Microchip Advancements in B58 Engine Control System Performance

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Control Evolution

The B58 engine control system has undergone significant evolution since its introduction, driven by advancements in microchip technology and the increasing demands for improved performance, efficiency, and emissions control. This evolution can be traced through several key stages, each marked by notable technological improvements and milestones.

In the initial phase of the B58 engine control system, the focus was on establishing a robust foundation for electronic engine management. Early iterations utilized relatively simple microcontrollers with limited processing power and memory. These systems primarily managed basic functions such as fuel injection timing and ignition control, with rudimentary closed-loop feedback mechanisms based on oxygen sensor inputs.

As microchip technology progressed, the second generation of B58 engine control systems saw a substantial increase in computational capabilities. This allowed for more sophisticated control algorithms and the integration of additional sensors. The enhanced processing power enabled real-time adjustments to engine parameters based on a wider range of inputs, including mass airflow, intake air temperature, and crankshaft position sensors. This period also marked the introduction of adaptive learning algorithms, allowing the system to fine-tune its performance over time.

The third stage of evolution brought about a significant leap in diagnostic capabilities and emissions control. More advanced microchips with expanded memory and faster processing speeds facilitated the implementation of comprehensive on-board diagnostics (OBD) systems. This allowed for more accurate fault detection and improved emissions monitoring, crucial for meeting increasingly stringent environmental regulations.

In recent years, the B58 engine control system has entered a phase characterized by high levels of integration and connectivity. Modern microchips now incorporate multiple cores and specialized co-processors, enabling parallel processing of various engine control tasks. This has led to more precise and responsive engine management, with the ability to make millisecond-level adjustments to optimize performance and efficiency.

The latest iterations of the B58 engine control system leverage artificial intelligence and machine learning algorithms. These advanced systems can predict and adapt to various driving conditions, driver behaviors, and environmental factors. The integration of connectivity features allows for over-the-air updates and real-time data exchange with other vehicle systems, contributing to a more holistic approach to vehicle performance and energy management.

Looking ahead, the evolution of the B58 engine control system is expected to continue, with a focus on further integration with electrification technologies. As hybrid and electric powertrains become more prevalent, the role of the engine control system will expand to encompass seamless coordination between internal combustion and electric propulsion systems, optimizing overall vehicle efficiency and performance.

In the initial phase of the B58 engine control system, the focus was on establishing a robust foundation for electronic engine management. Early iterations utilized relatively simple microcontrollers with limited processing power and memory. These systems primarily managed basic functions such as fuel injection timing and ignition control, with rudimentary closed-loop feedback mechanisms based on oxygen sensor inputs.

As microchip technology progressed, the second generation of B58 engine control systems saw a substantial increase in computational capabilities. This allowed for more sophisticated control algorithms and the integration of additional sensors. The enhanced processing power enabled real-time adjustments to engine parameters based on a wider range of inputs, including mass airflow, intake air temperature, and crankshaft position sensors. This period also marked the introduction of adaptive learning algorithms, allowing the system to fine-tune its performance over time.

The third stage of evolution brought about a significant leap in diagnostic capabilities and emissions control. More advanced microchips with expanded memory and faster processing speeds facilitated the implementation of comprehensive on-board diagnostics (OBD) systems. This allowed for more accurate fault detection and improved emissions monitoring, crucial for meeting increasingly stringent environmental regulations.

In recent years, the B58 engine control system has entered a phase characterized by high levels of integration and connectivity. Modern microchips now incorporate multiple cores and specialized co-processors, enabling parallel processing of various engine control tasks. This has led to more precise and responsive engine management, with the ability to make millisecond-level adjustments to optimize performance and efficiency.

The latest iterations of the B58 engine control system leverage artificial intelligence and machine learning algorithms. These advanced systems can predict and adapt to various driving conditions, driver behaviors, and environmental factors. The integration of connectivity features allows for over-the-air updates and real-time data exchange with other vehicle systems, contributing to a more holistic approach to vehicle performance and energy management.

Looking ahead, the evolution of the B58 engine control system is expected to continue, with a focus on further integration with electrification technologies. As hybrid and electric powertrains become more prevalent, the role of the engine control system will expand to encompass seamless coordination between internal combustion and electric propulsion systems, optimizing overall vehicle efficiency and performance.

