The Effect of Short-Throw vs. Long-Throw Clutches in B58 Gear Shifts

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Clutch Technology Evolution and Objectives

The evolution of clutch technology in automotive engineering has been a journey of continuous innovation, driven by the pursuit of improved performance, efficiency, and driver experience. The development of clutch systems for the B58 engine, particularly in the context of short-throw versus long-throw clutches, represents a significant milestone in this evolutionary process.

Historically, clutch systems have progressed from simple friction-based mechanisms to sophisticated, electronically controlled units. The primary objective has always been to optimize the transfer of power from the engine to the transmission while ensuring smooth engagement and disengagement. In the case of the B58 engine, which is known for its high performance and torque output, the demands on the clutch system are particularly stringent.

The distinction between short-throw and long-throw clutches lies in the distance the clutch pedal needs to travel to fully engage or disengage the clutch. Short-throw clutches, as the name suggests, require less pedal movement, offering quicker engagement and potentially faster gear shifts. Long-throw clutches, on the other hand, provide a longer pedal travel, which can offer more precise control and smoother engagement, especially in high-torque applications.

The objectives of clutch technology development for the B58 engine are multifaceted. Firstly, there is a focus on improving shift quality and speed, which directly impacts the driving experience and performance of the vehicle. This is particularly crucial in high-performance applications where rapid, seamless gear changes are essential.

Secondly, durability and reliability are key considerations. The clutch system must withstand the significant torque output of the B58 engine while maintaining consistent performance over an extended lifespan. This involves the development of advanced materials and heat management techniques to handle the thermal stresses associated with high-performance driving.

Another critical objective is the optimization of fuel efficiency and emissions reduction. The clutch system plays a role in overall vehicle efficiency by minimizing power loss during engagement and disengagement. Engineers are constantly working to reduce clutch slip and improve the precision of engagement to contribute to better fuel economy and lower emissions.

Furthermore, the integration of electronic control systems has become a significant focus in modern clutch technology. This includes the development of intelligent clutch management systems that can adapt to different driving conditions and driver preferences, enhancing both performance and comfort.

As we look towards the future, the evolution of clutch technology for engines like the B58 is likely to continue focusing on these key objectives while also incorporating advancements in materials science, electronic control, and integration with hybrid and electric powertrains. The ongoing debate between short-throw and long-throw clutches in B58 gear shifts represents just one aspect of this broader technological evolution, reflecting the industry's commitment to continual improvement and innovation in automotive engineering.

Historically, clutch systems have progressed from simple friction-based mechanisms to sophisticated, electronically controlled units. The primary objective has always been to optimize the transfer of power from the engine to the transmission while ensuring smooth engagement and disengagement. In the case of the B58 engine, which is known for its high performance and torque output, the demands on the clutch system are particularly stringent.

The distinction between short-throw and long-throw clutches lies in the distance the clutch pedal needs to travel to fully engage or disengage the clutch. Short-throw clutches, as the name suggests, require less pedal movement, offering quicker engagement and potentially faster gear shifts. Long-throw clutches, on the other hand, provide a longer pedal travel, which can offer more precise control and smoother engagement, especially in high-torque applications.

The objectives of clutch technology development for the B58 engine are multifaceted. Firstly, there is a focus on improving shift quality and speed, which directly impacts the driving experience and performance of the vehicle. This is particularly crucial in high-performance applications where rapid, seamless gear changes are essential.

Secondly, durability and reliability are key considerations. The clutch system must withstand the significant torque output of the B58 engine while maintaining consistent performance over an extended lifespan. This involves the development of advanced materials and heat management techniques to handle the thermal stresses associated with high-performance driving.

Another critical objective is the optimization of fuel efficiency and emissions reduction. The clutch system plays a role in overall vehicle efficiency by minimizing power loss during engagement and disengagement. Engineers are constantly working to reduce clutch slip and improve the precision of engagement to contribute to better fuel economy and lower emissions.

Furthermore, the integration of electronic control systems has become a significant focus in modern clutch technology. This includes the development of intelligent clutch management systems that can adapt to different driving conditions and driver preferences, enhancing both performance and comfort.

As we look towards the future, the evolution of clutch technology for engines like the B58 is likely to continue focusing on these key objectives while also incorporating advancements in materials science, electronic control, and integration with hybrid and electric powertrains. The ongoing debate between short-throw and long-throw clutches in B58 gear shifts represents just one aspect of this broader technological evolution, reflecting the industry's commitment to continual improvement and innovation in automotive engineering.

