Thermoelectric Generators and B58 Engine Waste Heat Utilization

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG and B58 WHR Background

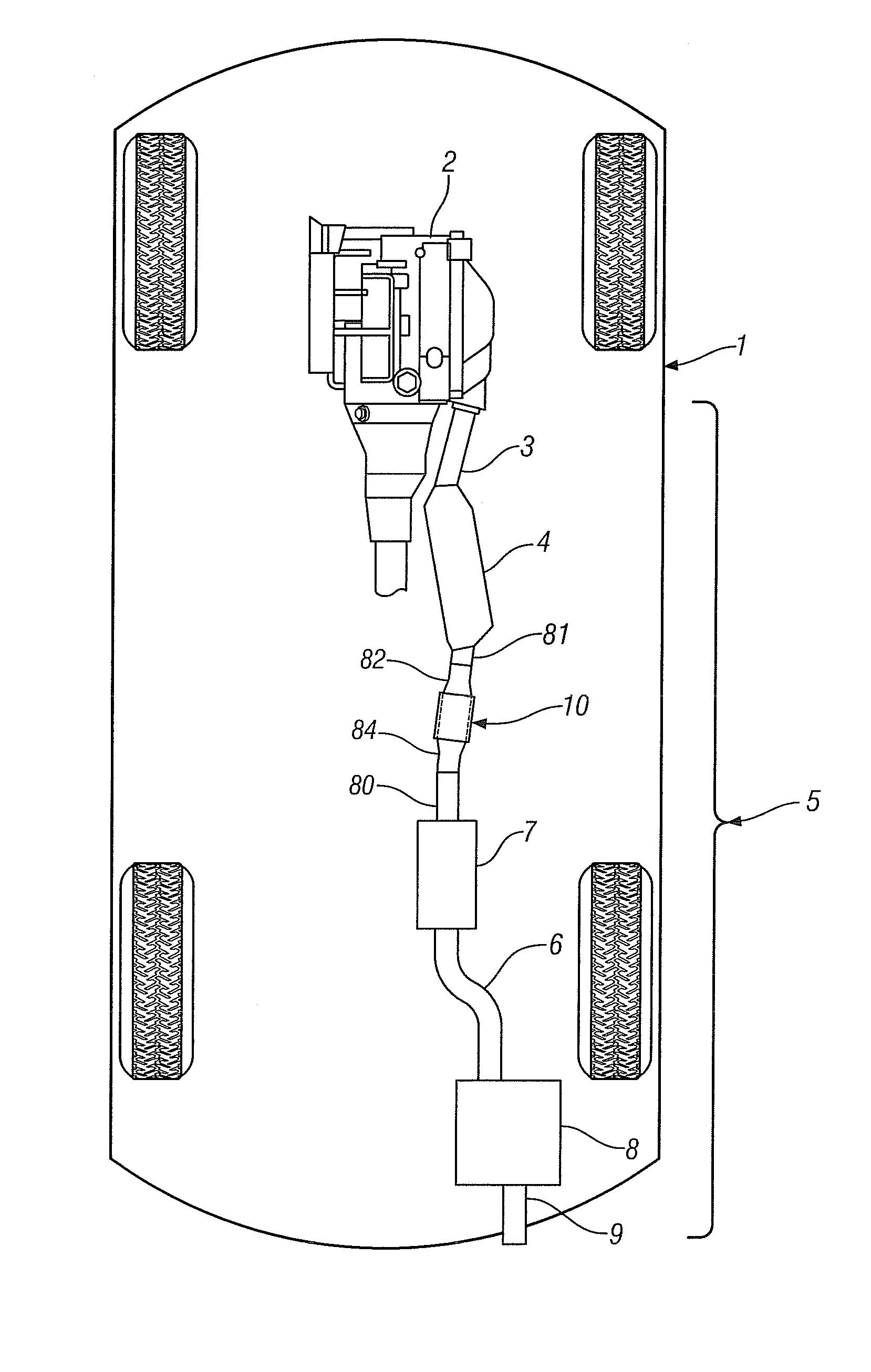

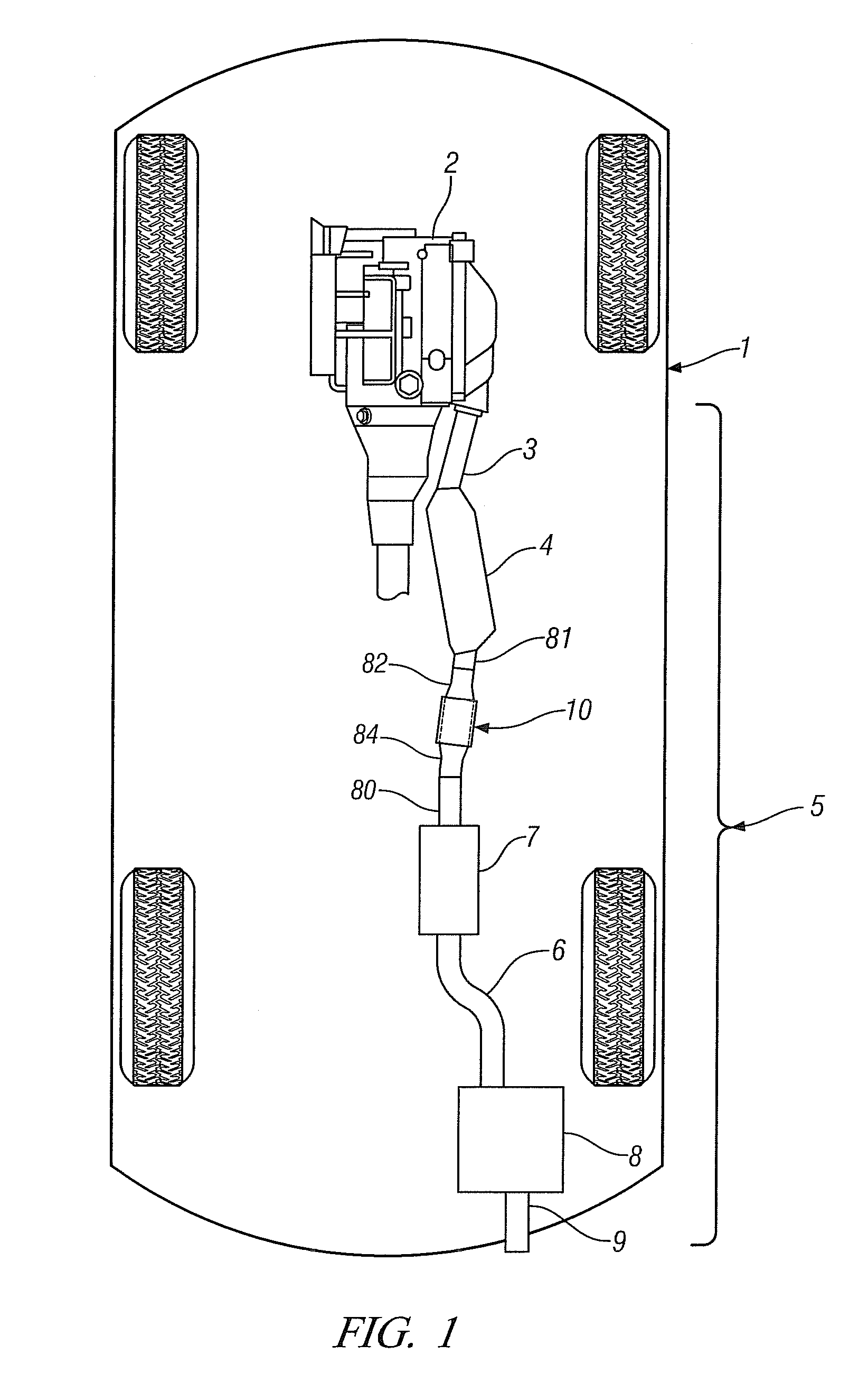

Thermoelectric generators (TEGs) and waste heat recovery (WHR) systems have gained significant attention in recent years as promising technologies for improving energy efficiency and reducing environmental impact. The B58 engine, a modern inline-six engine developed by BMW, serves as an excellent case study for exploring the potential of TEGs in automotive applications.

TEGs operate based on the Seebeck effect, which allows for the direct conversion of temperature differences into electrical energy. This principle makes them particularly suitable for harnessing waste heat from various sources, including internal combustion engines. The B58 engine, known for its high performance and efficiency, still loses a considerable amount of energy as waste heat through its exhaust system and cooling circuits.

The concept of waste heat recovery in automotive applications has been evolving for decades. Early attempts focused on mechanical systems, such as turbochargers, which utilize exhaust gas energy to improve engine performance. However, the emergence of TEGs has opened up new possibilities for converting waste heat directly into usable electrical energy, potentially reducing the load on the vehicle's alternator and improving overall fuel efficiency.