Market Demand Analysis

The market demand for advanced microchip solutions in engine control systems, particularly for the B58 engine, has been steadily increasing in recent years. This growth is driven by several factors, including stricter emissions regulations, the push for improved fuel efficiency, and the desire for enhanced performance in high-end vehicles.

Automotive manufacturers are constantly seeking ways to optimize engine performance while meeting increasingly stringent environmental standards. The B58 engine, known for its robust power output and efficiency, has become a prime target for microchip advancements to further improve its capabilities. As a result, there is a significant market opportunity for innovative microchip solutions that can enhance the B58 engine control system's performance.

The global automotive engine management system market, which includes microchip-based control systems, is experiencing substantial growth. This expansion is largely attributed to the rising demand for fuel-efficient vehicles and the increasing adoption of electric and hybrid powertrains. The integration of advanced microchips in engine control systems plays a crucial role in achieving these objectives.

In the premium and luxury vehicle segments, where the B58 engine is predominantly used, there is a particularly strong demand for cutting-edge engine control technologies. Consumers in these segments expect superior performance, smoother operation, and advanced features, all of which can be significantly enhanced through microchip advancements.

The trend towards connected and autonomous vehicles is also driving the demand for more sophisticated engine control systems. Advanced microchips are essential in enabling the integration of engine management with other vehicle systems, such as advanced driver assistance systems (ADAS) and infotainment platforms. This integration is becoming increasingly important as vehicles evolve into complex, interconnected machines.

Furthermore, the automotive industry's shift towards electrification has not diminished the importance of internal combustion engine optimization. Instead, it has intensified the need for advanced microchip solutions that can maximize the efficiency and performance of engines like the B58, especially in hybrid powertrains where they work in conjunction with electric motors.

The aftermarket sector also presents a significant opportunity for microchip advancements in B58 engine control systems. Performance enthusiasts and tuning companies are constantly seeking ways to extract more power and efficiency from these engines, creating a niche market for advanced microchip solutions that can be retrofitted or programmed into existing systems.

As environmental concerns continue to shape automotive regulations worldwide, the demand for microchips that can enable more precise engine control, real-time emissions management, and adaptive performance optimization is expected to grow. This trend is likely to sustain the market demand for advanced microchip solutions in B58 and similar high-performance engine control systems for the foreseeable future.

Automotive manufacturers are constantly seeking ways to optimize engine performance while meeting increasingly stringent environmental standards. The B58 engine, known for its robust power output and efficiency, has become a prime target for microchip advancements to further improve its capabilities. As a result, there is a significant market opportunity for innovative microchip solutions that can enhance the B58 engine control system's performance.

The global automotive engine management system market, which includes microchip-based control systems, is experiencing substantial growth. This expansion is largely attributed to the rising demand for fuel-efficient vehicles and the increasing adoption of electric and hybrid powertrains. The integration of advanced microchips in engine control systems plays a crucial role in achieving these objectives.

In the premium and luxury vehicle segments, where the B58 engine is predominantly used, there is a particularly strong demand for cutting-edge engine control technologies. Consumers in these segments expect superior performance, smoother operation, and advanced features, all of which can be significantly enhanced through microchip advancements.

The trend towards connected and autonomous vehicles is also driving the demand for more sophisticated engine control systems. Advanced microchips are essential in enabling the integration of engine management with other vehicle systems, such as advanced driver assistance systems (ADAS) and infotainment platforms. This integration is becoming increasingly important as vehicles evolve into complex, interconnected machines.

Furthermore, the automotive industry's shift towards electrification has not diminished the importance of internal combustion engine optimization. Instead, it has intensified the need for advanced microchip solutions that can maximize the efficiency and performance of engines like the B58, especially in hybrid powertrains where they work in conjunction with electric motors.

The aftermarket sector also presents a significant opportunity for microchip advancements in B58 engine control systems. Performance enthusiasts and tuning companies are constantly seeking ways to extract more power and efficiency from these engines, creating a niche market for advanced microchip solutions that can be retrofitted or programmed into existing systems.

As environmental concerns continue to shape automotive regulations worldwide, the demand for microchips that can enable more precise engine control, real-time emissions management, and adaptive performance optimization is expected to grow. This trend is likely to sustain the market demand for advanced microchip solutions in B58 and similar high-performance engine control systems for the foreseeable future.

