demands and fluctuations in global supply chains.

As BMW continues to expand its electrified vehicle offerings, the production of the B58 engine serves as a critical balancing act. The company must carefully manage the transition from conventional powertrains to electric drivetrains while maintaining profitability and meeting customer demand. The B58's ongoing production provides BMW with the flexibility to gradually shift its portfolio towards hybridization and full electrification without abruptly disrupting its existing production infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!