In the context of the B58 engine, the application of TEGs presents both opportunities and challenges. The engine's advanced design and thermal management system provide a stable and predictable heat source, which is advantageous for TEG implementation. However, the high-performance nature of the engine also means that integrating TEGs without compromising engine dynamics or adding significant weight is a complex engineering task.

The development of TEGs for automotive use has been driven by advancements in materials science and manufacturing techniques. Modern TEGs utilize semiconductor materials with improved thermoelectric properties, allowing for higher conversion efficiencies compared to earlier generations. This progress has made the prospect of integrating TEGs into production vehicles more feasible from both technical and economic standpoints.

The potential benefits of successfully implementing TEGs in the B58 engine extend beyond mere fuel savings. By recovering waste heat and converting it to electricity, TEGs could contribute to reducing the vehicle's overall carbon footprint, aligning with increasingly stringent environmental regulations. Additionally, the generated electricity could be used to power various vehicle systems, potentially enabling the downsizing of conventional alternators or supporting the electrification of auxiliary components.

As research in this field progresses, the focus is not only on improving the efficiency of TEGs themselves but also on optimizing their integration within the complex thermal and electrical systems of modern vehicles. The B58 engine, with its advanced design and widespread use in premium vehicles, provides an ideal platform for exploring these integration challenges and opportunities.