Current ECU Challenges

The current challenges faced by Electronic Control Units (ECUs) in the B58 engine control system are multifaceted and complex. As automotive technology advances, ECUs are required to manage an increasingly sophisticated array of engine functions while maintaining optimal performance and efficiency.

One of the primary challenges is the need for increased processing power to handle the growing complexity of engine control algorithms. Modern engines, including the B58, require real-time adjustments to multiple parameters such as fuel injection, ignition timing, and valve control. This demands ECUs with higher computational capabilities to process vast amounts of sensor data and make split-second decisions.

Another significant challenge is the integration of advanced emission control systems. With stringent environmental regulations, ECUs must continuously monitor and adjust engine operations to minimize emissions while maintaining performance. This requires sophisticated software algorithms and hardware capable of precise control over fuel mixture and exhaust gas recirculation.

The demand for improved fuel efficiency presents another hurdle for ECU development. Engineers must design control systems that can optimize engine performance across a wide range of operating conditions, balancing power output with fuel consumption. This often involves complex predictive models and adaptive learning algorithms that can fine-tune engine parameters based on driving patterns and conditions.

Thermal management is an increasingly critical aspect of ECU design. As engines become more compact and powerful, managing heat dissipation becomes crucial. ECUs must not only control engine temperature but also ensure their own operational stability under high-temperature conditions, often necessitating advanced cooling solutions and heat-resistant components.

Connectivity and cybersecurity pose new challenges for ECU development. With the rise of connected vehicles, ECUs must be capable of secure communication with other vehicle systems and external networks. This requires robust encryption protocols and secure hardware designs to protect against potential cyber threats and unauthorized access to engine control systems.

Lastly, the push towards electrification and hybrid powertrains adds another layer of complexity to ECU design. For engines like the B58, which may be used in hybrid configurations, ECUs must seamlessly integrate with electric drive systems, managing power distribution and optimizing the interplay between combustion and electric propulsion.

One of the primary challenges is the need for increased processing power to handle the growing complexity of engine control algorithms. Modern engines, including the B58, require real-time adjustments to multiple parameters such as fuel injection, ignition timing, and valve control. This demands ECUs with higher computational capabilities to process vast amounts of sensor data and make split-second decisions.

Another significant challenge is the integration of advanced emission control systems. With stringent environmental regulations, ECUs must continuously monitor and adjust engine operations to minimize emissions while maintaining performance. This requires sophisticated software algorithms and hardware capable of precise control over fuel mixture and exhaust gas recirculation.

The demand for improved fuel efficiency presents another hurdle for ECU development. Engineers must design control systems that can optimize engine performance across a wide range of operating conditions, balancing power output with fuel consumption. This often involves complex predictive models and adaptive learning algorithms that can fine-tune engine parameters based on driving patterns and conditions.

Thermal management is an increasingly critical aspect of ECU design. As engines become more compact and powerful, managing heat dissipation becomes crucial. ECUs must not only control engine temperature but also ensure their own operational stability under high-temperature conditions, often necessitating advanced cooling solutions and heat-resistant components.

Connectivity and cybersecurity pose new challenges for ECU development. With the rise of connected vehicles, ECUs must be capable of secure communication with other vehicle systems and external networks. This requires robust encryption protocols and secure hardware designs to protect against potential cyber threats and unauthorized access to engine control systems.

Lastly, the push towards electrification and hybrid powertrains adds another layer of complexity to ECU design. For engines like the B58, which may be used in hybrid configurations, ECUs must seamlessly integrate with electric drive systems, managing power distribution and optimizing the interplay between combustion and electric propulsion.

B58 Control Solutions

01 Microchip design and fabrication techniques

Advanced design and fabrication techniques are employed to enhance microchip performance. These include optimizing circuit layouts, implementing new materials, and utilizing advanced lithography processes to create smaller and more efficient chip structures. Such techniques contribute to improved speed, power efficiency, and overall performance of microchips.- Microchip design optimization: Improving microchip performance through advanced design techniques, including optimizing circuit layouts, reducing power consumption, and enhancing signal processing capabilities. These methods focus on maximizing efficiency and functionality within the limited space of a microchip.

- Thermal management in microchips: Implementing effective thermal management strategies to enhance microchip performance and reliability. This includes developing heat dissipation techniques, utilizing advanced materials, and optimizing chip architecture to reduce thermal stress and improve overall efficiency.