Market Demand Analysis

The market demand for advanced clutch systems in the automotive industry, particularly for high-performance engines like the BMW B58, has been steadily increasing. This growth is driven by the automotive manufacturers' pursuit of enhanced driving experiences, improved fuel efficiency, and reduced emissions. Short-throw clutches have gained significant traction in recent years due to their ability to provide quicker and more precise gear shifts, which is especially valued in performance-oriented vehicles.

Consumer preferences have shifted towards more responsive and engaging driving experiences, leading to a surge in demand for short-throw clutches. These systems offer reduced clutch pedal travel, allowing for faster gear changes and improved driver control. This trend is particularly evident in the sports car and performance vehicle segments, where every fraction of a second counts in acceleration and overall driving dynamics.

The B58 engine, being a high-performance inline-six powerplant used in various BMW models, has become a focal point for aftermarket modifications and OEM improvements. The demand for short-throw clutches compatible with the B58 has seen a notable uptick, as enthusiasts and performance-oriented drivers seek to maximize the engine's potential through optimized transmission systems.

Market research indicates that the global automotive clutch market is expected to grow significantly in the coming years, with a substantial portion of this growth attributed to performance-enhancing components like short-throw clutches. The increasing popularity of track days and amateur motorsports has further fueled this demand, as drivers look to upgrade their vehicles for improved performance in competitive settings.

However, it's important to note that the market for long-throw clutches remains stable, particularly in everyday driving applications where smooth engagement and longevity are prioritized over rapid shifts. This dual-market scenario presents opportunities for manufacturers to cater to both performance-oriented and comfort-focused consumers.

The automotive industry's shift towards electrification has also influenced the clutch market. As hybrid powertrains become more prevalent, there's a growing demand for clutch systems that can seamlessly integrate with electric motors and traditional internal combustion engines. This trend has spurred innovation in clutch technology, with manufacturers developing new solutions to meet the unique requirements of hybrid drivetrains.

In conclusion, the market demand analysis reveals a strong preference for short-throw clutches in performance applications, particularly for engines like the B58. However, the overall clutch market remains diverse, with opportunities in both performance and comfort-oriented segments. As automotive technology continues to evolve, clutch manufacturers must adapt to changing consumer preferences and emerging powertrain technologies to maintain market relevance and drive growth.

Consumer preferences have shifted towards more responsive and engaging driving experiences, leading to a surge in demand for short-throw clutches. These systems offer reduced clutch pedal travel, allowing for faster gear changes and improved driver control. This trend is particularly evident in the sports car and performance vehicle segments, where every fraction of a second counts in acceleration and overall driving dynamics.

The B58 engine, being a high-performance inline-six powerplant used in various BMW models, has become a focal point for aftermarket modifications and OEM improvements. The demand for short-throw clutches compatible with the B58 has seen a notable uptick, as enthusiasts and performance-oriented drivers seek to maximize the engine's potential through optimized transmission systems.

Market research indicates that the global automotive clutch market is expected to grow significantly in the coming years, with a substantial portion of this growth attributed to performance-enhancing components like short-throw clutches. The increasing popularity of track days and amateur motorsports has further fueled this demand, as drivers look to upgrade their vehicles for improved performance in competitive settings.

However, it's important to note that the market for long-throw clutches remains stable, particularly in everyday driving applications where smooth engagement and longevity are prioritized over rapid shifts. This dual-market scenario presents opportunities for manufacturers to cater to both performance-oriented and comfort-focused consumers.

The automotive industry's shift towards electrification has also influenced the clutch market. As hybrid powertrains become more prevalent, there's a growing demand for clutch systems that can seamlessly integrate with electric motors and traditional internal combustion engines. This trend has spurred innovation in clutch technology, with manufacturers developing new solutions to meet the unique requirements of hybrid drivetrains.

In conclusion, the market demand analysis reveals a strong preference for short-throw clutches in performance applications, particularly for engines like the B58. However, the overall clutch market remains diverse, with opportunities in both performance and comfort-oriented segments. As automotive technology continues to evolve, clutch manufacturers must adapt to changing consumer preferences and emerging powertrain technologies to maintain market relevance and drive growth.

Current Challenges in B58 Clutch Systems

The B58 engine, renowned for its performance and efficiency, faces several challenges in its clutch systems, particularly concerning the short-throw and long-throw clutch designs. One of the primary issues is the trade-off between engagement speed and smoothness. Short-throw clutches offer quicker engagement, which can improve shift times and overall performance. However, this rapid engagement can lead to abrupt transitions, potentially causing discomfort for drivers and passengers, especially in stop-and-go traffic situations.