TEGs operate based on the Seebeck effect, which allows for the direct conversion of temperature differences into electrical energy. This principle makes them particularly suitable for harnessing waste heat from various sources, including internal combustion engines. The B58 engine, known for its high performance and efficiency, still loses a considerable amount of energy as waste heat through its exhaust system and cooling circuits.

The concept of waste heat recovery in automotive applications has been evolving for decades. Early attempts focused on mechanical systems, such as turbochargers, which utilize exhaust gas energy to improve engine performance. However, the emergence of TEGs has opened up new possibilities for converting waste heat directly into usable electrical energy, potentially reducing the load on the vehicle's alternator and improving overall fuel efficiency.

In the context of the B58 engine, the application of TEGs presents both opportunities and challenges. The engine's advanced design and thermal management system provide a stable and predictable heat source, which is advantageous for TEG implementation. However, the high-performance nature of the engine also means that integrating TEGs without compromising engine dynamics or adding significant weight is a complex engineering task.

The development of TEGs for automotive use has been driven by advancements in materials science and manufacturing techniques. Modern TEGs utilize semiconductor materials with improved thermoelectric properties, allowing for higher conversion efficiencies compared to earlier generations. This progress has made the prospect of integrating TEGs into production vehicles more feasible from both technical and economic standpoints.

The potential benefits of successfully implementing TEGs in the B58 engine extend beyond mere fuel savings. By recovering waste heat and converting it to electricity, TEGs could contribute to reducing the vehicle's overall carbon footprint, aligning with increasingly stringent environmental regulations. Additionally, the generated electricity could be used to power various vehicle systems, potentially enabling the downsizing of conventional alternators or supporting the electrification of auxiliary components.

As research in this field progresses, the focus is not only on improving the efficiency of TEGs themselves but also on optimizing their integration within the complex thermal and electrical systems of modern vehicles. The B58 engine, with its advanced design and widespread use in premium vehicles, provides an ideal platform for exploring these integration challenges and opportunities.

Market Analysis for Automotive WHR

The automotive waste heat recovery (WHR) market is experiencing significant growth, driven by increasing environmental concerns and stringent emission regulations worldwide. As automotive manufacturers seek to improve fuel efficiency and reduce carbon emissions, WHR technologies, particularly thermoelectric generators (TEGs), are gaining traction as a promising solution.

The global automotive WHR market is projected to expand at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This growth is primarily attributed to the rising demand for fuel-efficient vehicles and the automotive industry's shift towards electrification and hybridization. The passenger car segment currently dominates the market, accounting for the largest share due to higher production volumes and increasing adoption of advanced technologies.

Geographically, Europe leads the automotive WHR market, followed by North America and Asia-Pacific. European countries, with their stringent emission norms and high focus on sustainable transportation, are at the forefront of WHR technology adoption. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing vehicle production, and growing environmental awareness in countries like China and India.

The B58 engine, developed by BMW, presents a significant opportunity for WHR implementation. As a high-performance inline-six engine used in various BMW models, the B58 generates substantial waste heat that can be harnessed for improved efficiency. The integration of TEGs in the B58 engine could potentially recover up to 5% of the waste heat, translating to a 2-3% improvement in overall fuel efficiency.

Key market drivers for automotive WHR include government regulations on emissions, increasing consumer demand for fuel-efficient vehicles, and the automotive industry's push towards sustainable technologies. The European Union's target to reduce CO2 emissions from new cars by 37.5% by 2030 is a major catalyst for WHR adoption in the region. Similarly, the Corporate Average Fuel Economy (CAFE) standards in the United States are pushing automakers to explore WHR technologies.

However, the market faces challenges such as high initial costs, technical complexities in system integration, and the need for lightweight, compact designs. The cost-effectiveness of WHR systems, particularly for mass-market vehicles, remains a concern for widespread adoption. Additionally, the automotive industry's gradual shift towards electric vehicles may impact the long-term growth prospects of WHR technologies in internal combustion engines.

Despite these challenges, the automotive WHR market shows promising growth potential. The increasing focus on sustainable transportation and the continuous improvement in TEG technologies are expected to drive market expansion in the coming years. As research and development efforts intensify, particularly in enhancing the efficiency and cost-effectiveness of TEGs, the automotive WHR market is poised for substantial growth and innovation.

The global automotive WHR market is projected to expand at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This growth is primarily attributed to the rising demand for fuel-efficient vehicles and the automotive industry's shift towards electrification and hybridization. The passenger car segment currently dominates the market, accounting for the largest share due to higher production volumes and increasing adoption of advanced technologies.

Geographically, Europe leads the automotive WHR market, followed by North America and Asia-Pacific. European countries, with their stringent emission norms and high focus on sustainable transportation, are at the forefront of WHR technology adoption. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing vehicle production, and growing environmental awareness in countries like China and India.

The B58 engine, developed by BMW, presents a significant opportunity for WHR implementation. As a high-performance inline-six engine used in various BMW models, the B58 generates substantial waste heat that can be harnessed for improved efficiency. The integration of TEGs in the B58 engine could potentially recover up to 5% of the waste heat, translating to a 2-3% improvement in overall fuel efficiency.