- Integration of microfluidic systems: Incorporating microfluidic systems into microchip designs to enhance performance in applications such as lab-on-a-chip devices. This integration allows for improved sample handling, analysis, and control at the microscale level, leading to more efficient and accurate results.

- Advanced packaging techniques: Utilizing innovative packaging methods to improve microchip performance, including 3D integration, wafer-level packaging, and advanced interconnect technologies. These techniques aim to reduce signal delays, improve power efficiency, and increase overall chip functionality.

- Performance testing and quality control: Developing and implementing sophisticated testing methodologies and quality control measures to ensure optimal microchip performance. This includes creating advanced diagnostic tools, stress testing procedures, and performance validation techniques to identify and address potential issues before chip deployment.

02 Thermal management in microchips

Effective thermal management is crucial for maintaining optimal microchip performance. Various methods are employed, such as advanced cooling systems, heat-dissipating materials, and thermal-aware design techniques. These approaches help to prevent overheating, reduce power consumption, and ensure stable operation of microchips under different conditions.Expand Specific Solutions03 Integration of sensors and actuators

Incorporating sensors and actuators into microchips enhances their functionality and performance. This integration allows for real-time monitoring of various parameters, such as temperature, pressure, and motion, enabling adaptive responses and improved overall system performance. The combination of sensing and processing capabilities on a single chip leads to more compact and efficient designs.Expand Specific Solutions04 Power management and energy efficiency

Improving power management and energy efficiency is a key focus in enhancing microchip performance. Techniques such as dynamic voltage and frequency scaling, power gating, and low-power design methodologies are implemented to reduce energy consumption while maintaining or improving processing capabilities. These approaches result in longer battery life for portable devices and reduced heat generation in high-performance systems.Expand Specific Solutions05 Advanced testing and quality control methods

Implementing sophisticated testing and quality control methods is essential for ensuring optimal microchip performance. These include automated testing procedures, fault detection and isolation techniques, and advanced diagnostic tools. Such methods help identify and rectify potential issues during the manufacturing process, resulting in higher yield rates and more reliable microchips.Expand Specific Solutions

Key ECU Manufacturers

The microchip advancements in B58 engine control system performance represent a mature technology in a highly competitive market. The automotive industry is in a transitional phase, with established players like GM, Volkswagen, and Robert Bosch GmbH competing alongside emerging companies in the electric vehicle sector. The market size for engine control systems is substantial, driven by the global automotive industry's continuous growth. Companies such as Litens Automotive and Mitsubishi Electric are actively developing innovative solutions, while research institutions like Chongqing University and Tianjin University contribute to technological progress. The competition is fierce, with a focus on improving fuel efficiency, reducing emissions, and enhancing overall engine performance through advanced microchip technologies.

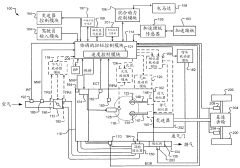

GM Global Technology Operations LLC

Technical Solution: GM has made significant advancements in microchip technology for the B58 engine control system, focusing on integration and scalability. Their approach involves developing a flexible, modular ECU platform that can be easily adapted to various engine configurations, including the B58[14]. GM's solution utilizes a multi-core microprocessor with dedicated hardware accelerators for specific engine control functions, such as ignition timing and fuel injection calculations. The company has implemented advanced model-based control algorithms that leverage the increased computational power to optimize engine performance and emissions in real-time[15]. GM's ECU also features extensive diagnostic capabilities, including on-board prognostics and health management systems that can predict potential issues before they affect engine performance[16].

Strengths: Extensive experience in engine control systems, strong integration with vehicle development processes. Weaknesses: Potential challenges in adapting the platform to non-GM engines and competition from specialized automotive semiconductor suppliers.

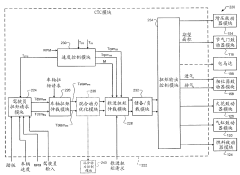

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced microchip solutions for the B58 engine control system, focusing on improving performance and efficiency. Their latest Engine Control Unit (ECU) for the B58 incorporates a high-performance microprocessor with multi-core architecture, enabling parallel processing of complex engine management tasks[1]. The ECU utilizes advanced 14nm semiconductor technology, resulting in reduced power consumption and improved thermal management[2]. Bosch's system integrates sophisticated algorithms for real-time combustion control, adaptive fuel injection, and predictive maintenance capabilities[3]. The ECU also features enhanced cybersecurity measures to protect against potential hacking attempts, ensuring the integrity of the engine control system[4].