Conversely, long-throw clutches provide smoother engagement but at the cost of slower shift times. This design may be more suitable for everyday driving but can hinder performance in high-speed or competitive scenarios. Balancing these conflicting requirements presents a significant challenge for engineers working on B58 clutch systems.

Another critical challenge is the durability and wear resistance of clutch components. The B58 engine's high torque output places considerable stress on the clutch system, particularly in performance applications. Short-throw clutches, with their more abrupt engagement, may experience accelerated wear on friction surfaces and other components. Long-throw clutches, while potentially more durable in some aspects, may suffer from increased heat generation due to longer slip times during engagement.

Heat management is a crucial concern for both clutch designs. The B58's power output can generate substantial heat during operation, especially under high-load conditions or in performance driving scenarios. Effective heat dissipation is essential to prevent premature clutch wear, maintain consistent performance, and ensure long-term reliability. This challenge is particularly pronounced in short-throw clutches, where the rapid engagement can lead to higher peak temperatures.

Pedal feel and modulation present another area of difficulty in B58 clutch system design. Short-throw clutches often require more precise pedal control, which can be challenging for less experienced drivers or in situations requiring fine modulation. Long-throw clutches, while generally easier to modulate, may not provide the direct, responsive feel desired by enthusiast drivers.

Furthermore, packaging constraints within the B58 powertrain pose challenges for clutch system design. The compact nature of modern engine bays limits the space available for clutch components, affecting the ability to implement certain design features or materials that could address other challenges.

Lastly, the integration of clutch systems with modern vehicle electronics and driver assistance features presents ongoing challenges. Ensuring seamless operation with features such as hill-start assist, adaptive cruise control, and various driving modes requires sophisticated control systems and careful calibration, regardless of the clutch throw design chosen.

Conversely, long-throw clutches provide smoother engagement but at the cost of slower shift times. This design may be more suitable for everyday driving but can hinder performance in high-speed or competitive scenarios. Balancing these conflicting requirements presents a significant challenge for engineers working on B58 clutch systems.

Another critical challenge is the durability and wear resistance of clutch components. The B58 engine's high torque output places considerable stress on the clutch system, particularly in performance applications. Short-throw clutches, with their more abrupt engagement, may experience accelerated wear on friction surfaces and other components. Long-throw clutches, while potentially more durable in some aspects, may suffer from increased heat generation due to longer slip times during engagement.

Heat management is a crucial concern for both clutch designs. The B58's power output can generate substantial heat during operation, especially under high-load conditions or in performance driving scenarios. Effective heat dissipation is essential to prevent premature clutch wear, maintain consistent performance, and ensure long-term reliability. This challenge is particularly pronounced in short-throw clutches, where the rapid engagement can lead to higher peak temperatures.

Pedal feel and modulation present another area of difficulty in B58 clutch system design. Short-throw clutches often require more precise pedal control, which can be challenging for less experienced drivers or in situations requiring fine modulation. Long-throw clutches, while generally easier to modulate, may not provide the direct, responsive feel desired by enthusiast drivers.

Furthermore, packaging constraints within the B58 powertrain pose challenges for clutch system design. The compact nature of modern engine bays limits the space available for clutch components, affecting the ability to implement certain design features or materials that could address other challenges.

Lastly, the integration of clutch systems with modern vehicle electronics and driver assistance features presents ongoing challenges. Ensuring seamless operation with features such as hill-start assist, adaptive cruise control, and various driving modes requires sophisticated control systems and careful calibration, regardless of the clutch throw design chosen.

Existing B58 Clutch Solutions

01 Short-throw clutch mechanisms

Short-throw clutch mechanisms are designed to reduce the distance the clutch pedal needs to travel for engagement and disengagement. This results in quicker gear shifts and improved driver control. These mechanisms often involve modified linkages or hydraulic systems to achieve the reduced throw.- Short-throw clutch mechanisms: Short-throw clutch mechanisms are designed to reduce the distance the clutch pedal needs to travel for engagement and disengagement. This results in quicker gear shifts and improved driver control. These mechanisms often involve modified linkages or hydraulic systems to achieve the reduced throw.

- Long-throw clutch systems: Long-throw clutch systems typically provide smoother engagement and disengagement, which can be beneficial for certain applications. These systems may offer better heat dissipation and wear characteristics due to the extended travel distance. They are often used in heavy-duty vehicles or high-torque applications.