Key market drivers for automotive WHR include government regulations on emissions, increasing consumer demand for fuel-efficient vehicles, and the automotive industry's push towards sustainable technologies. The European Union's target to reduce CO2 emissions from new cars by 37.5% by 2030 is a major catalyst for WHR adoption in the region. Similarly, the Corporate Average Fuel Economy (CAFE) standards in the United States are pushing automakers to explore WHR technologies.

However, the market faces challenges such as high initial costs, technical complexities in system integration, and the need for lightweight, compact designs. The cost-effectiveness of WHR systems, particularly for mass-market vehicles, remains a concern for widespread adoption. Additionally, the automotive industry's gradual shift towards electric vehicles may impact the long-term growth prospects of WHR technologies in internal combustion engines.

Despite these challenges, the automotive WHR market shows promising growth potential. The increasing focus on sustainable transportation and the continuous improvement in TEG technologies are expected to drive market expansion in the coming years. As research and development efforts intensify, particularly in enhancing the efficiency and cost-effectiveness of TEGs, the automotive WHR market is poised for substantial growth and innovation.

TEG Technology Challenges

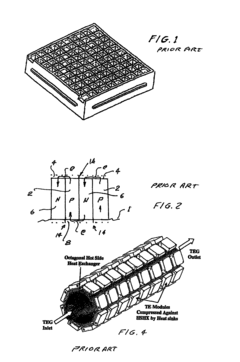

Thermoelectric generators (TEGs) face several significant challenges that hinder their widespread adoption and efficiency in waste heat recovery applications, particularly in the context of B58 engine waste heat utilization. One of the primary obstacles is the relatively low conversion efficiency of current TEG materials. Most commercially available TEGs operate at an efficiency of around 5-8%, which limits their practical application in automotive environments where space and weight constraints are critical.

The temperature gradient across the TEG is another crucial factor affecting its performance. In B58 engine applications, maintaining a consistent and optimal temperature difference between the hot and cold sides of the TEG can be challenging due to fluctuating engine operating conditions. This variability in temperature gradients leads to inconsistent power output and reduced overall efficiency.