Strengths: Industry-leading expertise in automotive electronics, extensive R&D capabilities, and strong partnerships with major automakers. Weaknesses: High development costs and potential supply chain vulnerabilities due to global semiconductor shortages.

Innovative ECU Patents

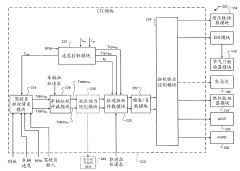

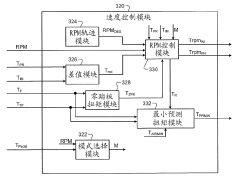

Speed control systems and methods for internal combustion engines

PatentInactiveCN102102591A

Innovation

- An engine control system including a mode selection module, axle torque arbitration module, speed control module and propulsion torque arbitration module is designed to generate predicted and immediate torque requests through driver input and engine speed prediction to accurately control engine output torque.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development of engine control systems, including those for the B58 engine. These regulations aim to reduce harmful emissions and improve air quality, driving manufacturers to innovate and enhance their engine management technologies.

The European Union's Euro 6d standards, implemented in 2020, set strict limits on nitrogen oxides (NOx) and particulate matter emissions for passenger vehicles. These standards have necessitated advanced emission control strategies and more sophisticated engine management systems. In the United States, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have also tightened their emissions requirements, pushing automakers to develop more efficient and cleaner engines.

To meet these stringent regulations, microchip advancements in the B58 engine control system have focused on several key areas. Real-time monitoring and adjustment of fuel injection, ignition timing, and air-fuel ratios have become critical components of modern engine management. Advanced sensors and high-speed processors enable more precise control over these parameters, allowing for optimized combustion and reduced emissions across various operating conditions.

Another significant area of development is in the integration of aftertreatment systems. Microchip advancements have enabled more effective control of selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and gasoline particulate filters (GPF). These systems require complex management strategies to ensure optimal performance and longevity while maintaining compliance with emissions standards.

The implementation of on-board diagnostics (OBD) systems has also been enhanced through microchip advancements. These systems continuously monitor the performance of emissions-related components and alert drivers to potential issues. The increased processing power and memory capacity of modern microchips allow for more sophisticated diagnostic algorithms and data logging capabilities.

Furthermore, advancements in microchip technology have facilitated the development of more advanced model-based control strategies. These strategies use complex algorithms to predict and optimize engine performance in real-time, taking into account a wide range of variables such as ambient conditions, fuel quality, and driving patterns. This approach allows for more precise emissions control across a broader range of operating conditions.

As emissions regulations continue to evolve, microchip advancements in the B58 engine control system will play a crucial role in meeting future standards. The trend towards electrification and hybrid powertrains will likely require even more sophisticated control systems, integrating management of both internal combustion engines and electric motors. This integration will demand further innovations in microchip technology to handle the increased complexity and processing requirements of these advanced powertrain systems.

The European Union's Euro 6d standards, implemented in 2020, set strict limits on nitrogen oxides (NOx) and particulate matter emissions for passenger vehicles. These standards have necessitated advanced emission control strategies and more sophisticated engine management systems. In the United States, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have also tightened their emissions requirements, pushing automakers to develop more efficient and cleaner engines.

To meet these stringent regulations, microchip advancements in the B58 engine control system have focused on several key areas. Real-time monitoring and adjustment of fuel injection, ignition timing, and air-fuel ratios have become critical components of modern engine management. Advanced sensors and high-speed processors enable more precise control over these parameters, allowing for optimized combustion and reduced emissions across various operating conditions.

Another significant area of development is in the integration of aftertreatment systems. Microchip advancements have enabled more effective control of selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and gasoline particulate filters (GPF). These systems require complex management strategies to ensure optimal performance and longevity while maintaining compliance with emissions standards.

The implementation of on-board diagnostics (OBD) systems has also been enhanced through microchip advancements. These systems continuously monitor the performance of emissions-related components and alert drivers to potential issues. The increased processing power and memory capacity of modern microchips allow for more sophisticated diagnostic algorithms and data logging capabilities.

Furthermore, advancements in microchip technology have facilitated the development of more advanced model-based control strategies. These strategies use complex algorithms to predict and optimize engine performance in real-time, taking into account a wide range of variables such as ambient conditions, fuel quality, and driving patterns. This approach allows for more precise emissions control across a broader range of operating conditions.