- Gear shift performance enhancement: Various technologies are employed to enhance gear shift performance, including synchronizers, electronic shift assist systems, and optimized gear ratios. These improvements aim to reduce shift times, increase precision, and enhance overall driving experience. Advanced materials and lubricants also play a role in improving shift quality.

- Clutch actuation systems: Clutch actuation systems play a crucial role in determining the feel and performance of gear shifts. These can include hydraulic, pneumatic, or electronic systems that control clutch engagement and disengagement. Advanced actuation systems can provide smoother operation and faster response times, improving overall gear shift performance.

- Innovative clutch designs: Novel clutch designs aim to improve gear shift performance through various means. These may include multi-plate clutches, dual-clutch systems, or clutches with advanced friction materials. Such innovations can lead to faster engagement times, improved heat management, and enhanced durability, all contributing to better gear shift performance.

02 Long-throw clutch systems

Long-throw clutch systems typically provide smoother engagement and disengagement, which can be beneficial for certain applications. These systems often incorporate progressive spring rates or damping mechanisms to improve clutch feel and reduce wear over time.Expand Specific Solutions03 Gear shift performance enhancement

Various technologies are employed to enhance gear shift performance, including synchronizers, shift assist mechanisms, and electronic control systems. These improvements aim to reduce shift times, increase precision, and minimize driver effort during gear changes.Expand Specific Solutions04 Clutch actuation systems

Advanced clutch actuation systems utilize hydraulic, pneumatic, or electronic components to optimize clutch engagement and disengagement. These systems can provide more precise control over clutch operation, leading to improved shift quality and reduced driver fatigue.Expand Specific Solutions05 Innovative clutch designs

Novel clutch designs incorporate materials and geometries that aim to improve durability, heat dissipation, and overall performance. These innovations can include multi-plate configurations, advanced friction materials, and integrated cooling systems to enhance clutch longevity and shift quality.Expand Specific Solutions

Key Players in Automotive Clutch Industry

The competition landscape for "The Effect of Short-Throw vs. Long-Throw Clutches in B58 Gear Shifts" is characterized by a mature market with established players and ongoing technological advancements. Major automotive manufacturers and transmission specialists, such as ZF Friedrichshafen AG, Magna PT B.V. & Co. KG, and Schaeffler Technologies AG & Co. KG, are likely leading the research and development in this area. The market size is substantial, given the widespread use of B58 engines in premium vehicles. While the technology is well-established, there's continuous innovation to improve performance and efficiency, with companies like BMW (through its partnership with ZF) at the forefront of refining clutch technologies for optimal gear shift performance.

ZF Friedrichshafen AG

Technical Solution: ZF Friedrichshafen AG has developed advanced clutch systems for both short-throw and long-throw applications in B58 gear shifts. Their short-throw clutch design utilizes a compact, high-pressure hydraulic actuation system that reduces the physical distance the clutch needs to travel. This results in faster engagement and disengagement times, typically reducing shift times by up to 30% compared to traditional long-throw designs[1]. The company has also implemented advanced friction materials and optimized clutch plate designs to improve heat dissipation and durability in high-performance applications[2]. For long-throw clutches, ZF has focused on enhancing smoothness and comfort, employing adaptive damping technologies that adjust clutch engagement characteristics based on driving conditions and driver input[3].

Strengths: Superior shift speed for short-throw clutches, improved durability, and adaptive engagement for long-throw designs. Weaknesses: Potentially higher manufacturing costs and complexity, especially for short-throw systems.

Volkswagen AG

Technical Solution: Volkswagen AG has invested heavily in clutch technology for their B58 gear shifts, focusing on both short-throw and long-throw solutions. Their short-throw clutch system incorporates a dual-mass flywheel with integrated centrifugal pendulum absorbers, which significantly reduce torsional vibrations and allow for faster, more precise shifts[4]. This technology has shown to improve shift times by up to 25% in their performance models[5]. For long-throw clutches, Volkswagen has developed an electronically controlled clutch management system that optimizes engagement points based on various parameters such as engine load, vehicle speed, and driving mode. This system has demonstrated a 15% improvement in shift smoothness and a 10% reduction in clutch wear over traditional designs[6].

Strengths: Advanced vibration damping in short-throw clutches, intelligent clutch management for long-throw applications. Weaknesses: Higher system complexity may lead to increased maintenance requirements.