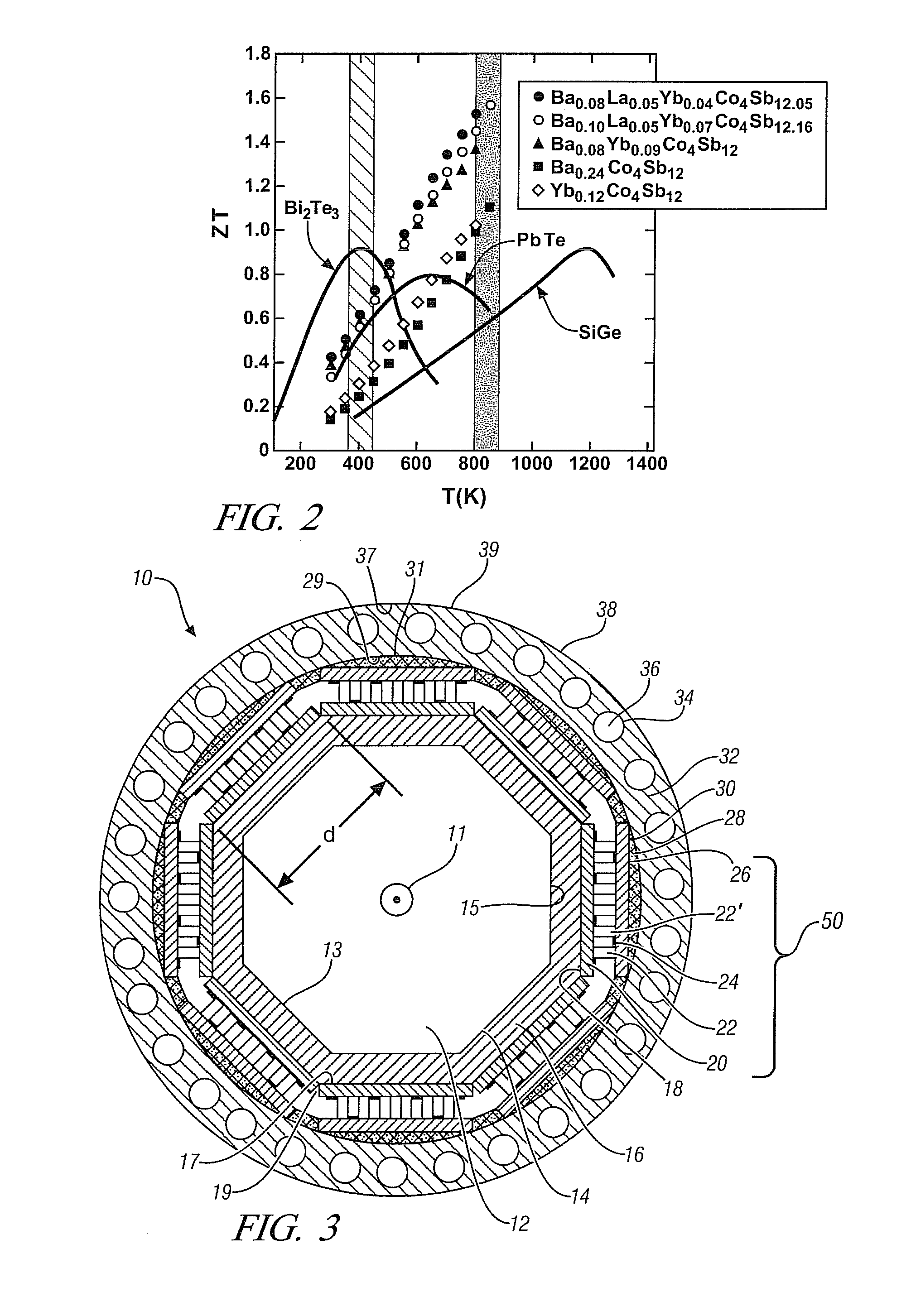

Material limitations pose a significant hurdle in TEG development. The search for materials with high thermoelectric figure of merit (ZT) that can operate effectively at the temperature ranges typical of engine exhaust systems (400-600°C) remains ongoing. Current high-performance thermoelectric materials often contain rare or toxic elements, raising concerns about cost, sustainability, and environmental impact.

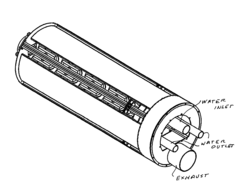

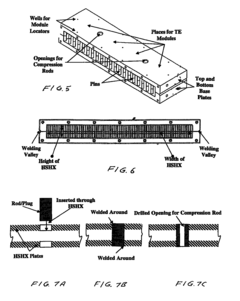

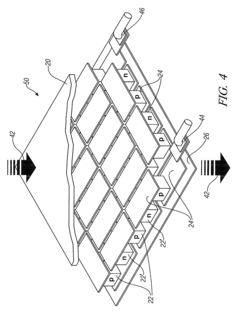

Thermal management is a critical challenge in TEG integration with B58 engines. Effective heat transfer from the exhaust gases to the TEG hot side, while maintaining a cool temperature on the cold side, requires sophisticated heat exchanger designs. Balancing the need for maximum heat transfer with minimal back pressure on the engine exhaust system is a complex engineering task.

Durability and reliability of TEGs in the harsh automotive environment present another set of challenges. Thermal cycling, vibrations, and exposure to corrosive exhaust gases can lead to degradation of TEG materials and connections over time. Ensuring long-term stability and performance of TEGs under these conditions is crucial for their viability in automotive applications.

Cost-effectiveness remains a significant barrier to widespread adoption of TEGs in automotive waste heat recovery. The current high cost of thermoelectric materials and manufacturing processes makes it difficult to justify the integration of TEGs in mass-produced vehicles, especially when compared to alternative waste heat recovery technologies.

Lastly, system integration challenges exist in incorporating TEGs into existing engine designs. Optimizing the placement of TEGs to maximize heat recovery without compromising engine performance or vehicle design requires careful consideration and often involves trade-offs between power generation potential and practical implementation constraints.

The temperature gradient across the TEG is another crucial factor affecting its performance. In B58 engine applications, maintaining a consistent and optimal temperature difference between the hot and cold sides of the TEG can be challenging due to fluctuating engine operating conditions. This variability in temperature gradients leads to inconsistent power output and reduced overall efficiency.

Material limitations pose a significant hurdle in TEG development. The search for materials with high thermoelectric figure of merit (ZT) that can operate effectively at the temperature ranges typical of engine exhaust systems (400-600°C) remains ongoing. Current high-performance thermoelectric materials often contain rare or toxic elements, raising concerns about cost, sustainability, and environmental impact.

Thermal management is a critical challenge in TEG integration with B58 engines. Effective heat transfer from the exhaust gases to the TEG hot side, while maintaining a cool temperature on the cold side, requires sophisticated heat exchanger designs. Balancing the need for maximum heat transfer with minimal back pressure on the engine exhaust system is a complex engineering task.

Durability and reliability of TEGs in the harsh automotive environment present another set of challenges. Thermal cycling, vibrations, and exposure to corrosive exhaust gases can lead to degradation of TEG materials and connections over time. Ensuring long-term stability and performance of TEGs under these conditions is crucial for their viability in automotive applications.

Cost-effectiveness remains a significant barrier to widespread adoption of TEGs in automotive waste heat recovery. The current high cost of thermoelectric materials and manufacturing processes makes it difficult to justify the integration of TEGs in mass-produced vehicles, especially when compared to alternative waste heat recovery technologies.

Lastly, system integration challenges exist in incorporating TEGs into existing engine designs. Optimizing the placement of TEGs to maximize heat recovery without compromising engine performance or vehicle design requires careful consideration and often involves trade-offs between power generation potential and practical implementation constraints.