As emissions regulations continue to evolve, microchip advancements in the B58 engine control system will play a crucial role in meeting future standards. The trend towards electrification and hybrid powertrains will likely require even more sophisticated control systems, integrating management of both internal combustion engines and electric motors. This integration will demand further innovations in microchip technology to handle the increased complexity and processing requirements of these advanced powertrain systems.

Cybersecurity in ECUs

Cybersecurity in Electronic Control Units (ECUs) has become a critical concern in the automotive industry, particularly with the advancement of microchip technology in engine control systems like the B58. As vehicles become increasingly connected and reliant on complex electronic systems, the potential vulnerabilities to cyber attacks have grown exponentially.

The B58 engine control system, known for its high performance and efficiency, relies heavily on sophisticated ECUs to manage various aspects of engine operation. These ECUs are responsible for controlling fuel injection, ignition timing, turbocharger boost pressure, and numerous other parameters that directly impact engine performance and emissions. With the integration of more advanced microchips, the B58 system has achieved remarkable improvements in processing speed and data handling capabilities.

However, this increased connectivity and computational power also presents new challenges in terms of cybersecurity. Potential threats to ECUs include unauthorized access, data manipulation, and even remote control of vehicle systems. These risks are not merely theoretical; several high-profile incidents have demonstrated the real-world implications of ECU vulnerabilities.

To address these concerns, automotive manufacturers and suppliers are implementing multi-layered security approaches. These strategies typically involve a combination of hardware-based security features and software protection mechanisms. Hardware security modules (HSMs) are being integrated into ECUs to provide secure storage for cryptographic keys and to perform sensitive operations in a protected environment.

Secure boot processes ensure that only authenticated firmware can be loaded onto the ECU, preventing the execution of malicious code. Additionally, runtime integrity checks continuously monitor the system for any unauthorized modifications. Encryption of communication channels between ECUs and external interfaces helps protect against eavesdropping and man-in-the-middle attacks.

The automotive industry is also adopting standardized security frameworks, such as the ISO/SAE 21434 standard for cybersecurity engineering. This standard provides guidelines for implementing security measures throughout the entire vehicle lifecycle, from design and development to production and maintenance.

As microchip technology continues to advance, ECU cybersecurity measures must evolve in tandem. Future developments may include the implementation of artificial intelligence-based intrusion detection systems, blockchain technology for secure over-the-air updates, and quantum-resistant cryptographic algorithms to protect against emerging threats.

The B58 engine control system, known for its high performance and efficiency, relies heavily on sophisticated ECUs to manage various aspects of engine operation. These ECUs are responsible for controlling fuel injection, ignition timing, turbocharger boost pressure, and numerous other parameters that directly impact engine performance and emissions. With the integration of more advanced microchips, the B58 system has achieved remarkable improvements in processing speed and data handling capabilities.

However, this increased connectivity and computational power also presents new challenges in terms of cybersecurity. Potential threats to ECUs include unauthorized access, data manipulation, and even remote control of vehicle systems. These risks are not merely theoretical; several high-profile incidents have demonstrated the real-world implications of ECU vulnerabilities.

To address these concerns, automotive manufacturers and suppliers are implementing multi-layered security approaches. These strategies typically involve a combination of hardware-based security features and software protection mechanisms. Hardware security modules (HSMs) are being integrated into ECUs to provide secure storage for cryptographic keys and to perform sensitive operations in a protected environment.

Secure boot processes ensure that only authenticated firmware can be loaded onto the ECU, preventing the execution of malicious code. Additionally, runtime integrity checks continuously monitor the system for any unauthorized modifications. Encryption of communication channels between ECUs and external interfaces helps protect against eavesdropping and man-in-the-middle attacks.

The automotive industry is also adopting standardized security frameworks, such as the ISO/SAE 21434 standard for cybersecurity engineering. This standard provides guidelines for implementing security measures throughout the entire vehicle lifecycle, from design and development to production and maintenance.

As microchip technology continues to advance, ECU cybersecurity measures must evolve in tandem. Future developments may include the implementation of artificial intelligence-based intrusion detection systems, blockchain technology for secure over-the-air updates, and quantum-resistant cryptographic algorithms to protect against emerging threats.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!