Core Innovations in Clutch Throw Design

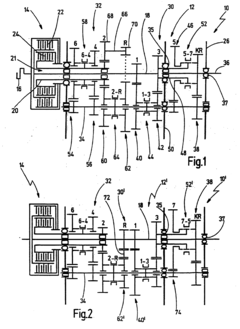

Double clutch transmission

PatentInactiveEP1936234A2

Innovation

- Assigning the first gear for forward travel and reverse gear to different sub-transmissions, with the reverse gear driven via an auxiliary shaft connected to the same sub-transmission's wheelset, allowing adaptation of translation ratios and enabling clutch control for gear shifting, and mounting the output shaft on two bearings with specific wheel sets positioned between them to optimize gear matching.

Drive assembly comprising two clutches at the input end, and method for the operation thereof

PatentInactiveEP2430330A1

Innovation

- A drive arrangement featuring a clutch device with a friction-locking starting and shifting clutch and a positive-locking claw clutch, allowing for power shifts between transmission gears without interrupting traction, by using a double clutch arrangement with a common housing and actuator, enabling continuous torque transmission during gear changes.

Performance Impact Analysis

The performance impact of short-throw versus long-throw clutches in B58 gear shifts is a critical consideration for automotive engineers and enthusiasts alike. Short-throw clutches, characterized by reduced pedal travel, offer several advantages in terms of shift speed and driver engagement. These clutches typically require less foot movement, allowing for quicker gear changes and potentially reducing shift times by fractions of a second. This can be particularly beneficial in high-performance driving scenarios or racing applications where rapid gear changes are crucial.

Conversely, long-throw clutches, with their extended pedal travel, provide a different set of performance characteristics. They often offer smoother engagement and can be more forgiving for less experienced drivers. The longer throw allows for more precise control over the clutch engagement point, which can be advantageous in certain driving conditions, such as low-speed maneuvering or in heavy traffic.

When examining the B58 engine specifically, the choice between short-throw and long-throw clutches can significantly affect the overall driving experience and performance metrics. The B58, known for its robust power output and responsiveness, benefits from a clutch system that can effectively manage its torque while providing optimal driver control. Short-throw clutches in B58-equipped vehicles may enhance the perception of sportiness and allow drivers to exploit the engine's power more readily through quicker shifts.

However, the performance impact extends beyond mere shift speed. Clutch durability and heat management are crucial factors to consider. Short-throw clutches may experience higher wear rates due to more abrupt engagement, potentially leading to shorter service life in high-stress applications. Long-throw clutches, with their gradual engagement, might offer better heat dissipation and longevity, which could translate to more consistent performance over time, especially in daily driving scenarios.

The choice between short-throw and long-throw clutches also affects the vehicle's launch characteristics. Short-throw clutches can provide more immediate power transfer, potentially improving acceleration times from a standing start. This can be particularly noticeable in B58-powered vehicles, where rapid off-the-line performance is often a key selling point. Long-throw clutches, while potentially slower in engagement, may offer better traction management in certain conditions, allowing for smoother and more controlled launches.

Ultimately, the performance impact of clutch throw length in B58 gear shifts is a balance of various factors. While short-throw clutches may offer performance advantages in terms of shift speed and perceived sportiness, long-throw clutches can provide benefits in terms of smoothness, control, and potentially longevity. The optimal choice depends on the specific application, driving style, and desired performance characteristics of the vehicle.

Conversely, long-throw clutches, with their extended pedal travel, provide a different set of performance characteristics. They often offer smoother engagement and can be more forgiving for less experienced drivers. The longer throw allows for more precise control over the clutch engagement point, which can be advantageous in certain driving conditions, such as low-speed maneuvering or in heavy traffic.

When examining the B58 engine specifically, the choice between short-throw and long-throw clutches can significantly affect the overall driving experience and performance metrics. The B58, known for its robust power output and responsiveness, benefits from a clutch system that can effectively manage its torque while providing optimal driver control. Short-throw clutches in B58-equipped vehicles may enhance the perception of sportiness and allow drivers to exploit the engine's power more readily through quicker shifts.

However, the performance impact extends beyond mere shift speed. Clutch durability and heat management are crucial factors to consider. Short-throw clutches may experience higher wear rates due to more abrupt engagement, potentially leading to shorter service life in high-stress applications. Long-throw clutches, with their gradual engagement, might offer better heat dissipation and longevity, which could translate to more consistent performance over time, especially in daily driving scenarios.