Current B58 WHR Solutions

01 Thermoelectric generators for automotive waste heat recovery

Thermoelectric generators are utilized in automotive applications to convert waste heat from exhaust systems into electrical energy. These systems improve overall vehicle efficiency by harnessing thermal energy that would otherwise be lost, contributing to fuel economy and reduced emissions.- Thermoelectric generators for automotive waste heat recovery: Thermoelectric generators are utilized in automotive applications to convert waste heat from exhaust systems into electrical energy. These systems improve overall vehicle efficiency by harnessing thermal energy that would otherwise be lost, contributing to fuel economy and reduced emissions.

- Industrial waste heat recovery using thermoelectric systems: Thermoelectric generators are employed in industrial settings to capture and convert waste heat from various processes into usable electricity. This approach enhances energy efficiency in manufacturing plants, power stations, and other industrial facilities, reducing overall energy consumption and operational costs.

- Integration of thermoelectric generators with solar thermal systems: Hybrid systems combining thermoelectric generators with solar thermal collectors are developed to maximize energy harvesting. These integrated systems utilize both solar radiation and waste heat to generate electricity, improving overall system efficiency and providing a more consistent power output.

- Thermoelectric waste heat recovery in electronic devices: Thermoelectric generators are incorporated into electronic devices to recover waste heat generated by processors and other components. This technology helps improve device efficiency, extend battery life, and potentially power auxiliary functions in smartphones, laptops, and other portable electronics.

- Optimization of thermoelectric materials for enhanced waste heat utilization: Research focuses on developing and optimizing thermoelectric materials to improve conversion efficiency and performance in waste heat recovery applications. This includes exploring new material compositions, nanostructuring techniques, and manufacturing processes to enhance the thermoelectric figure of merit and overall system effectiveness.

02 Industrial waste heat recovery using thermoelectric systems

Thermoelectric generators are employed in industrial settings to capture and convert waste heat from various processes into usable electricity. This approach enhances energy efficiency in manufacturing, power generation, and other industrial applications, reducing overall energy consumption and operational costs.Expand Specific Solutions03 Integrated thermoelectric systems for small-scale applications

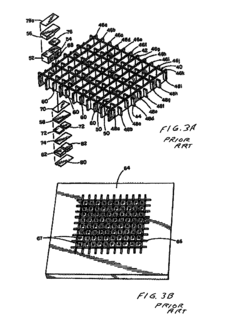

Compact thermoelectric generators are designed for small-scale waste heat recovery in consumer electronics, household appliances, and portable devices. These systems utilize temperature differentials to generate electricity, improving device efficiency and potentially extending battery life in portable applications.Expand Specific Solutions04 Thermoelectric materials and module design optimization

Research focuses on developing and optimizing thermoelectric materials and module designs to enhance conversion efficiency and power output. This includes exploring new material compositions, nanostructuring techniques, and innovative module architectures to improve the performance of waste heat recovery systems.Expand Specific Solutions05 Hybrid systems combining thermoelectric generators with other technologies

Innovative approaches integrate thermoelectric generators with other waste heat recovery technologies, such as organic Rankine cycles or heat pipes. These hybrid systems aim to maximize energy recovery from waste heat sources by leveraging the strengths of multiple technologies, potentially achieving higher overall system efficiency.Expand Specific Solutions

Key Players in Automotive TEG

The research on Thermoelectric Generators and B58 Engine Waste Heat Utilization is in a developing stage, with the market showing significant growth potential. The global thermoelectric generator market is expected to expand rapidly due to increasing demand for energy-efficient solutions. Companies like BMW, Ford, and Toyota are at the forefront of integrating this technology into automotive applications, particularly for waste heat recovery in engines. While the technology is not yet fully mature, major players such as Gentherm, LG Electronics, and Mitsubishi Heavy Industries are investing heavily in R&D to improve efficiency and reduce costs. The competitive landscape is diverse, with both established automotive manufacturers and specialized technology firms vying for market share in this emerging field.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive thermoelectric generator system tailored for automotive applications, with a particular focus on compatibility with various engine types, including the B58. Their TEG technology utilizes a cascaded design, incorporating different thermoelectric materials optimized for specific temperature ranges within the exhaust system[5]. This approach allows for improved efficiency across the wide temperature spectrum found in automotive exhaust gases. Bosch's system includes advanced heat exchangers that maximize thermal contact between the exhaust gases and the thermoelectric modules while minimizing back pressure on the engine. The company has reported achieving power outputs of up to 600W in real-world driving conditions, contributing significantly to reducing alternator load and improving overall vehicle efficiency[6]. Bosch has also invested in developing manufacturing processes to reduce the cost of TEG systems, aiming to make the technology more accessible for mass-market vehicles.

Strengths: Extensive automotive industry experience, advanced manufacturing capabilities, and a system design optimized for various engine types. Weaknesses: Balancing system complexity with cost-effectiveness and the challenge of integrating TEGs into existing vehicle electrical systems.

Gentherm, Inc.

Technical Solution: Gentherm has developed advanced thermoelectric generator (TEG) systems specifically designed for automotive waste heat recovery. Their technology utilizes high-performance thermoelectric materials and innovative heat exchanger designs to convert exhaust heat into usable electricity. The company's TEG modules are optimized for integration with vehicle exhaust systems, capable of generating up to 5% of the vehicle's electrical power needs[1]. Gentherm's solution includes a proprietary control system that manages power output based on driving conditions and engine load, ensuring optimal efficiency across various operating scenarios[2]. The company has also focused on reducing the cost and improving the durability of TEG systems, making them more viable for mass-market adoption in automotive applications.

Strengths: Specialized expertise in automotive TEG systems, proven performance in real-world conditions, and advanced control systems for optimized efficiency. Weaknesses: Relatively high initial cost compared to traditional alternators, and potential challenges in scaling production for mass-market adoption.

TEG Efficiency Innovations

Waste heat thermoelectric generator with auxiliary burner

PatentInactiveUS8927849B2

Innovation

- A thermoelectric generator design that directs hot gases through multiple separate paths to maintain uniform temperatures across all modules, utilizing an auxiliary burner-blower unit to provide a consistent heat source when waste heat is absent, and incorporating a distributed energy delivery system with finned hot media ducts and water-cooled heat sinks to optimize heat transfer and reduce backpressure.

Thermoelectric generators incorporating phase-change materials for waste heat recovery from engine exhaust

PatentActiveUS20120073276A1

Innovation

- Integration of thermoelectric modules with phase-change materials in the exhaust conduit system to convert thermal energy from exhaust gases into electrical energy, using bypass pipes and air admittance to manage temperature and prevent overheating of thermoelectric modules.

Environmental Impact of WHR

The implementation of Waste Heat Recovery (WHR) systems, particularly in the context of thermoelectric generators and B58 engine applications, has significant environmental implications. These systems contribute to improved energy efficiency and reduced emissions, aligning with global efforts to mitigate climate change and promote sustainable energy practices.

One of the primary environmental benefits of WHR systems is the reduction in overall fuel consumption. By capturing and utilizing waste heat that would otherwise be lost to the environment, these systems increase the overall efficiency of the engine. This leads to a decrease in the amount of fuel required to produce the same power output, resulting in lower carbon dioxide (CO2) emissions. For the B58 engine, which is known for its performance capabilities, the integration of WHR technology can help balance power output with environmental responsibility.

The reduction in greenhouse gas emissions extends beyond CO2. WHR systems can also contribute to lowering emissions of other pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. This is particularly relevant in urban environments where air quality is a significant concern. By improving the overall combustion efficiency and reducing the thermal load on the engine, WHR systems can help meet increasingly stringent emission standards without compromising engine performance.

Furthermore, the use of thermoelectric generators in WHR systems presents an opportunity for clean energy generation. These solid-state devices convert heat directly into electricity without moving parts or working fluids, offering a silent and maintenance-free solution for energy recovery. This aspect is particularly beneficial in reducing the overall environmental footprint of vehicles equipped with B58 engines, as it minimizes the need for additional mechanical systems that could potentially introduce new sources of emissions or require environmentally harmful lubricants.

The environmental impact of WHR systems also extends to the manufacturing and end-of-life phases. While the production of thermoelectric materials and associated components does have an environmental cost, the long-term benefits of reduced emissions and improved fuel efficiency typically outweigh these initial impacts. Additionally, many of the materials used in thermoelectric generators, such as bismuth telluride, can be recycled, further reducing the life-cycle environmental impact of these systems.

However, it is important to consider potential negative environmental impacts. The increased complexity of engines equipped with WHR systems may lead to more challenging maintenance procedures and potentially shorter engine lifespans if not properly managed. This could result in increased waste generation and resource consumption for replacements. Additionally, the rare earth elements often used in high-performance thermoelectric materials may pose environmental concerns related to mining and processing.

In conclusion, the environmental impact of WHR systems, particularly those utilizing thermoelectric generators in B58 engines, is predominantly positive. The technology offers significant potential for reducing emissions, improving energy efficiency, and contributing to more sustainable transportation solutions. As research and development in this field continue, further improvements in material efficiency and system integration are likely to enhance the environmental benefits of WHR technology.

One of the primary environmental benefits of WHR systems is the reduction in overall fuel consumption. By capturing and utilizing waste heat that would otherwise be lost to the environment, these systems increase the overall efficiency of the engine. This leads to a decrease in the amount of fuel required to produce the same power output, resulting in lower carbon dioxide (CO2) emissions. For the B58 engine, which is known for its performance capabilities, the integration of WHR technology can help balance power output with environmental responsibility.

The reduction in greenhouse gas emissions extends beyond CO2. WHR systems can also contribute to lowering emissions of other pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. This is particularly relevant in urban environments where air quality is a significant concern. By improving the overall combustion efficiency and reducing the thermal load on the engine, WHR systems can help meet increasingly stringent emission standards without compromising engine performance.

Furthermore, the use of thermoelectric generators in WHR systems presents an opportunity for clean energy generation. These solid-state devices convert heat directly into electricity without moving parts or working fluids, offering a silent and maintenance-free solution for energy recovery. This aspect is particularly beneficial in reducing the overall environmental footprint of vehicles equipped with B58 engines, as it minimizes the need for additional mechanical systems that could potentially introduce new sources of emissions or require environmentally harmful lubricants.