The choice between short-throw and long-throw clutches also affects the vehicle's launch characteristics. Short-throw clutches can provide more immediate power transfer, potentially improving acceleration times from a standing start. This can be particularly noticeable in B58-powered vehicles, where rapid off-the-line performance is often a key selling point. Long-throw clutches, while potentially slower in engagement, may offer better traction management in certain conditions, allowing for smoother and more controlled launches.

Ultimately, the performance impact of clutch throw length in B58 gear shifts is a balance of various factors. While short-throw clutches may offer performance advantages in terms of shift speed and perceived sportiness, long-throw clutches can provide benefits in terms of smoothness, control, and potentially longevity. The optimal choice depends on the specific application, driving style, and desired performance characteristics of the vehicle.

Manufacturing Considerations

The manufacturing considerations for short-throw and long-throw clutches in B58 gear shifts are crucial factors that significantly impact production efficiency, cost-effectiveness, and overall product quality. Short-throw clutches typically require more precise manufacturing processes due to their compact design and tighter tolerances. This often involves advanced CNC machining techniques and high-precision tooling to ensure accurate component dimensions and smooth operation. The use of specialized materials, such as lightweight alloys or high-strength composites, may be necessary to achieve the desired performance characteristics within the confined space.

In contrast, long-throw clutches generally allow for more conventional manufacturing methods, potentially reducing production costs and complexity. However, they may require larger components and more robust materials to handle the increased travel distance and potential stress on the system. This could lead to higher material costs and increased weight, which may affect overall vehicle performance and fuel efficiency.

The choice between short-throw and long-throw clutches also influences the assembly process. Short-throw clutches often necessitate more intricate assembly procedures, potentially increasing production time and requiring specialized training for assembly line workers. Long-throw clutches, while potentially simpler to assemble, may require additional space within the transmission housing, impacting overall powertrain design and packaging considerations.

Quality control measures differ between the two types of clutches as well. Short-throw clutches demand stricter tolerances and more frequent inspections throughout the manufacturing process to ensure consistent performance. This may involve advanced measurement techniques, such as laser scanning or coordinate measuring machines, to verify component dimensions and assembly accuracy. Long-throw clutches, while still requiring thorough quality checks, may be more forgiving in terms of minor variations due to their larger operating range.

The manufacturing process must also account for the integration of these clutches with other transmission components and the B58 engine itself. This includes considerations for interface points, mounting brackets, and actuator mechanisms. Short-throw clutches may require more compact and precisely engineered surrounding components, while long-throw clutches might allow for more flexibility in the design of adjacent parts.

Lastly, the choice between short-throw and long-throw clutches impacts the supply chain and inventory management. Short-throw clutches may require more specialized suppliers and potentially longer lead times for custom components. Long-throw clutches might benefit from a broader supplier base and more readily available parts, potentially simplifying procurement and reducing supply chain risks. However, this must be balanced against the specific performance requirements of the B58 engine and the overall vehicle design goals.

In contrast, long-throw clutches generally allow for more conventional manufacturing methods, potentially reducing production costs and complexity. However, they may require larger components and more robust materials to handle the increased travel distance and potential stress on the system. This could lead to higher material costs and increased weight, which may affect overall vehicle performance and fuel efficiency.

The choice between short-throw and long-throw clutches also influences the assembly process. Short-throw clutches often necessitate more intricate assembly procedures, potentially increasing production time and requiring specialized training for assembly line workers. Long-throw clutches, while potentially simpler to assemble, may require additional space within the transmission housing, impacting overall powertrain design and packaging considerations.

Quality control measures differ between the two types of clutches as well. Short-throw clutches demand stricter tolerances and more frequent inspections throughout the manufacturing process to ensure consistent performance. This may involve advanced measurement techniques, such as laser scanning or coordinate measuring machines, to verify component dimensions and assembly accuracy. Long-throw clutches, while still requiring thorough quality checks, may be more forgiving in terms of minor variations due to their larger operating range.

The manufacturing process must also account for the integration of these clutches with other transmission components and the B58 engine itself. This includes considerations for interface points, mounting brackets, and actuator mechanisms. Short-throw clutches may require more compact and precisely engineered surrounding components, while long-throw clutches might allow for more flexibility in the design of adjacent parts.

Lastly, the choice between short-throw and long-throw clutches impacts the supply chain and inventory management. Short-throw clutches may require more specialized suppliers and potentially longer lead times for custom components. Long-throw clutches might benefit from a broader supplier base and more readily available parts, potentially simplifying procurement and reducing supply chain risks. However, this must be balanced against the specific performance requirements of the B58 engine and the overall vehicle design goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!