The environmental impact of WHR systems also extends to the manufacturing and end-of-life phases. While the production of thermoelectric materials and associated components does have an environmental cost, the long-term benefits of reduced emissions and improved fuel efficiency typically outweigh these initial impacts. Additionally, many of the materials used in thermoelectric generators, such as bismuth telluride, can be recycled, further reducing the life-cycle environmental impact of these systems.

However, it is important to consider potential negative environmental impacts. The increased complexity of engines equipped with WHR systems may lead to more challenging maintenance procedures and potentially shorter engine lifespans if not properly managed. This could result in increased waste generation and resource consumption for replacements. Additionally, the rare earth elements often used in high-performance thermoelectric materials may pose environmental concerns related to mining and processing.

In conclusion, the environmental impact of WHR systems, particularly those utilizing thermoelectric generators in B58 engines, is predominantly positive. The technology offers significant potential for reducing emissions, improving energy efficiency, and contributing to more sustainable transportation solutions. As research and development in this field continue, further improvements in material efficiency and system integration are likely to enhance the environmental benefits of WHR technology.

Cost-Benefit Analysis of TEG

The cost-benefit analysis of Thermoelectric Generators (TEGs) for B58 engine waste heat utilization reveals a complex interplay of economic factors and technological potential. Initial investment costs for TEG systems remain relatively high, primarily due to the expense of thermoelectric materials and manufacturing processes. However, these costs are gradually decreasing as production scales up and material efficiencies improve.

The primary benefit of TEG implementation in B58 engines lies in fuel efficiency gains. By converting waste heat into usable electricity, TEGs can reduce the alternator load on the engine, potentially improving fuel economy by 2-5% depending on driving conditions. This translates to significant fuel cost savings over the lifetime of the vehicle, especially for high-mileage applications such as long-haul trucking or fleet operations.

Maintenance costs for TEGs are generally low, as they have no moving parts and are highly reliable. This contrasts favorably with traditional waste heat recovery systems, which often require more frequent maintenance and have higher associated costs. The longevity of TEG systems, often matching or exceeding the lifespan of the vehicle itself, further enhances their cost-effectiveness.

Environmental benefits, while not directly quantifiable in monetary terms, contribute to the overall value proposition of TEGs. Reduced fuel consumption leads to lower emissions, potentially helping manufacturers meet increasingly stringent environmental regulations and avoid associated penalties.

The payback period for TEG systems in B58 engines varies depending on factors such as fuel prices, annual mileage, and specific system efficiency. Current estimates suggest a payback period of 3-5 years for heavy-duty vehicles, with longer periods for passenger vehicles. As technology improves and costs decrease, these payback periods are expected to shorten.

Scalability presents both opportunities and challenges. While mass production could significantly reduce unit costs, the current limited market for automotive TEGs means that economies of scale have not yet been fully realized. This creates a chicken-and-egg scenario where widespread adoption is needed to drive down costs, but lower costs are necessary to encourage adoption.

In conclusion, while the upfront costs of TEG systems for B58 engines are currently high, the long-term benefits in fuel savings, reduced emissions, and low maintenance requirements present a compelling case for their implementation, particularly in high-usage scenarios. As technology advances and production scales up, the cost-benefit ratio is expected to improve, potentially making TEGs a standard feature in future automotive designs.

The primary benefit of TEG implementation in B58 engines lies in fuel efficiency gains. By converting waste heat into usable electricity, TEGs can reduce the alternator load on the engine, potentially improving fuel economy by 2-5% depending on driving conditions. This translates to significant fuel cost savings over the lifetime of the vehicle, especially for high-mileage applications such as long-haul trucking or fleet operations.

Maintenance costs for TEGs are generally low, as they have no moving parts and are highly reliable. This contrasts favorably with traditional waste heat recovery systems, which often require more frequent maintenance and have higher associated costs. The longevity of TEG systems, often matching or exceeding the lifespan of the vehicle itself, further enhances their cost-effectiveness.

Environmental benefits, while not directly quantifiable in monetary terms, contribute to the overall value proposition of TEGs. Reduced fuel consumption leads to lower emissions, potentially helping manufacturers meet increasingly stringent environmental regulations and avoid associated penalties.

The payback period for TEG systems in B58 engines varies depending on factors such as fuel prices, annual mileage, and specific system efficiency. Current estimates suggest a payback period of 3-5 years for heavy-duty vehicles, with longer periods for passenger vehicles. As technology improves and costs decrease, these payback periods are expected to shorten.

Scalability presents both opportunities and challenges. While mass production could significantly reduce unit costs, the current limited market for automotive TEGs means that economies of scale have not yet been fully realized. This creates a chicken-and-egg scenario where widespread adoption is needed to drive down costs, but lower costs are necessary to encourage adoption.

In conclusion, while the upfront costs of TEG systems for B58 engines are currently high, the long-term benefits in fuel savings, reduced emissions, and low maintenance requirements present a compelling case for their implementation, particularly in high-usage scenarios. As technology advances and production scales up, the cost-benefit ratio is expected to improve, potentially making TEGs a standard feature in future automotive designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!